Login Screen

This screen will open when you access the system link provided to your company.

Enter the Login

Enter the Password

Click on Enter BeeStock®.

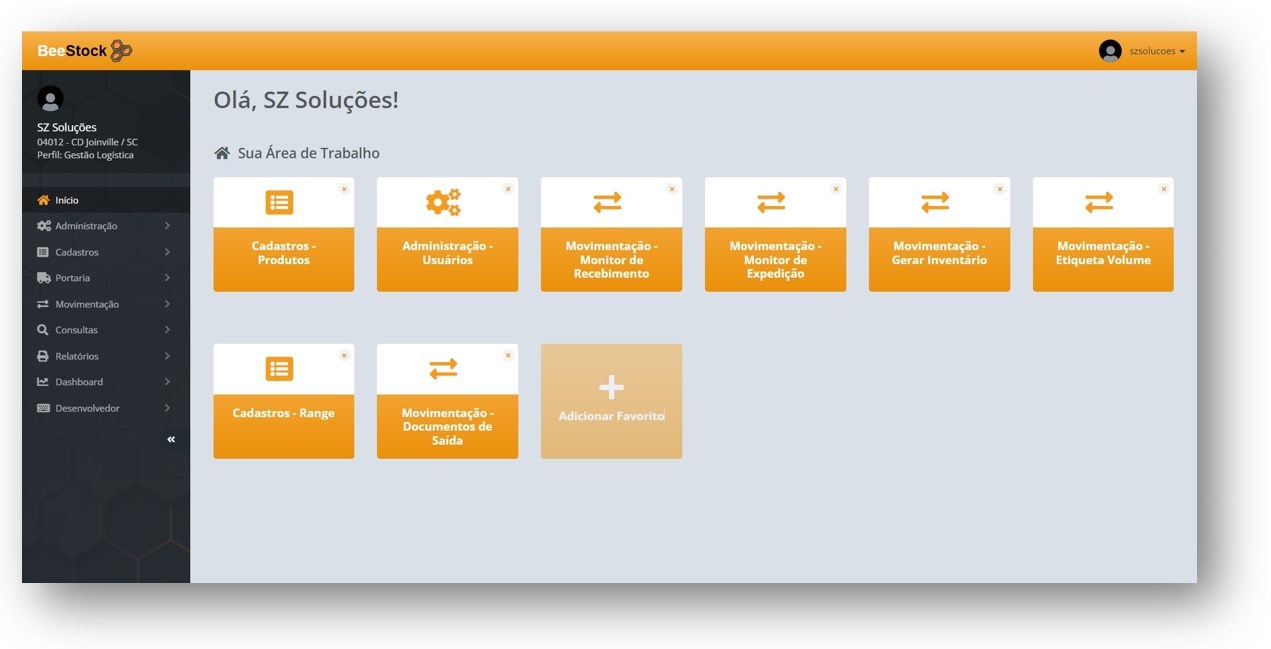

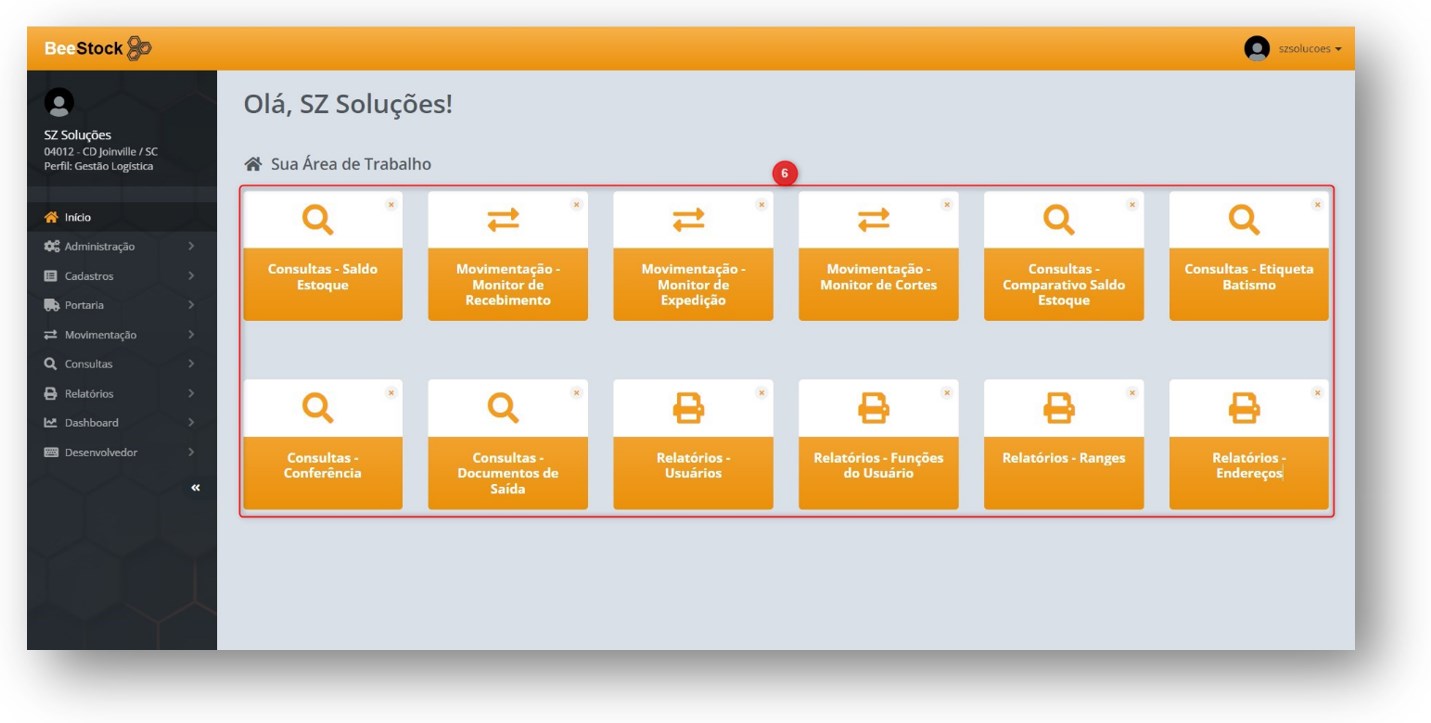

Your Workspace

Located in the Home menu, the Your Workspace screen is the user’s home page and offers the possibility to create shortcuts to any screen in the system, allowing the user to quickly access the most used screens without the need to navigate between menus. In this way, it will be possible to use the system in a more practical and objective way.\

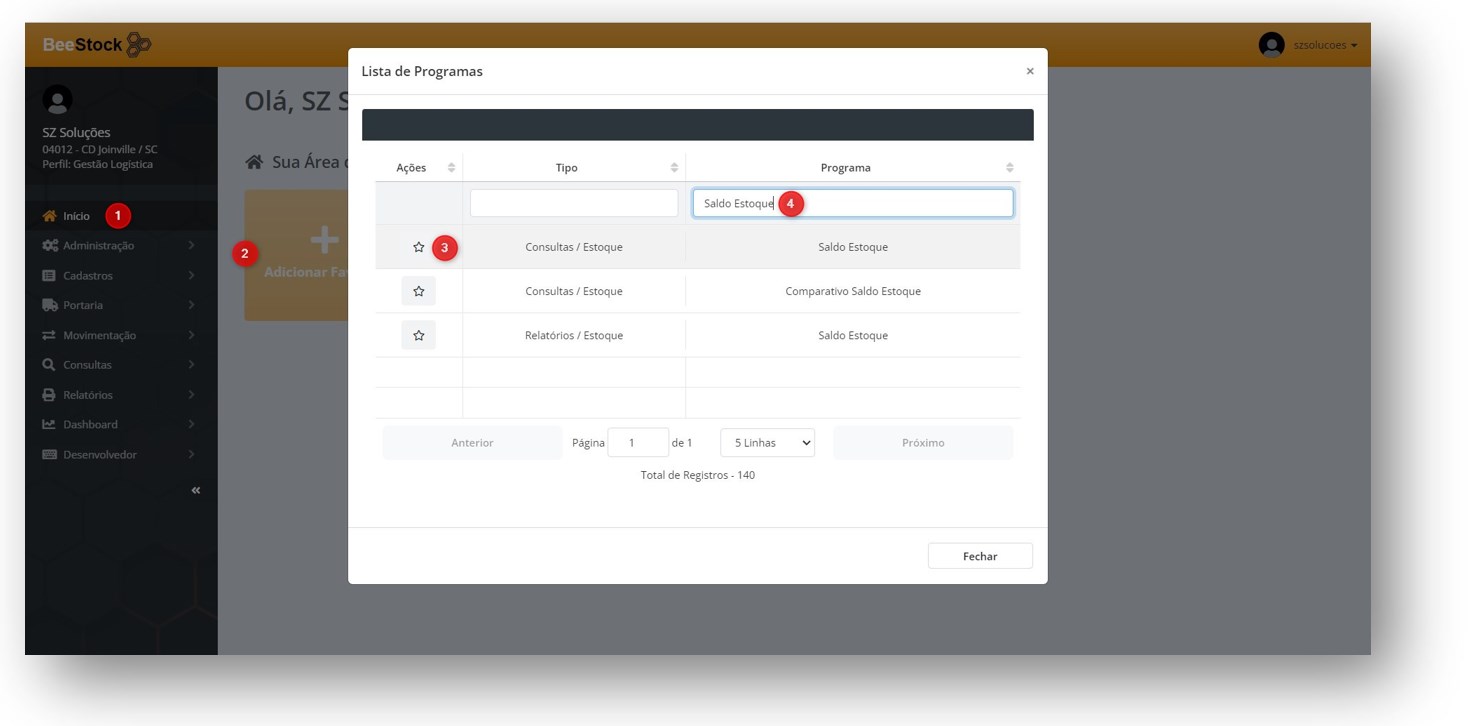

To add shortcuts to Your Workspace, follow these steps:

Access the Home screen.

Click the Add Favorite button to display the Program List.

Locate in the list or search the filters for the name of the desired program.

Click the Star icon in the chosen menu to create the shortcut on your home page.

To remove the shortcut, click the x in the upper right corner of the card.

To add new shortcuts you must repeat the previous steps, however, it is important to note that there is a limit of 12 cards per screen.

Therefore, when reaching this limit, you must remove cards before adding new shortcuts.

Still have questions?

Help us improve!

Enviar Feedback

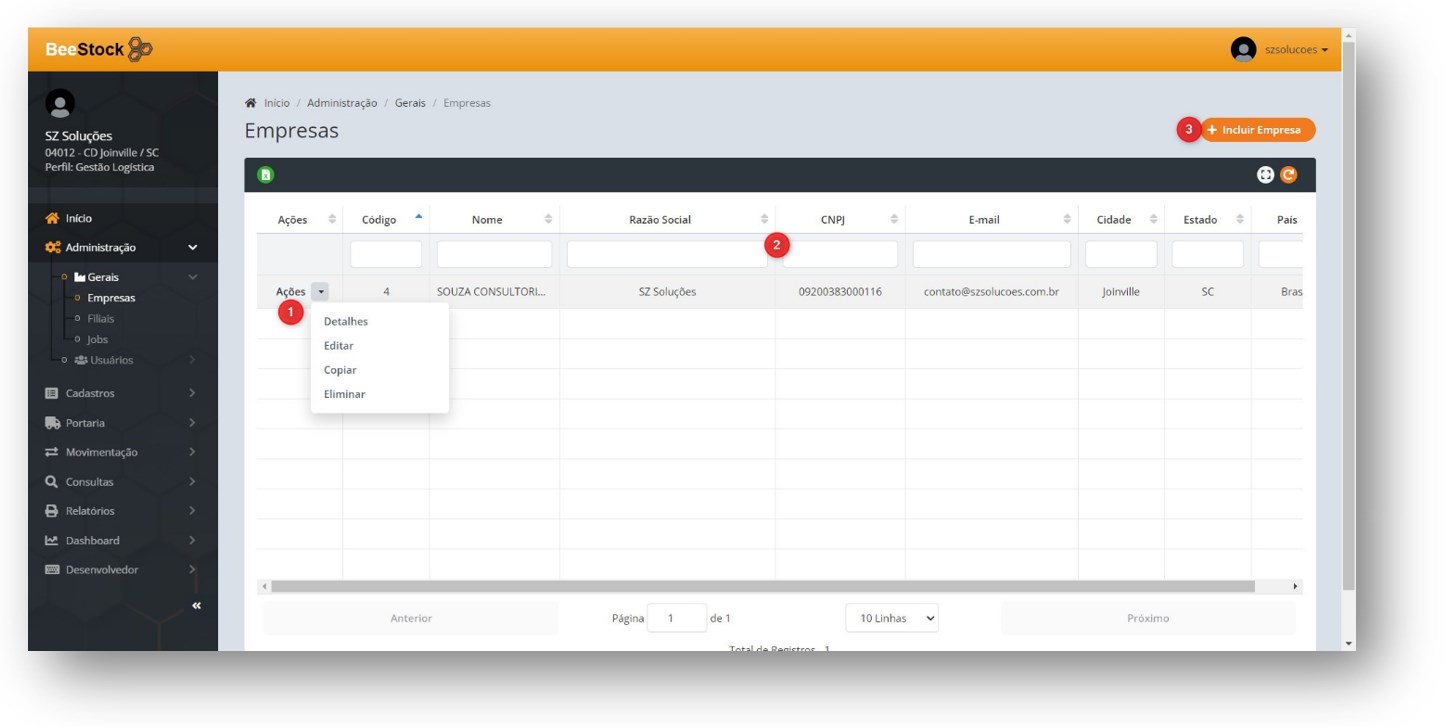

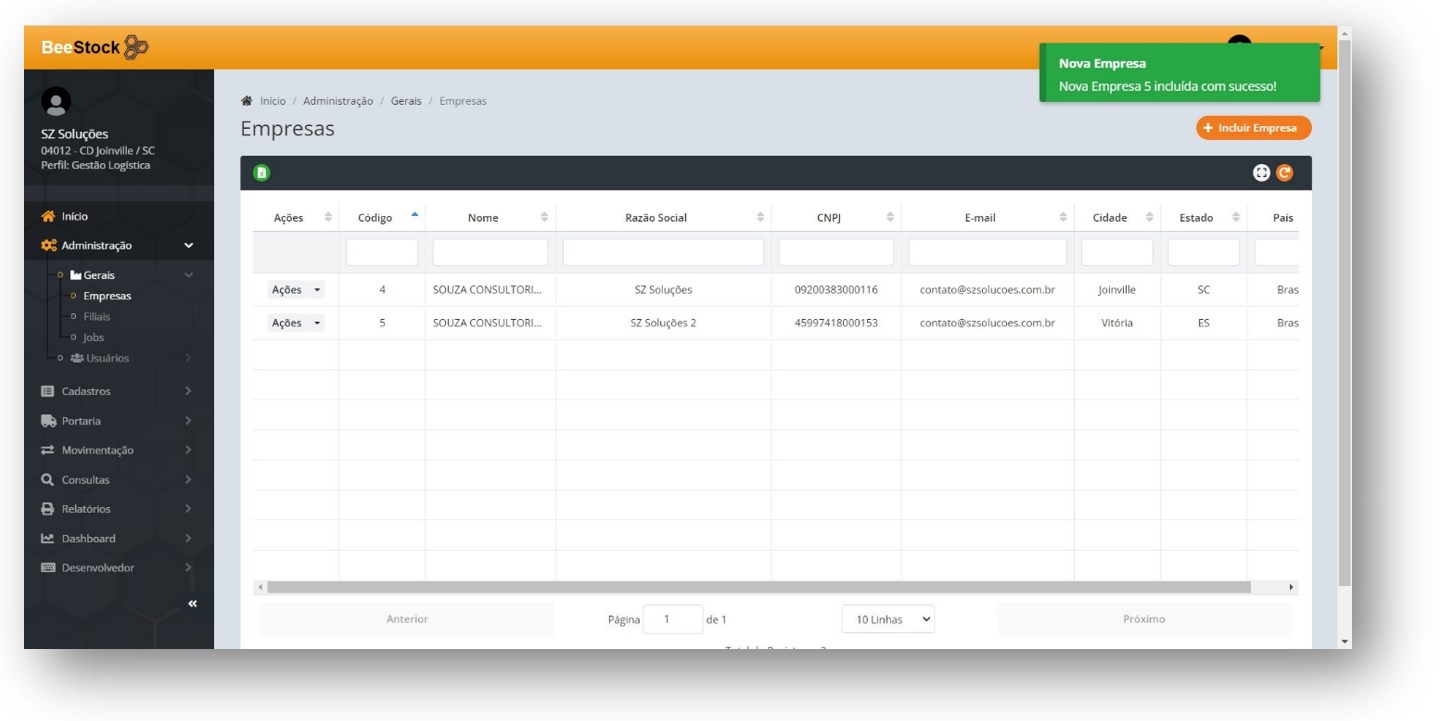

Company Registration

Located in the Administration > General > Companies menu, it allows users to create and manage their company registrations.

This screen contains the following information:

1. Click on Actions to access the following functionalities:

- Details

- Edit

- Copy

- Delete

2. The main grid will list all companies already registered in the system.

3. + Add Company button to register a new company

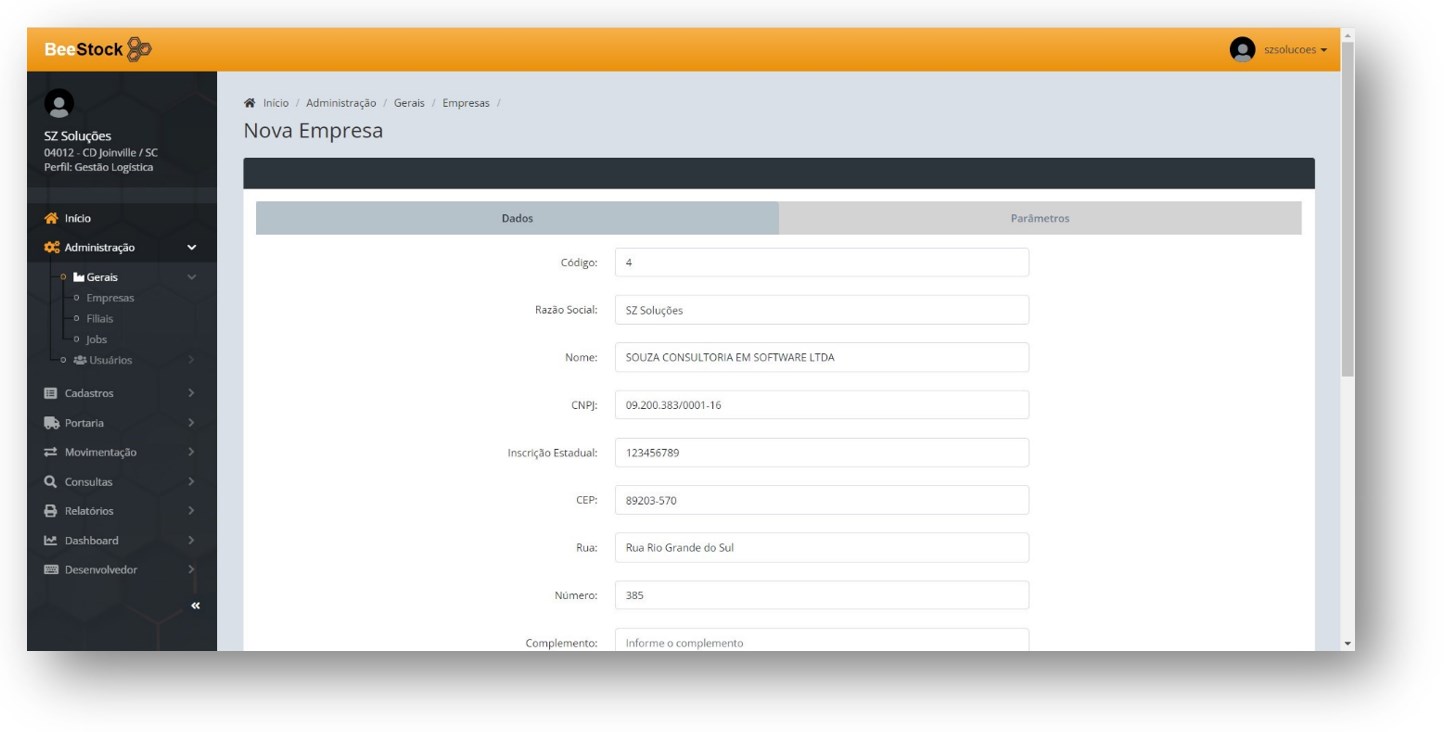

4. When you click on + Add Company to register a new company, the screen below will open: Where you must fill in the company data.

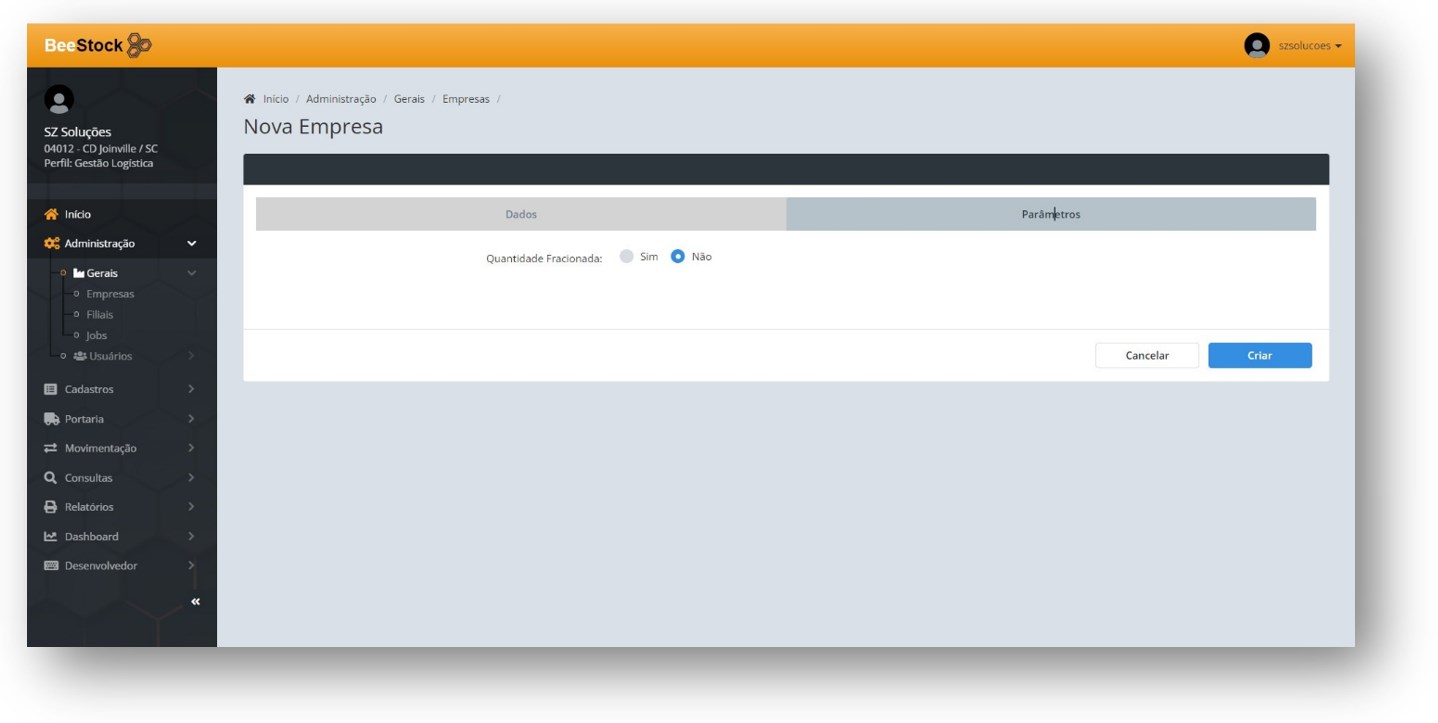

5. In the Parameters tab, you must:

- Define whether the company will work with Fractional Quantity.

- Click on Create.

6. The confirmation message New Company X successfully included! will be displayed.

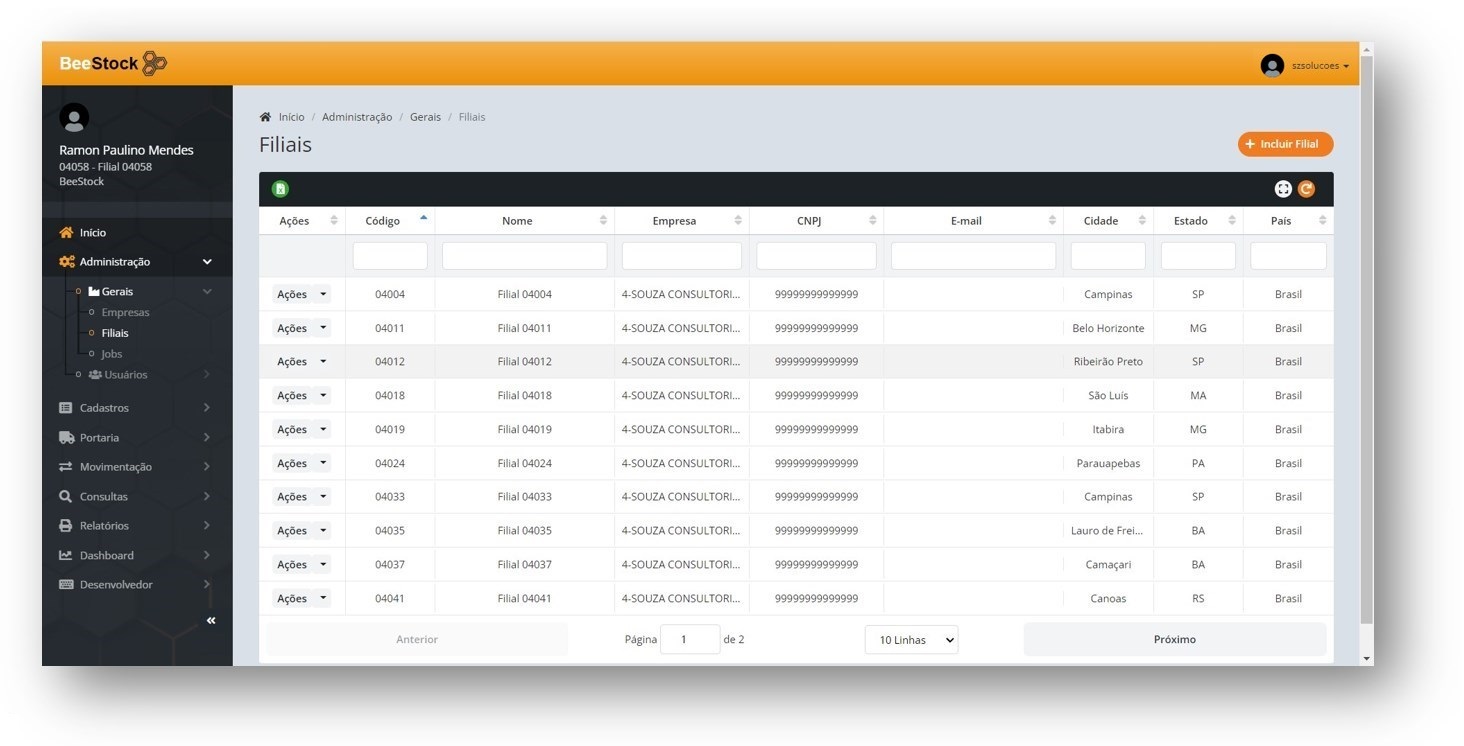

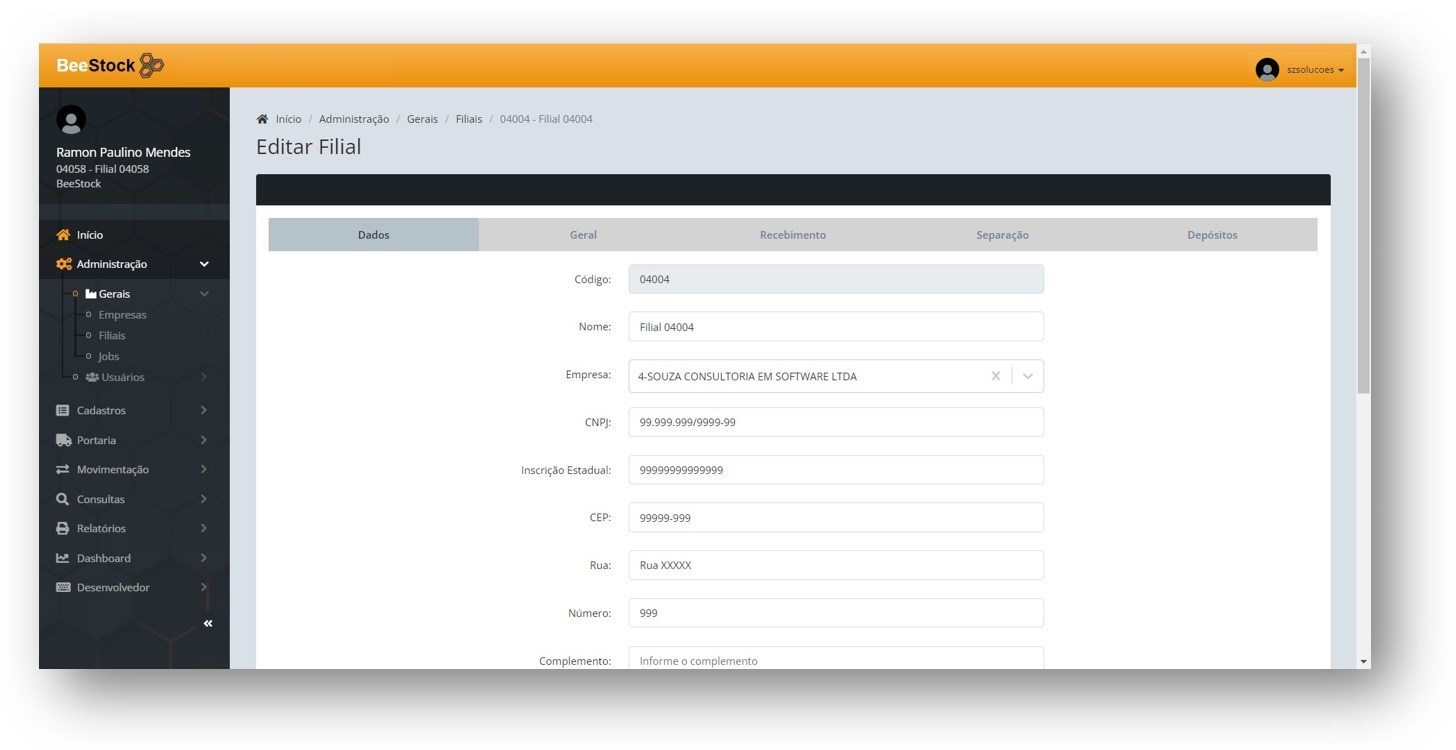

Branch Registration

Located in the Administration > General > Branches menu.

This screen will list all branches registered in the system, as well as their parameters for specific configurations per branch.

1. Click the orange +Add Branch button.

2. On the Data tab, fill in the information:

- Company Name

- State Registration

- Zip Code

- Number

- Complement

- Neighborhood

- City

- Country

- E-mail

- Observation

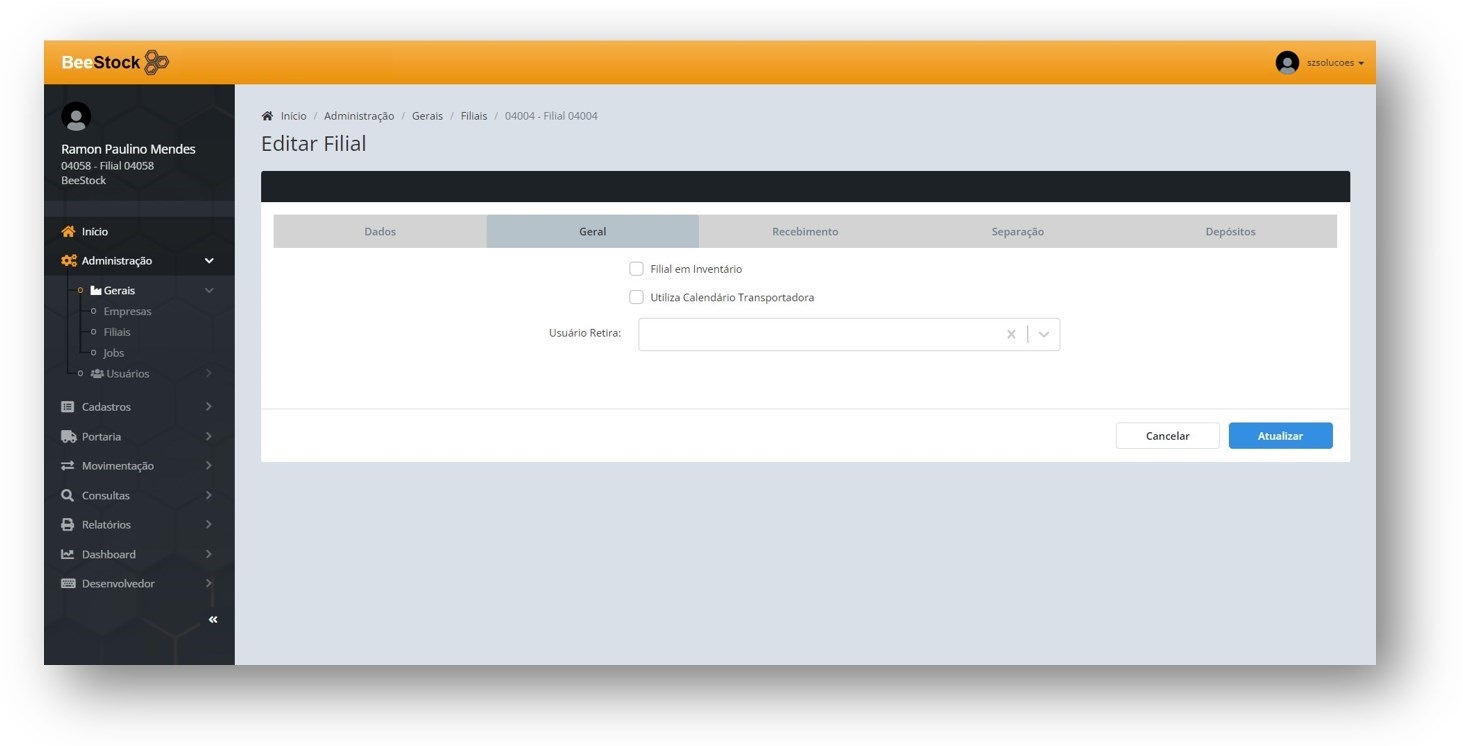

3. On the General tab

- Branch in Inventory, which if checked, will block all movements of this branch during the general inventory.

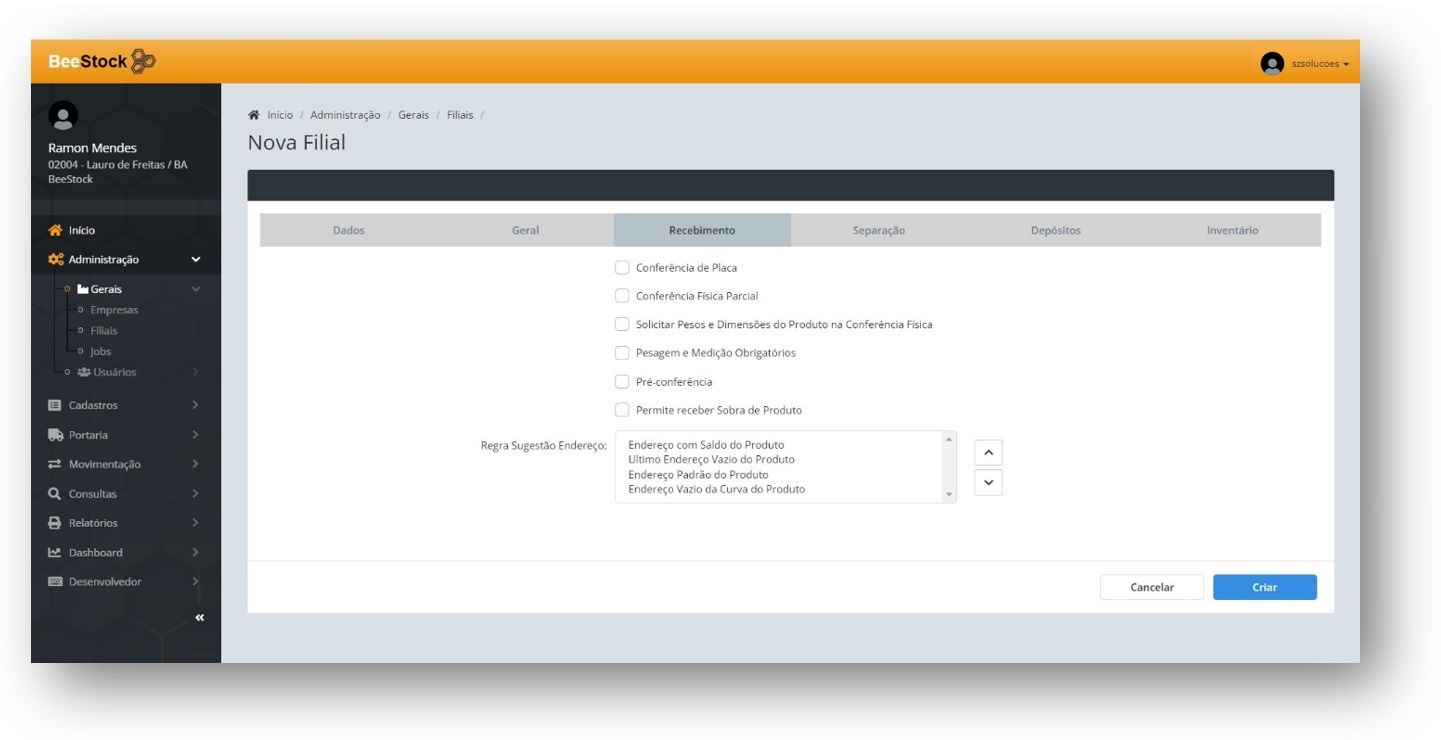

4. On the Receiving tab

- License Plate Check informs if the inbound documents in this branch should go through the license plate checking process.

- Partial Fiscal Check informs if in this branch it will be possible to carry out the partial physical check, such as, for example, the total quantity being checked in two or more times, or if it should be checked completely at once.

- Request Product Weights and Dimensions will request weights and dimensions in the message parameter and mandatory measurements in the physical check.

- Pre-Check enables the use of the pre-check label in the entry process.

- Allows receiving excess product, if checked, will send the received balance as excess to the warehouses configured on the Warehouse tab.

- Address suggestion rule allows the manager to define the order that the system should use for suggesting addresses in the material entry process, being them:

- Address with product balance.

- Last empty product address.

- Product default address.

- Empty address of the product curve.

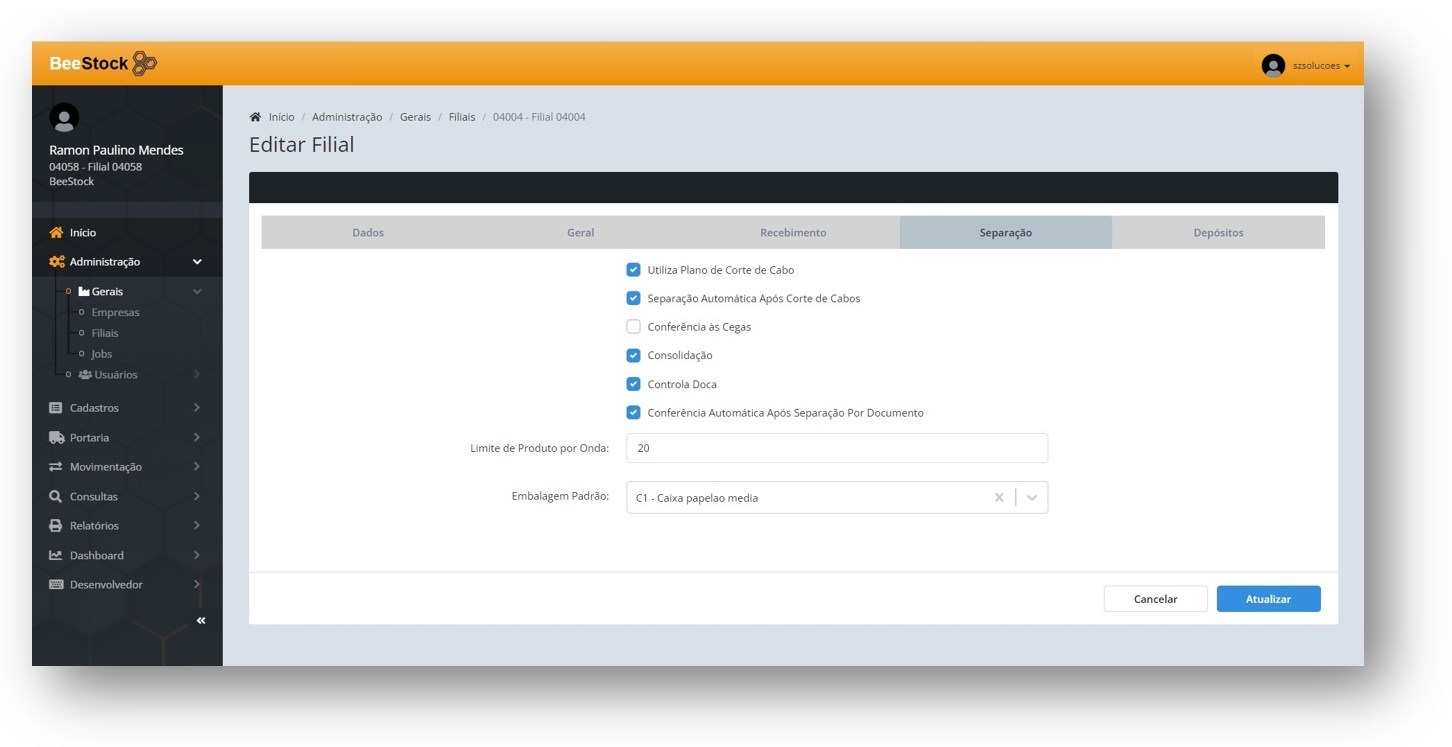

5. On the Picking tab

- Use cable cutting plan informs if the cable cutting plan will be used in this branch for product picking.

- Automatic picking after cable cutting informs if, after cable cutting, product picking will be performed automatically.

- Blind Check informs if the product check in picking will be performed blindly, that is, without prior knowledge of the product to be checked.

- Consolidation informs if the picking of products will be carried out by consolidation, that is, grouping products from different documents in the same picking wave.

- Control dock informs if the picking of products will be done by dock.

- Automatic check after separation by document informs if, after separation by document, the product check will be performed automatically.

- Limit of products per wave must be filled with the maximum number of products and one-handed per wave to be searched by the picker.

- Default packaging must be informed the default packaging suggested in the check and used automatically as packaging if the parameter Automatic Check After Picking by Document is checked.

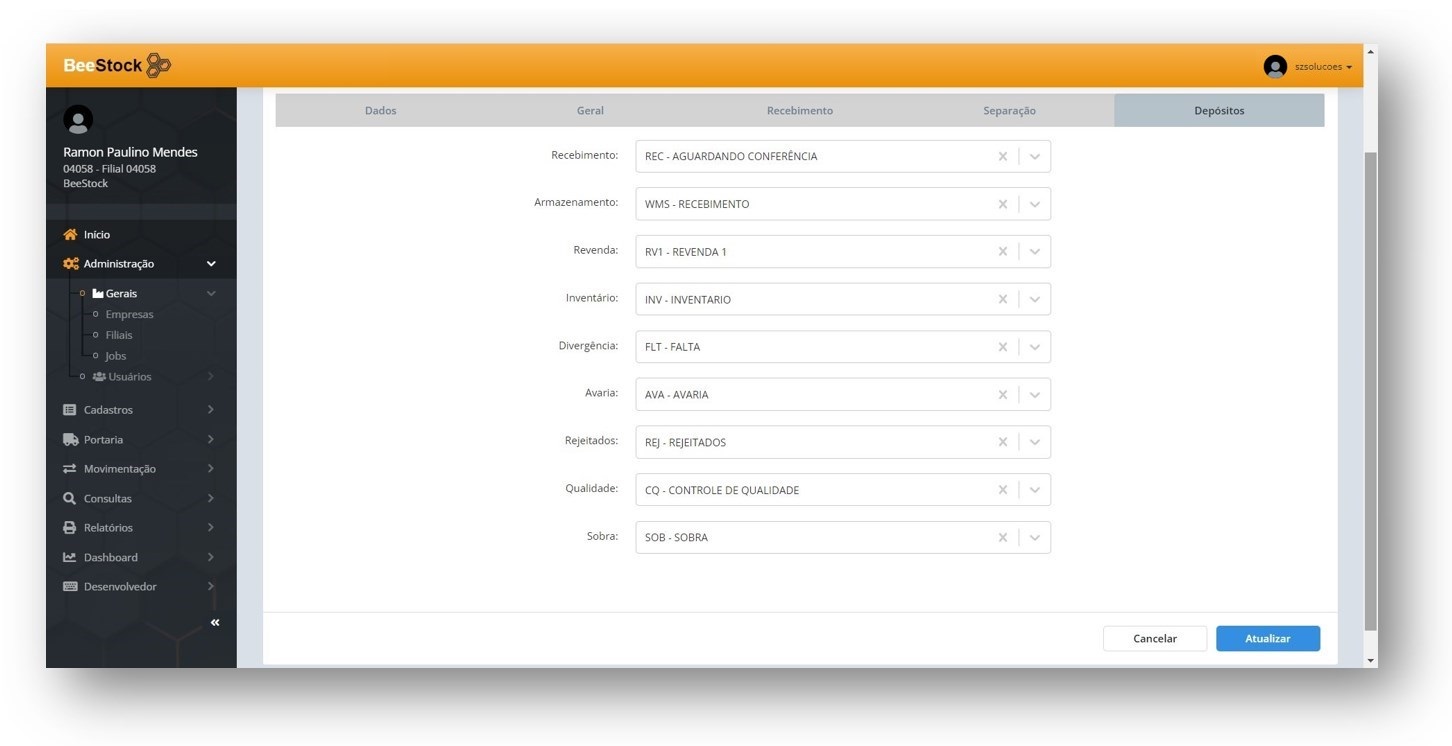

6. On the Warehouse tab, the warehouses for each stage of the process must be informed.

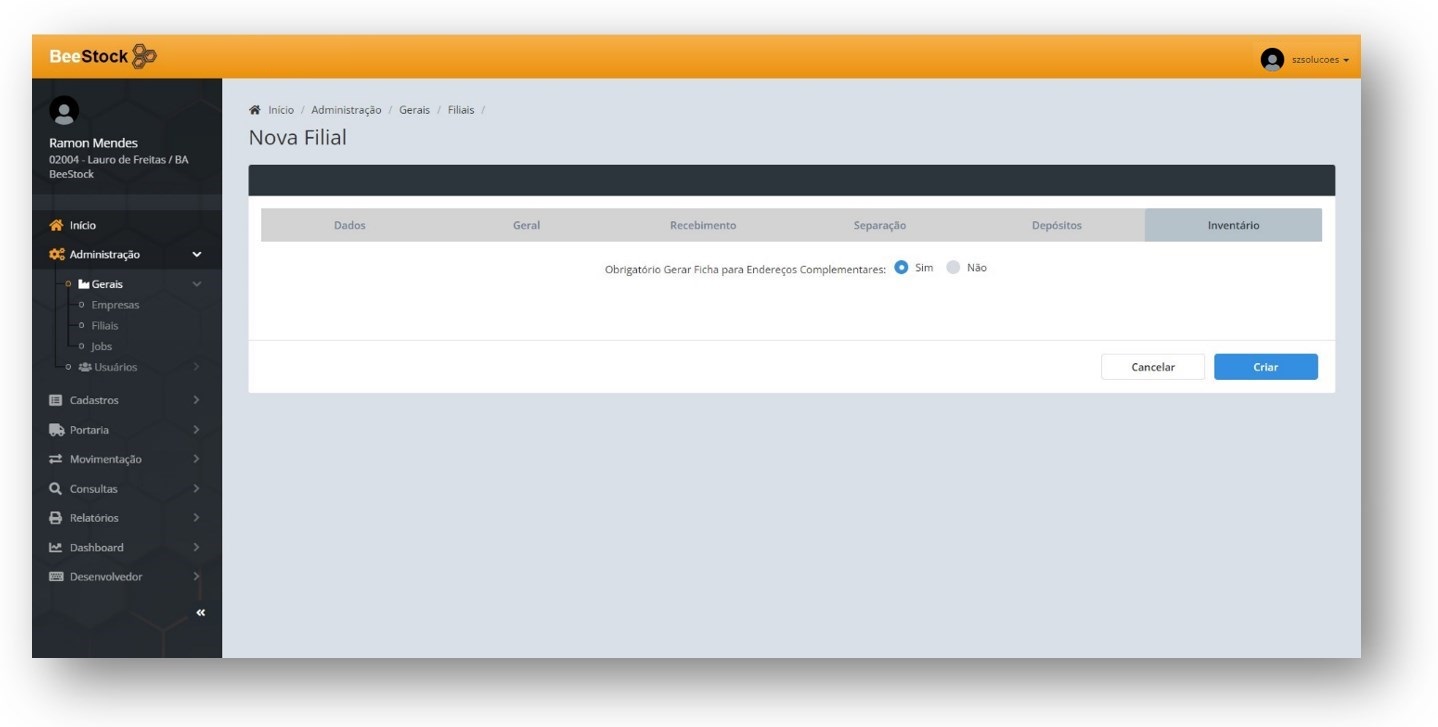

7. On the Inventory tab.

Mandatory to generate a card for complementary addresses will bring this option checked automatically when clicking on Generate Card on the inventory card generation screen.

8. Click on Create to finish registering the new branch.

Jobs

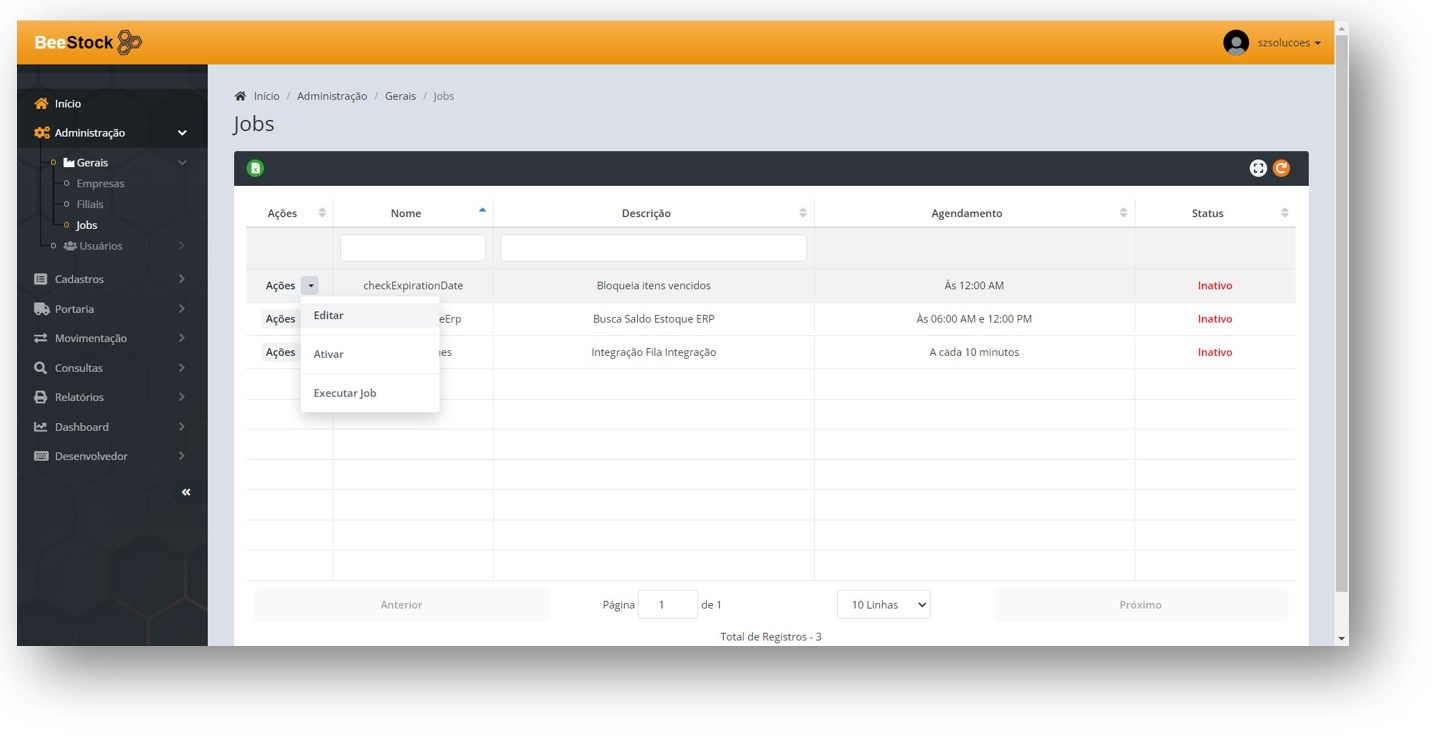

Located in the Administration > General > Jobs menu, in this screen it will be possible to manage the scheduling of automatic executions of system routines.

We recommend caution when changing parameters on this screen, if you have any questions, you should request assistance from SZ Soluções Support, as these are routines that influence the entire system.

In the desired Job, in Actions it is possible to Edit, Activate / Inactivate and Run Job.

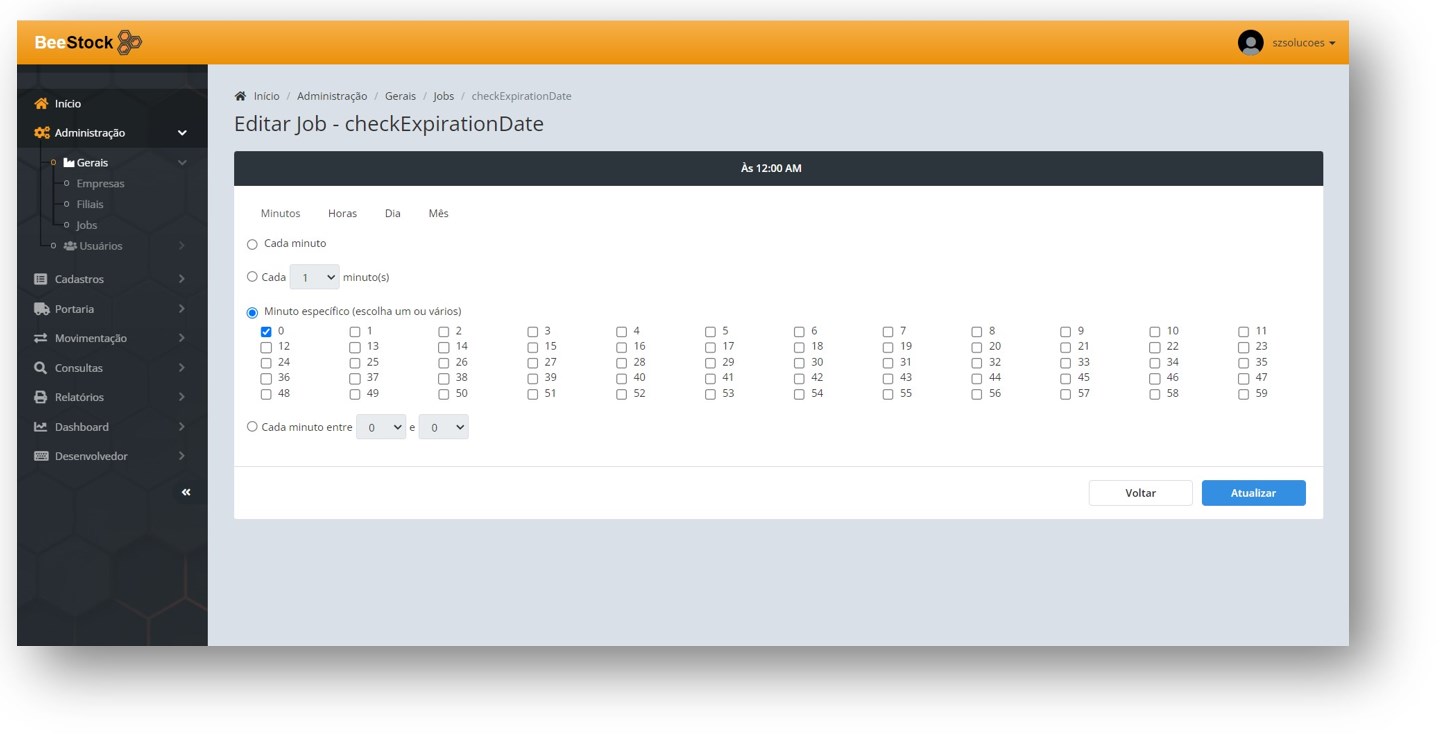

- Clicking on Actions > Edit will display the current schedule, allowing you to change the frequency of the automatic execution of the Job in question, clicking on Update will save the changes.

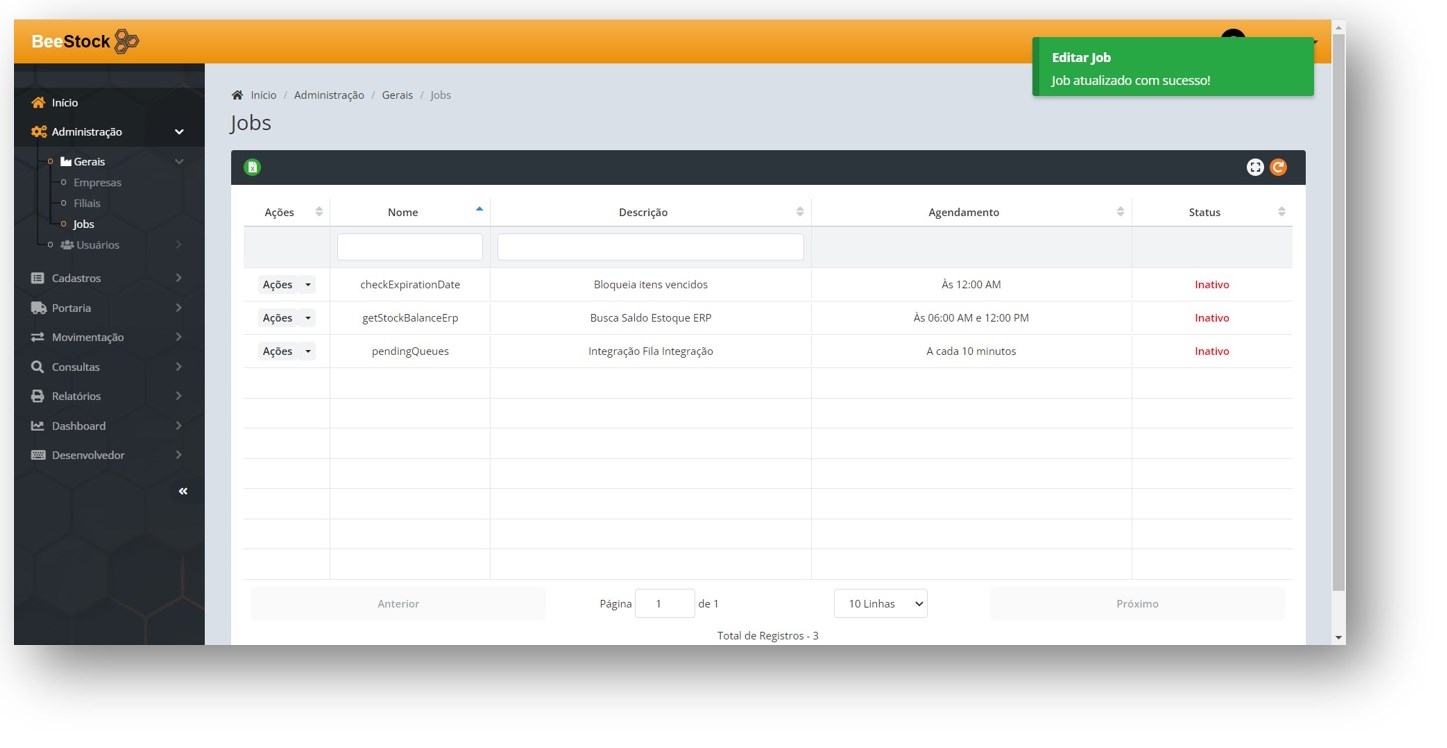

- The message Job updated successfully! will be displayed, and the changes made will be applied.

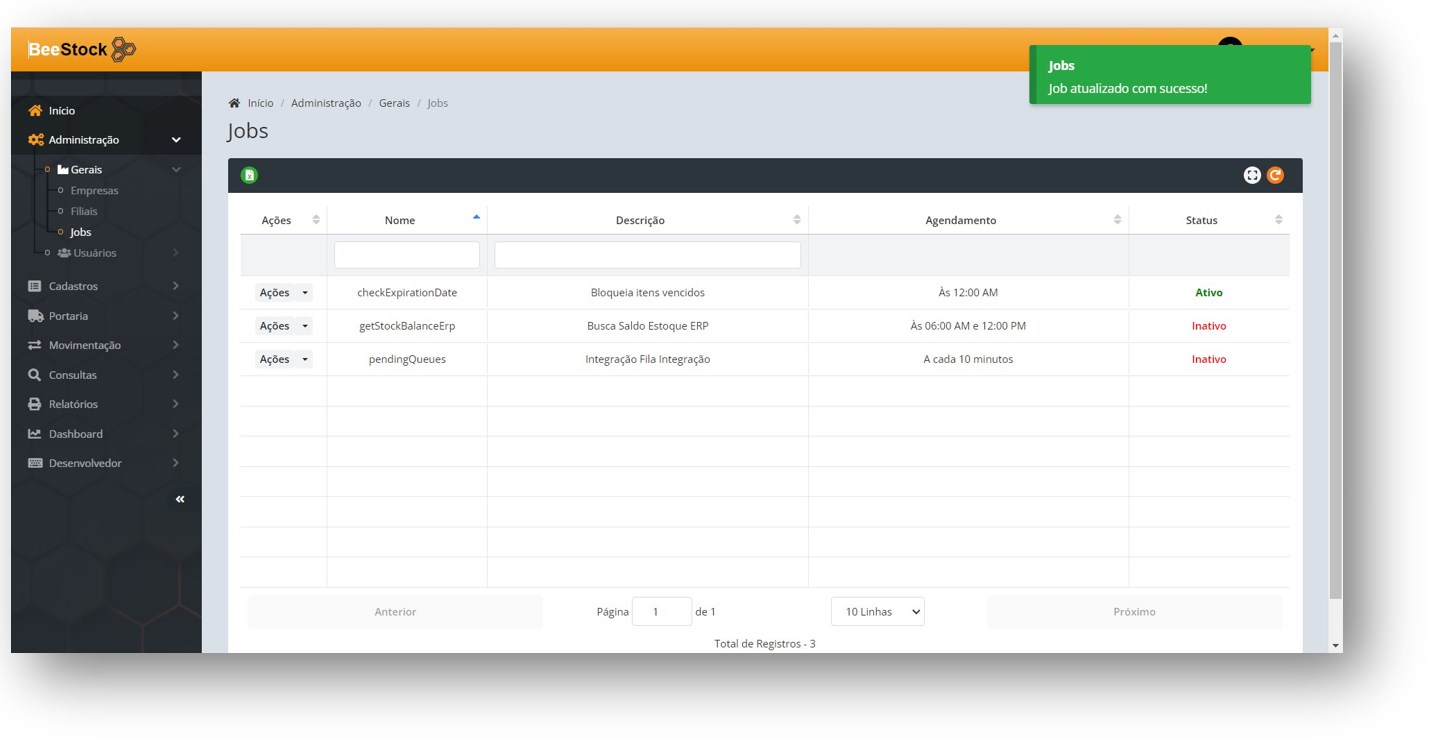

- Clicking on Actions > Activate / Inactivate, the confirmation message Job successfully updated! will be displayed.

User Registration

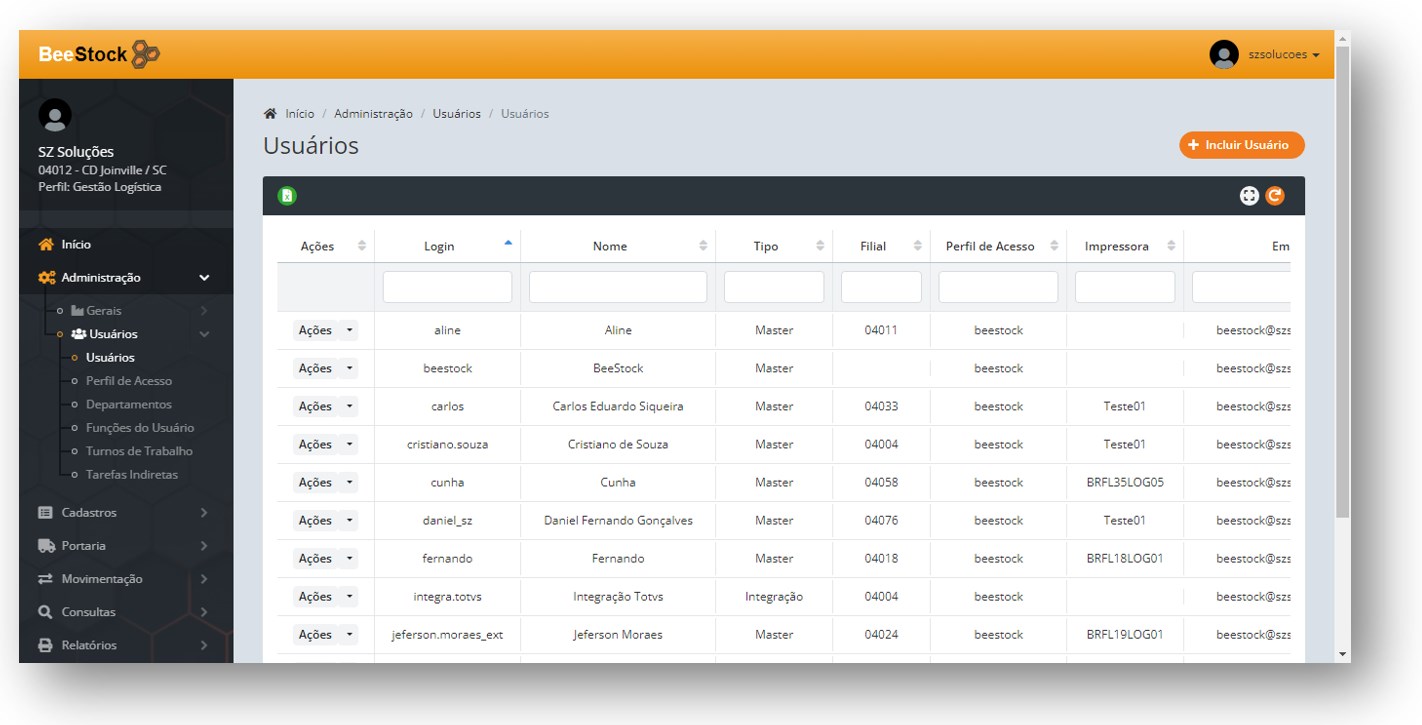

Located in the Administration > Users > Users menu, this screen will list all users registered in the system as well as their access parameters.

Step by Step to include a new user:

1. Click the orange +Add User button.

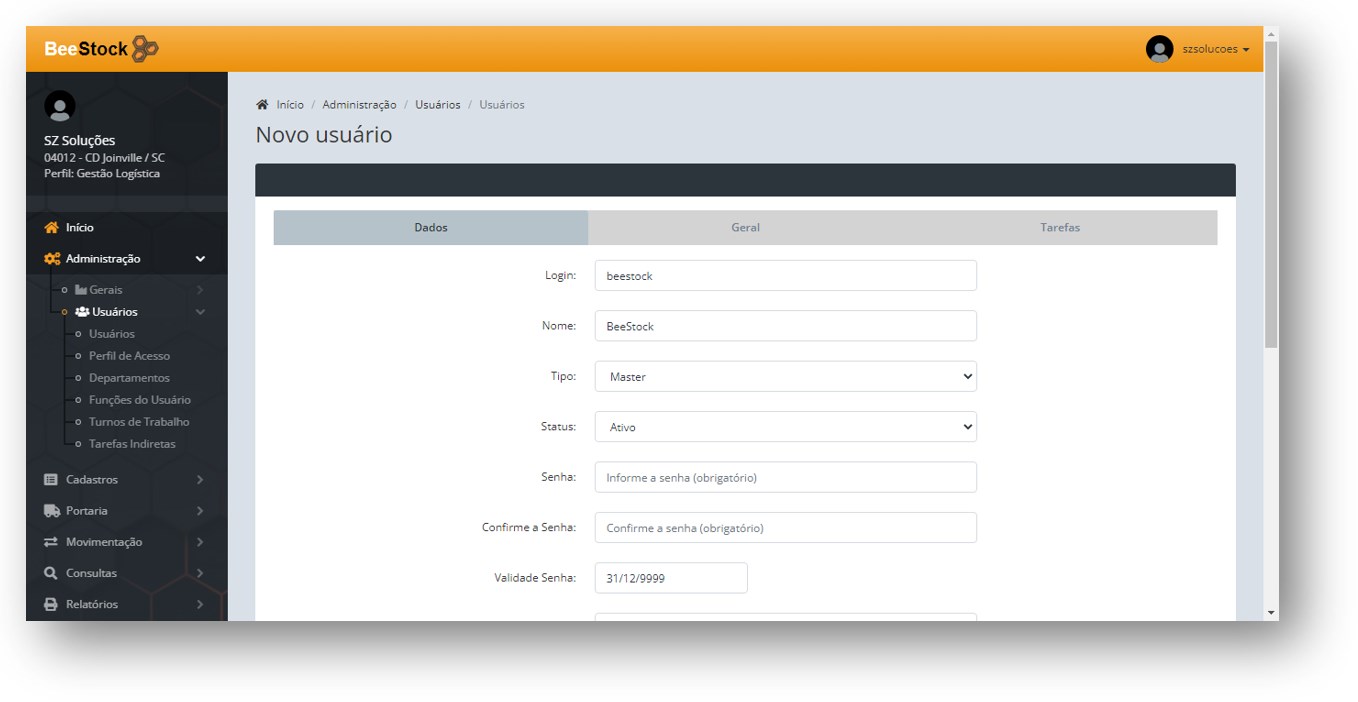

2. On the Data tab, fill in the information:

- Login

- Name

- Type

- Status

- Password

- Confirm Password

- Password Validity

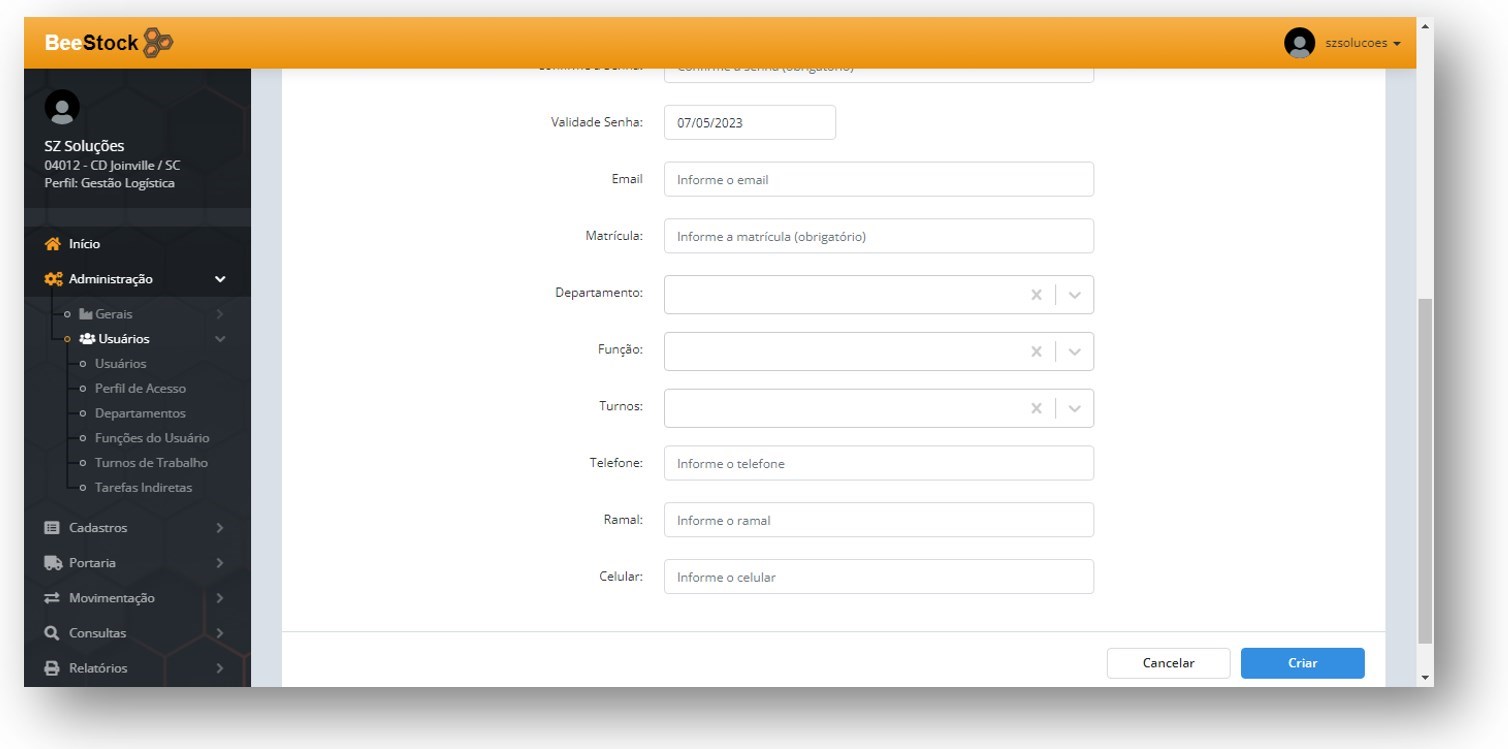

- E-mail

- Registration

- Department

- Function

- Shifts

- Phone

- Extension

- Cellphone

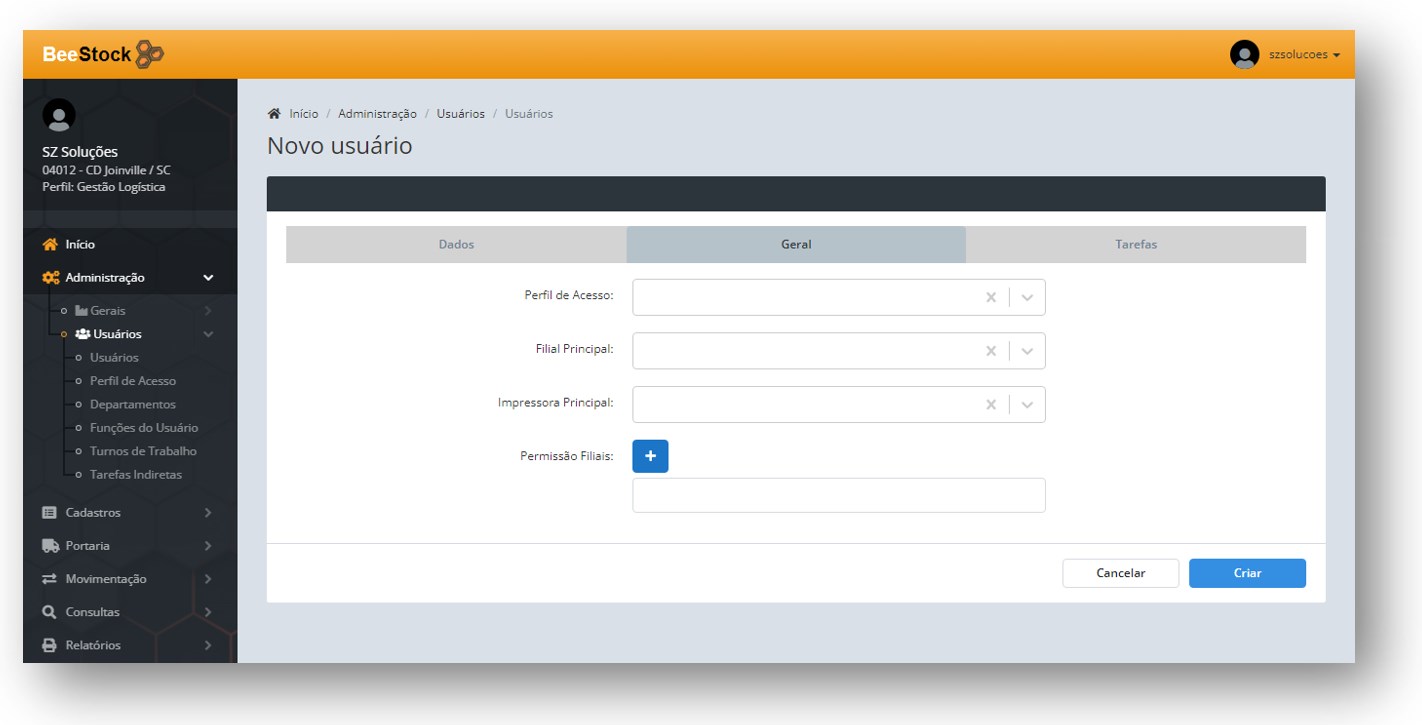

3. On the General tab

- Access Profile, you must select the access profile with the set of permissions that the user must exercise according to their function.

- Main Branch, you must select the user’s main branch.

- Main Printer, you must select the user’s main printer.

- Branch Permission, you must select all branches that the user will have access to.

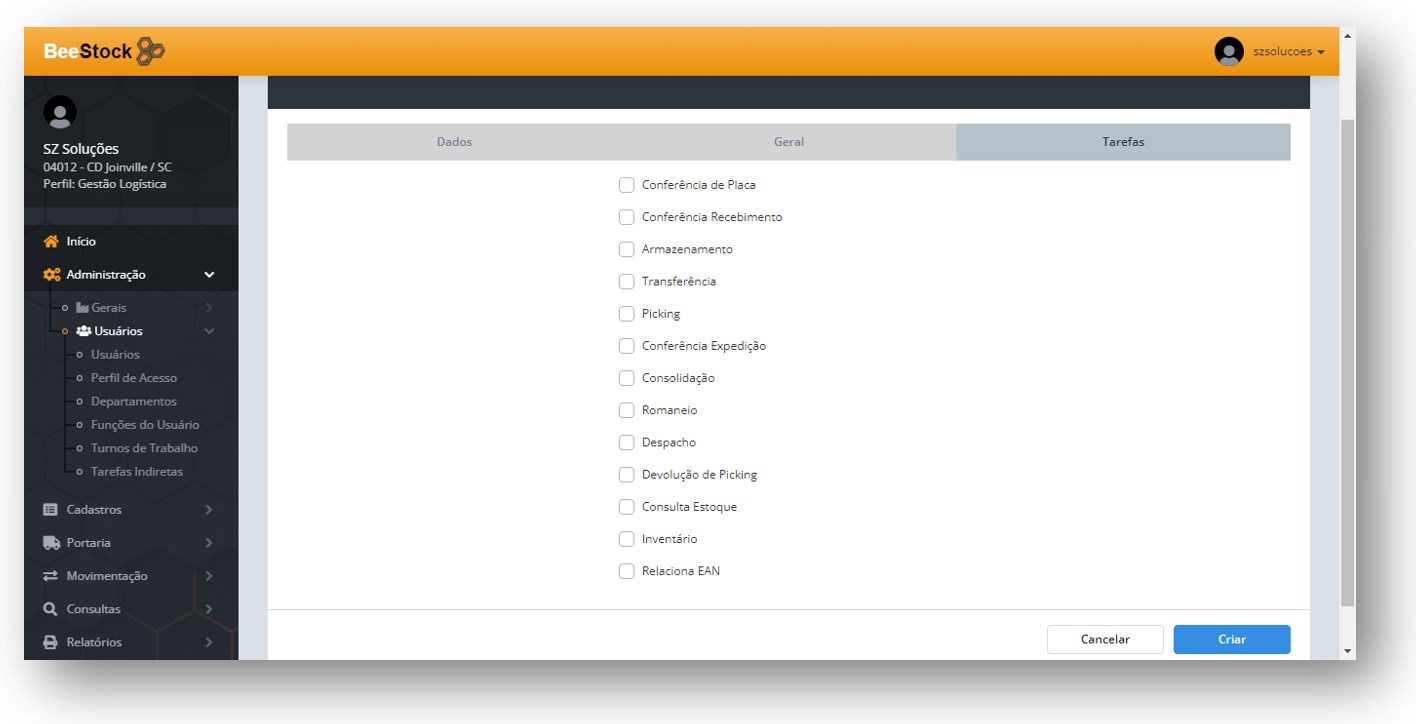

4. On the Tasks tab

- License Plate Check - informs if this employee will have access to the license plate check process.

- Receiving Check - informs if this employee will have access to the receiving check process.

- Storage - informs if this employee will have access to the storage process.

- Transfer - informs if this employee will have access to the transfer process.

- Picking - informs if this employee will have access to the picking process.

- Shipping Check - informs if this employee will have access to the shipping check process.

- Consolidation - informs if this employee will have access to the consolidation process.

- Shipping List - informs if this employee will have access to the shipping list process.

- Dispatch - informs if this employee will have access to the dispatch process.

- Picking Return - informs if this employee will have access to the picking return process.

- Inventory Inquiry - informs if this employee will have access to the inventory inquiry process.

- Inventory - informs if this employee will have access to the inventory process.

- Relate EAN - informs if this employee will have access to the Relate EAN process.

5. Click Create to finish registering the new user.

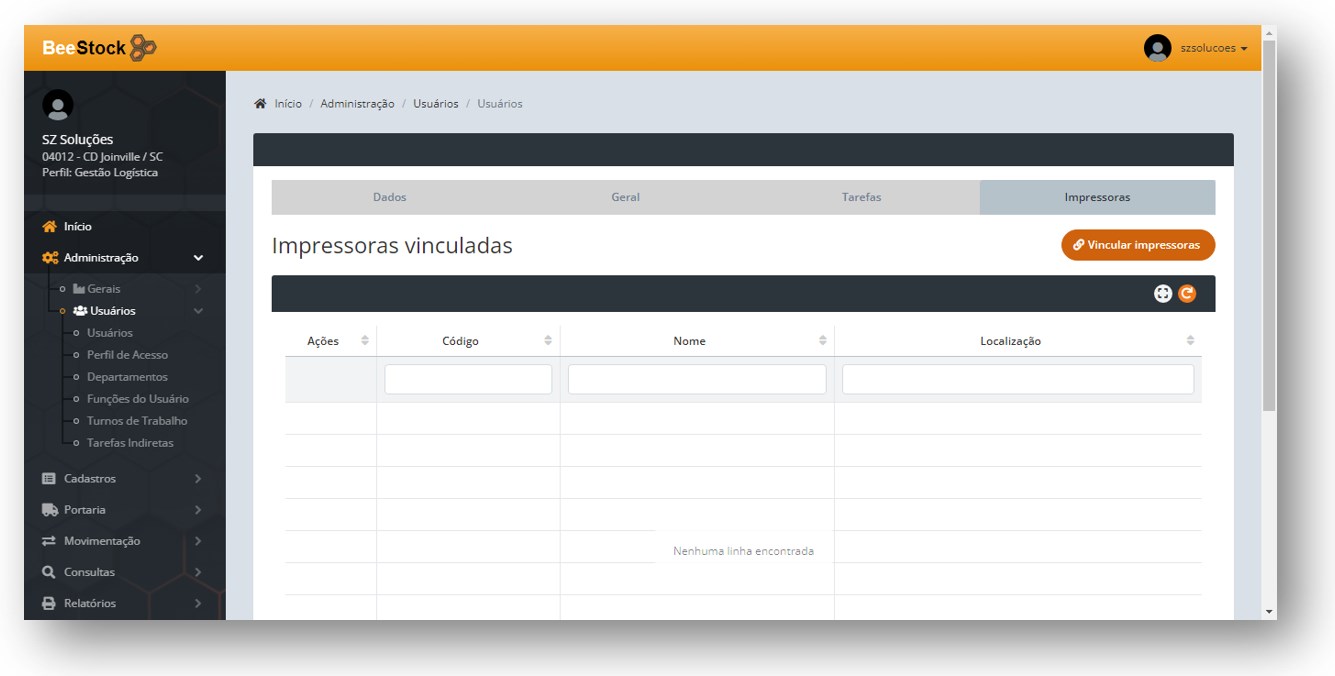

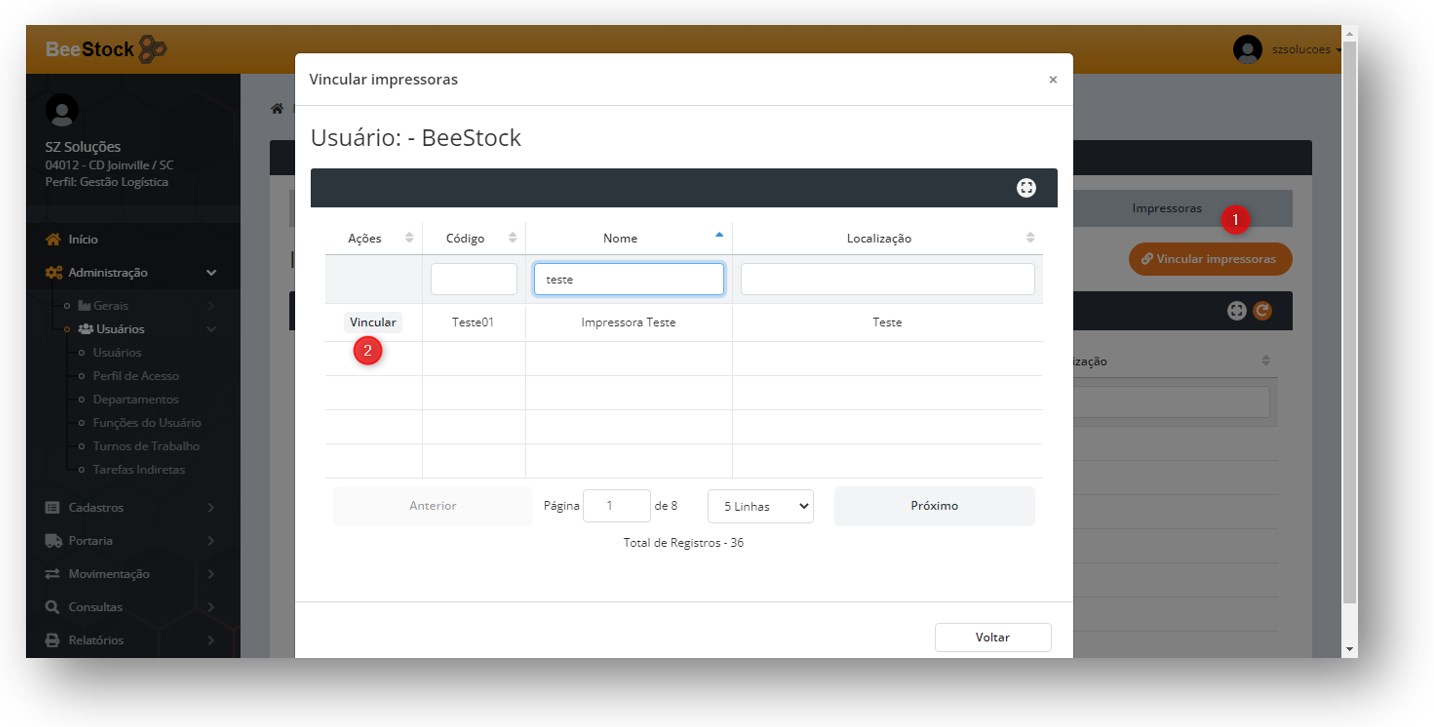

6. After creating the user, we can edit it, and when we do that there is a printer tab:

7. Clicking on Link Printers we can choose the printers that will be linked to the user.

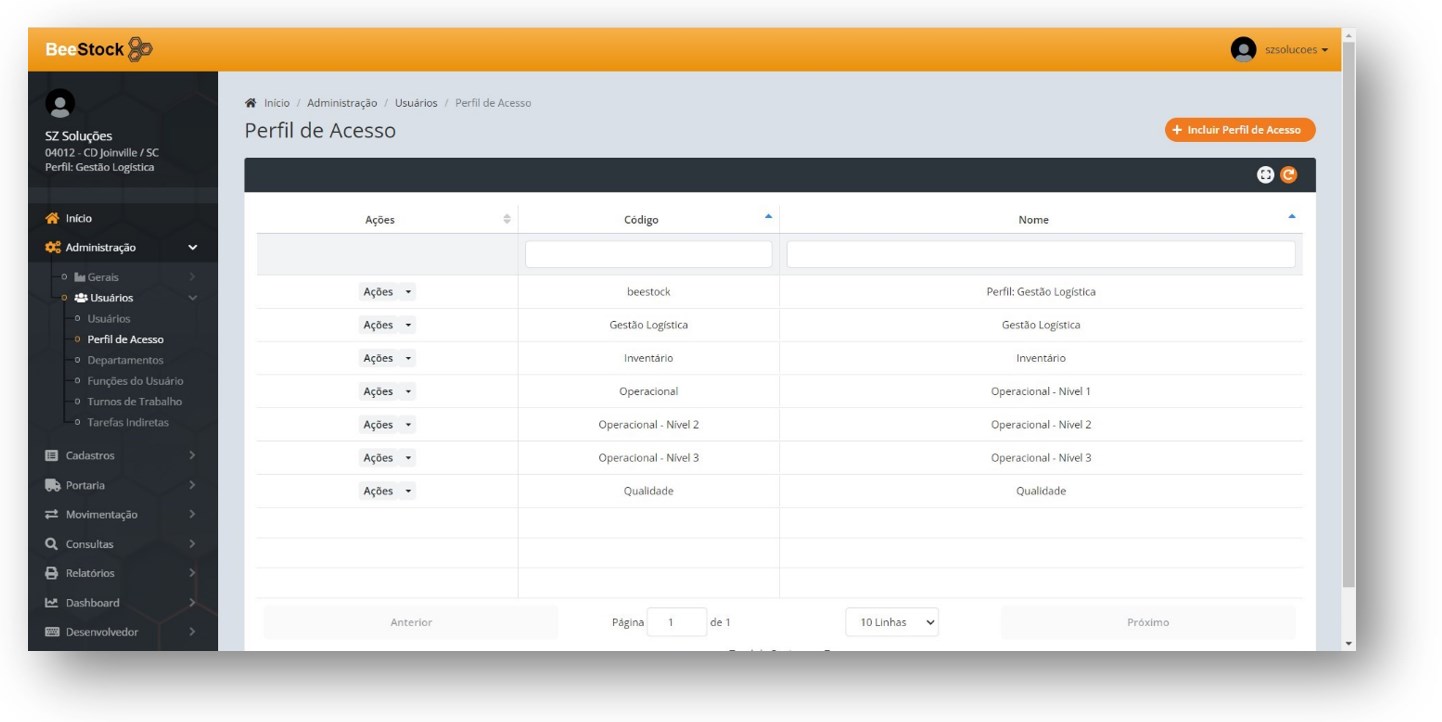

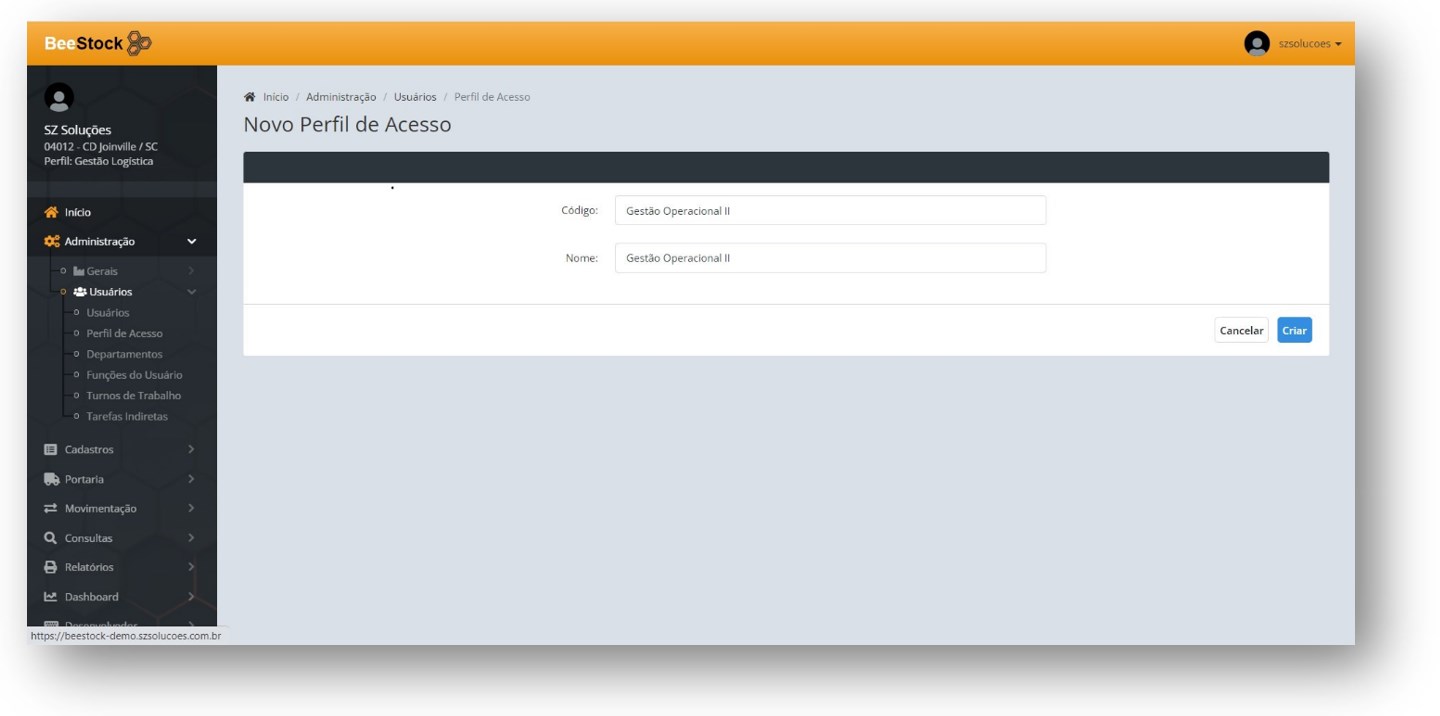

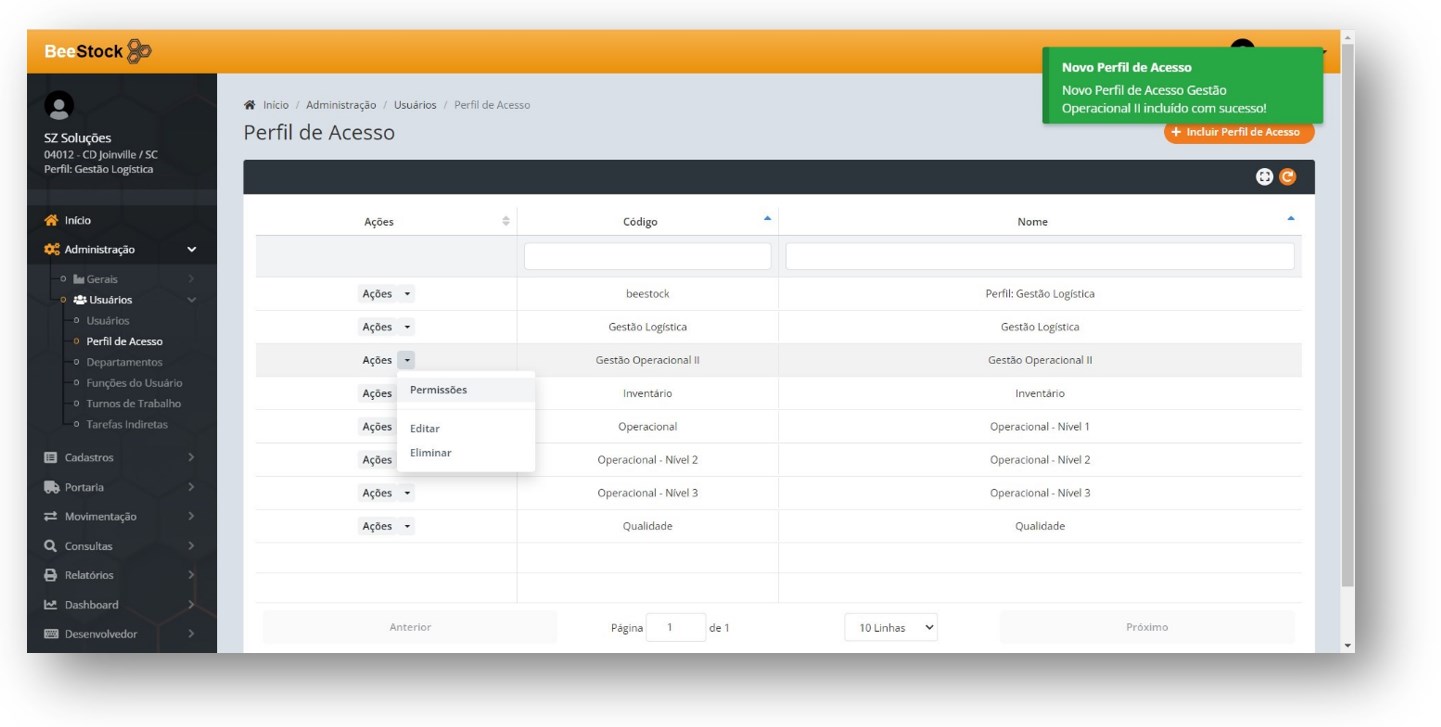

Access Profile

Located in the Administration > Users > Access Profile menu, this screen will list all created access profiles.

To register a new access profile:

1. Click on +Add Access Profile

2. Enter the Code

3. Enter the Name

4. Click the Create button

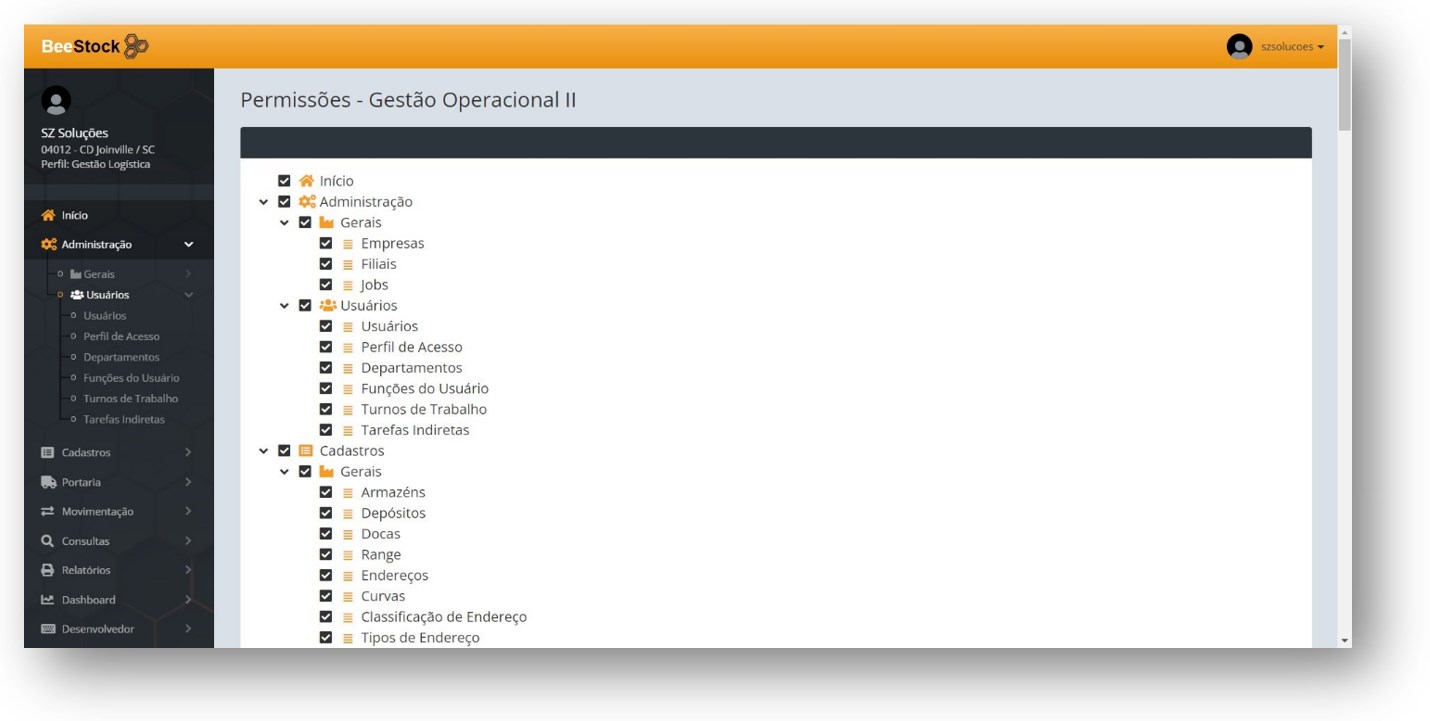

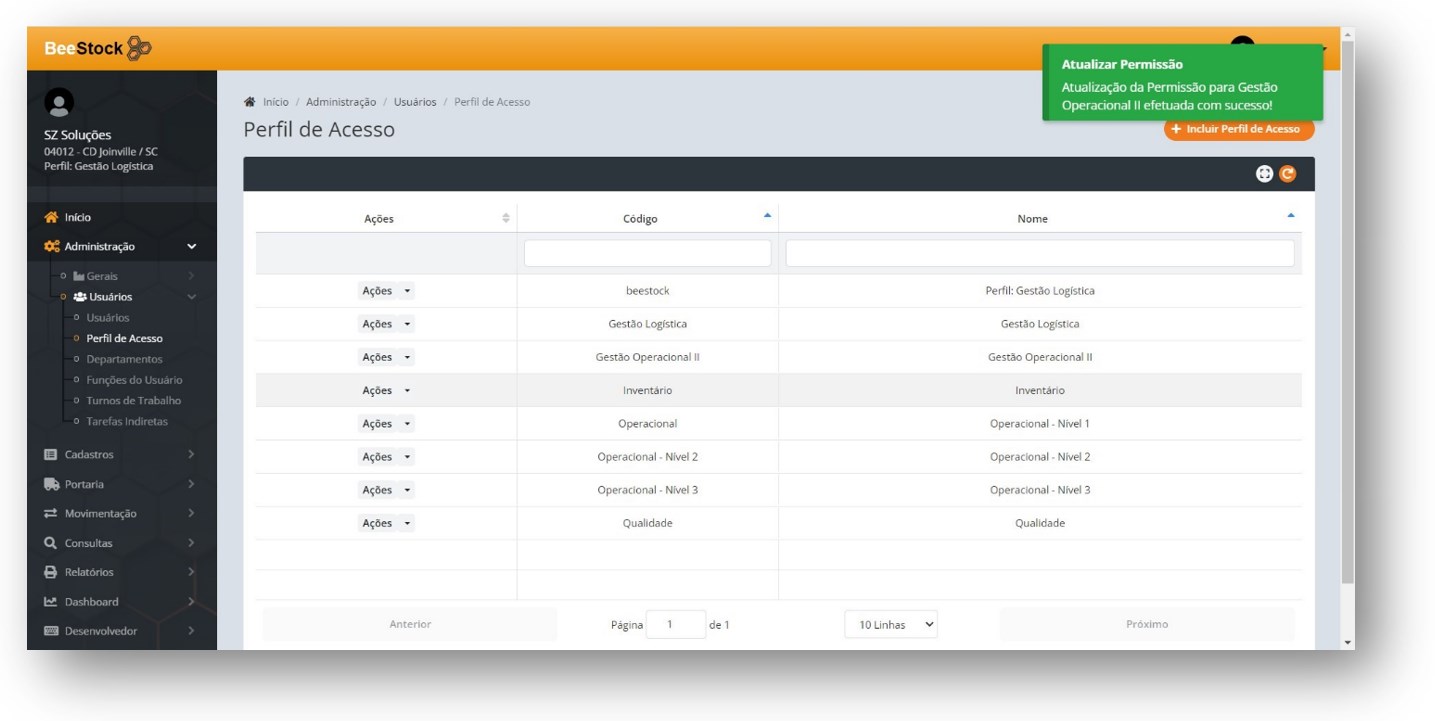

5. To edit an existing profile click on Actions > Permissions.

Make the necessary changes by checking or unchecking the checkboxes for each screen/menu you want to allow or remove access to.

6. The modal will open for you to select which screens the users belonging to the group in question will have access to.

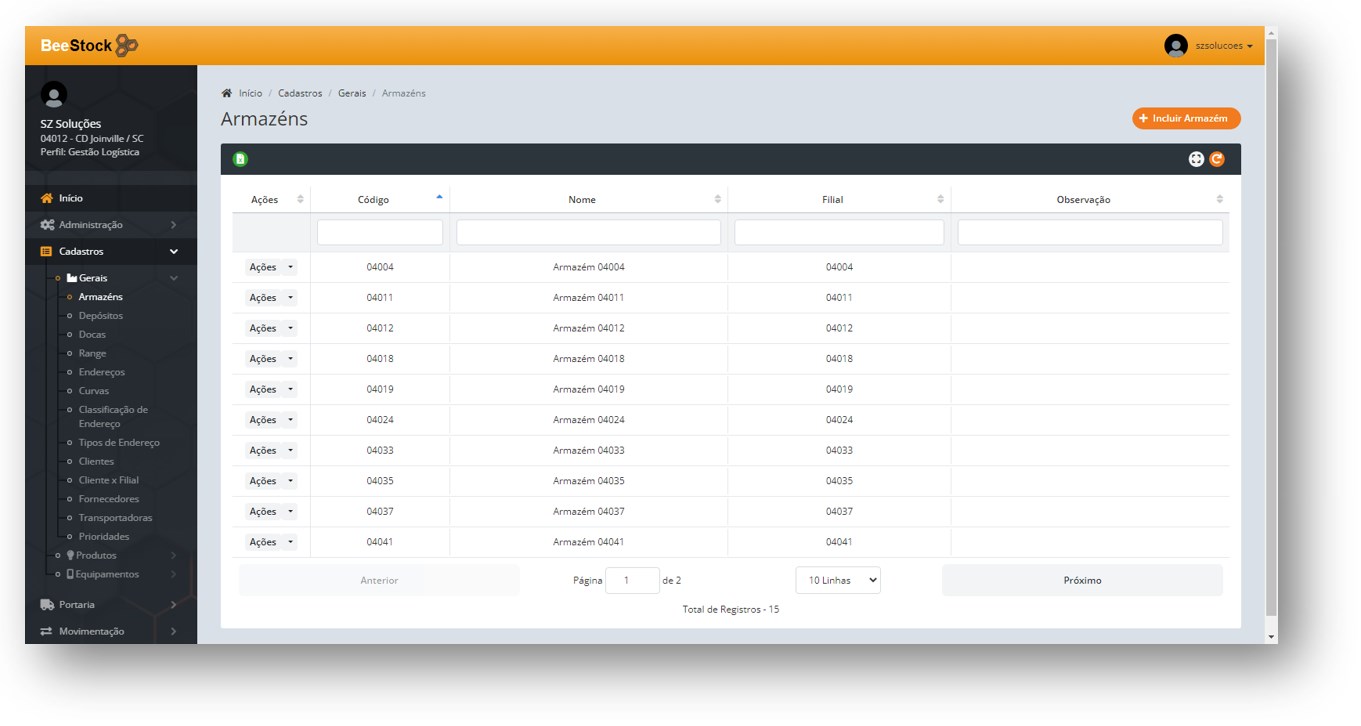

Warehouse Registration

Located in the Registers > General > Warehouses menu, this screen will list all system warehouses that will be used on other screens.

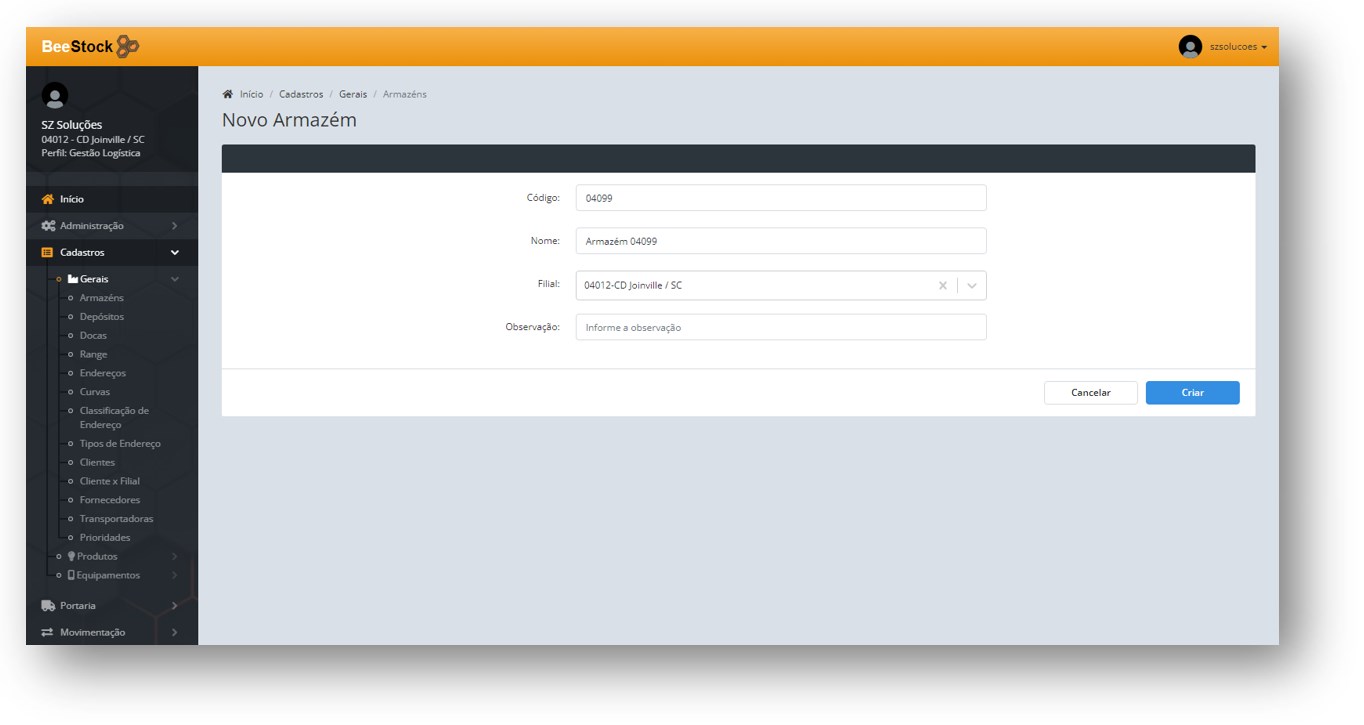

Step by Step To include a new warehouse:

1. Click the orange +Add Warehouse button.

2. On the New Warehouse screen, fill in the information:

- Code

- Name

- Branch

- Observation

3. Click the Create button.

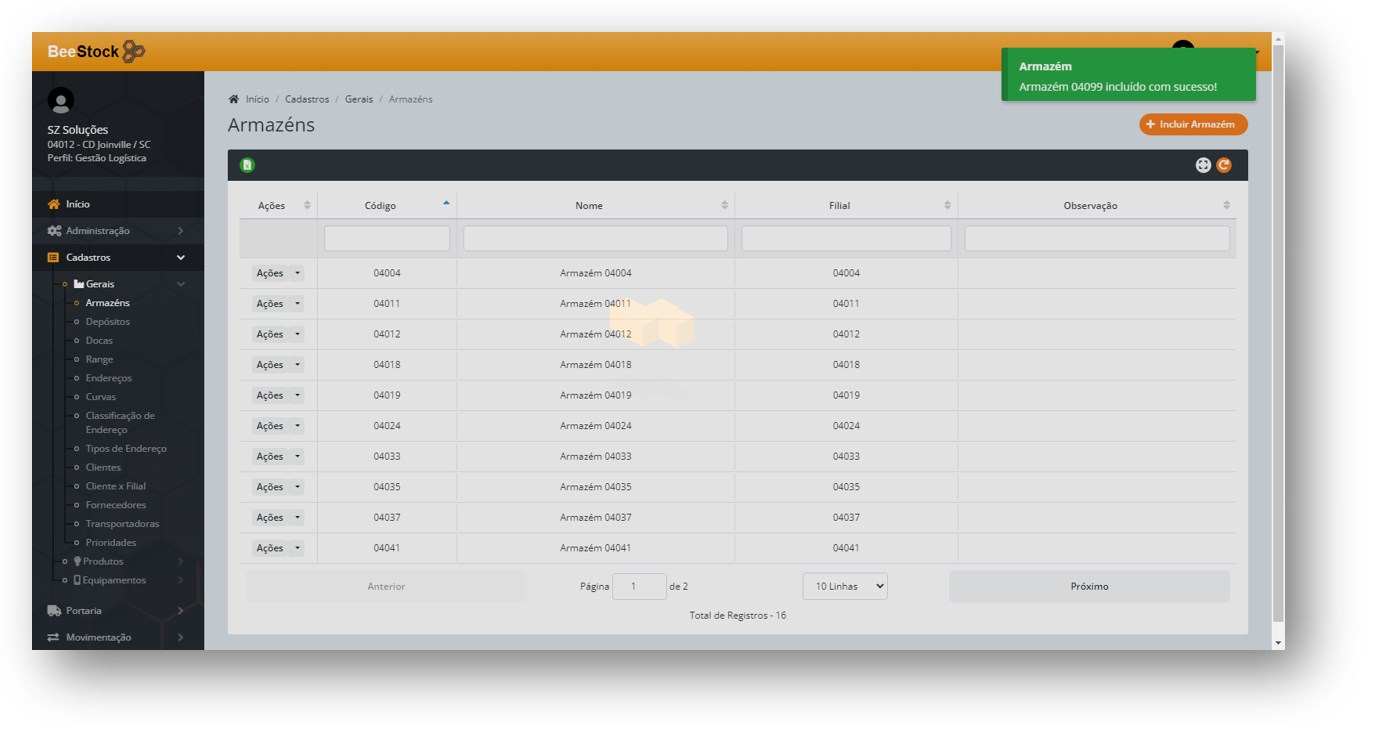

4. The confirmation message Warehouse XXXXX successfully included! will be displayed.

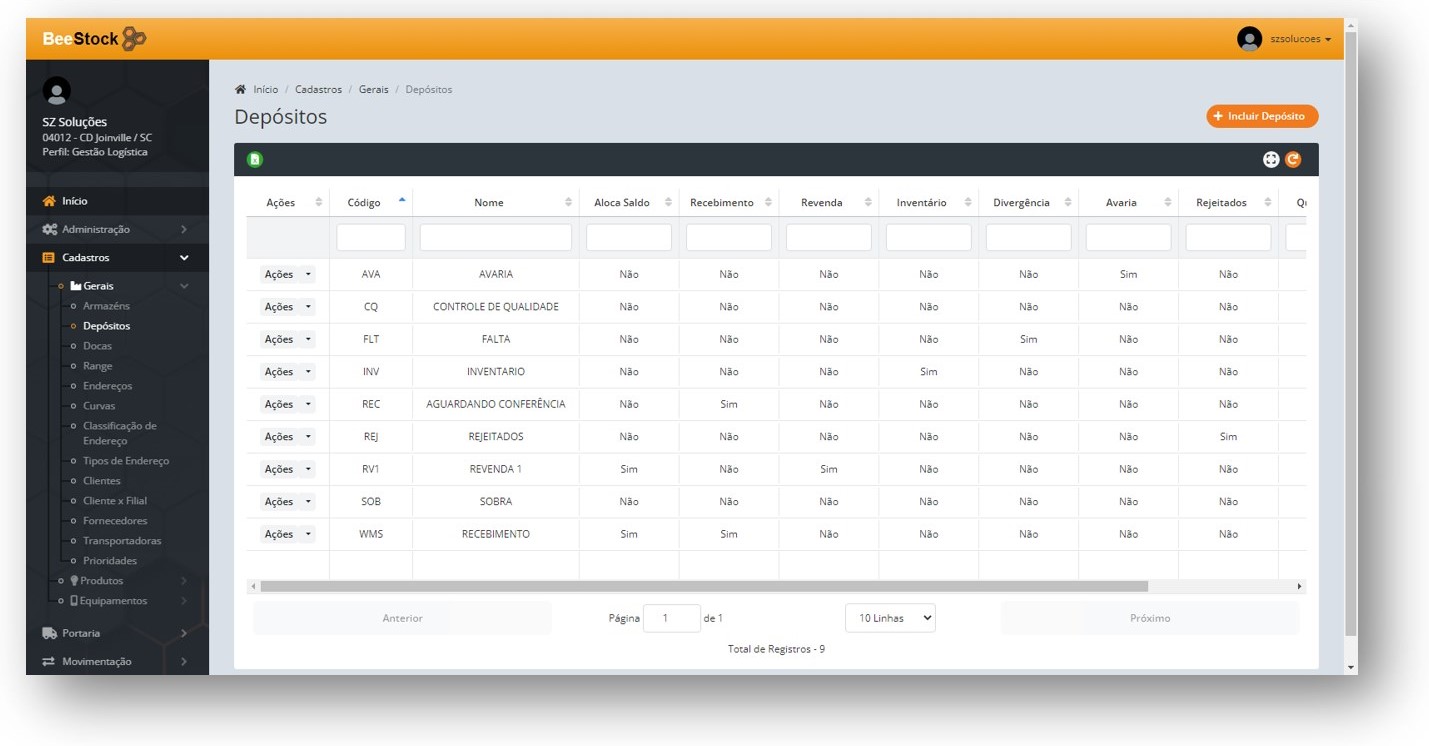

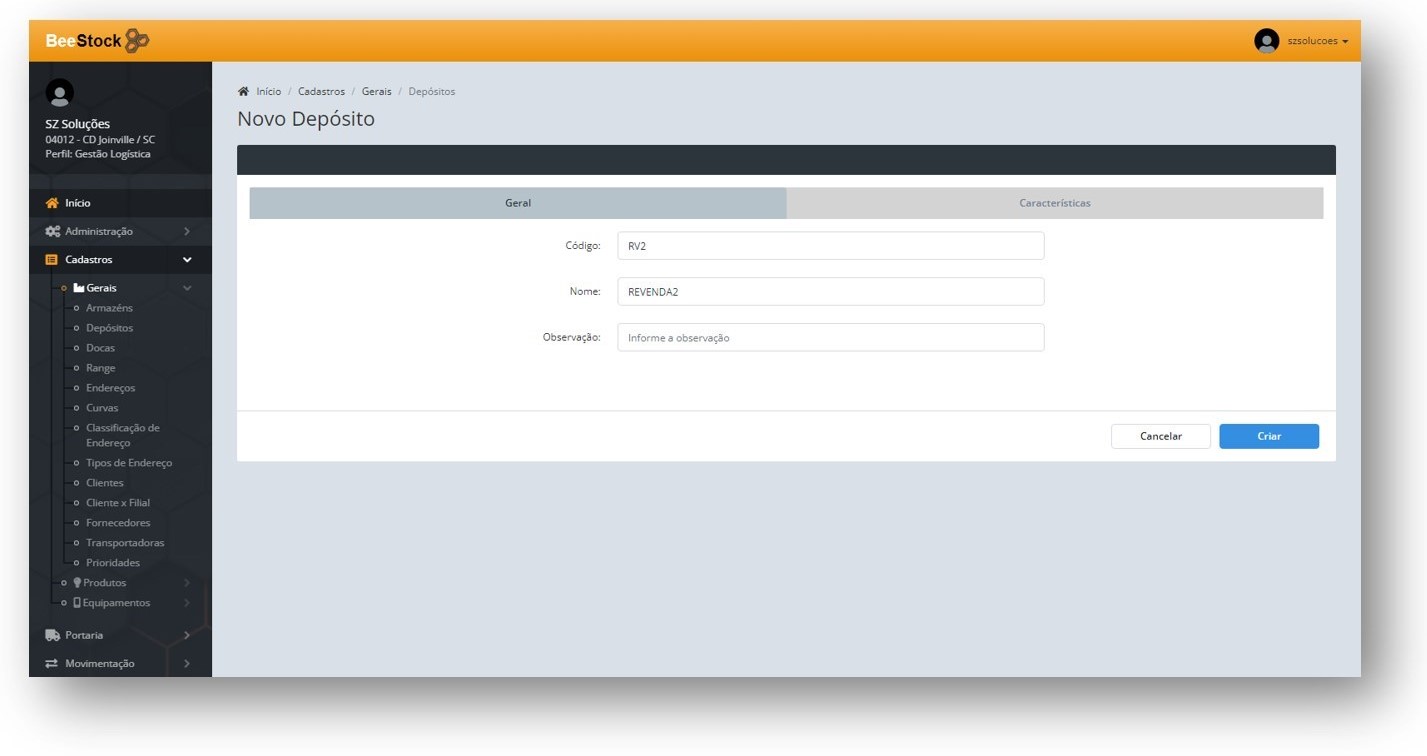

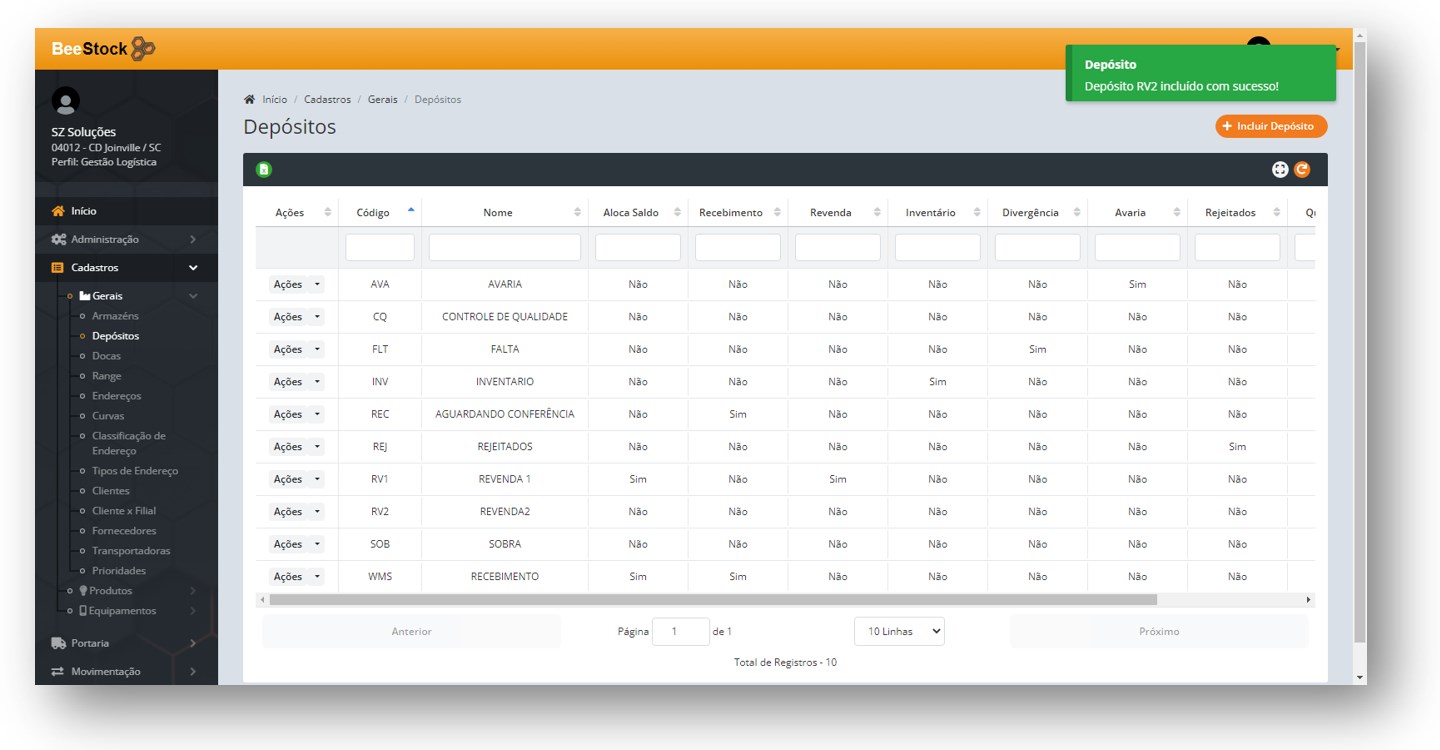

Warehouse Registration

Located in the Registers > General > Warehouse menu, this screen will list all system warehouses that will be used on other screens.

Step by Step To include a new warehouse:

1. Click the orange +Add Warehouse button.

2. On the New Warehouse screen, fill in the information on the General tab:

- Code

- Name

- Observation

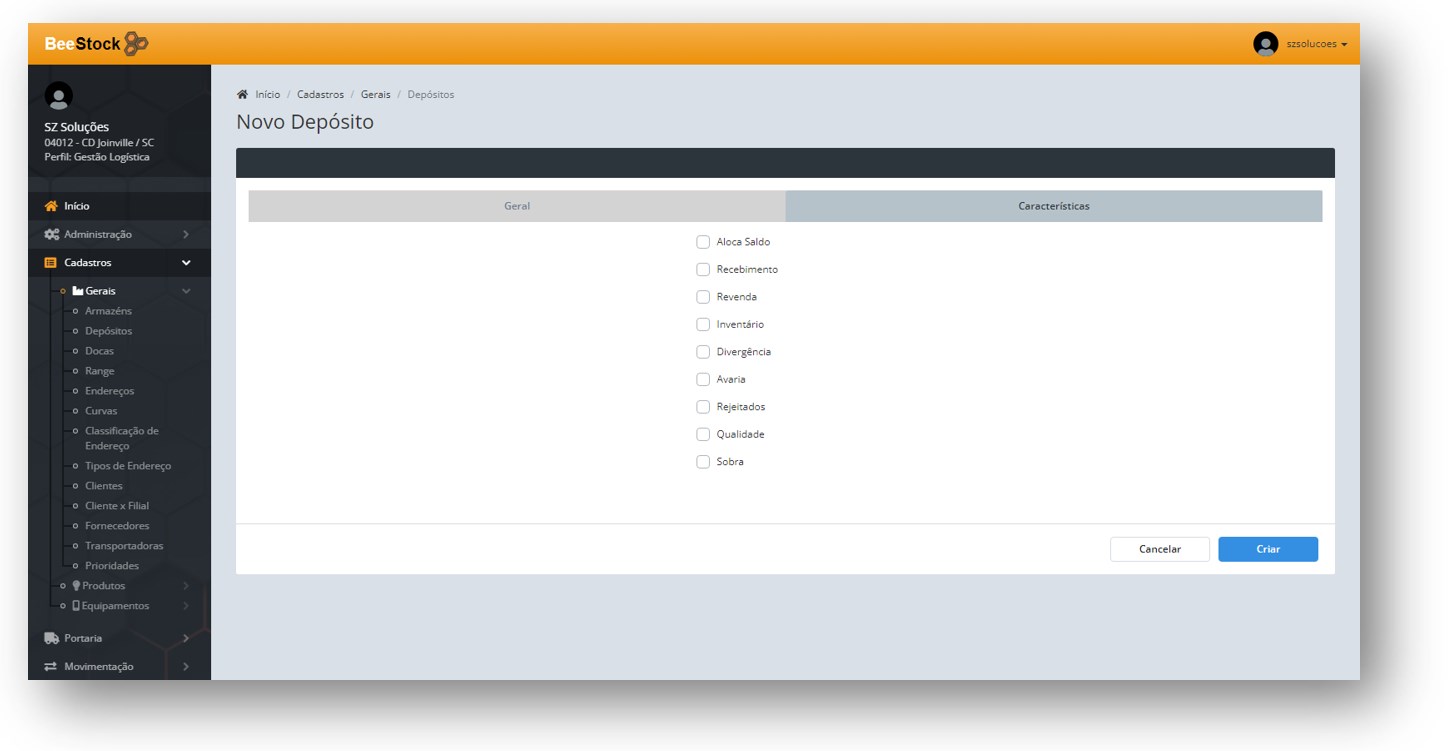

3. On the Characteristics tab, select the information:

- Allocate Balance

- Receiving

- Resale

- Inventory

- Divergence

- Damage

- Rejected

- Quality

- Excess

4. Click the Create button.

5. The confirmation message Warehouse XXXX successfully included! will be displayed.

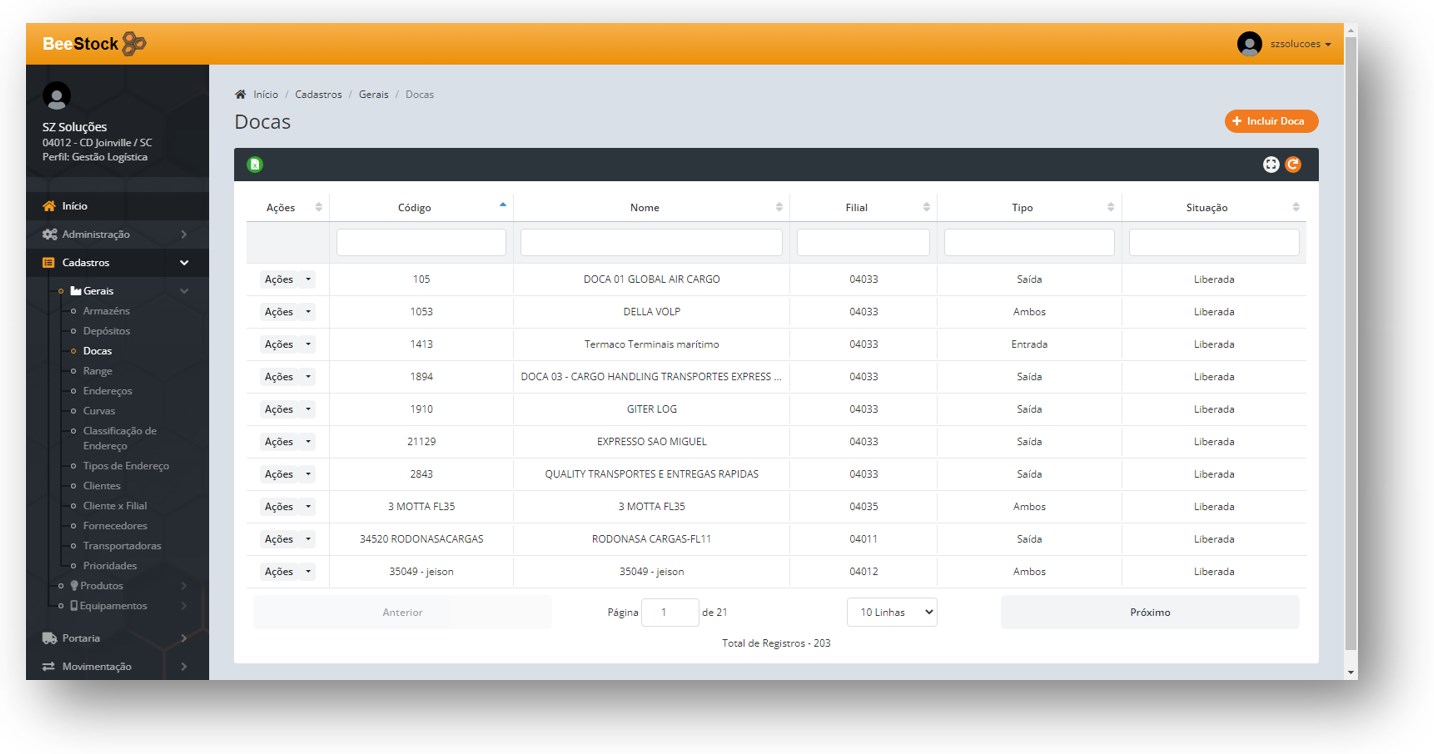

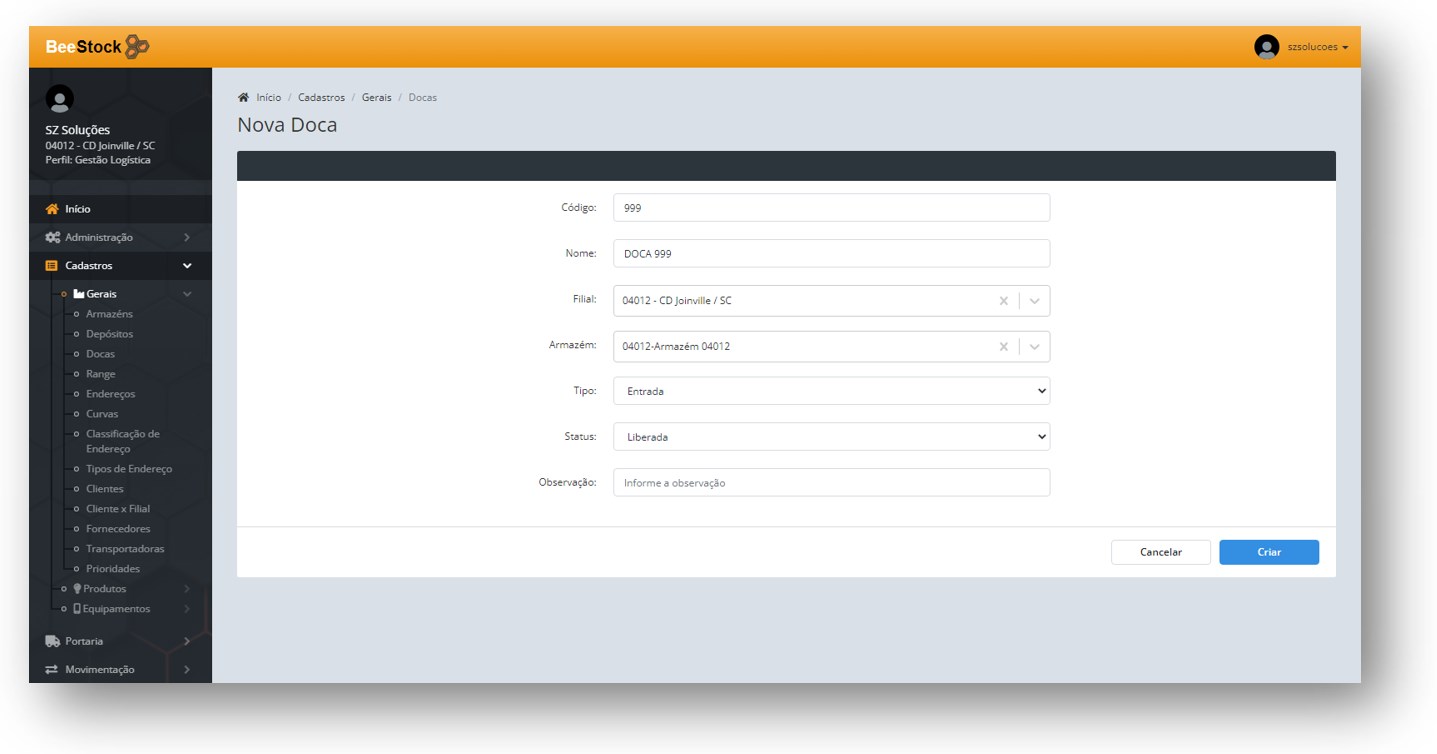

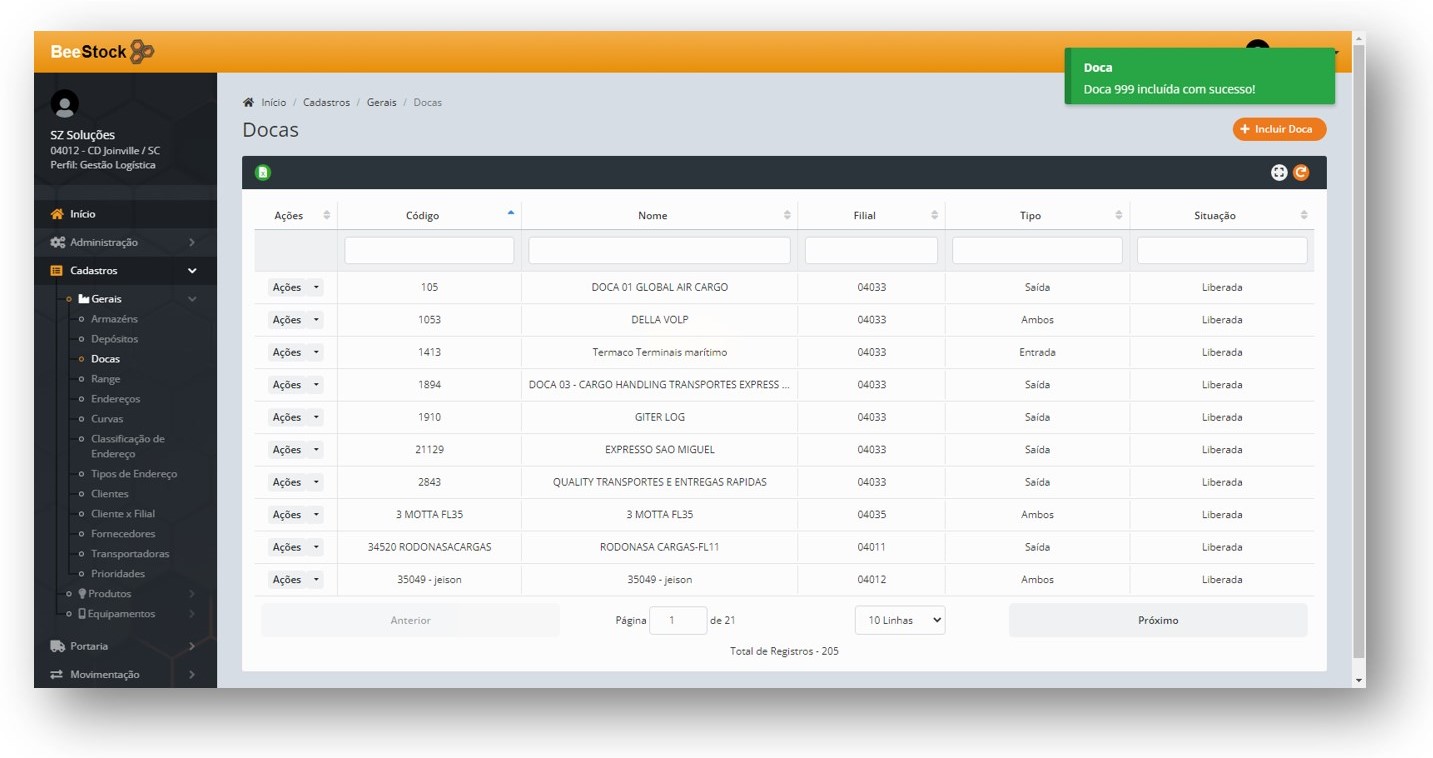

Dock Registration

Located in the Registers > General > Docks menu, this screen will list all system docks that will be used on other screens.

Step by Step To include a new dock:

1. Click the orange +Add Dock button.

2. On the Dock screen, fill in the information:

- Code

- Name

- Branch

- Warehouse

- Type

- Status

- Observation

3. Click the Create button.

4. The confirmation message Dock XXX successfully included! will be displayed.

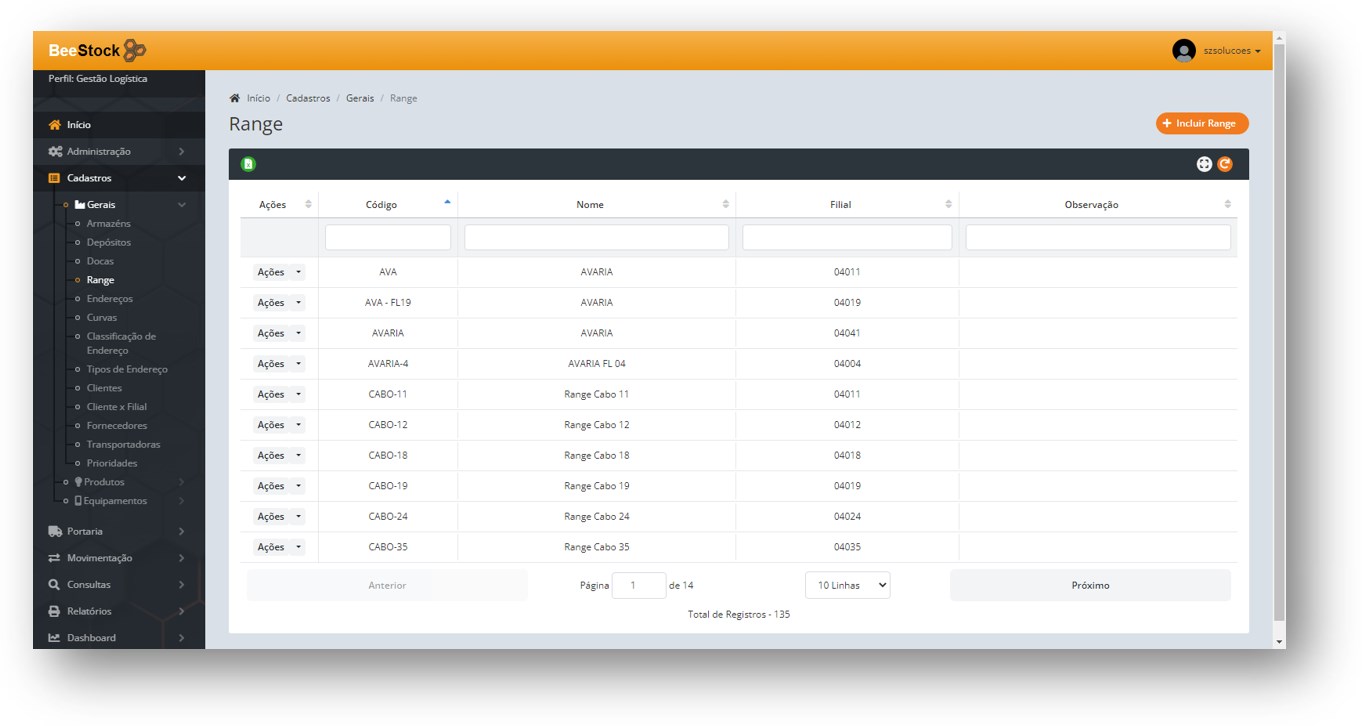

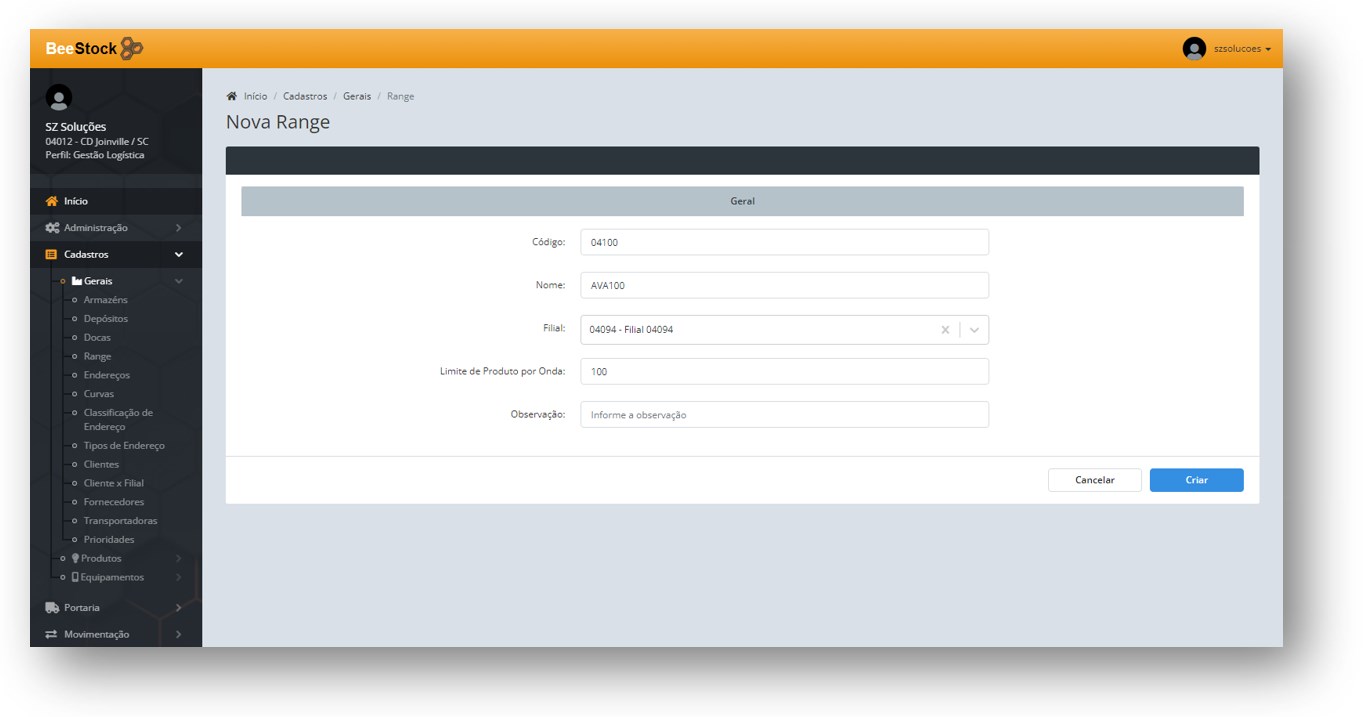

Range Registration

Located in the Registers > General > Range menu, this screen will list all system ranges that will be used on other screens.

Step by Step To include a new range:

1. Click the orange +Add Range button.

2. On the Range screen, fill in the information:

- Code

- Name

- Branch

- Product Limit per Wave

- Observation

3. Click the Create button.

4. The confirmation message Range XXXXX successfully created! will be displayed.

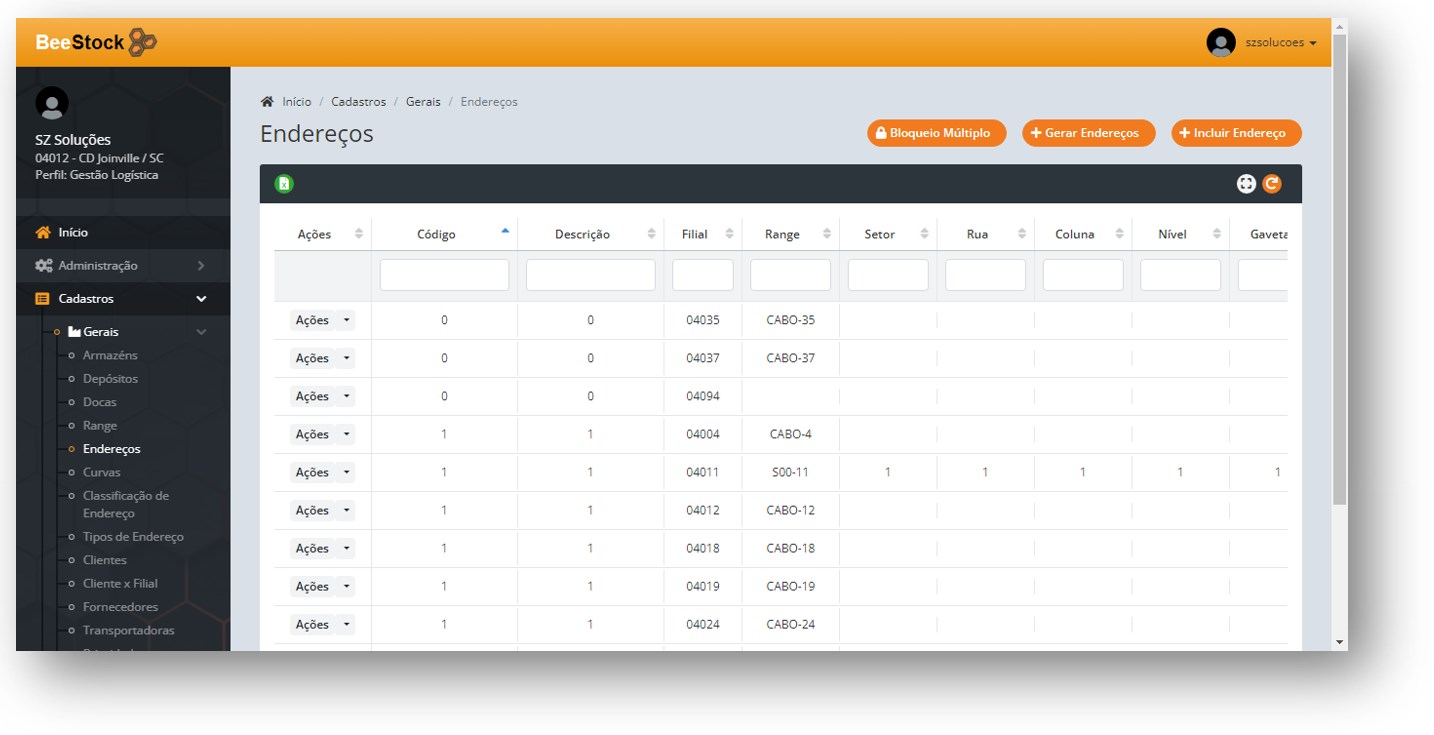

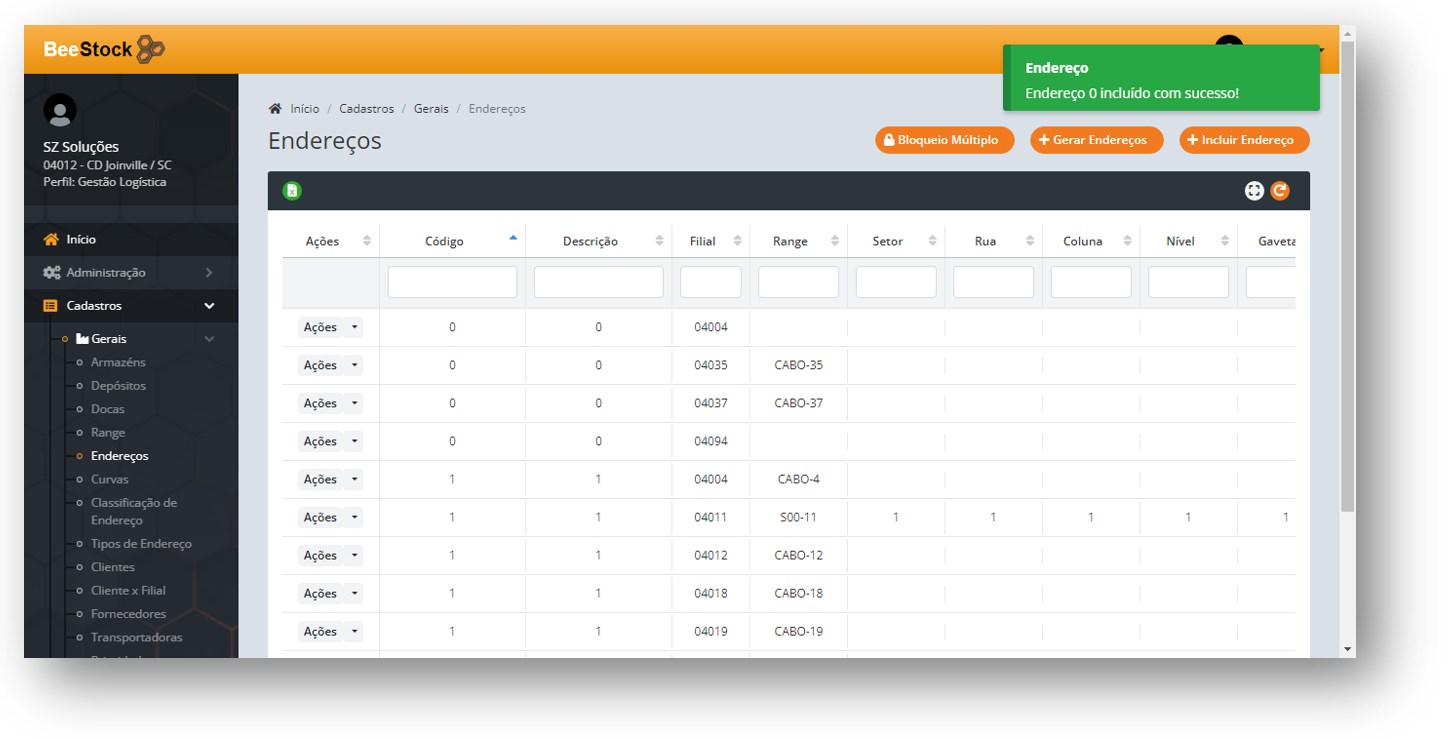

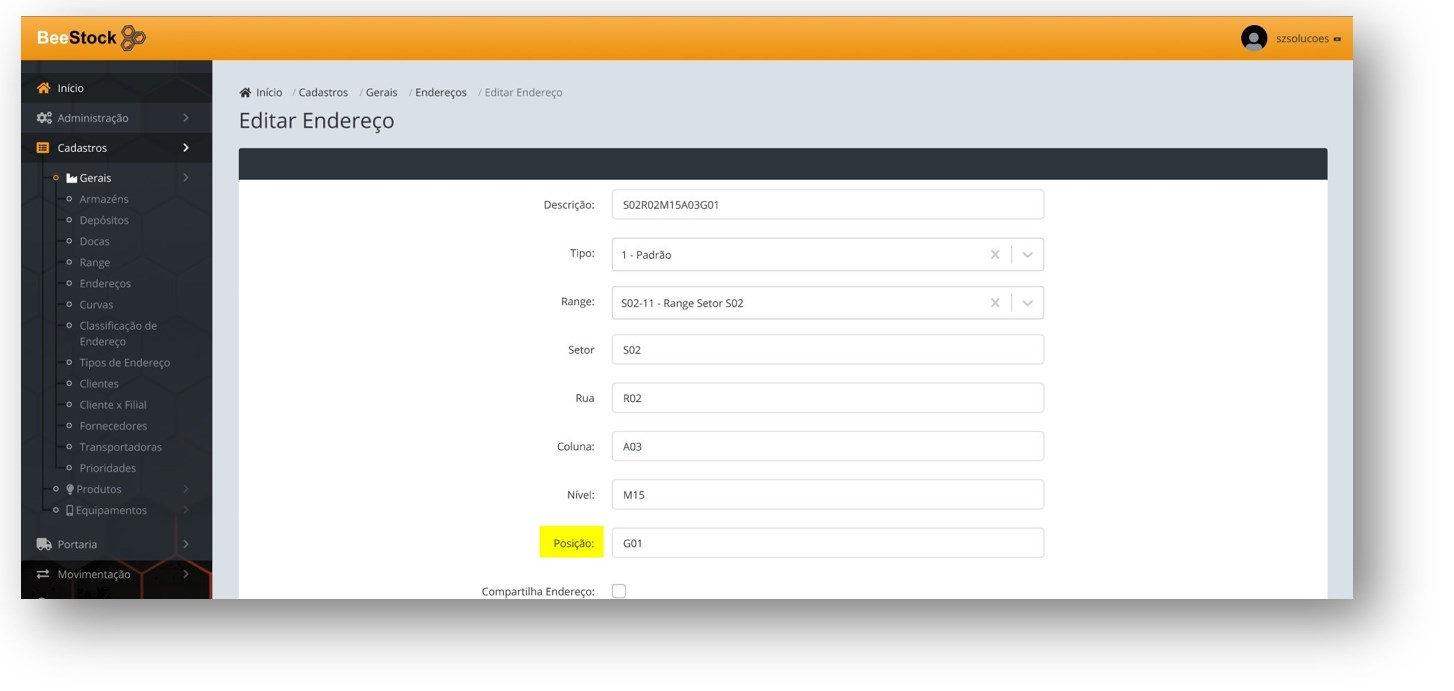

Address Registration

Located in the Registers > General > Addresses menu, this screen will list all system addresses that will be used on other screens.

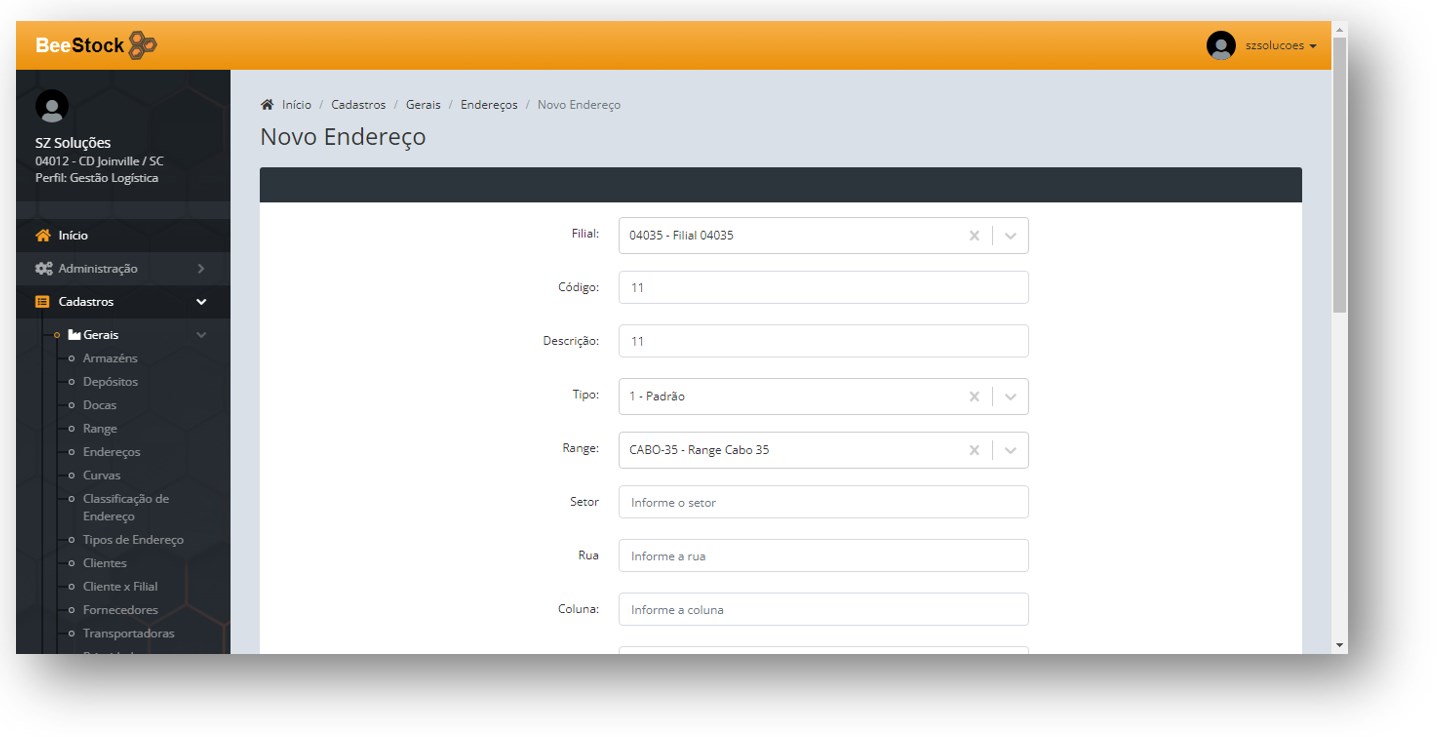

Step by Step To include a new address:

1. Click the orange +Add Address button.

2. On the New Address screen, fill in the information:

- Branch

- Code

- Description

- Type

- Range

- Sector

- Street

- Column

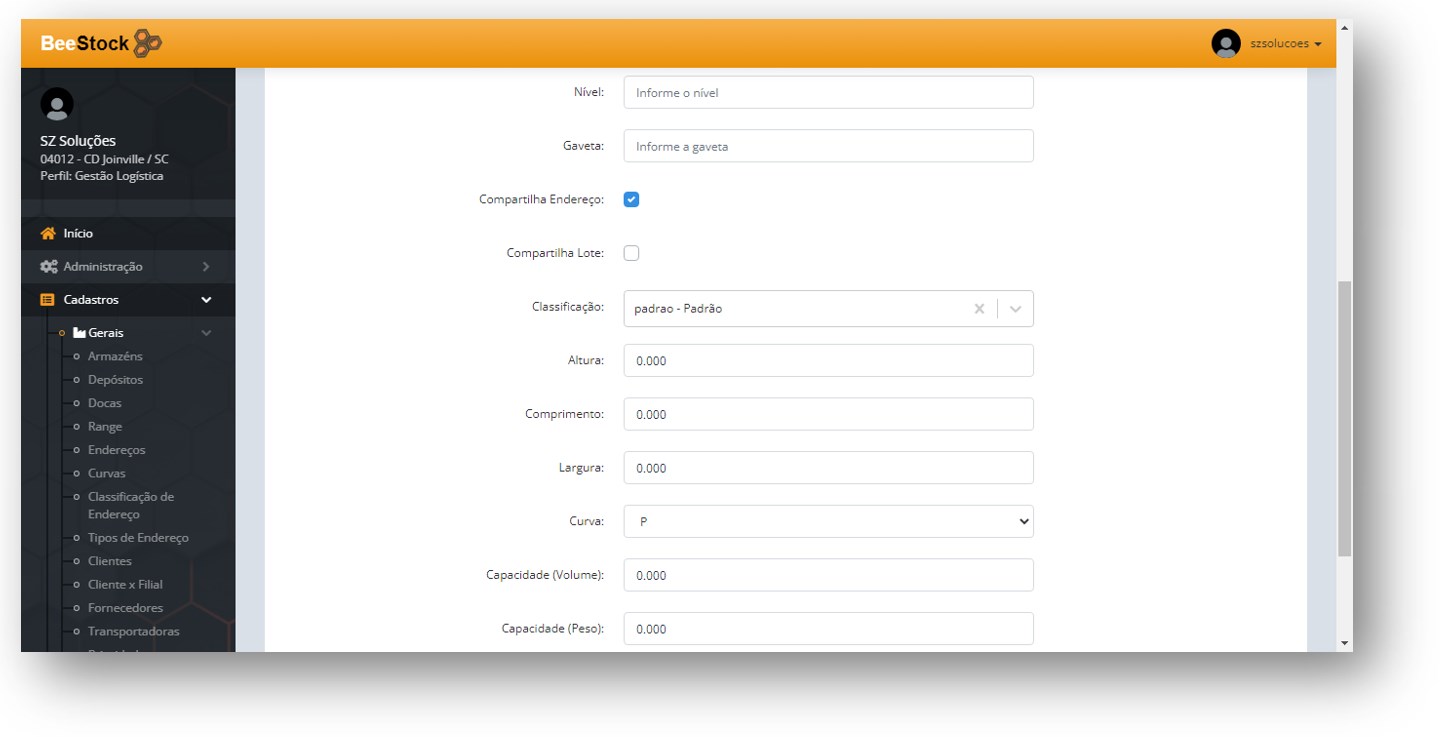

- Level

- Drawer

- Share Address

- Share Batch

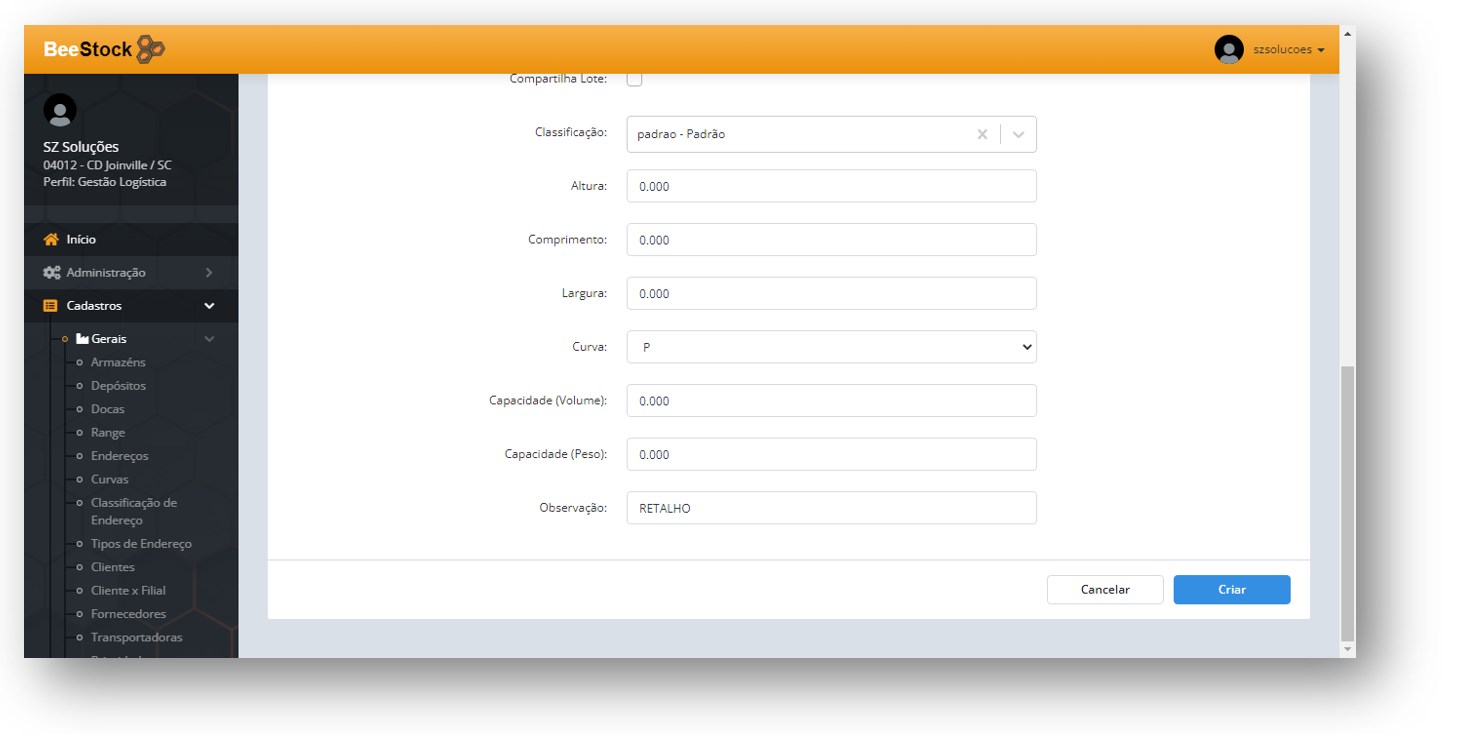

- Classification

- Height

- Length

- Width

- Curve

- Capacity (Volume)

- Capacity (Weight)

- Observation

3. Clicking on Create, the address will be created:

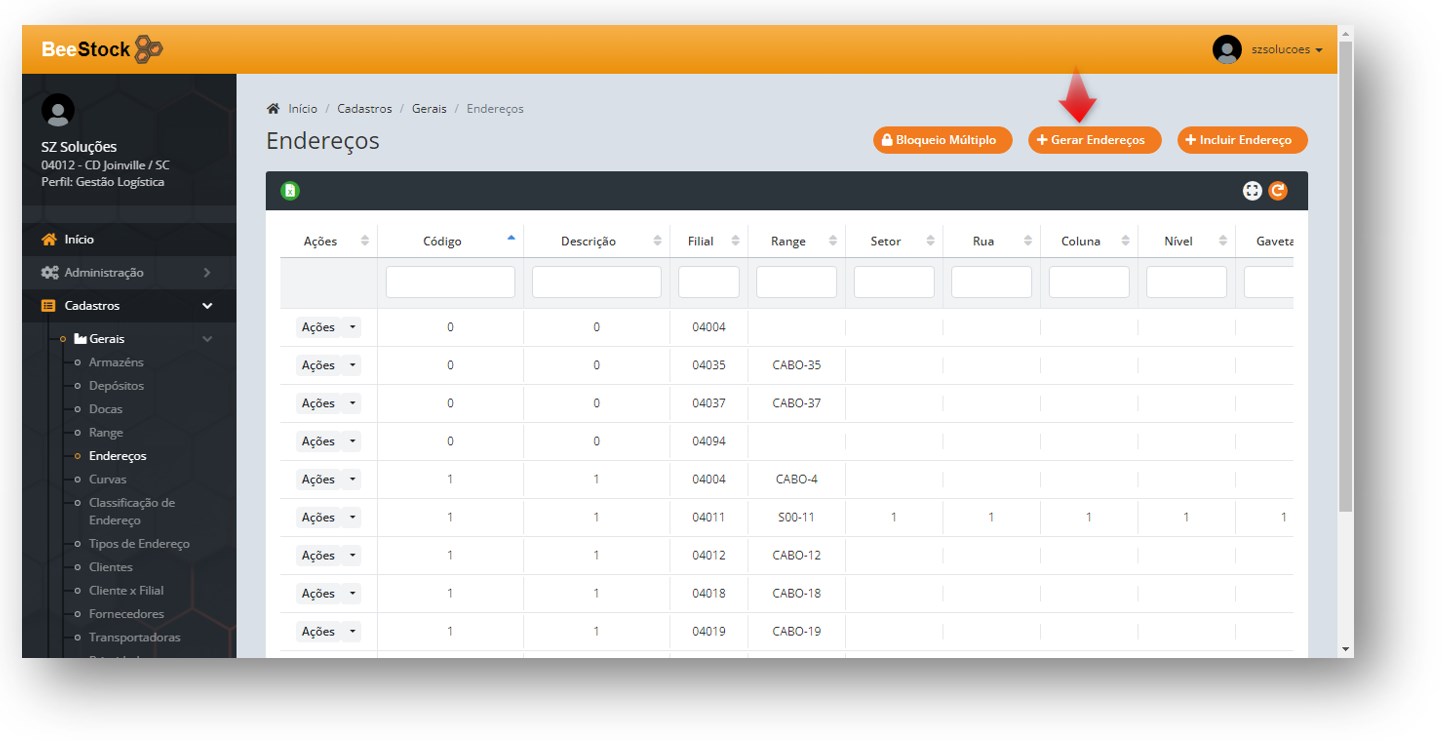

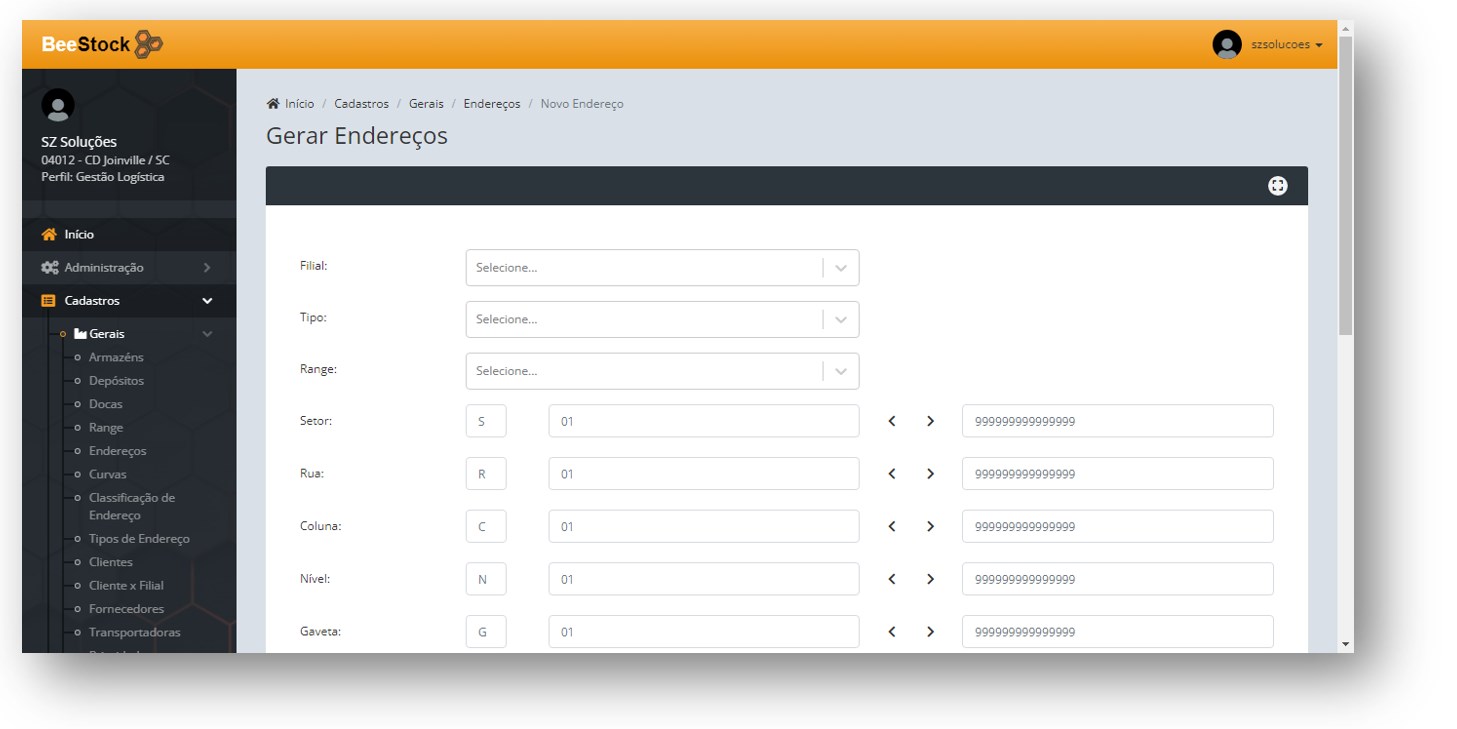

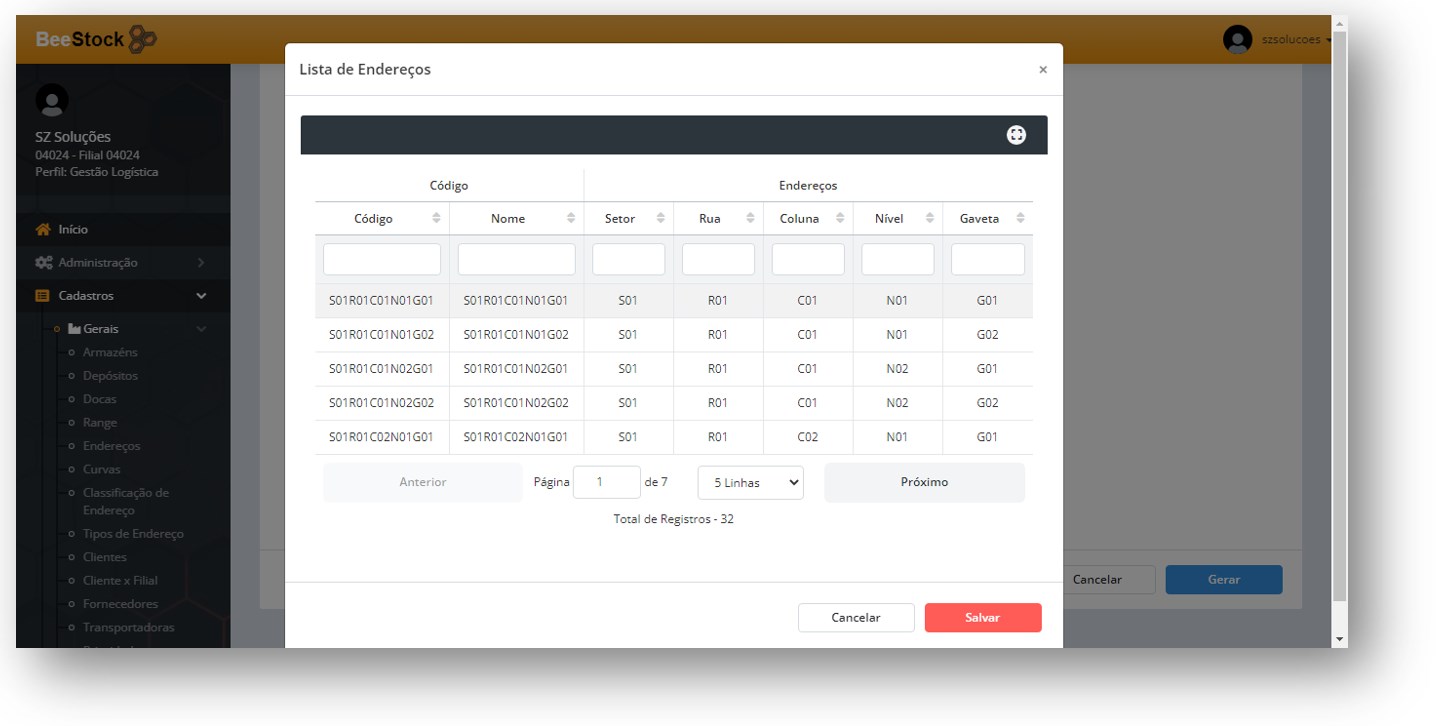

4. In the Generate Addresses button you can create multiple addresses automatically:

5. On the Generate Addresses screen, fill in the information:

- Branch

- Type

- Range

- Sector

- Street

- Column

- Level

- Drawer

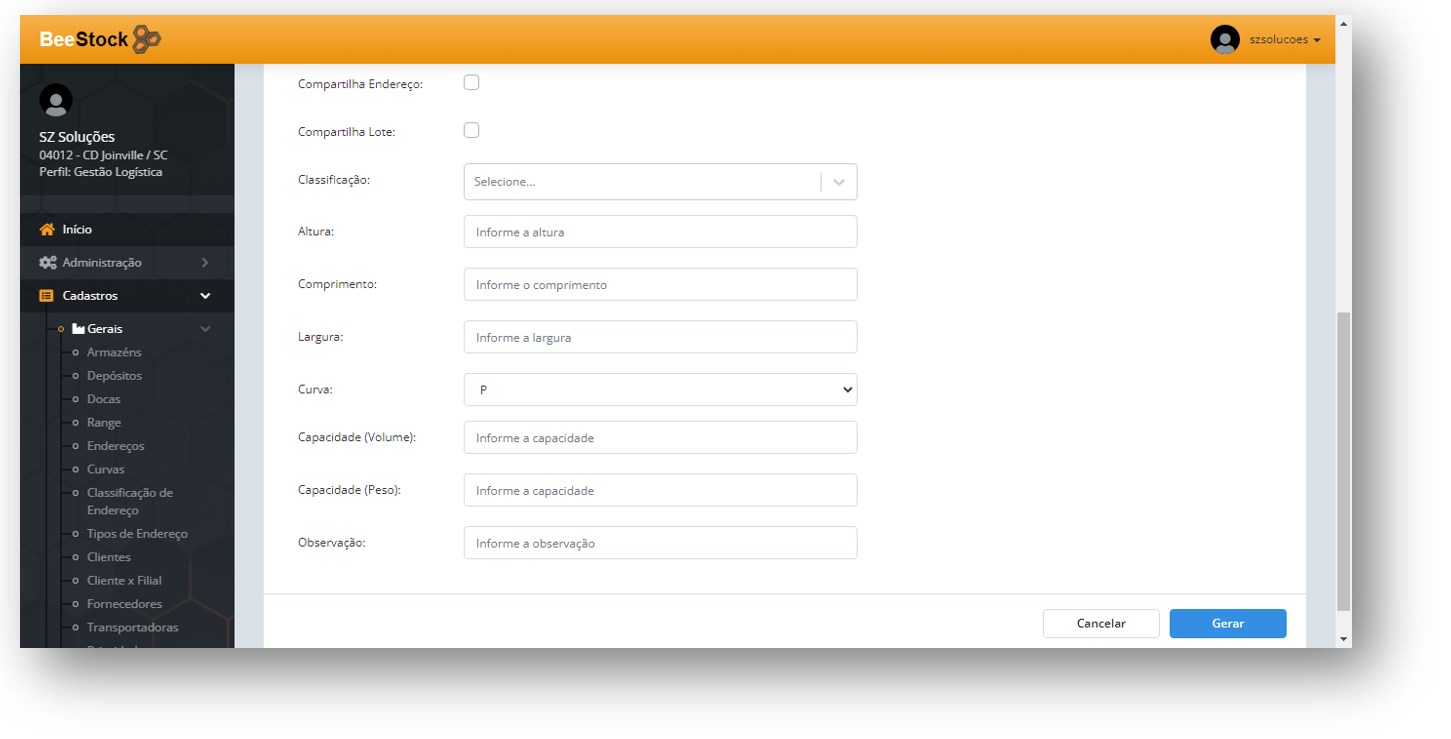

- Share Address

- Share Batch

- Classification

- Height

- Length

- Width

- Curve

- Capacity (Volume)

- Capacity (Weight)

- Observation

6. Clicking on Generate you will be able to preview the addresses:

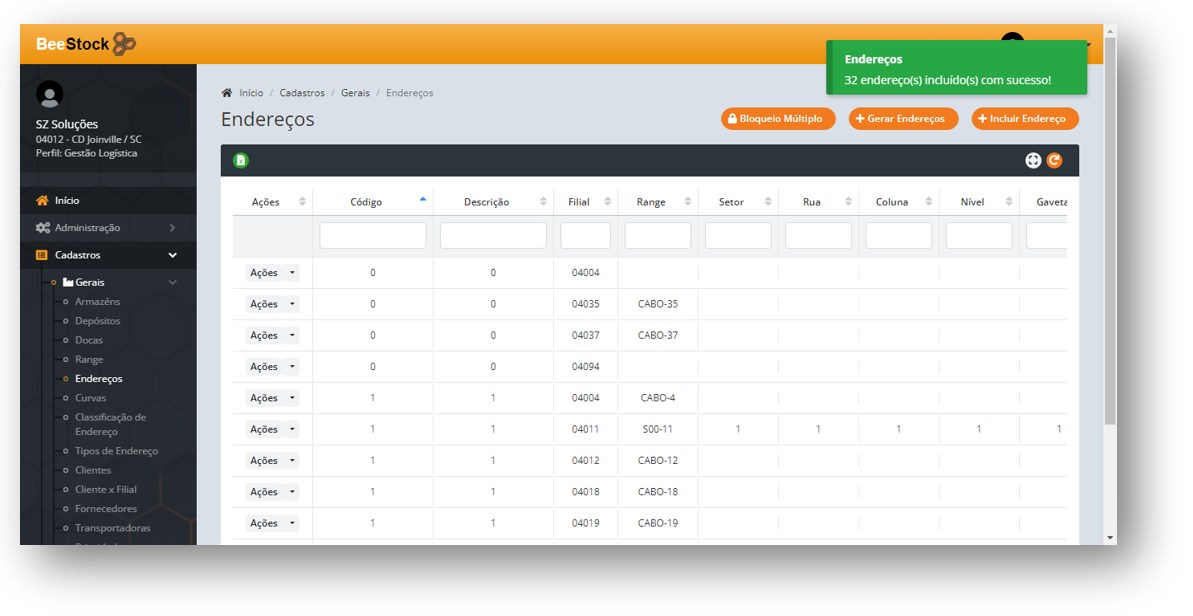

7. Clicking on Save will generate the addresses.

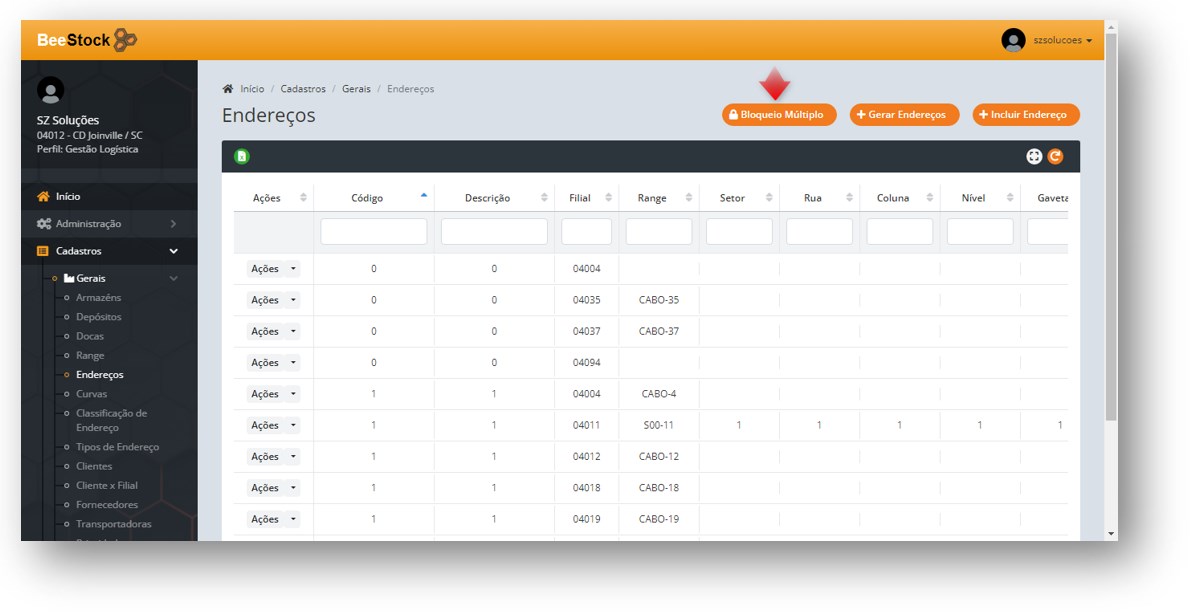

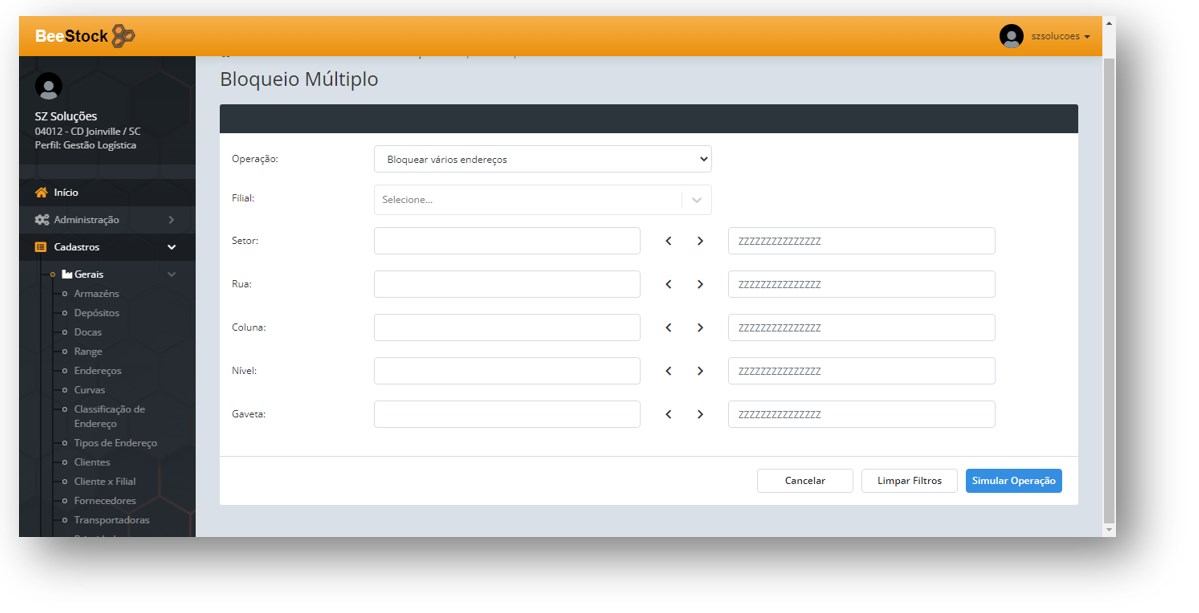

8. In the Multiple Lock button you can block or unblock transactions for multiple addresses at once:

9. On the Multiple Lock screen, fill in the information for the addresses that should be blocked or unblocked:

- Operation

- Branch

- Sector

- Street

- Column

- Level

- Drawer

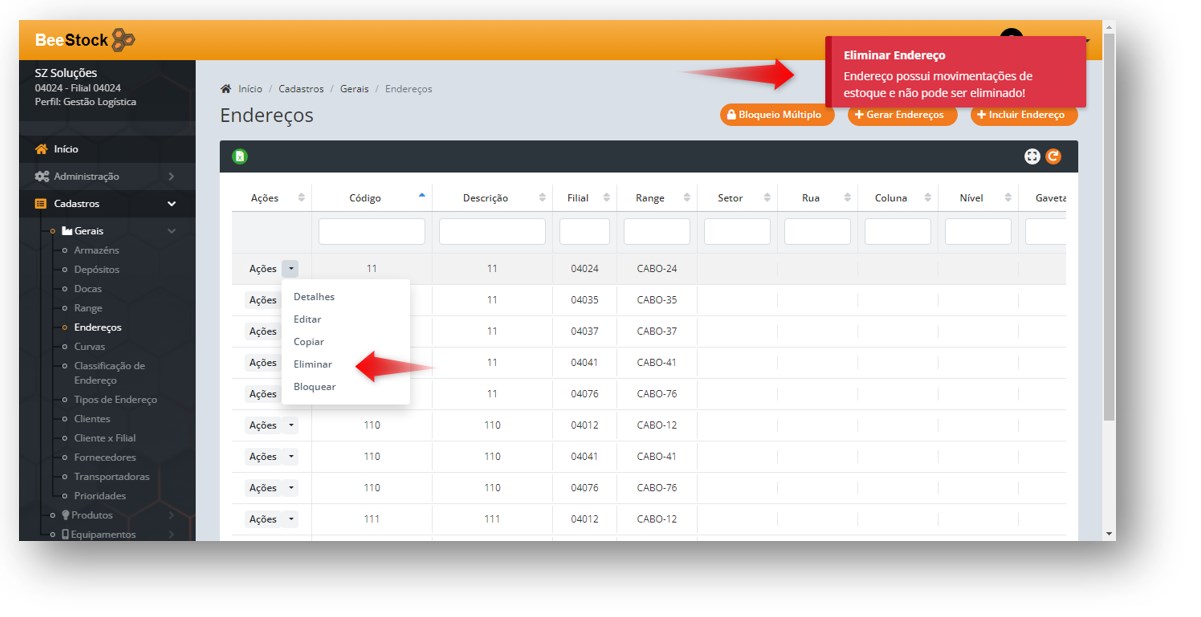

10. When you try to delete an address that has already had a transaction, the following error will occur:

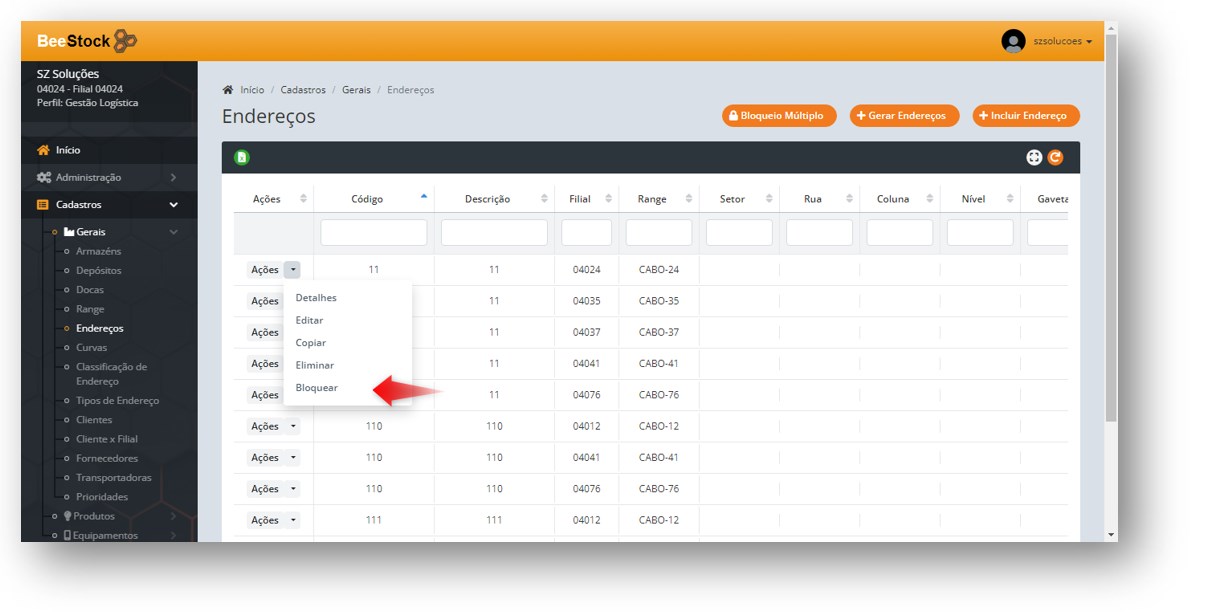

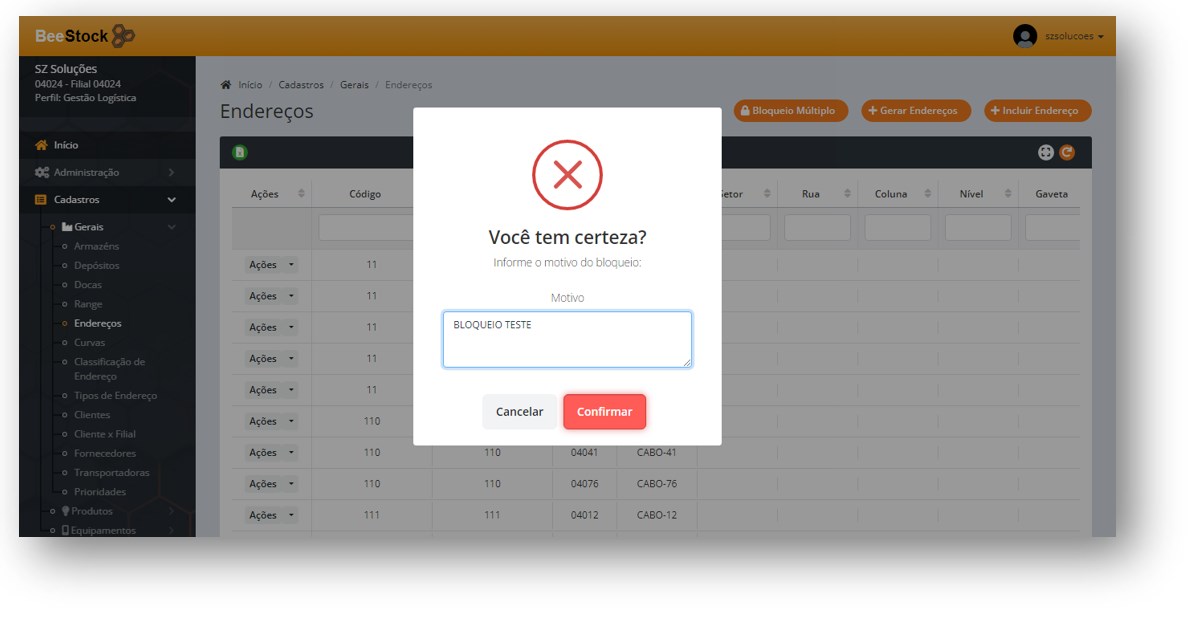

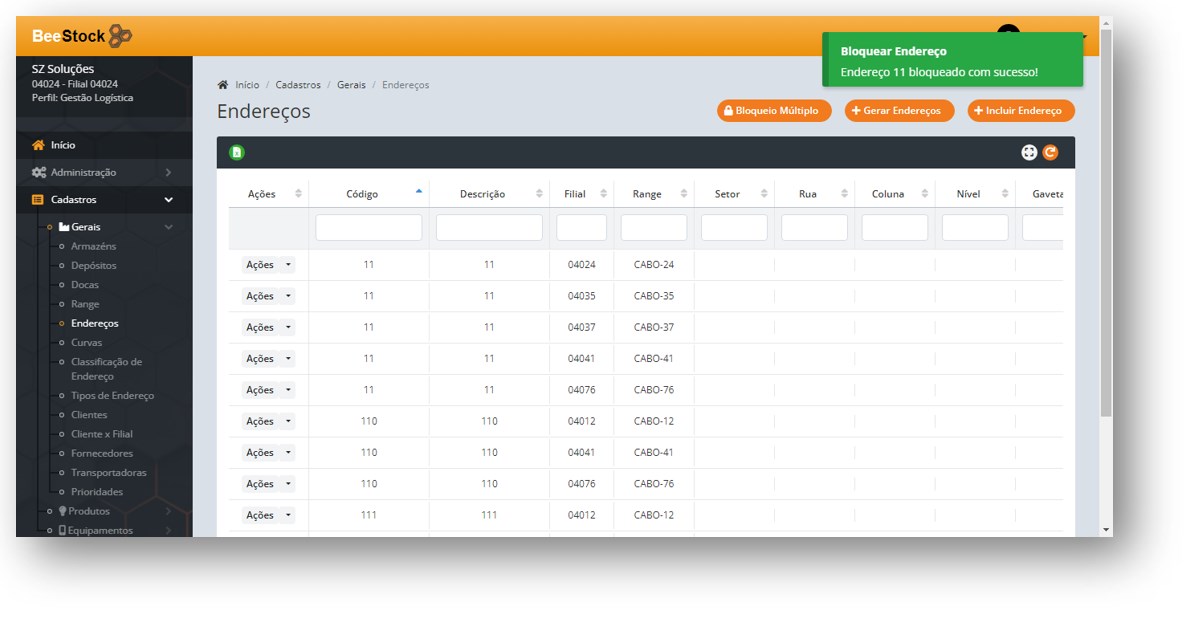

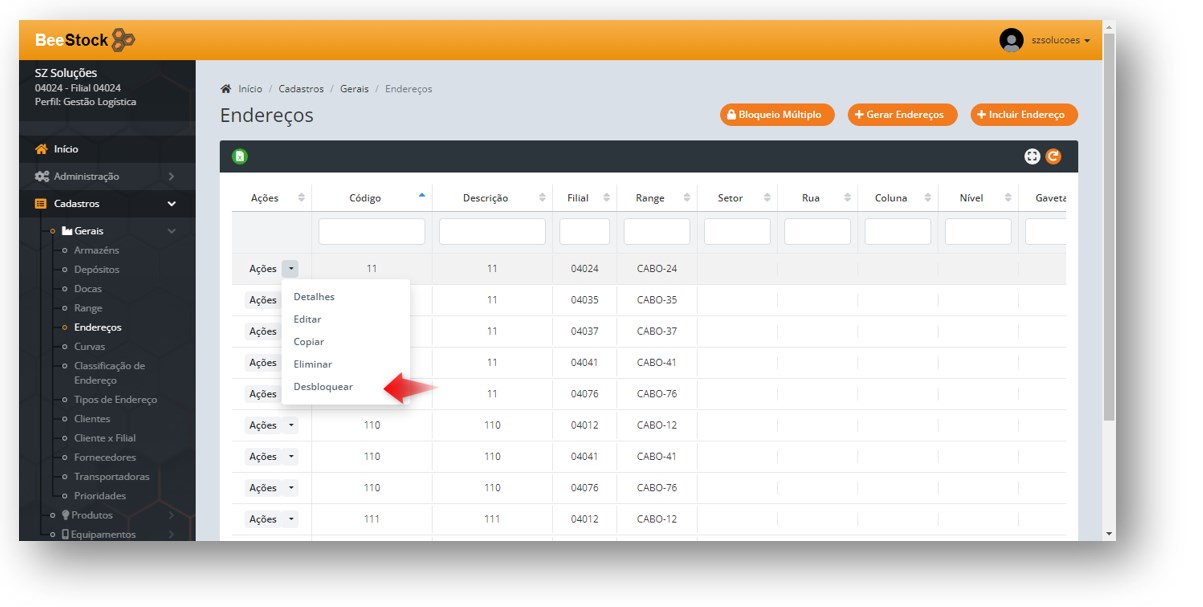

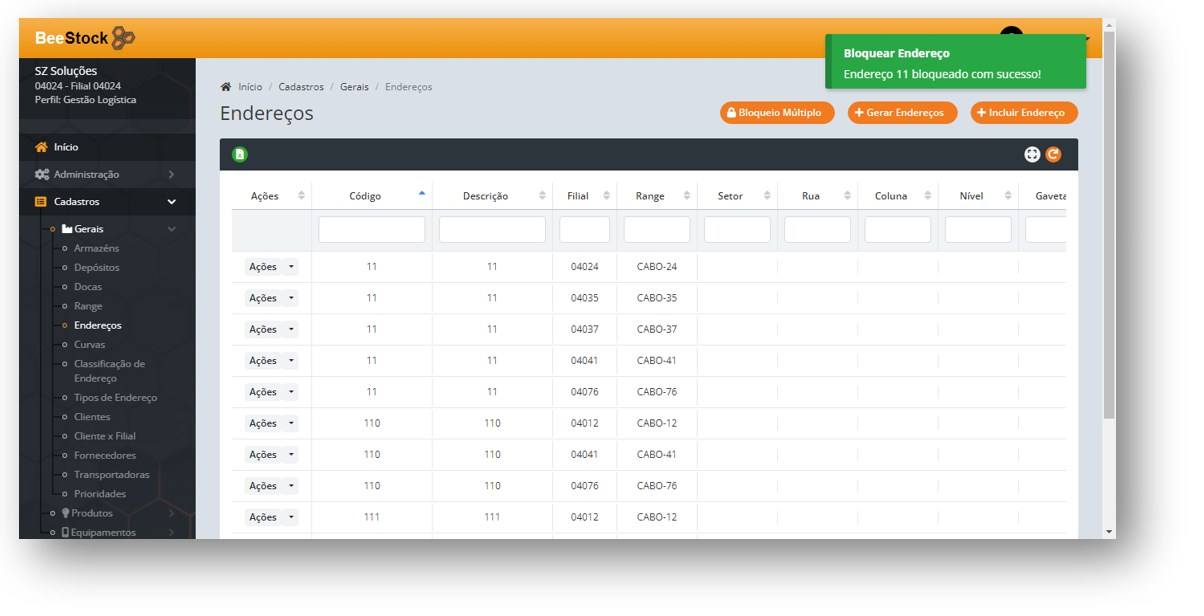

11. If it is not possible to delete the address, we can block it, by clicking on Actions > Block, so it will not be possible to carry out transactions at the address.

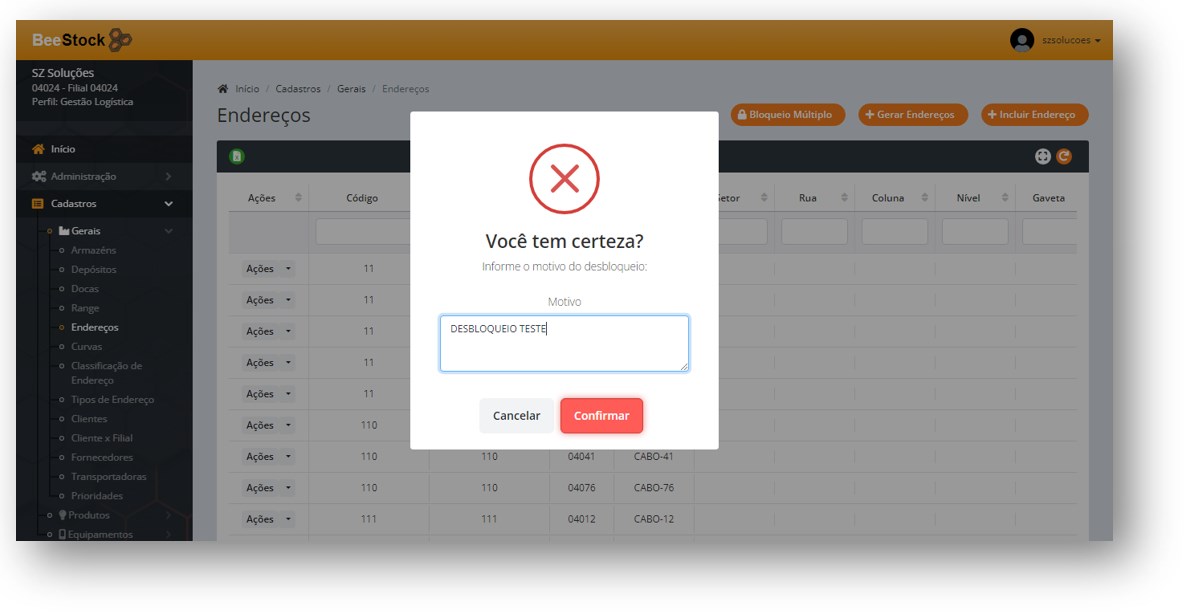

12. We can also unlock the address by clicking on Actions > Unlock.

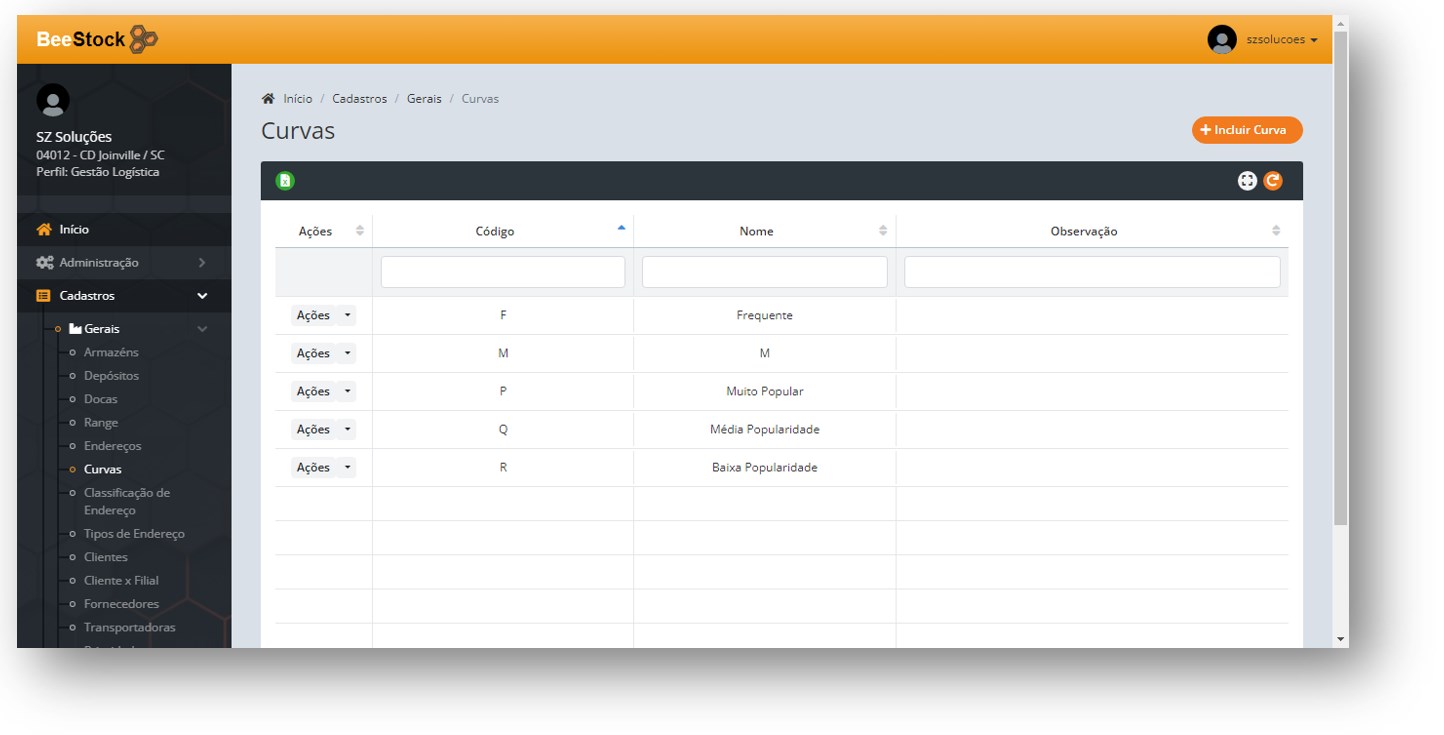

Curve Registration

Located in the Registers > General > Curves menu, this screen will list all system curves that will be used on other screens.

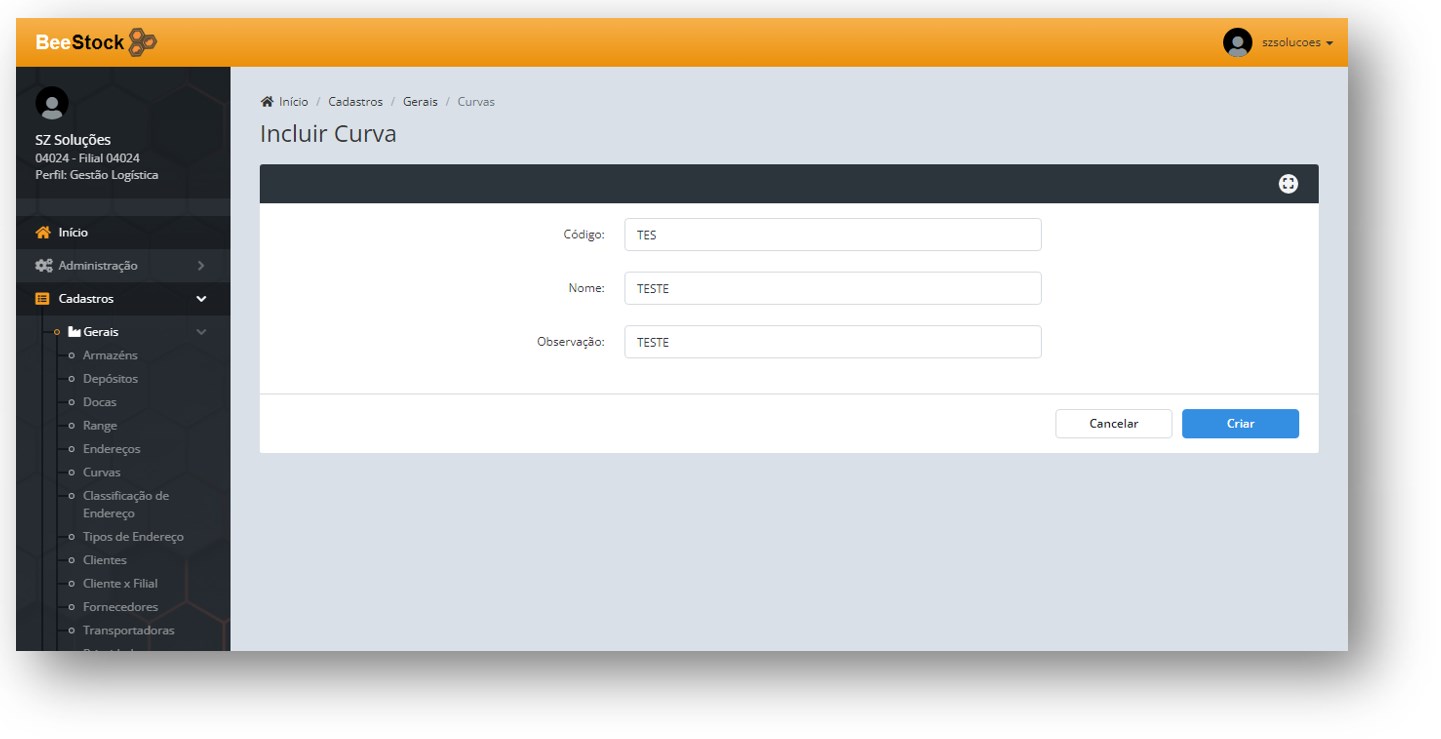

Step by Step To include a new curve:

1. Click the orange +Add Curve button.

2. On the Add Curve screen, the user cannot create a curve that already exists or with more than 3 characters. Fill in the information:

- Code

- Name

- Observation

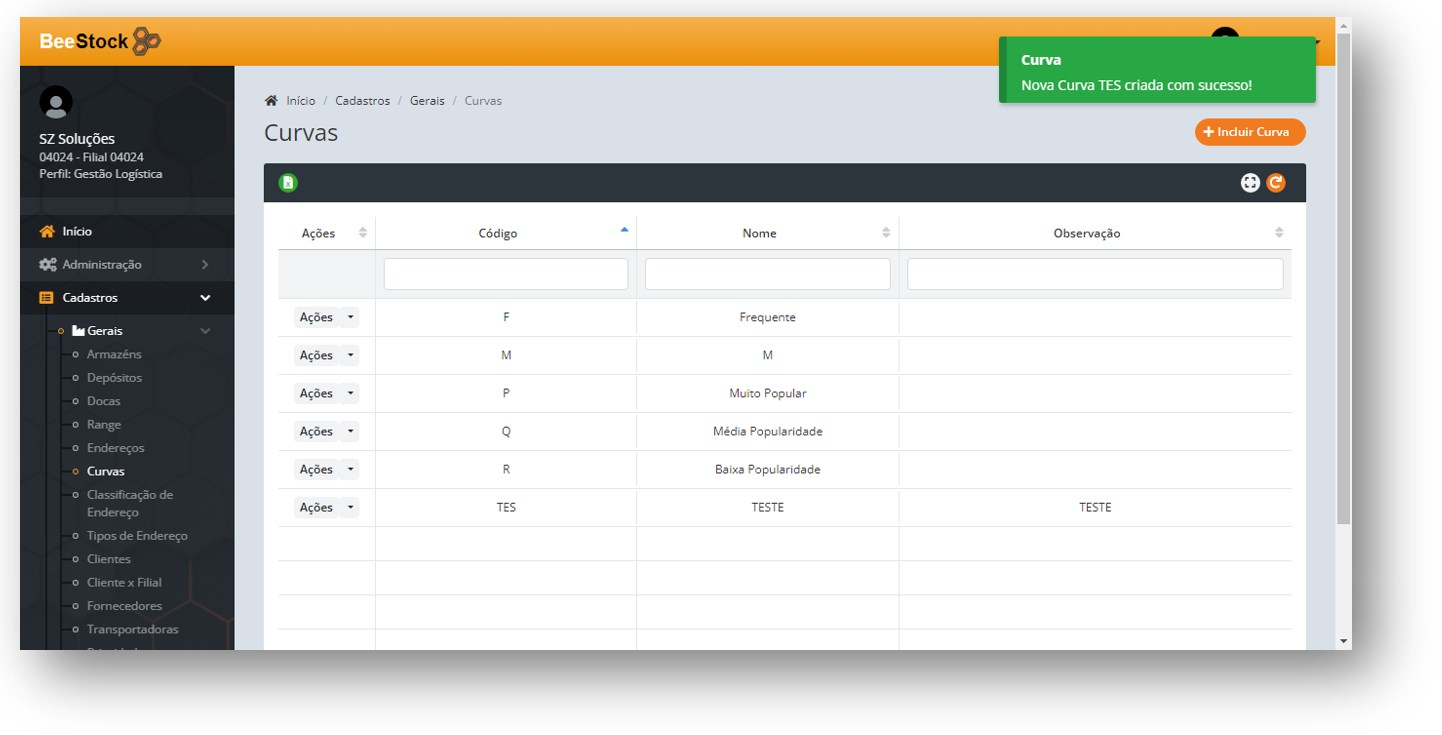

3. Clicking on Create, the curve will be created:

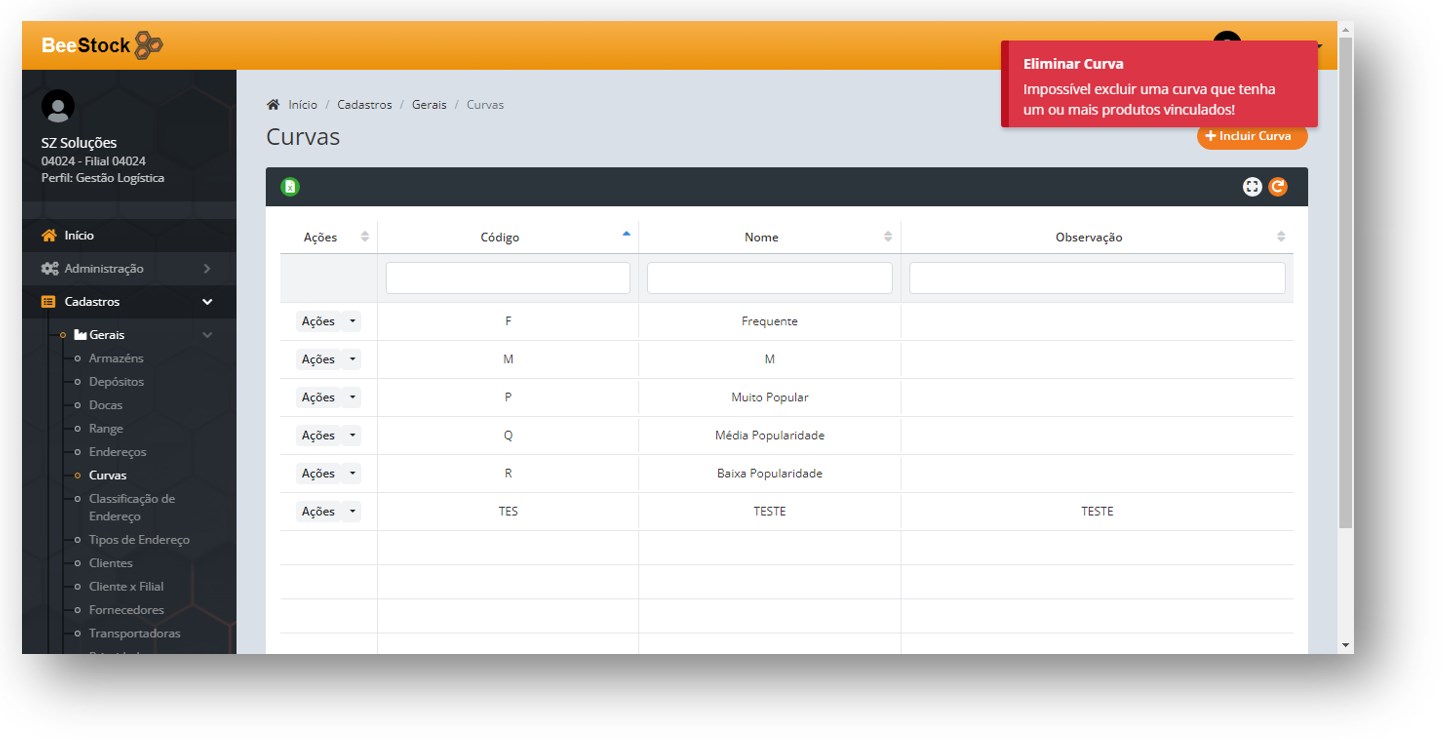

4. In the Actions > Delete button you can only delete a curve that is not used in addresses or products.

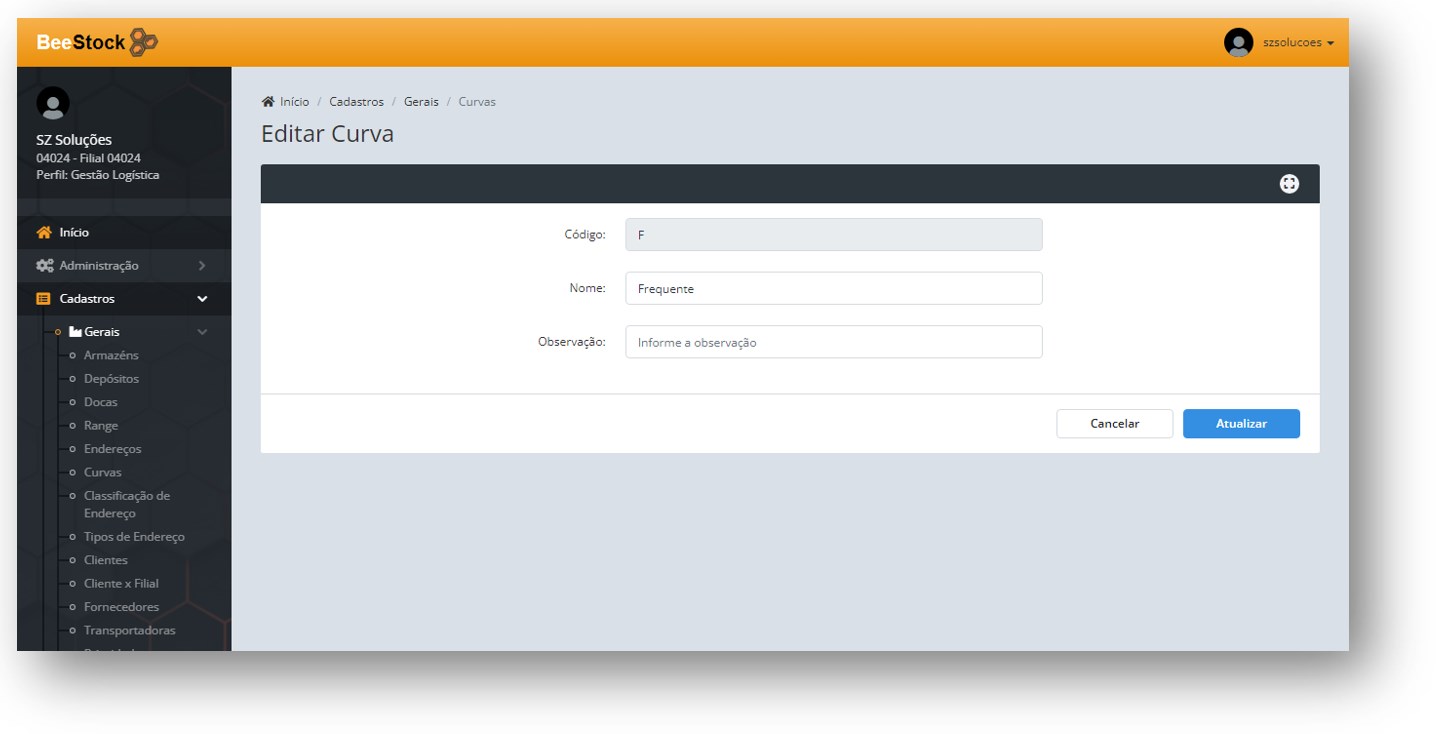

5. In the Actions > Edit button the user can only change the Name and Observation.

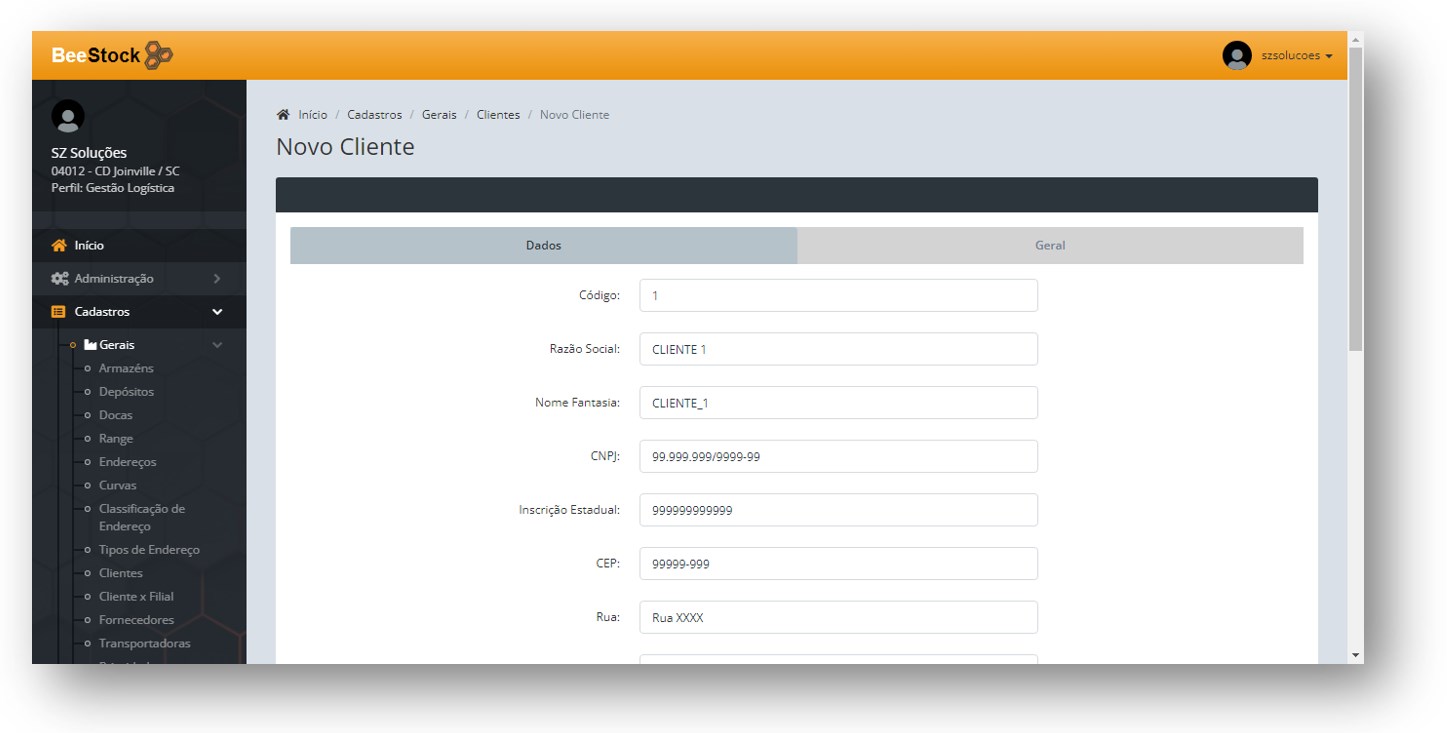

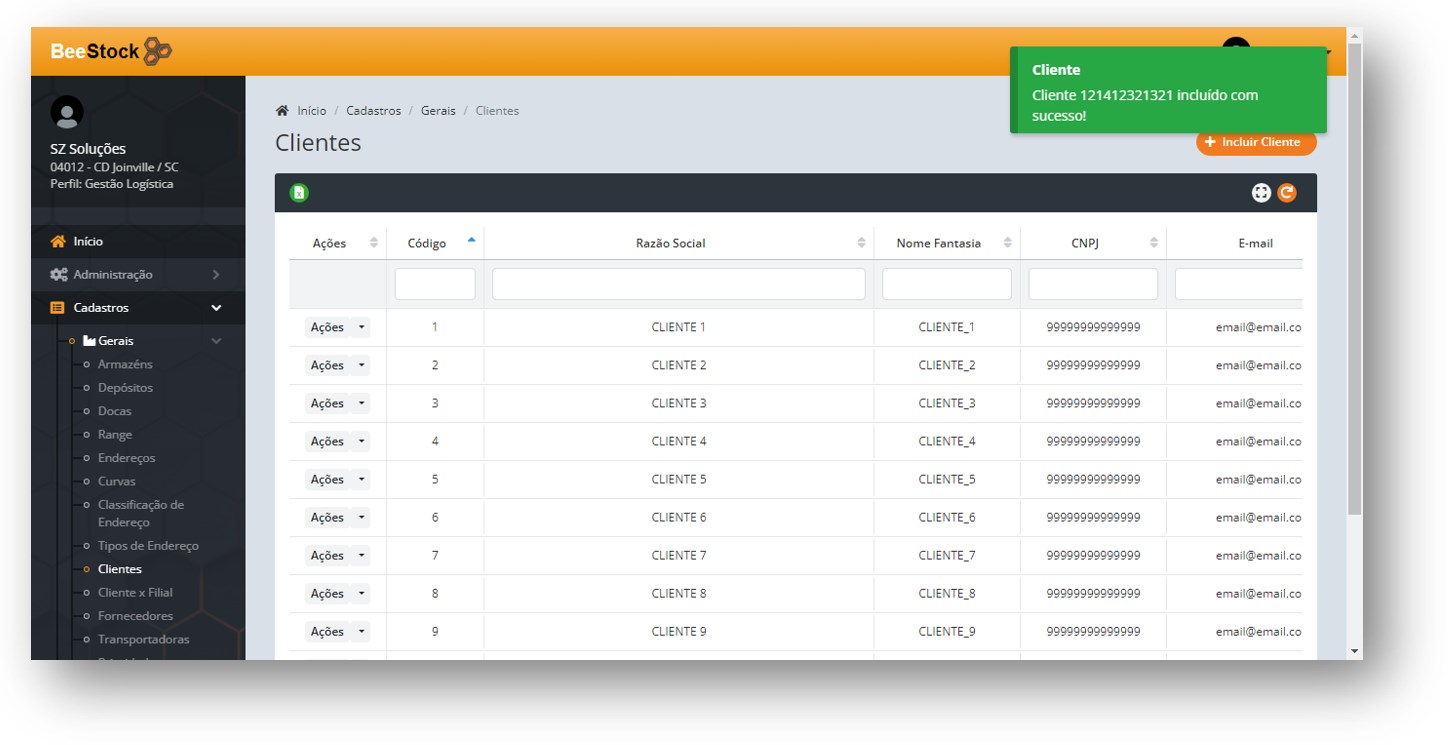

Customer Registration

Located in the Registers > General > Customers menu, this screen will list all system customers that will be used on other screens.

Step by Step To include a new Customer:

1. Click the orange +Add Customer button.

2. On the New Customer screen, fill in the information on the Data tab:

- Code

- Corporate Name

- Trade Name

- CNPJ (Brazilian Company Tax ID)

- State Registration

- Zip Code

- Street

- Number

- Complement

- Neighborhood

- City

- State

- Country

- E-mail

- Phone

- Observation

3. On the New Customer screen, fill in the information on the General tab:

- Requires Single Volume

- Special Label

4. Clicking on Create, the customer will be created:

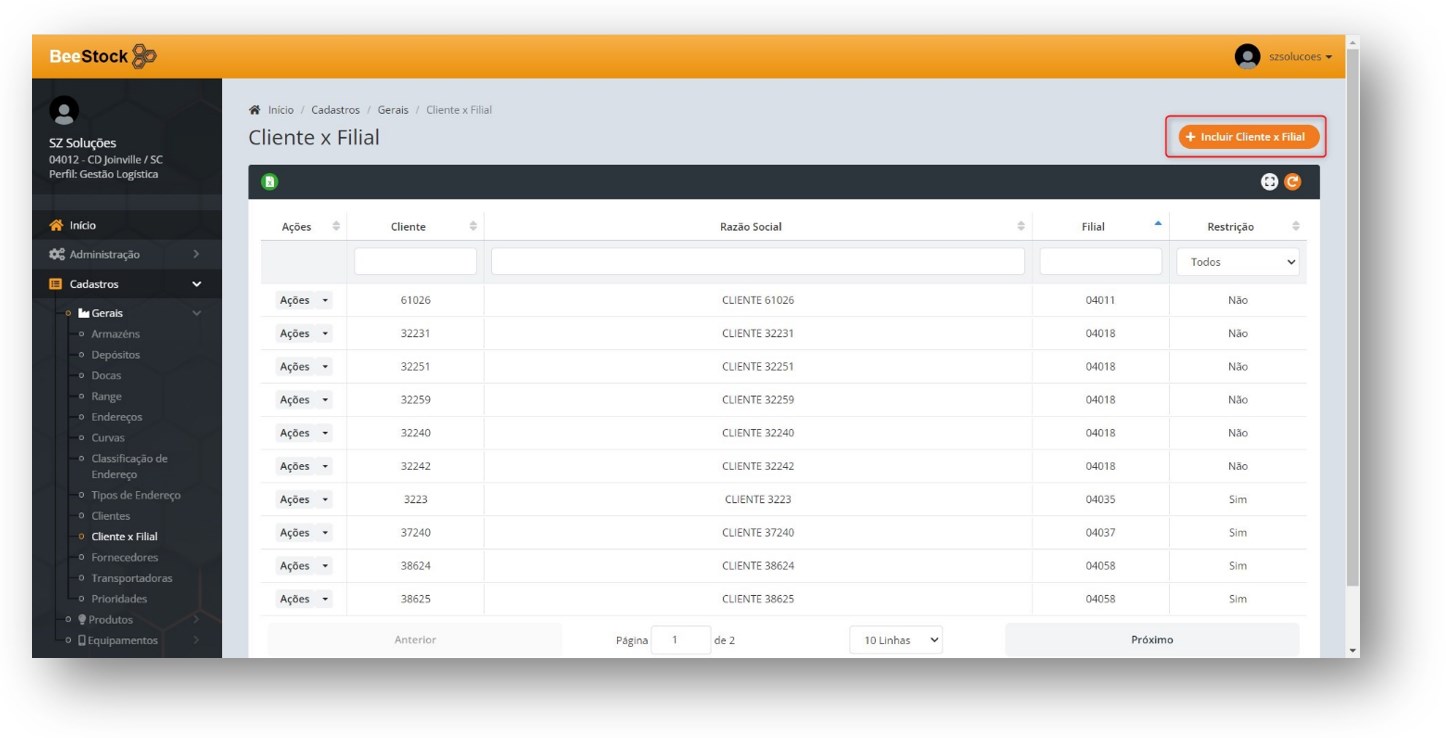

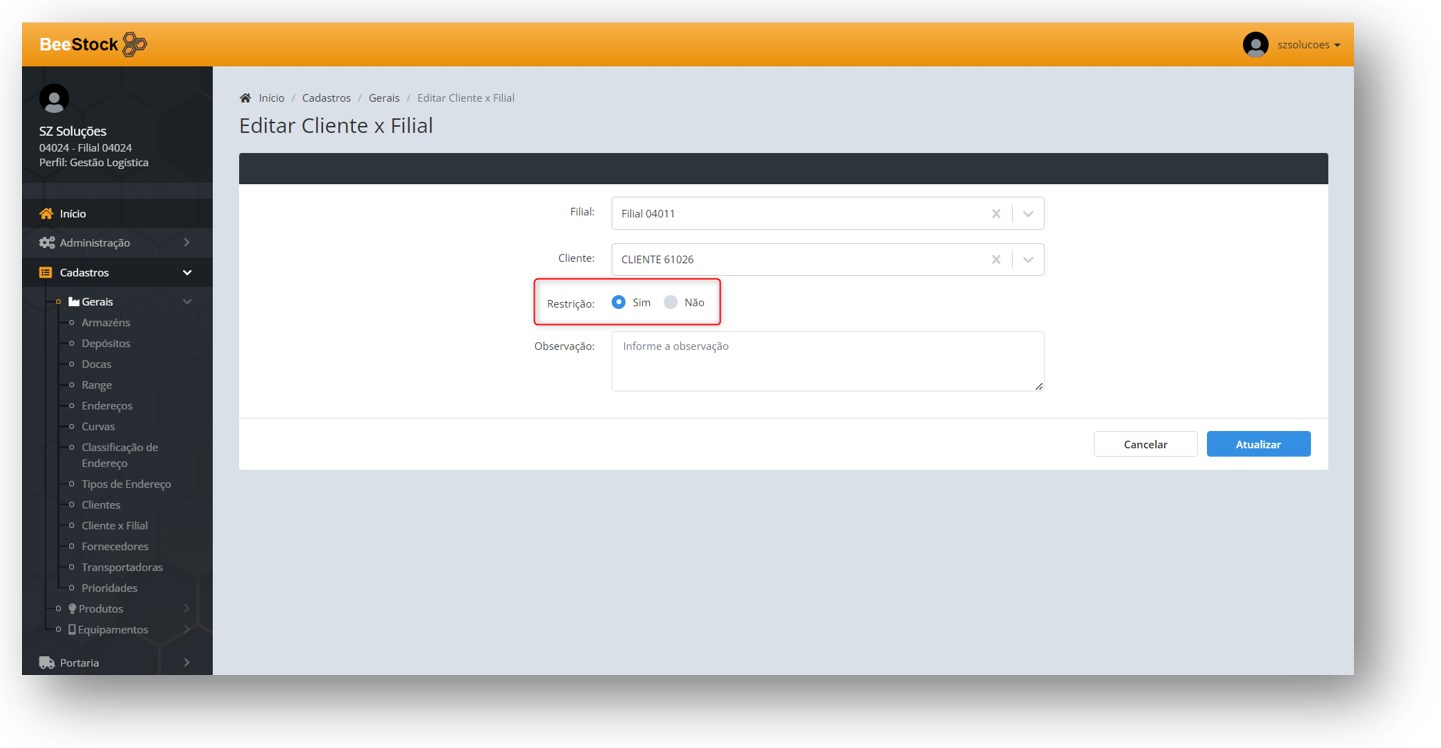

Customer x Branch

Located in Registers > General > Customer x Branch, its purpose is to include a restriction on the customer so that the shipping process is not completed without the release of this restriction.

1. Click on + Add Customer x Branch.

2. To register the restriction, the user must inform:

- Branch

- Customer

- Observation (Optional)

3. Click on Update.

Supplier Registration

Located in Registers > General > Suppliers, on this screen, suppliers will be manually registered or integrated suppliers will be consulted.

As shown in the image below, when registering a supplier, the user must enter the following data:

- Code

- Corporate Name

- Trade Name

- CNPJ (Brazilian Company Tax ID)

- State Registration

- Zip Code

- Street

- Number

- Complement

- Neighborhood

- City

- State

- Country

- E-mail

- Phone

- Observation

In addition to allowing the creation of a new supplier, in Actions the user has the options to:

- Detail

- Edit

- Copy

- Delete

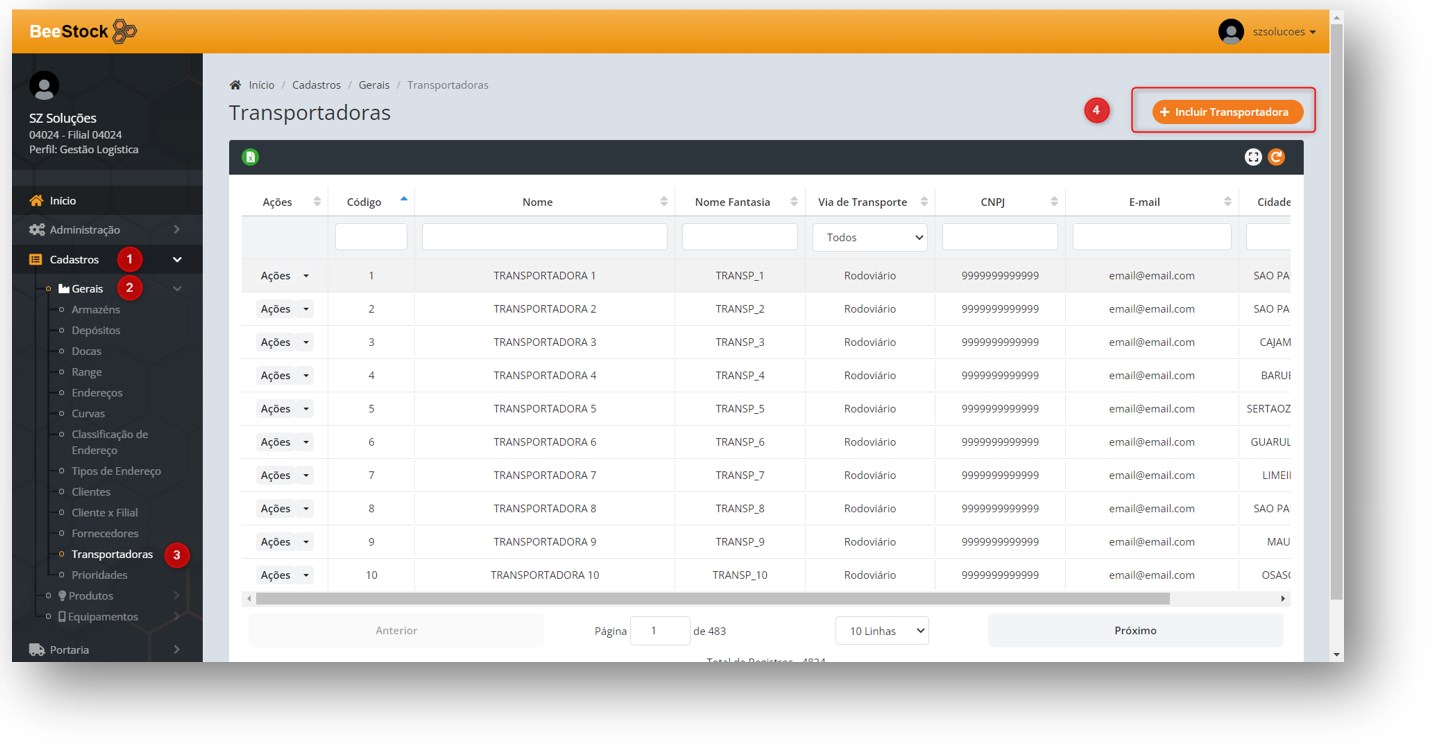

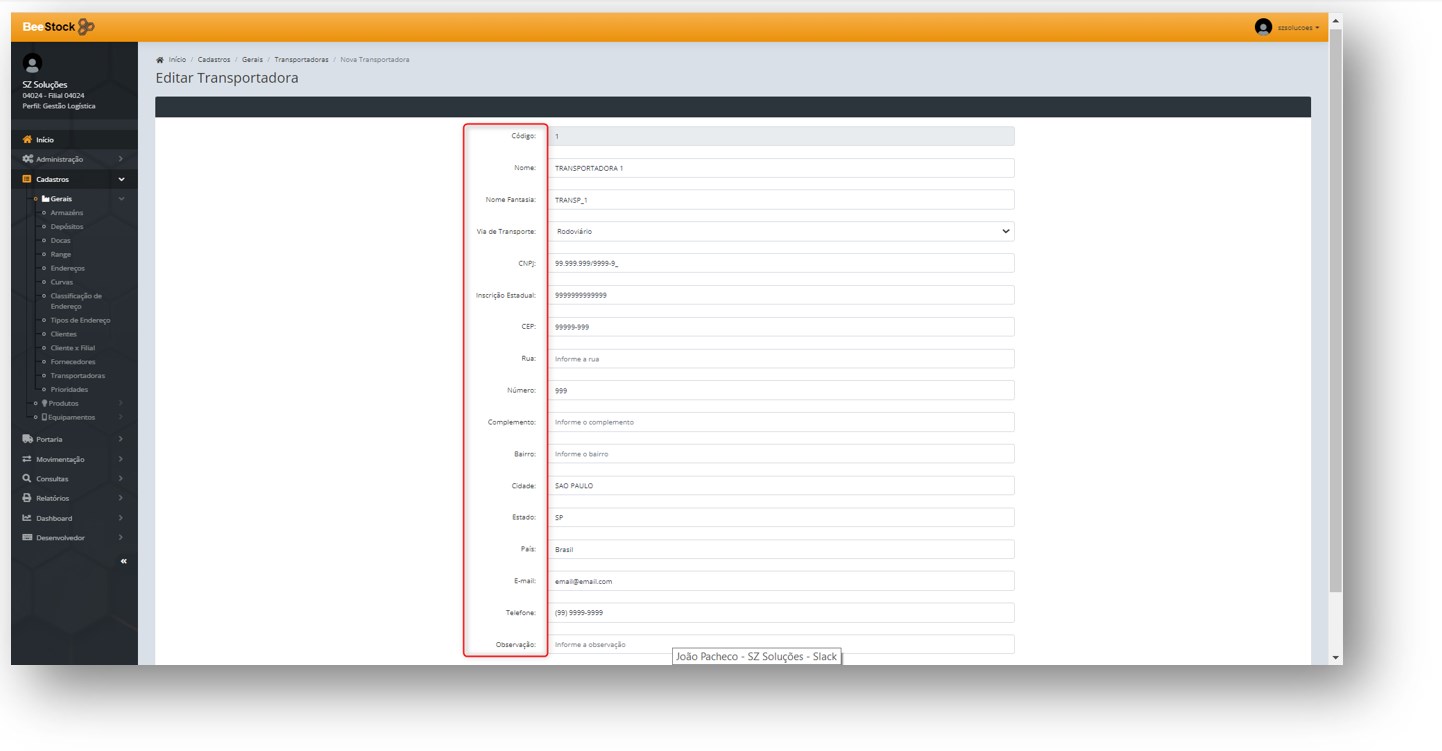

Carrier Registration

Located in Registers > General > Carriers, it is used to manually register carriers or by receiving integration from the ERP system.

As shown in the image below, when registering a carrier, the user must enter the following data:

- Code

- Name

- Trade Name

- Transport Route

- CNPJ (Brazilian Company Tax ID)

- State Registration

- Zip Code

- Street

- Number

- Complement

- Neighborhood

- City

- State

- Country

- E-mail

- Phone

- Observation

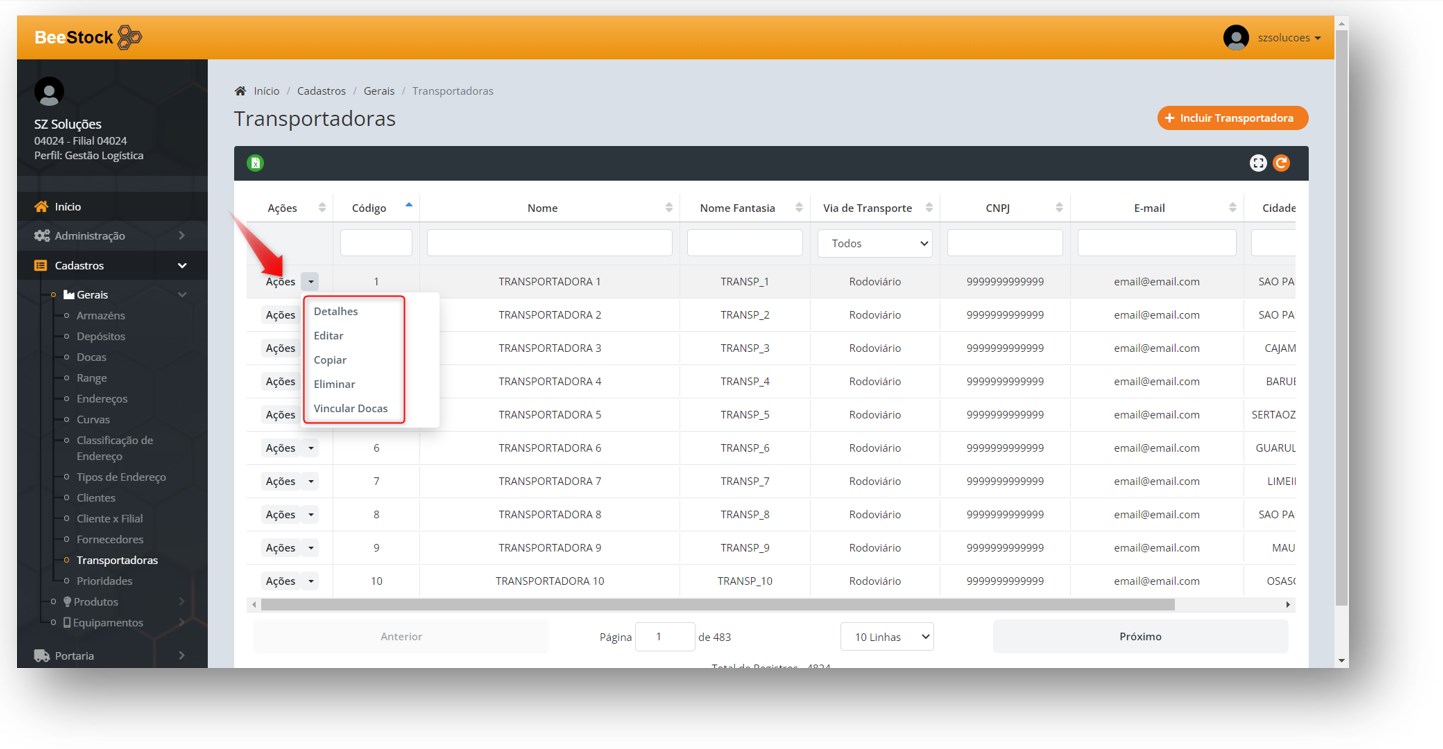

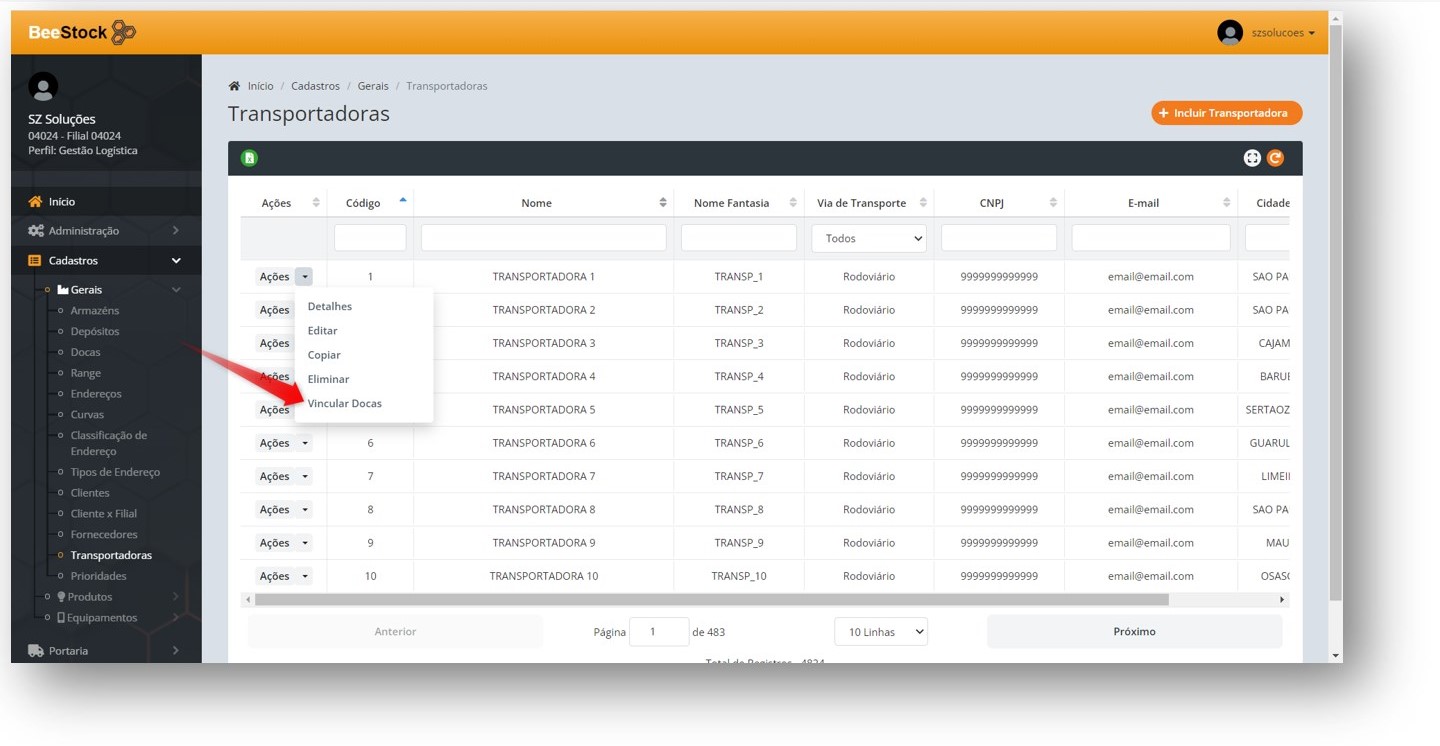

In addition to allowing the creation of a new carrier, in Actions the user has the options to:

- Detail

- Edit

- Copy

- Delete

- Link Docks

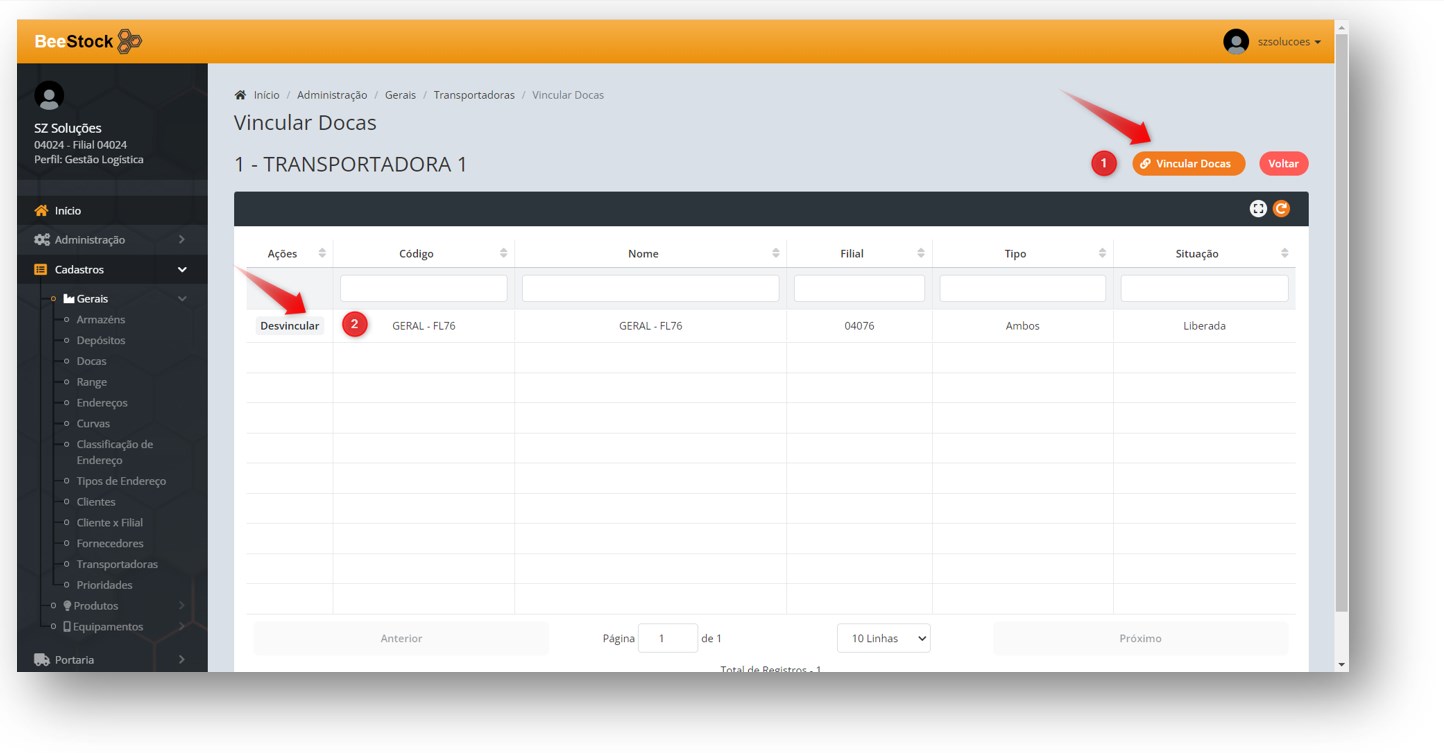

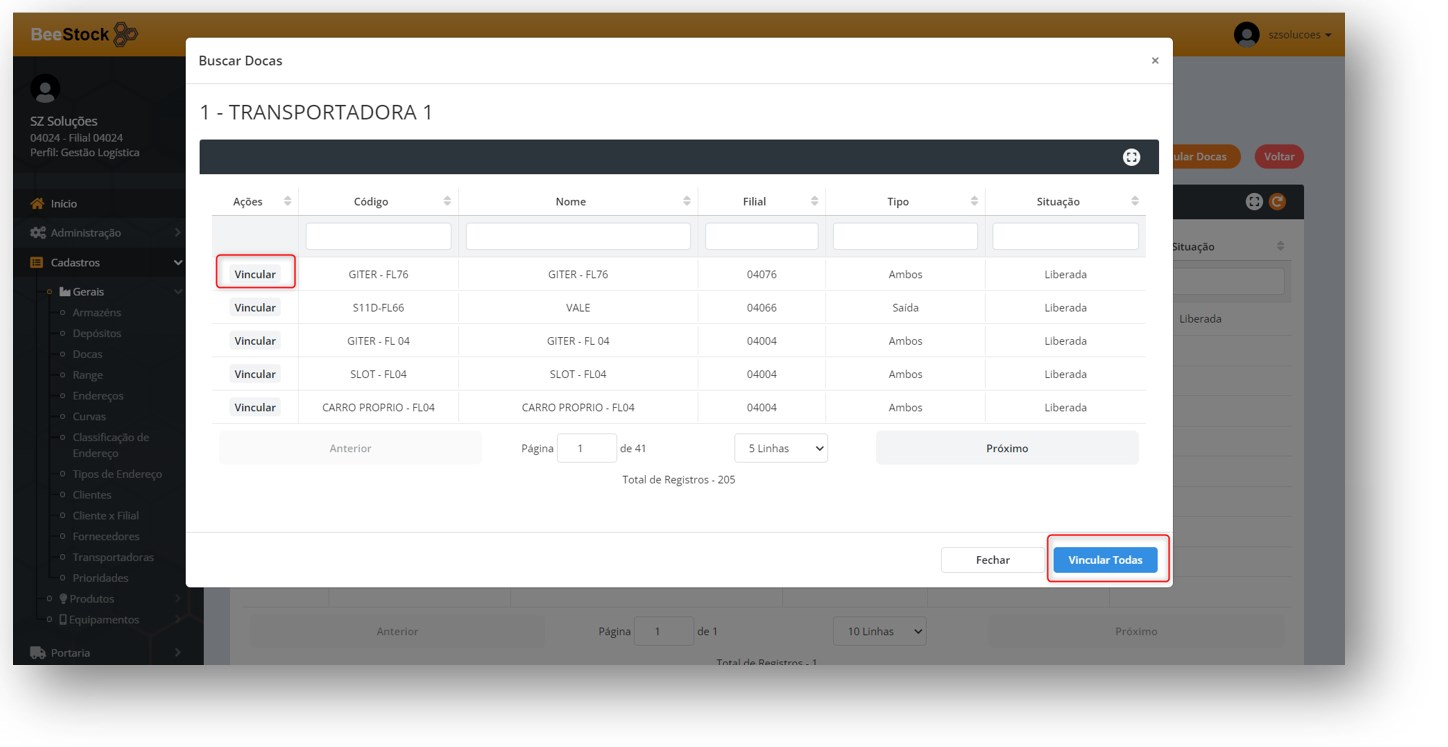

Process of linking a carrier to a dock:

1 – Select the desired carrier, click on Actions and then on Link Docks.

2 – After performing the previous step, the user will be able to link a dock in Link Docks (1) and/or use the Unlink action (2) to unlink a dock.

3 - When clicking on Link Docks, as in the previous image, the user will be able to link a pre-registered dock, just click on Link, or even link all docks at once by clicking on Link All, if you wish.

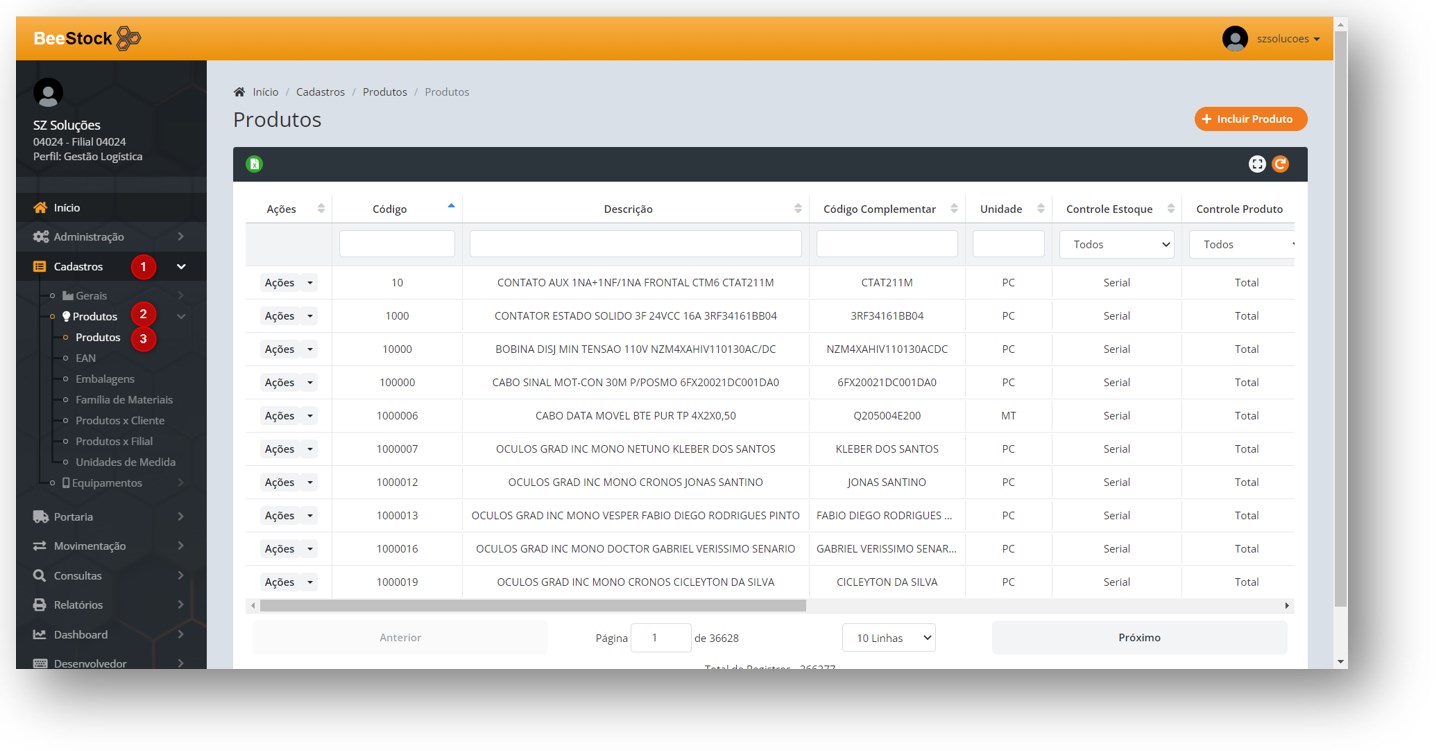

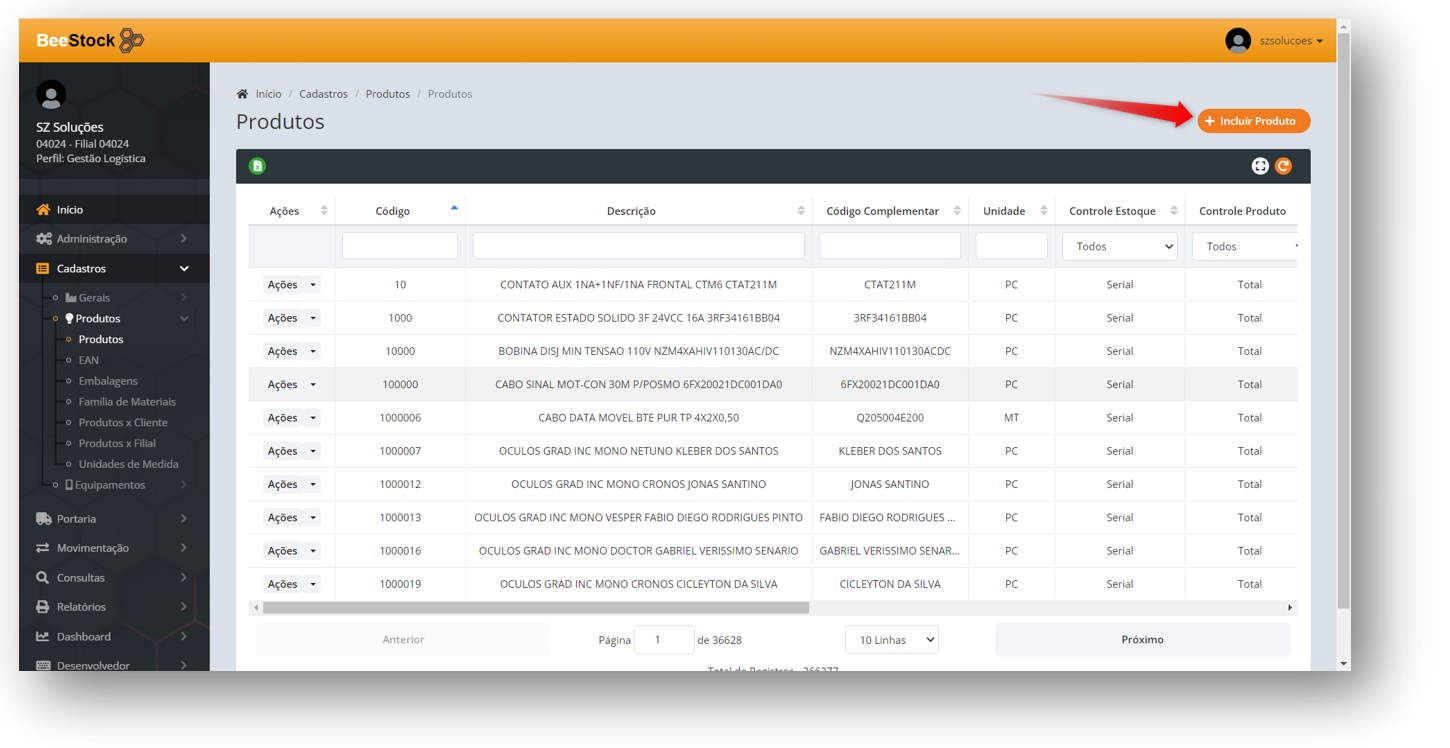

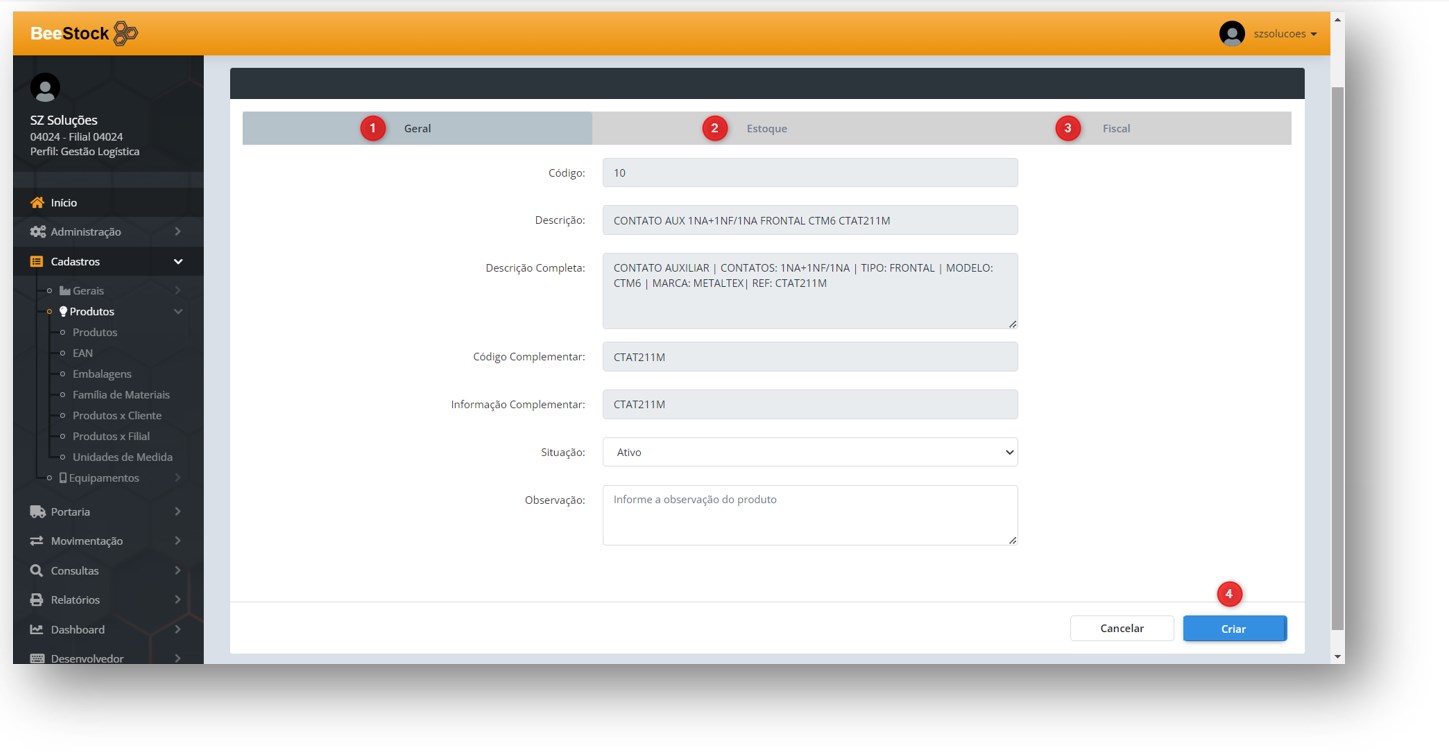

Product Registration

Located in Registers > Products > Products, it is used to manually register products or by receiving integration from the ERP system.

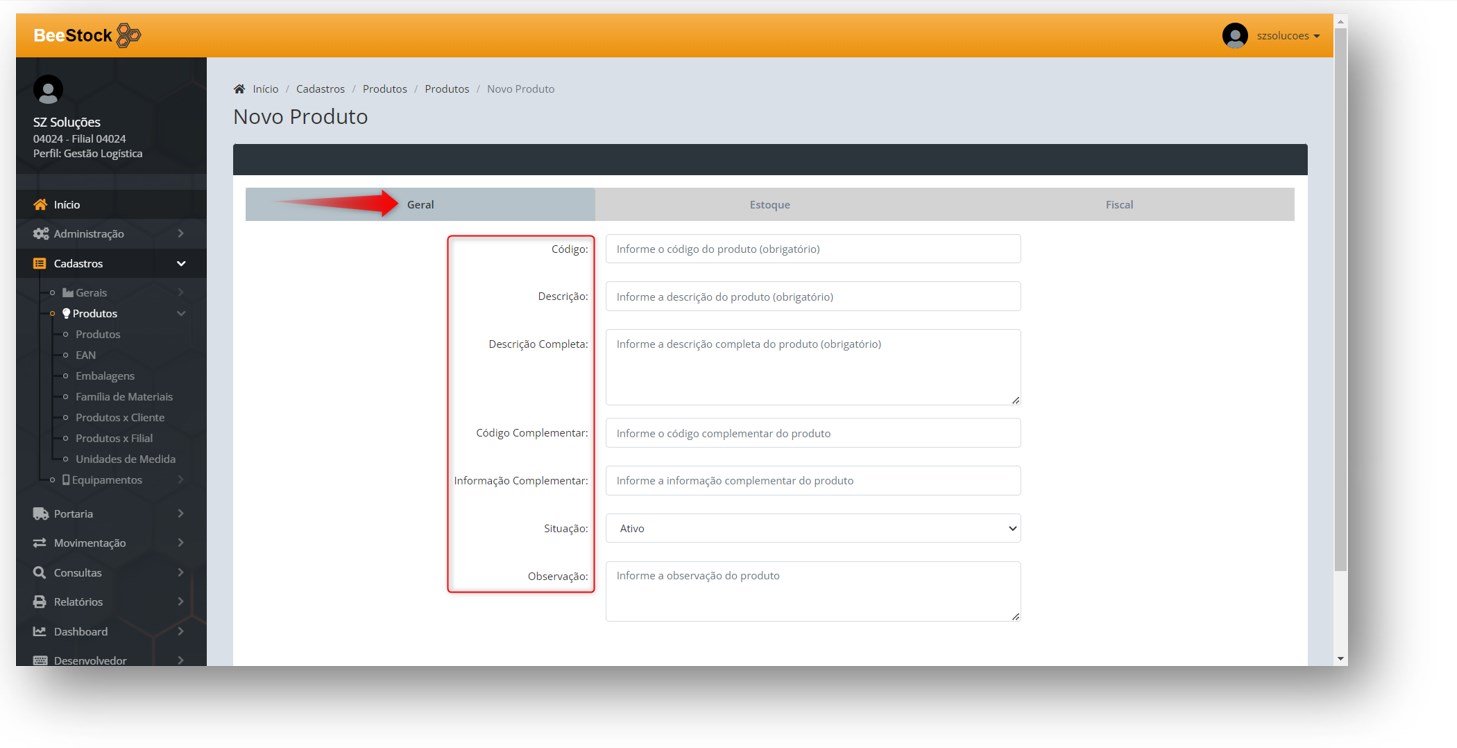

1 – Trigger the + Add Product action in the upper right corner.

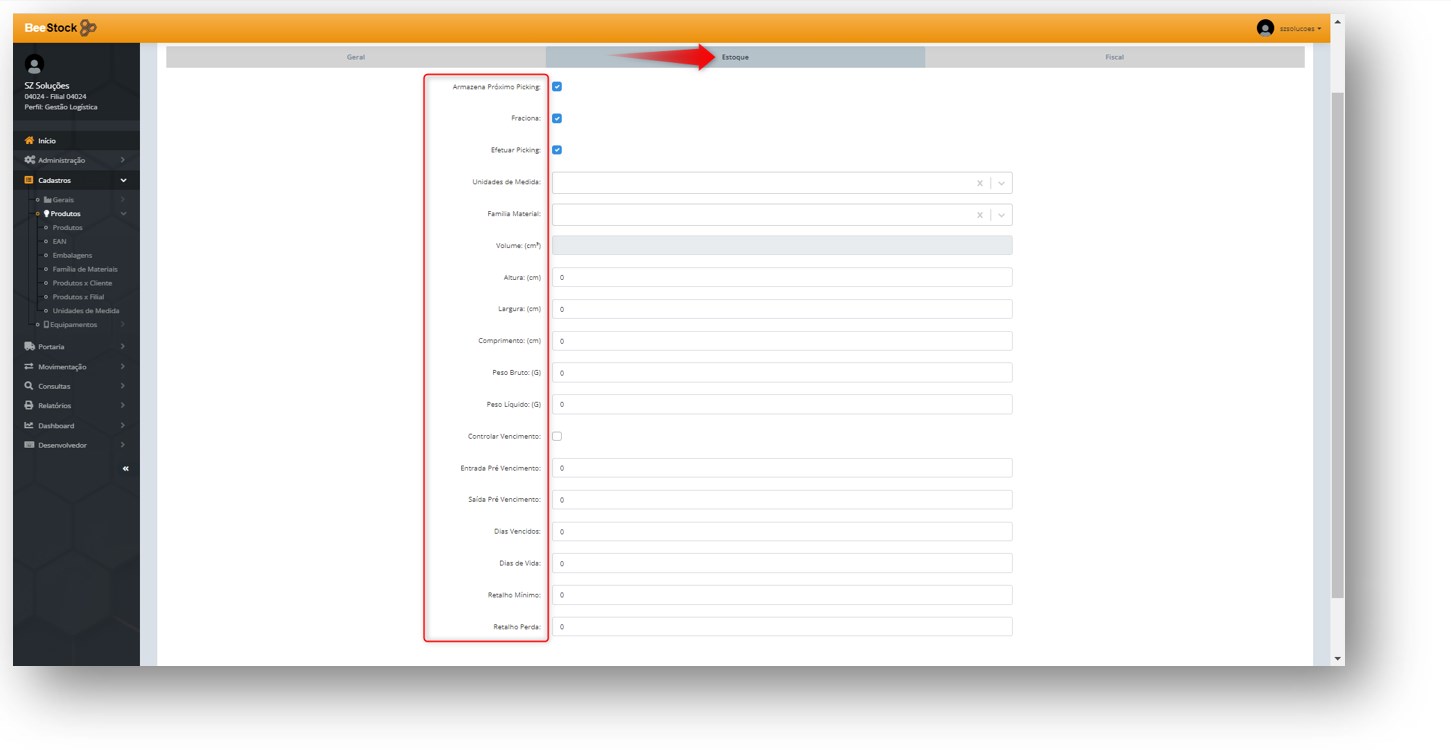

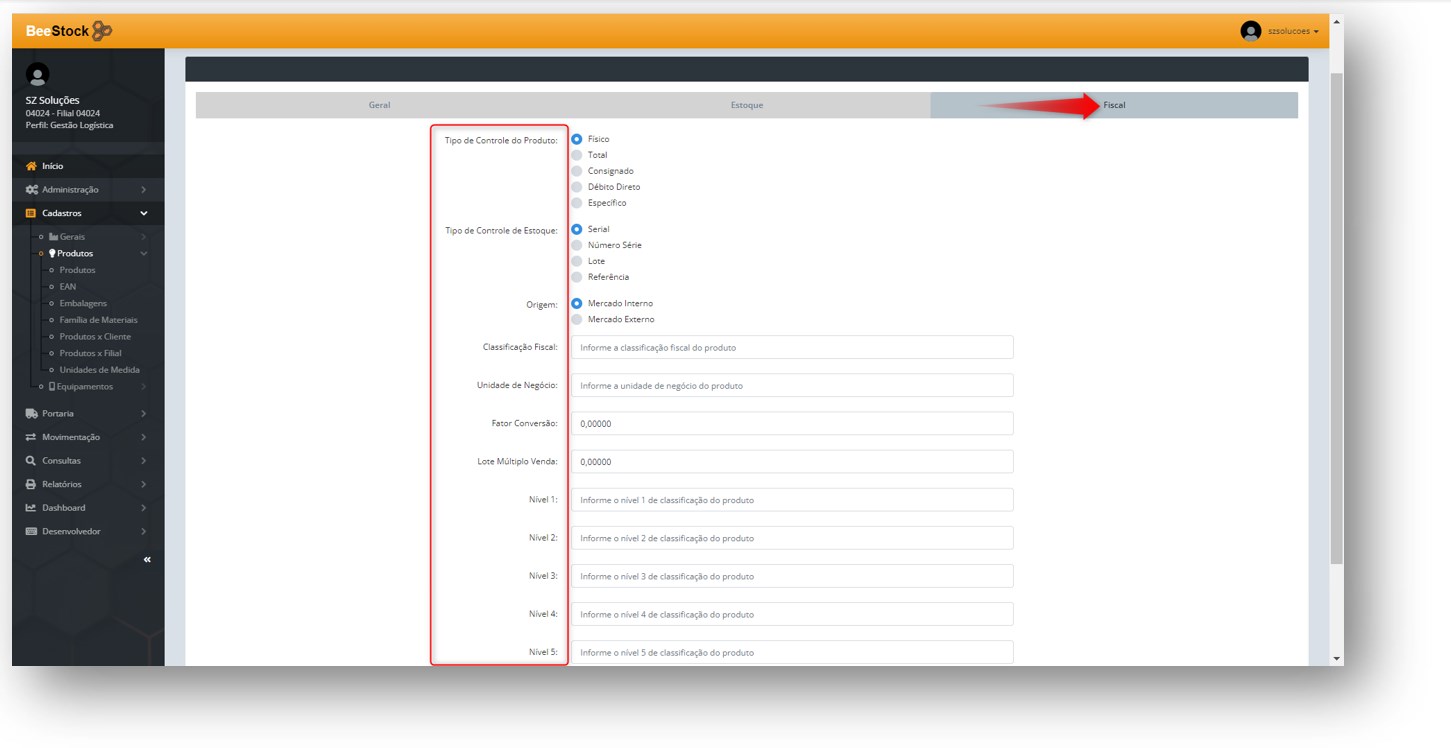

2 – Fill in the product information on the General, Inventory and Fiscal tabs and click on Create.

Detailing the information to be registered in the three tabs of the product registration:

1 - General tab - consists of basic product information as follows:

- Code

- Description

- Full Description

- Complementary Code

- Complementary Information

- Situation

- Observations

2 - Inventory tab - inventory information related to the product that will impact the shipping, receiving, etc. processes to be carried out in BeeStock® is entered.

- Store near Picking

- Fraction

- Perform Picking

- Unit of Measure

- Material Family

- Volume: (cm)

- Height: (cm)

- Width: (cm)

- Length: (cm)

- Gross Weight: (G)

- Net Weight: (G)

- Control Expiration Date

- Pre-Expiration Entry

- Pre-Expiration Output

- Days Expired

- Shelf Life

- Minimum Scrap

- Scrap Loss

3 - Fiscal tab - as well as the information on the Inventory tab, on the Fiscal tab, important tax information about the product is also entered, which will impact the shipping, receiving, etc. processes to be carried out in BeeStock®.

- Product Control Type

- Inventory Control Type

- Origin

- Fiscal Classification

- Business Unit

- Conversion Factor

- Multiple Sales Batch

- Level 1

- Level 2

- Level 3

- Level 4

- Level 5

In addition to the option to include a new product, when selecting a registered product and clicking on Actions, there is the possibility to:

- Detail

- Edit

- Copy

- Delete

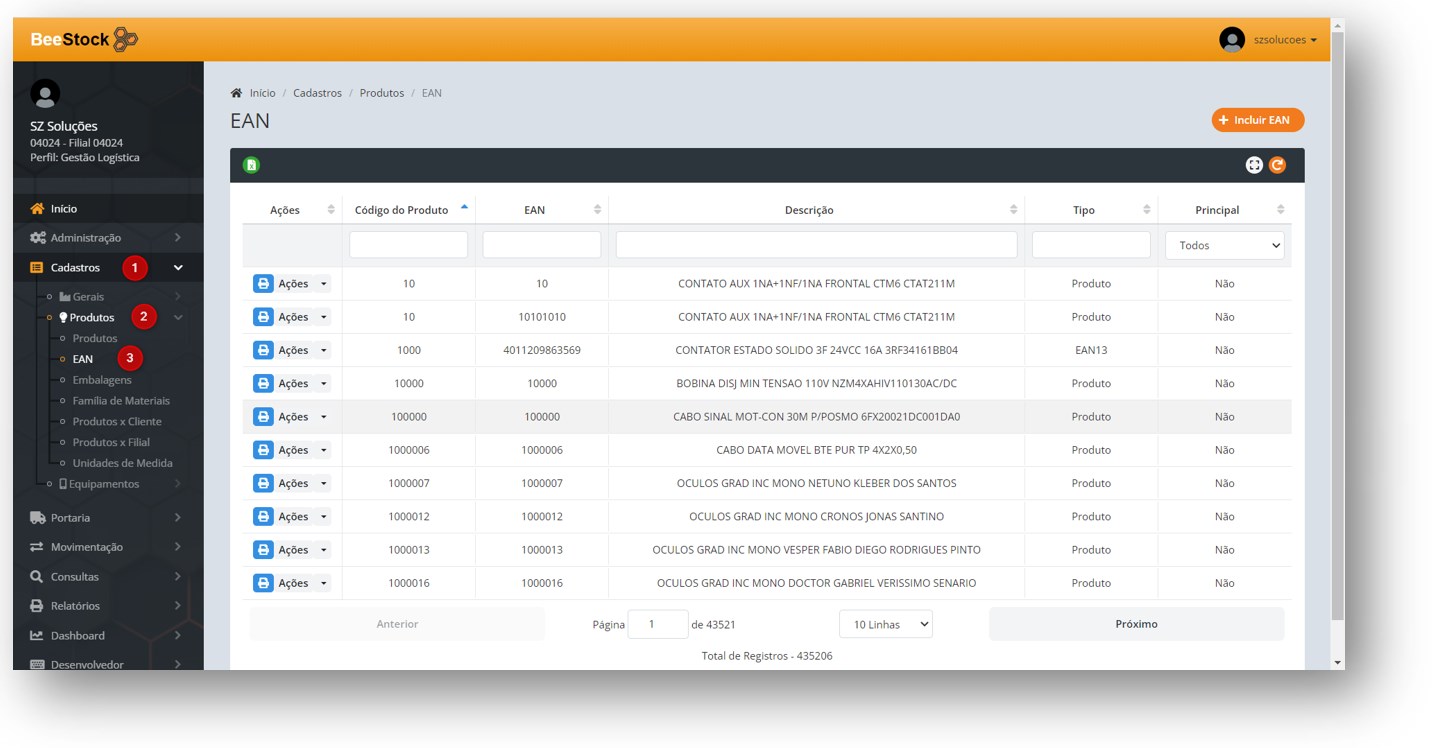

EAN Registration

Located in Registers > Products > EAN, it is possible for the product to have more than one barcode per product, with a different number of digits than 13, according to the customer’s needs.

EAN is product identification information used both in the goods receipt process and in the shipping process.

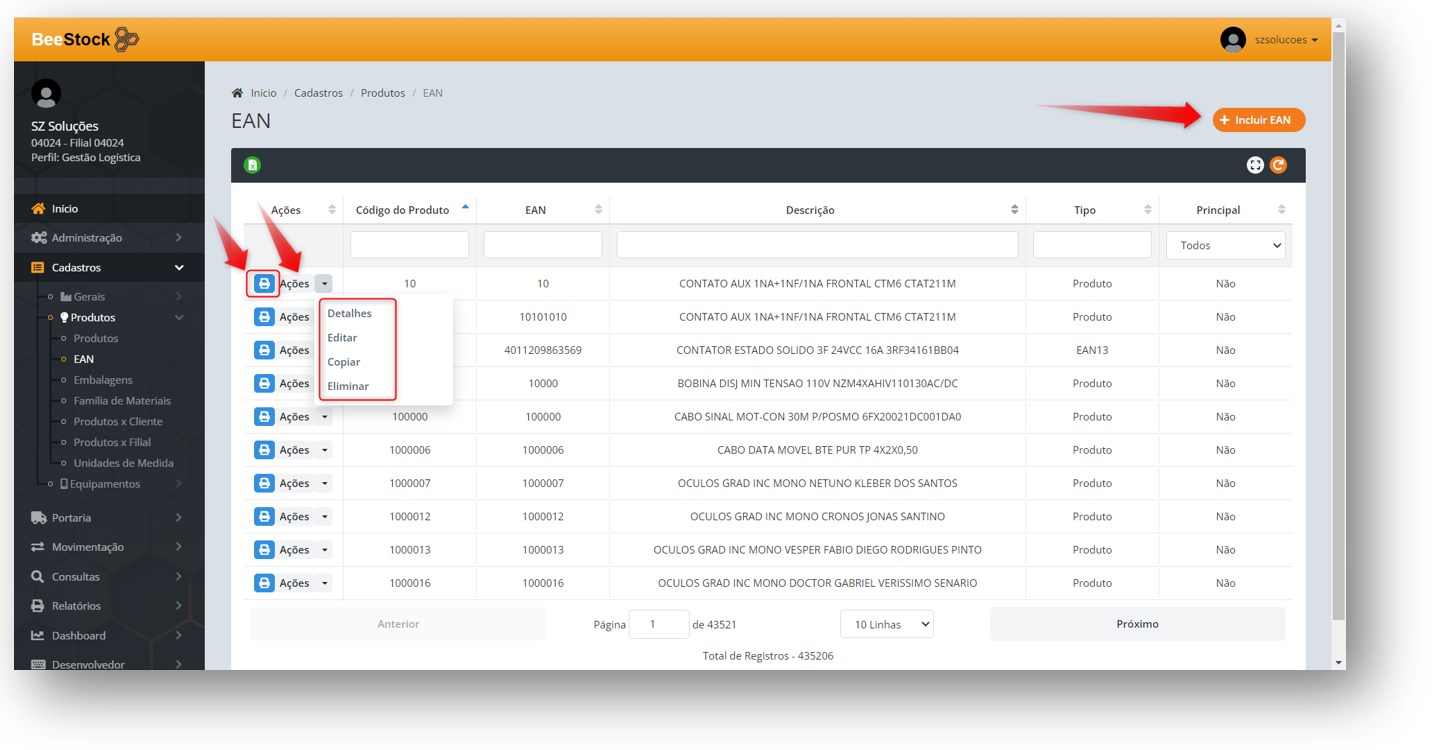

From the EAN Registration screen, the user has the option to:

- Print

- Detail

- Edit

- Copy

- Delete

- + Add EAN

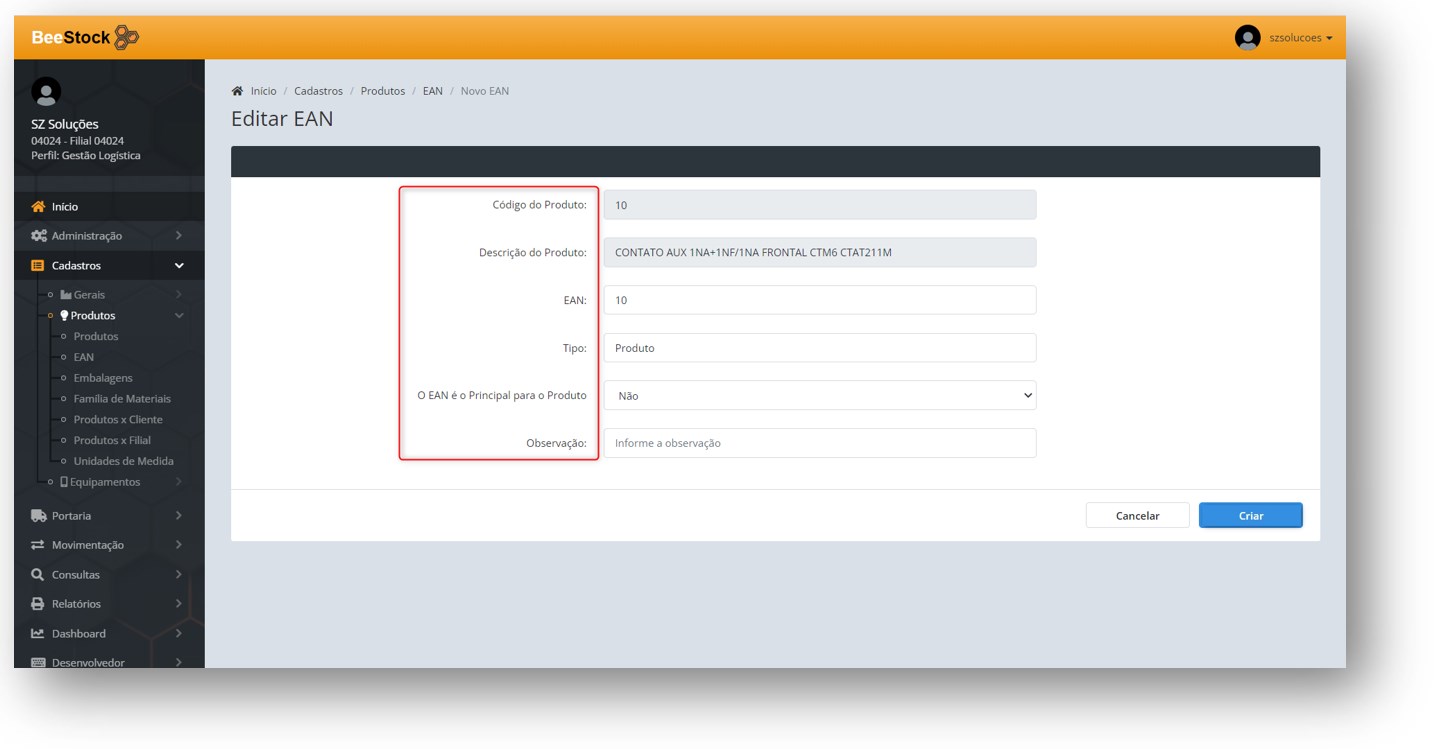

When clicking on + Add EAN, the user must fill in the following fields:

- Product Code

- Product Description

- EAN

- Type

- EAN is the main one for the product

- Observation

And click the Create button.

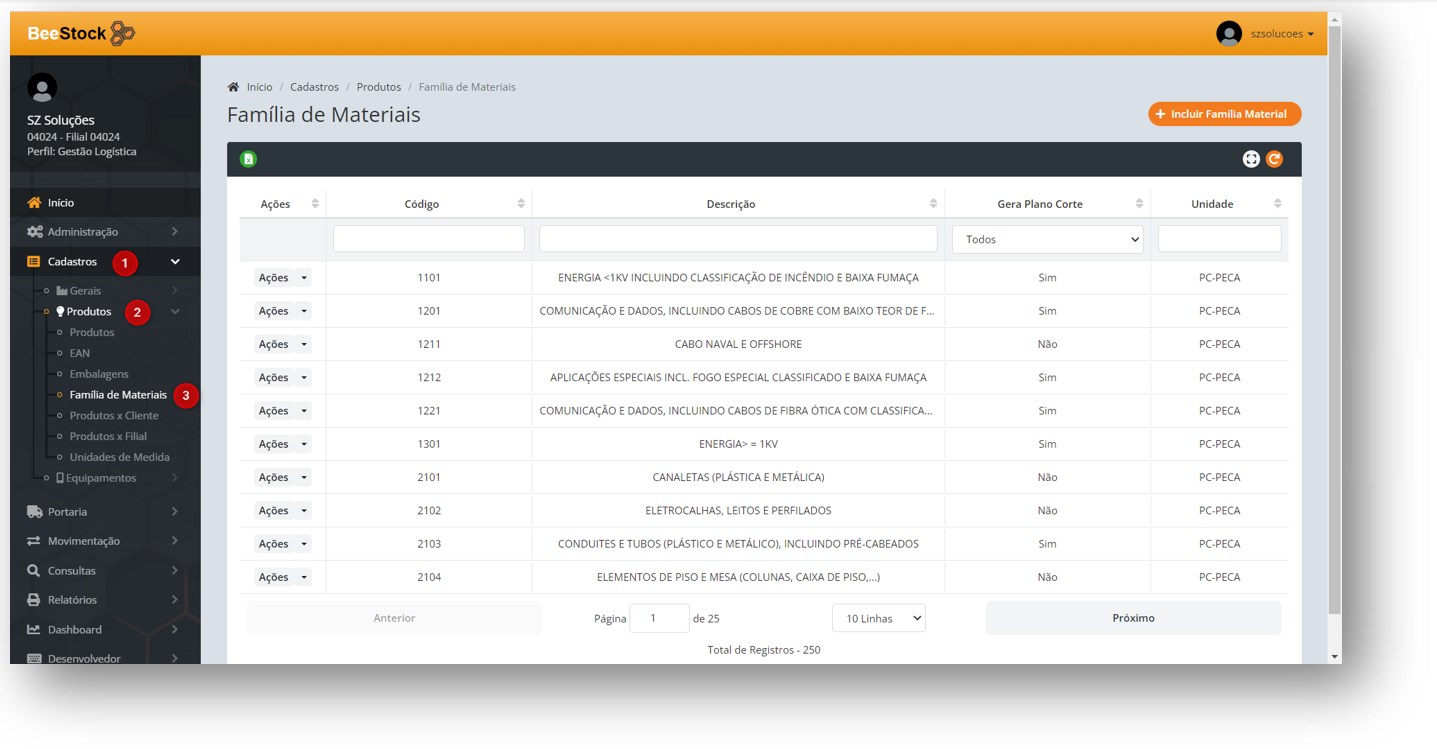

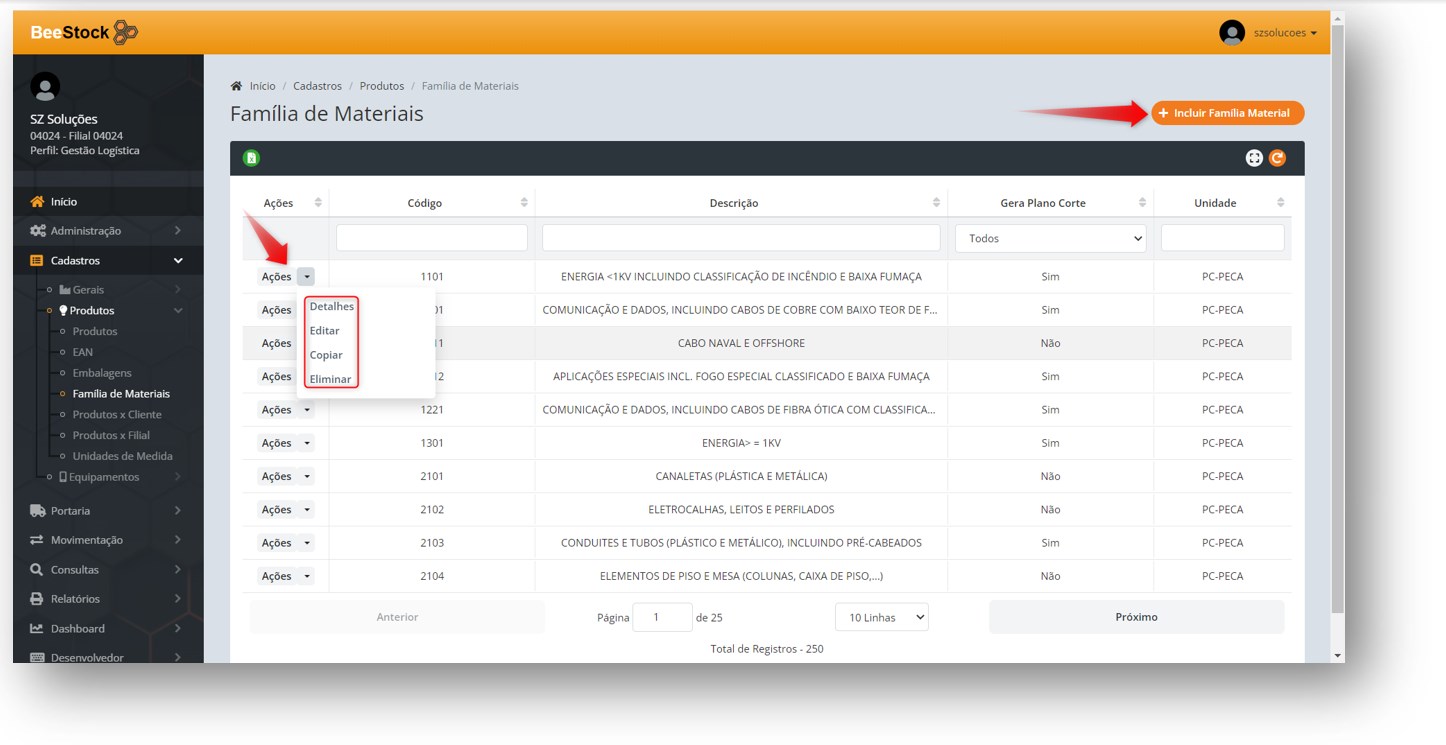

Material Family

Located in Registers > Products > Material Family, it is an identification given to a group of products in which they are classified, for example, by product line, color, size, destination, etc.

Its purpose is to optimize the organization of the product register and facilitate various daily activities related to processes related to products.

From the Material Family registration screen, the user has the option to:

Detail

Edit

Copy

Delete

Add Material Family

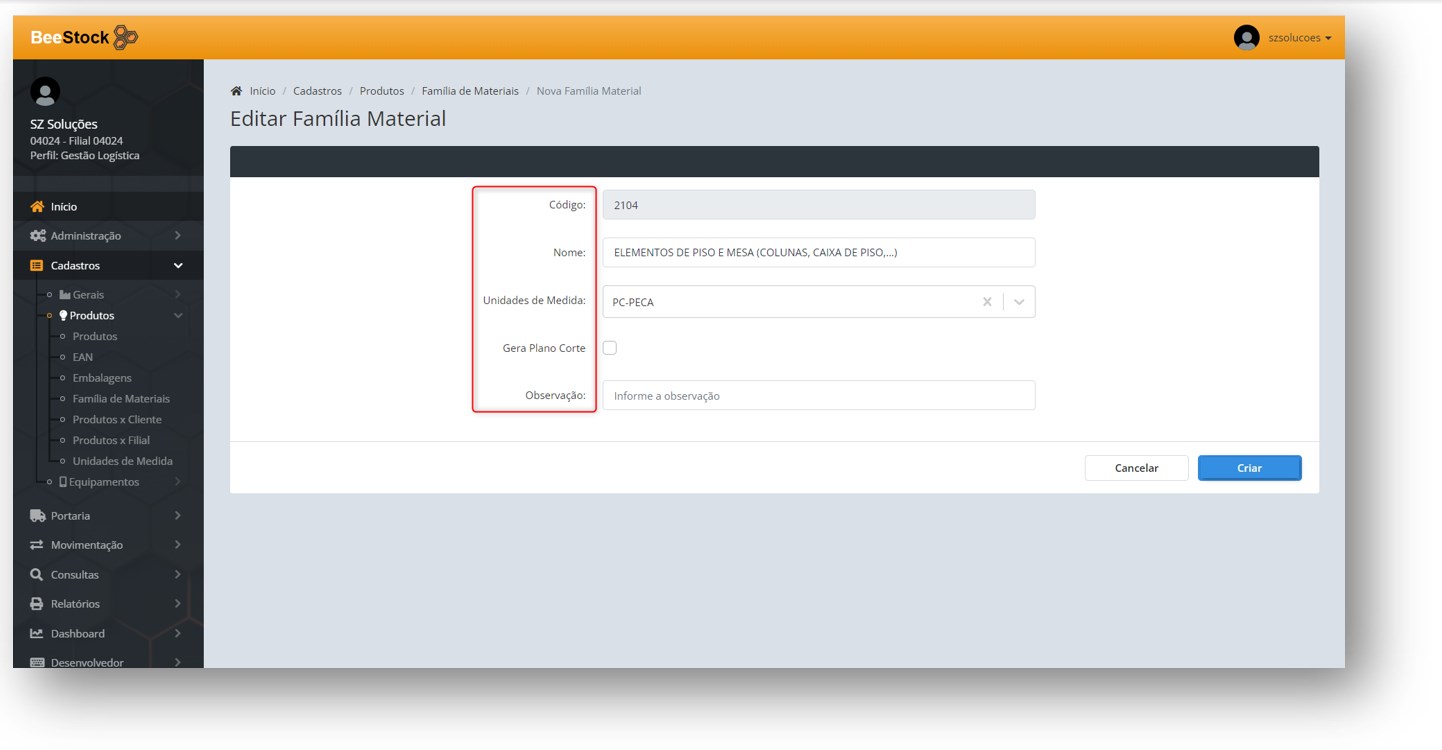

When clicking on + Add Material Family, the user must fill in the following fields:

Code

Name

Unit of Measure

Generate Cutting Plan (parameter generally used for products such as cables, sold in meters and needing to be cut according to the customer’s needs)

Observations

Click the Create button

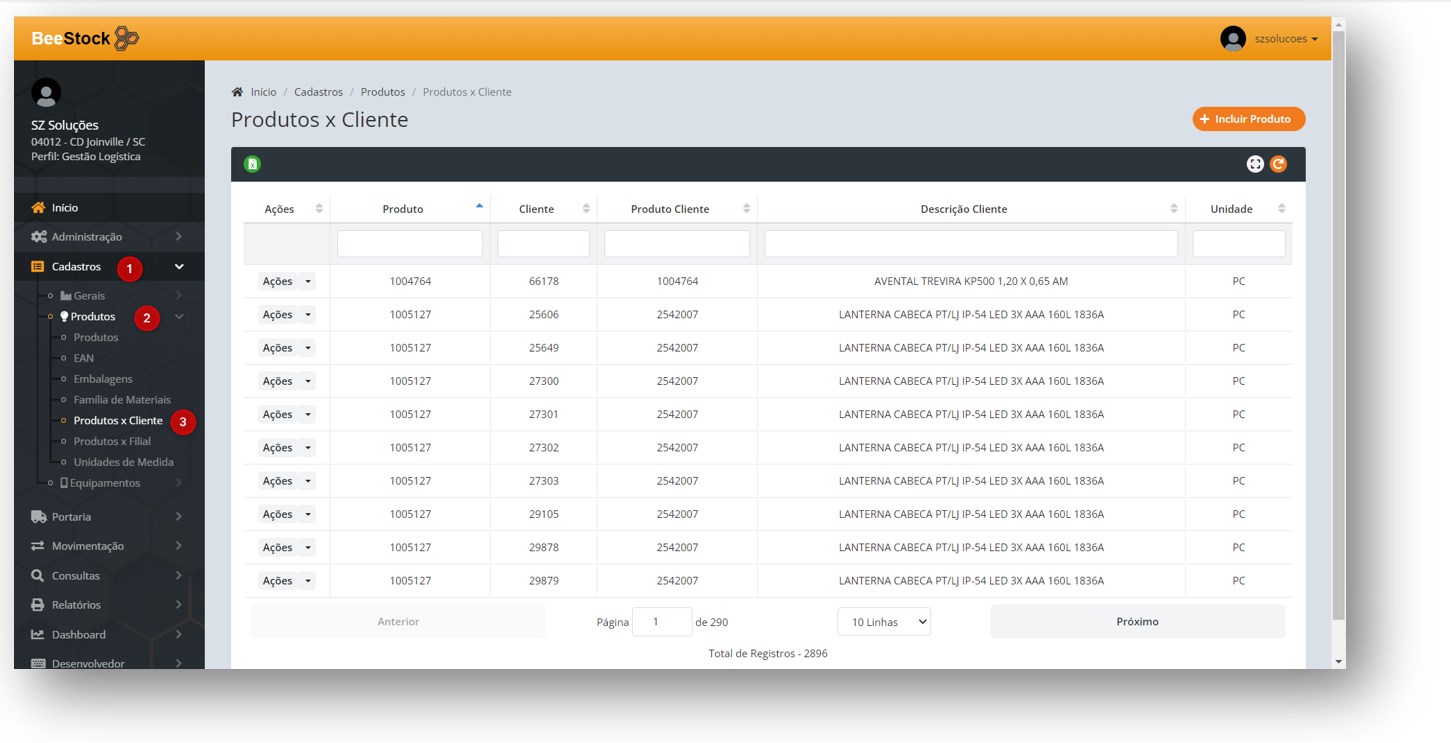

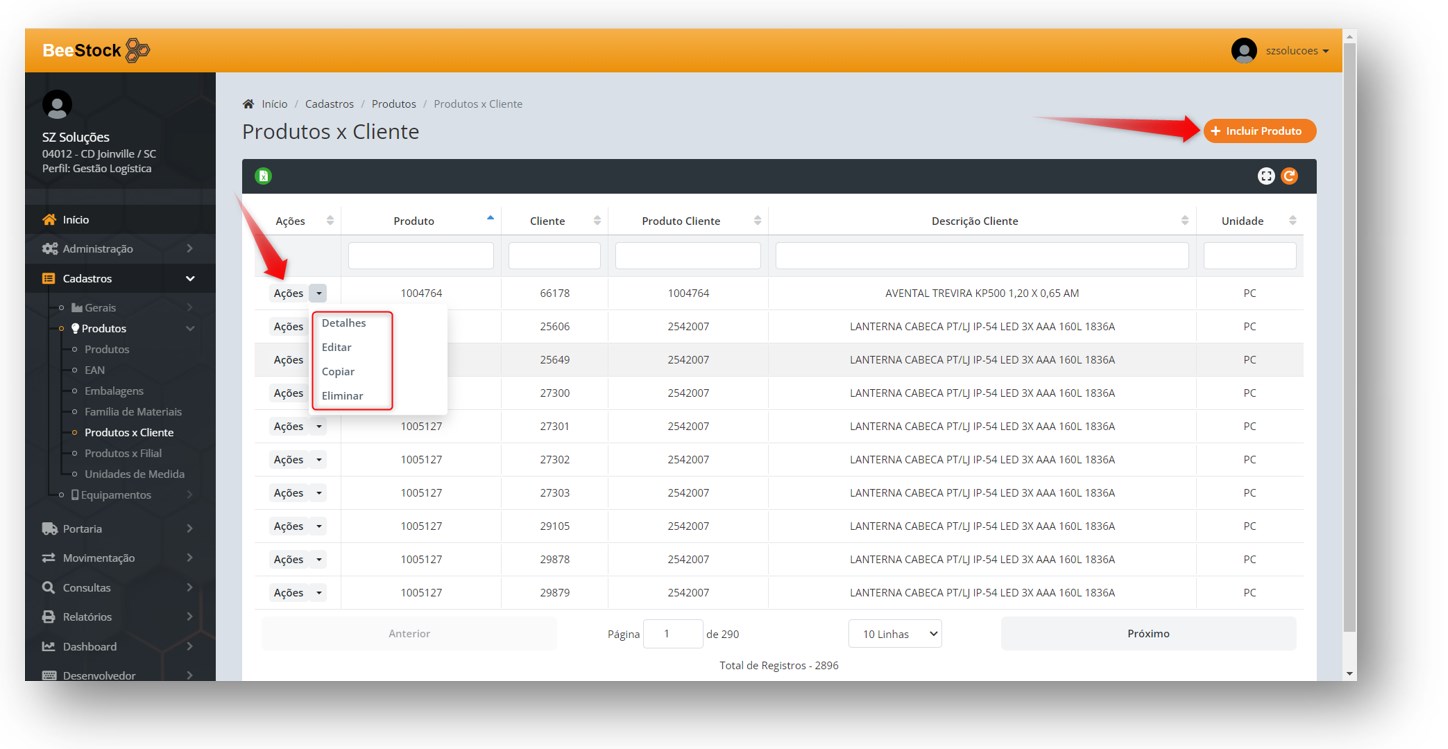

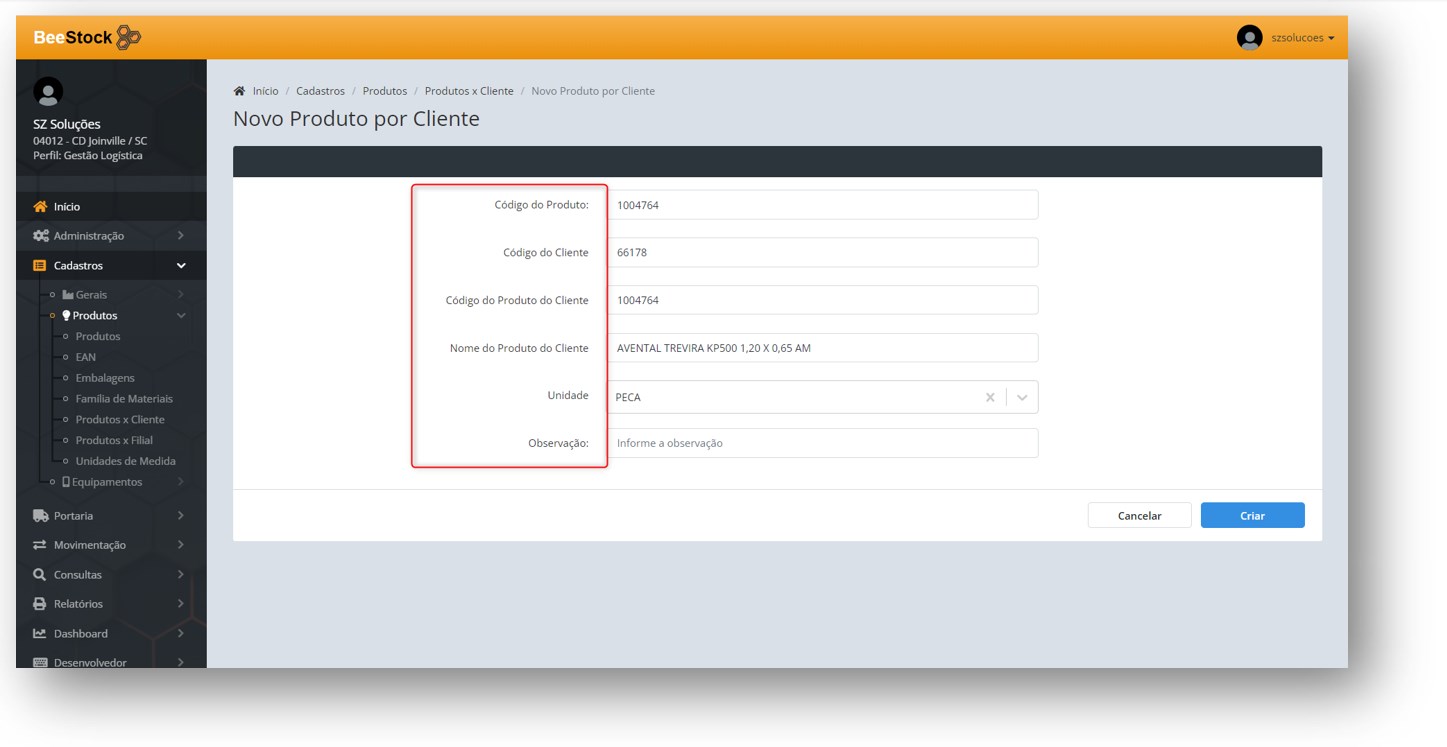

Customer x Product Registration

Located in Registers > Products > Customer x Product, it is used to register specific product information related to the customer.

From the Customer x Product registration screen, the user has the option to:

Detail

Edit

Copy

Delete

Add Product

When adding a new product by customer, the user must fill in the following fields, as shown in the image and description below, and click the Create button:

Product Code

Customer Code

Customer Product Code

Unit (unit of measure)

Observations

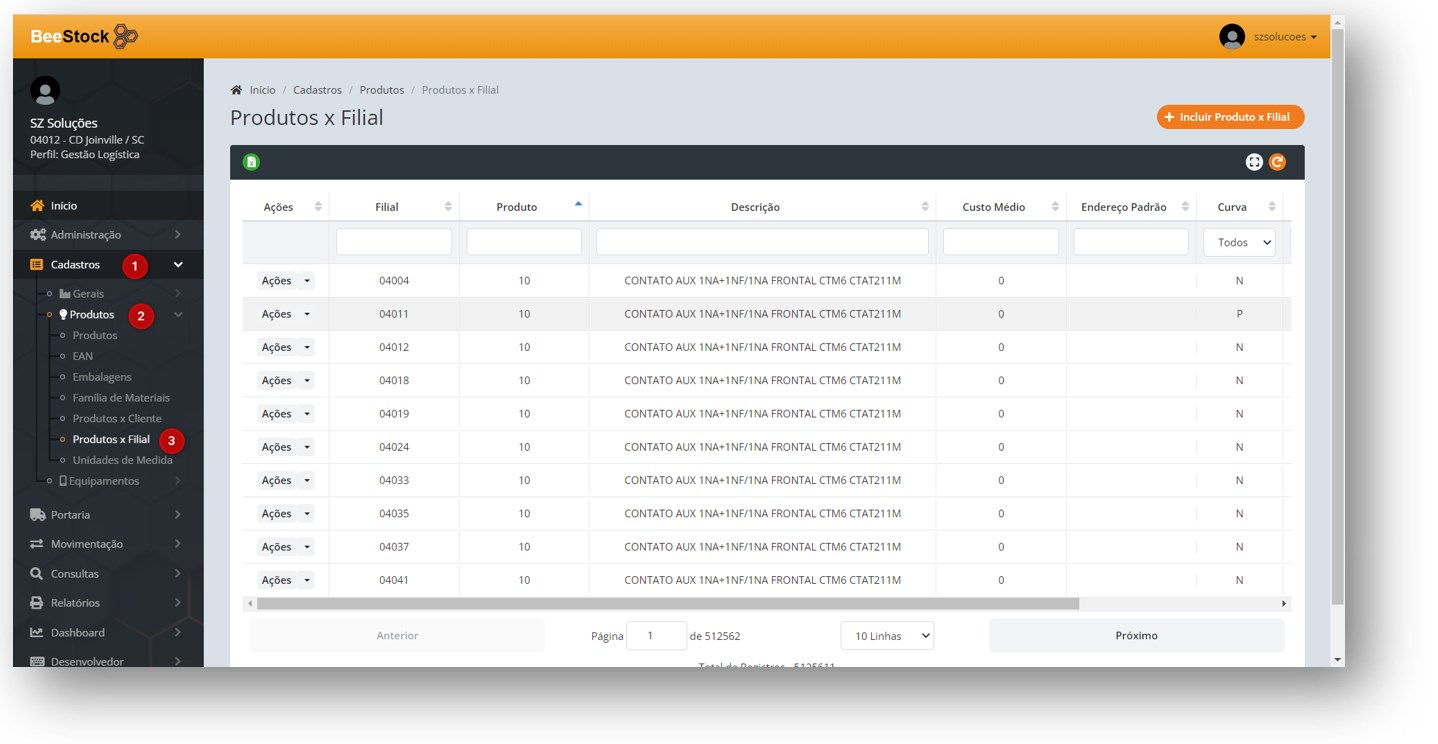

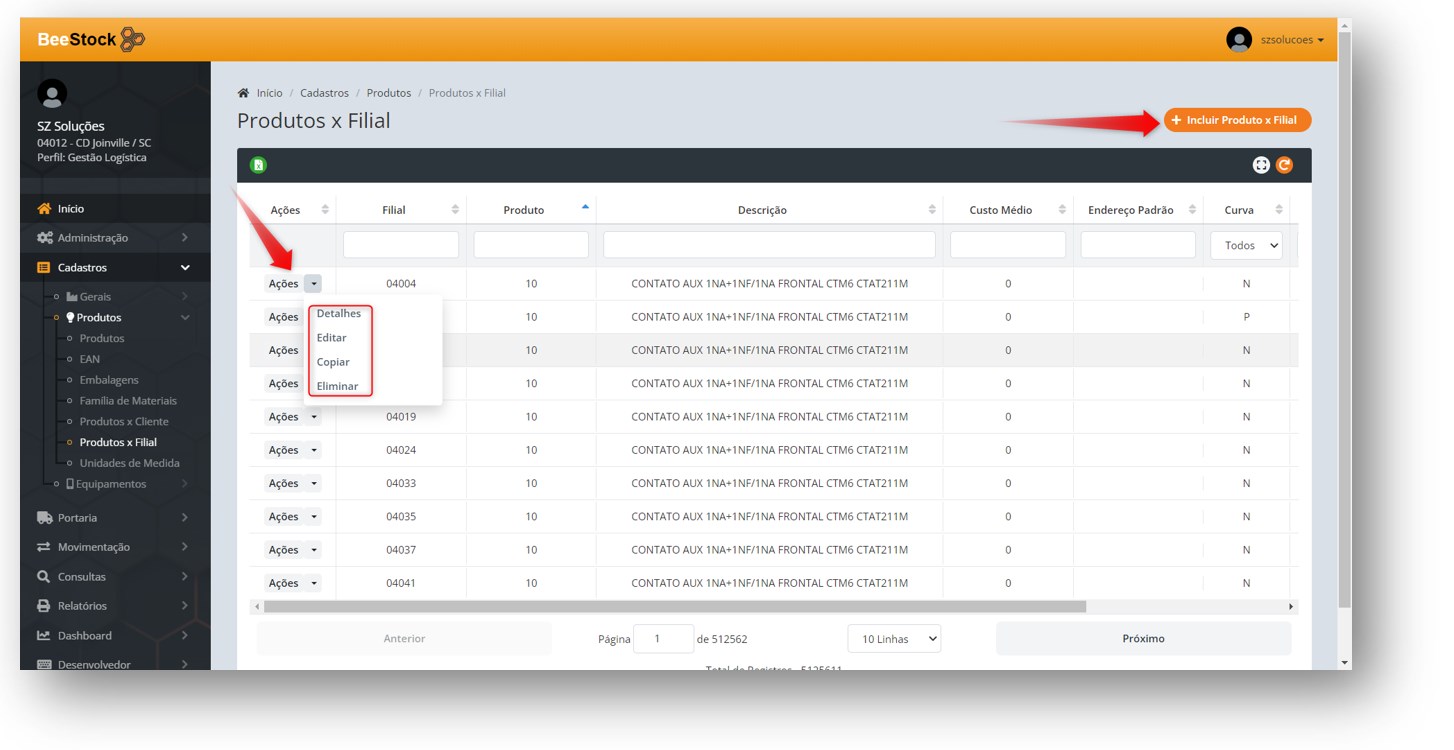

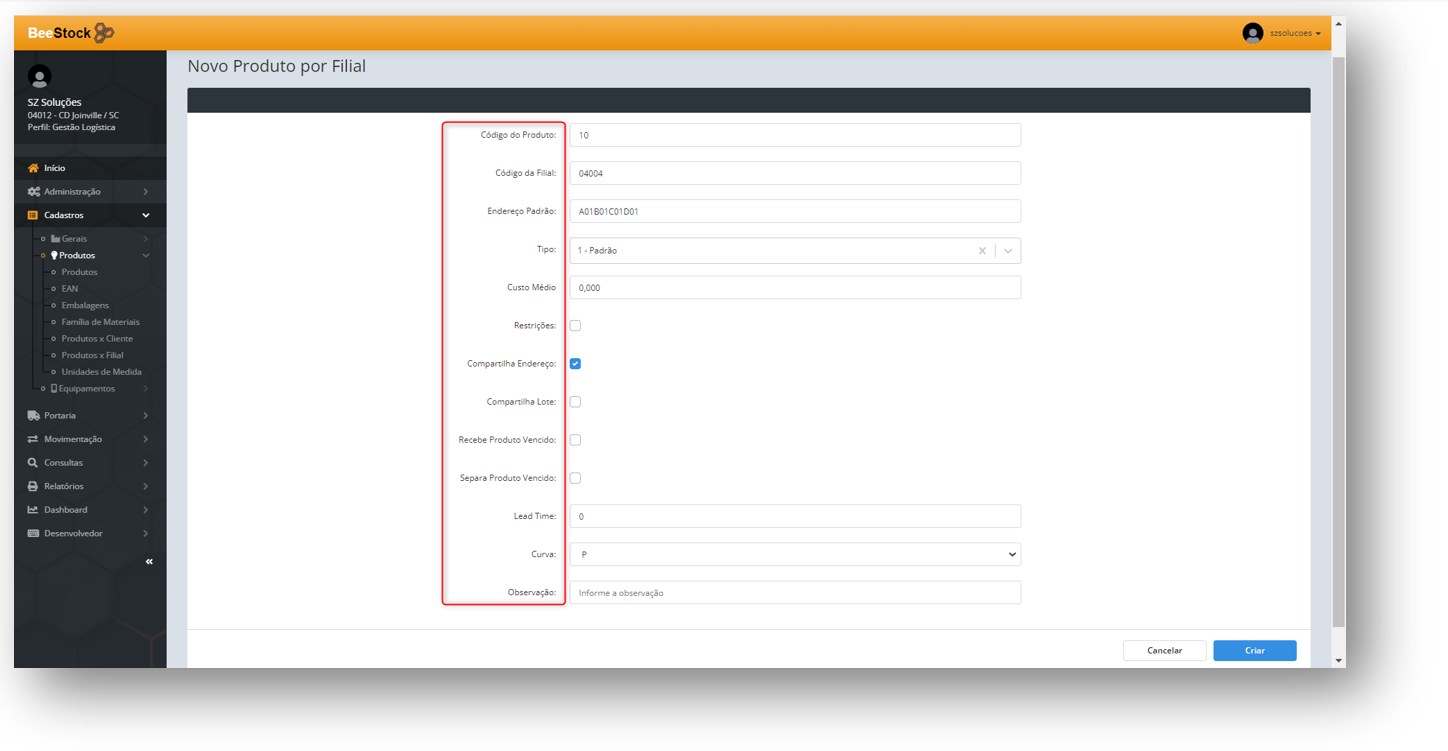

Product x Branch Registration

Located in Registers > Products > Product x Branch, it is used to register specific product information related to a branch.

From the Product x Branch registration screen, the user has the option to:

Detail

Edit

Copy

Delete

Add Product x Branch

When adding a new product by branch, the user must fill in the following fields, as shown in the image and description below, and click the Create button in the lower right corner:

Product Code

Branch Code

Default Address (Allows the inclusion of a default address to be suggested upon receipt of a product)

Type

Average Cost (Average cost of the product received via ERP integration)

Restrictions

Share Address (When selecting this option, the product may share the allocated address with different products, that is, it can be stored in an address that already has another different product, as well as a different product can be received at the address where it is stored)

Share Batch (When selecting this option, similar to what happens with Share Address, the product can be stored in an address that has products with batches different from its own

Receives Expired Product (Option used for products that are controlled by expiration date, allows the product to be received even if its expiration date has expired)

Pick Expired Product (Allows the product to be shipped even if its expiration date has expired)

Lead Time

Curve (Method of classifying products in stock according to their importance, value, stock turnover, etc.)

Observation

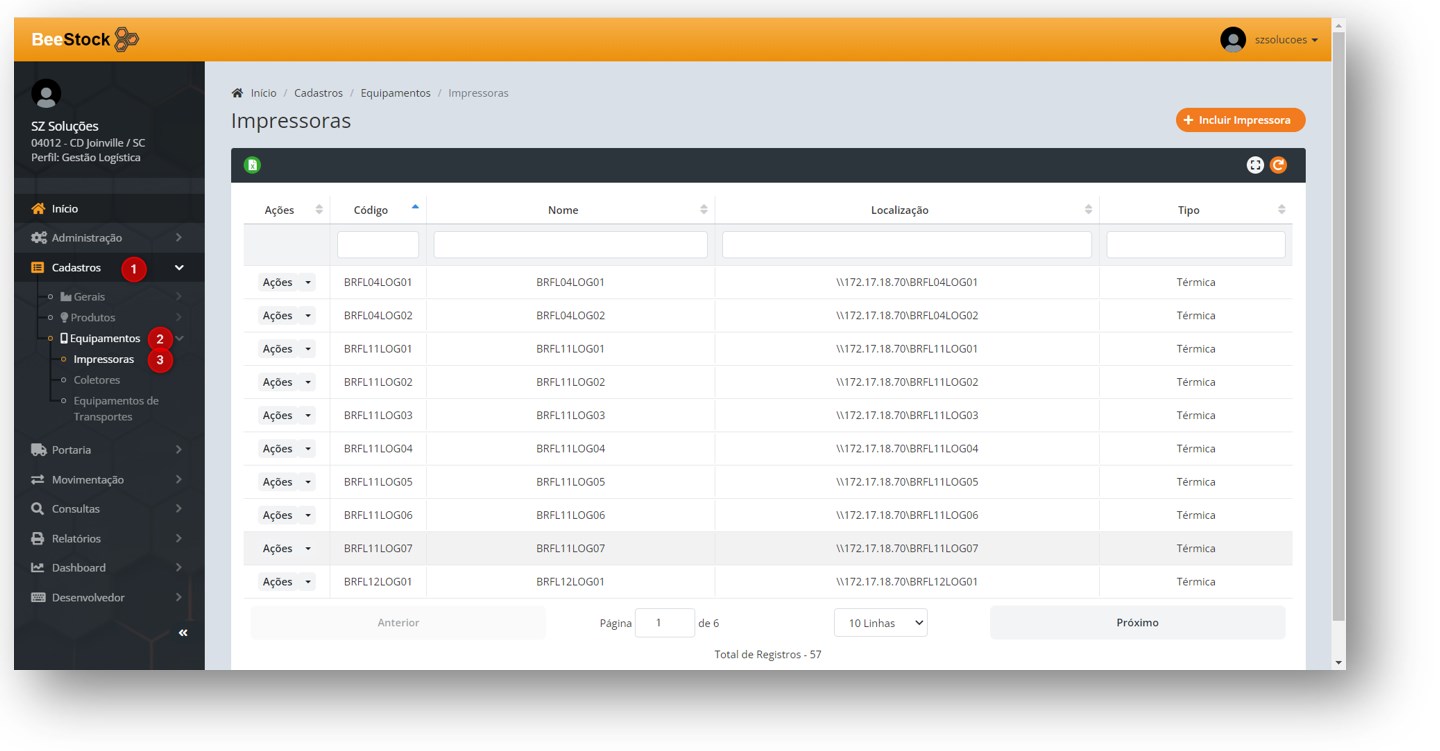

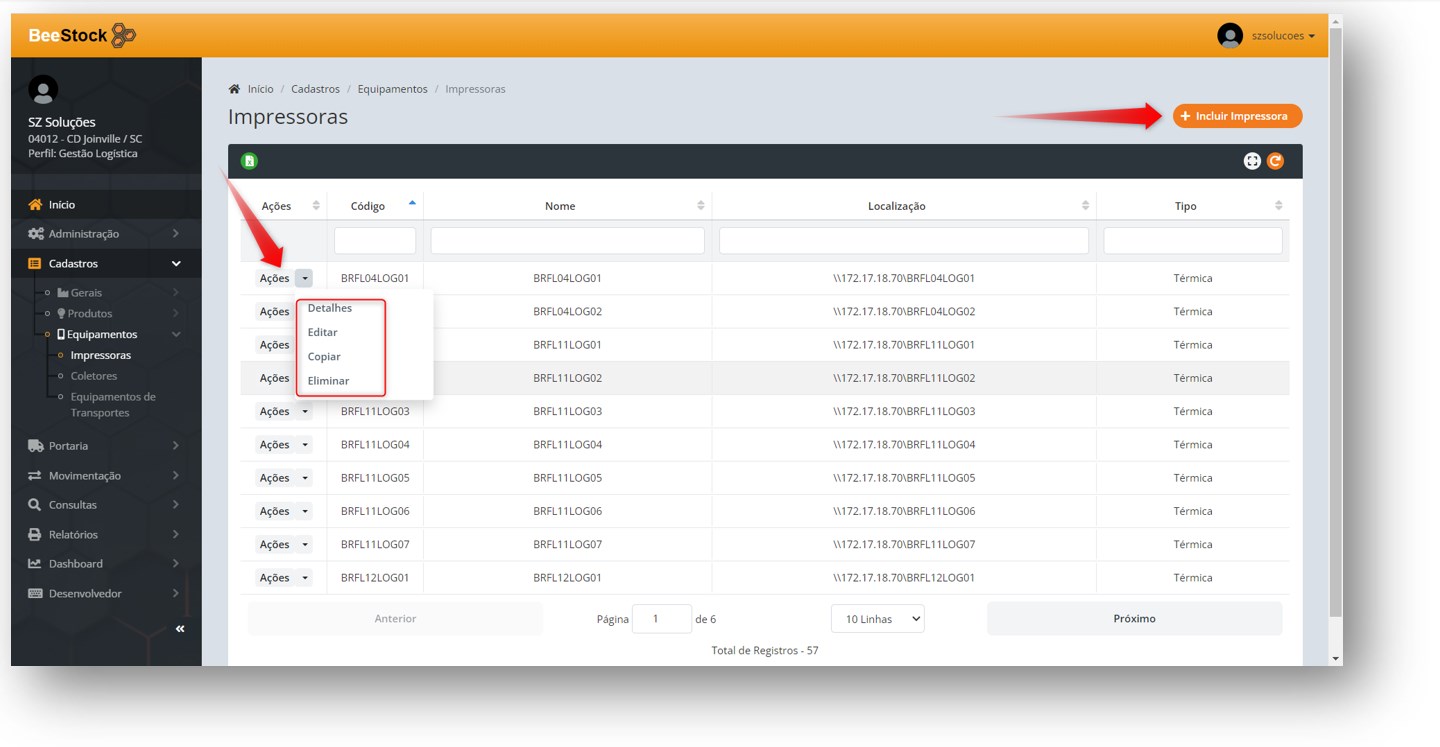

Printer Registration

Located in Registers > Equipment > Printers, it is used to register printers to be used.

From the Printers registration screen, the user has the option to:

Detail

Edit

Copy

Delete

Add Printer

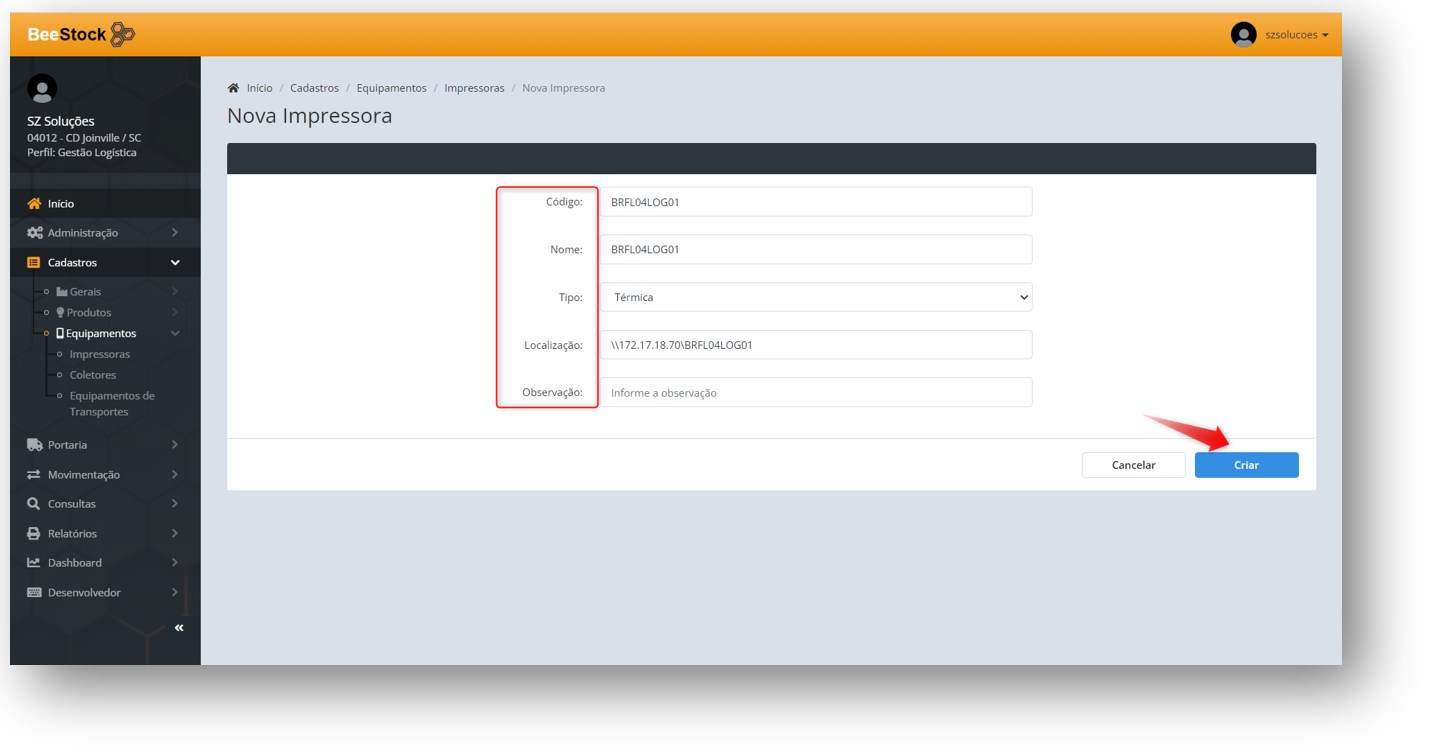

When adding a new printer, the user must fill in the following fields, as shown in the image and description below:

Code

Name

Type

Location

Observation

Click the Create button in the lower right corner.

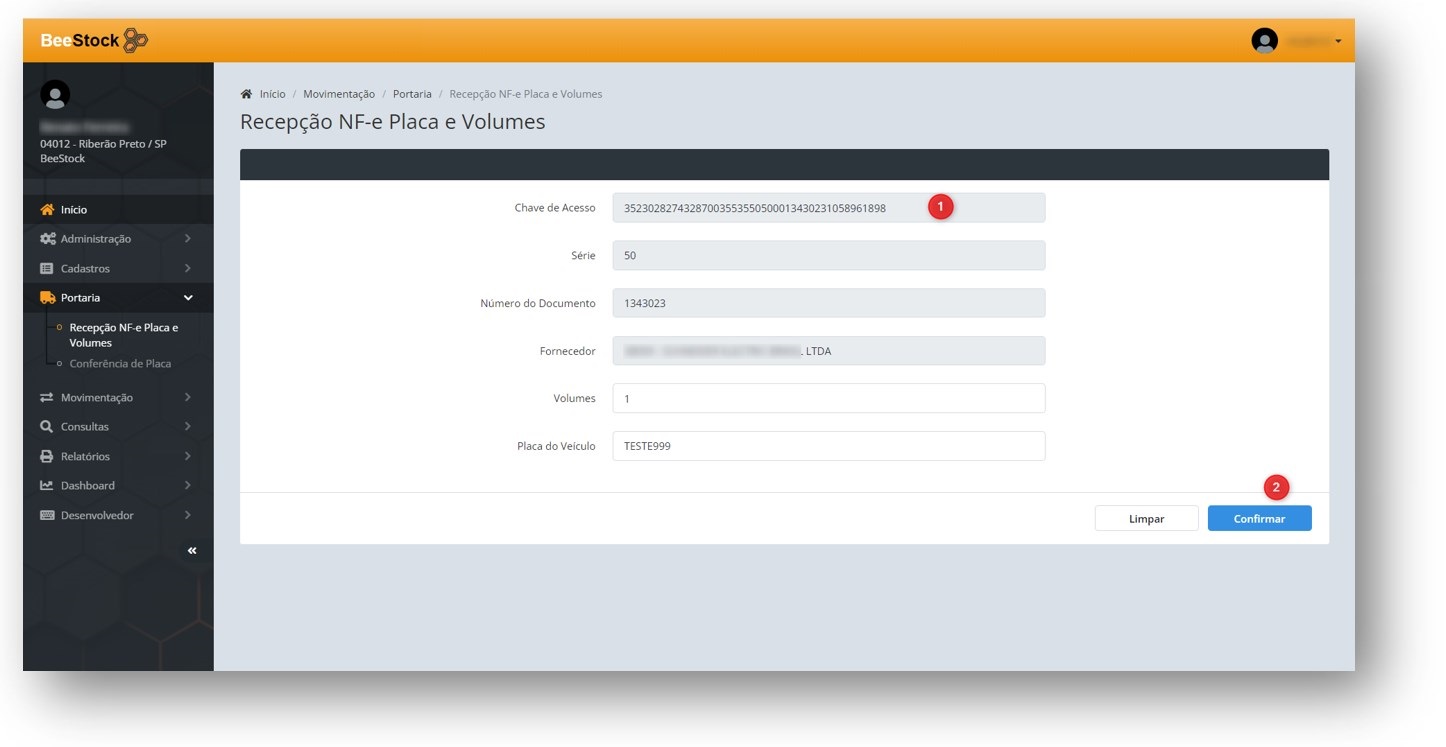

NF-e Plate and Volume Reception

NF-e Plate and Volume Reception

Located in Gatehouse > NF-e Plate and Volume Reception, it is used to register the actual license plate of the vehicle linked to the data of the inbound document that will be received.

On this screen, you must enter:

Volumes (Total Quantity of Volumes)

Vehicle Plate

So that the Plate Check Flow - Collector or via Web Plate Check can be performed later.

Plate Check

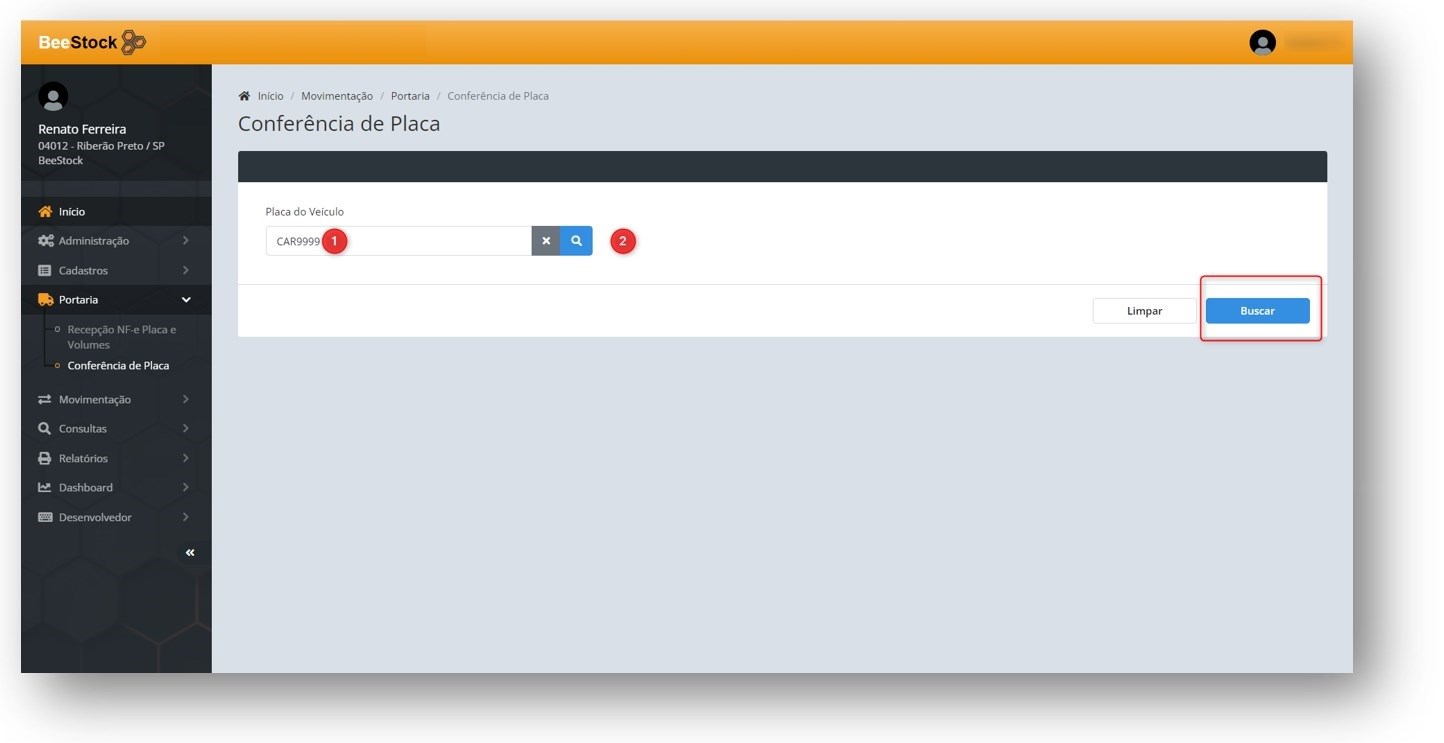

Located in Gatehouse > Plate Check, it is used to check the vehicle plate and volumes of the document to be received.

The user has the possibility to enter the plate data directly in the fields:

Vehicle Plate and press Enter.

Or click on the magnifying glass to search for one of the available plates

After that, just click the Search button to select the desired plate

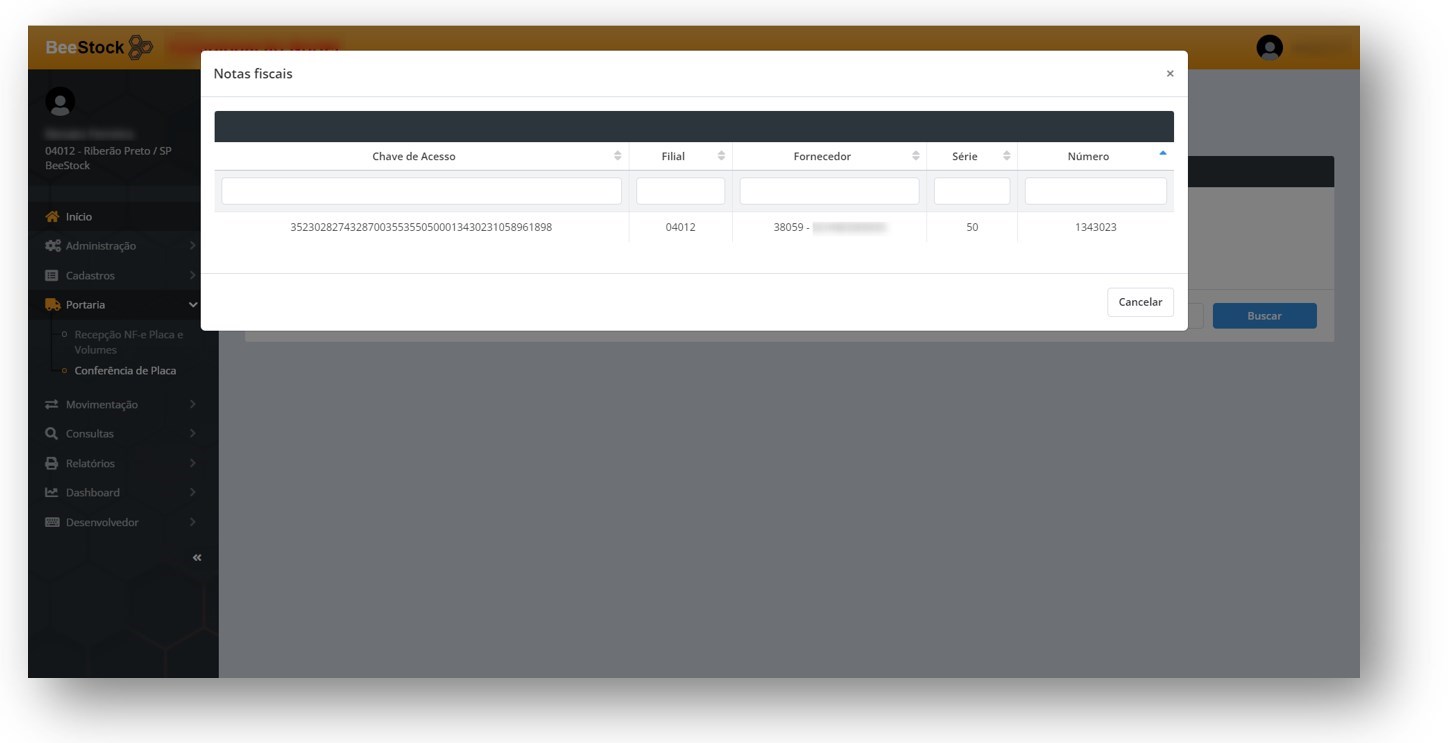

Example for selecting a document for plate checking after the search mentioned above.

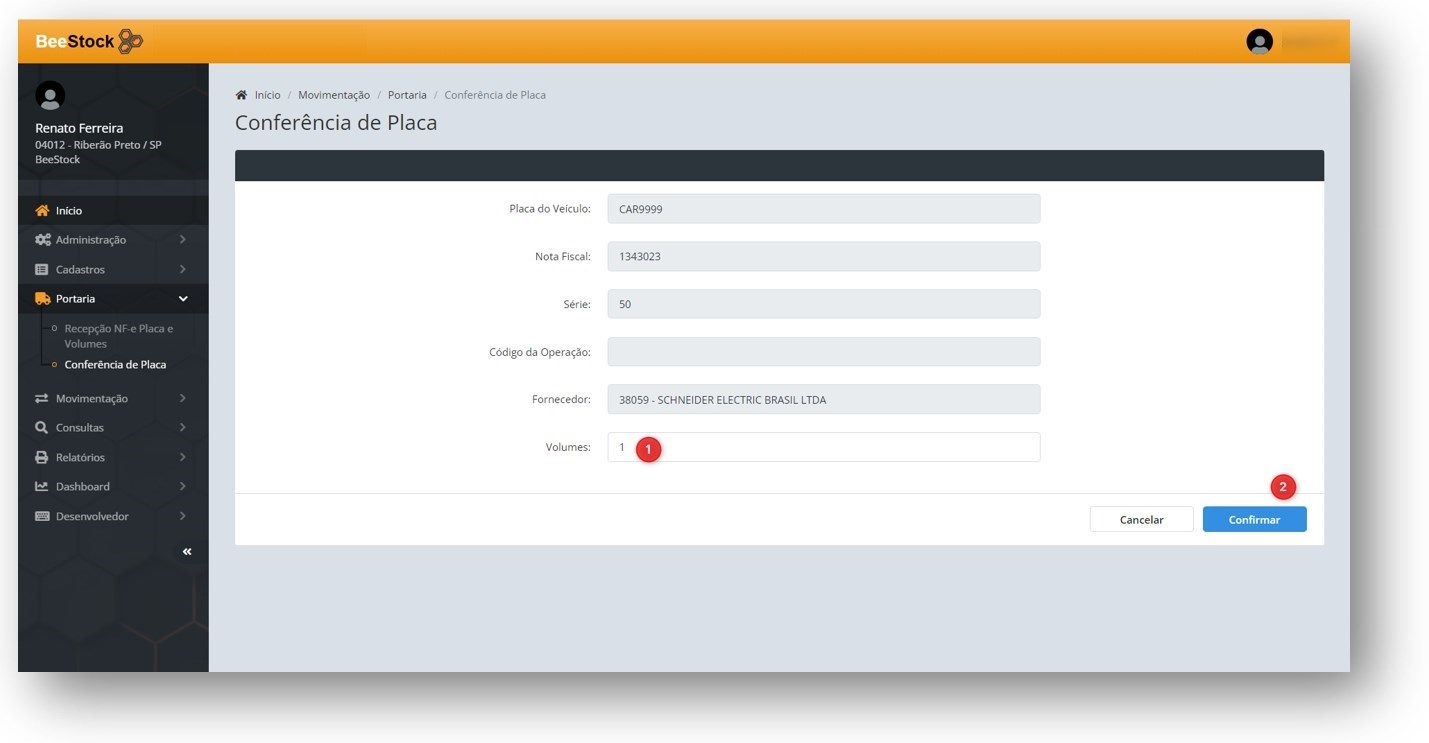

After selecting the document, the user checks if the data informed on the screen matches the vehicle and the document being received, informs the number of volumes (1) and clicks on Confirm (2).

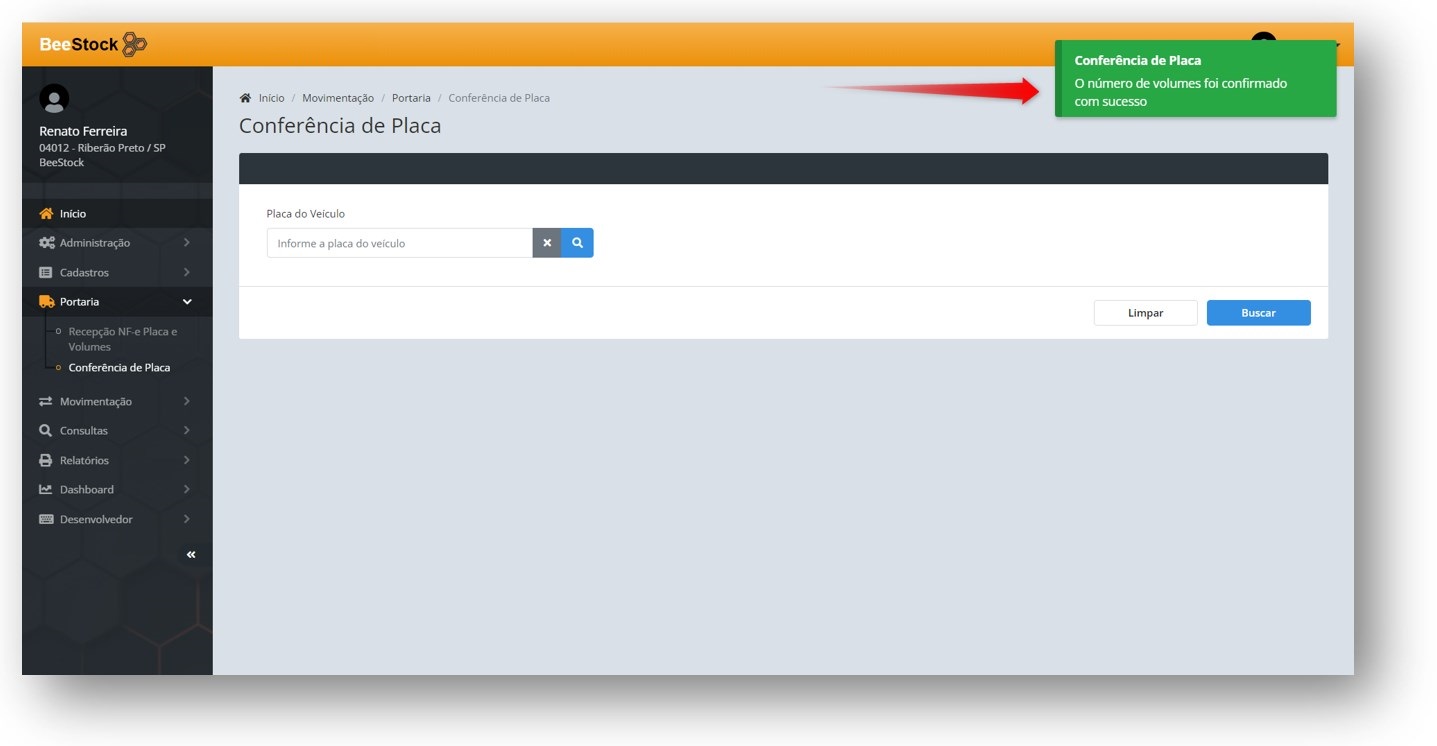

After confirming the plate check, the system informs that the information has been successfully validated and the document becomes pending for the physical receiving check.

Plate Check Flow - Collector

Located in Inbound > Plate Check, it is used to check the vehicle plate and volumes of the document to be received.

The user must enter the vehicle plate and click on the Magnifying Glass next to the Plate field to bring up the data of the intended document.

After entering the vehicle plate, the data of the related document is automatically filled in, requiring the user to inform the quantity of volumes and click on Confirm to complete the plate check.

If the number of volumes informed is different from the quantity registered for the document in the Reception at NF-e Plate and Volume Reception, the system informs the discrepancy so that the user can confirm or cancel if the volume count is incorrect or continue with the new quantity found.

If the number of volumes informed matches the one registered for the document, upon confirmation, the plate check is completed and the document becomes pending for the physical receiving check.

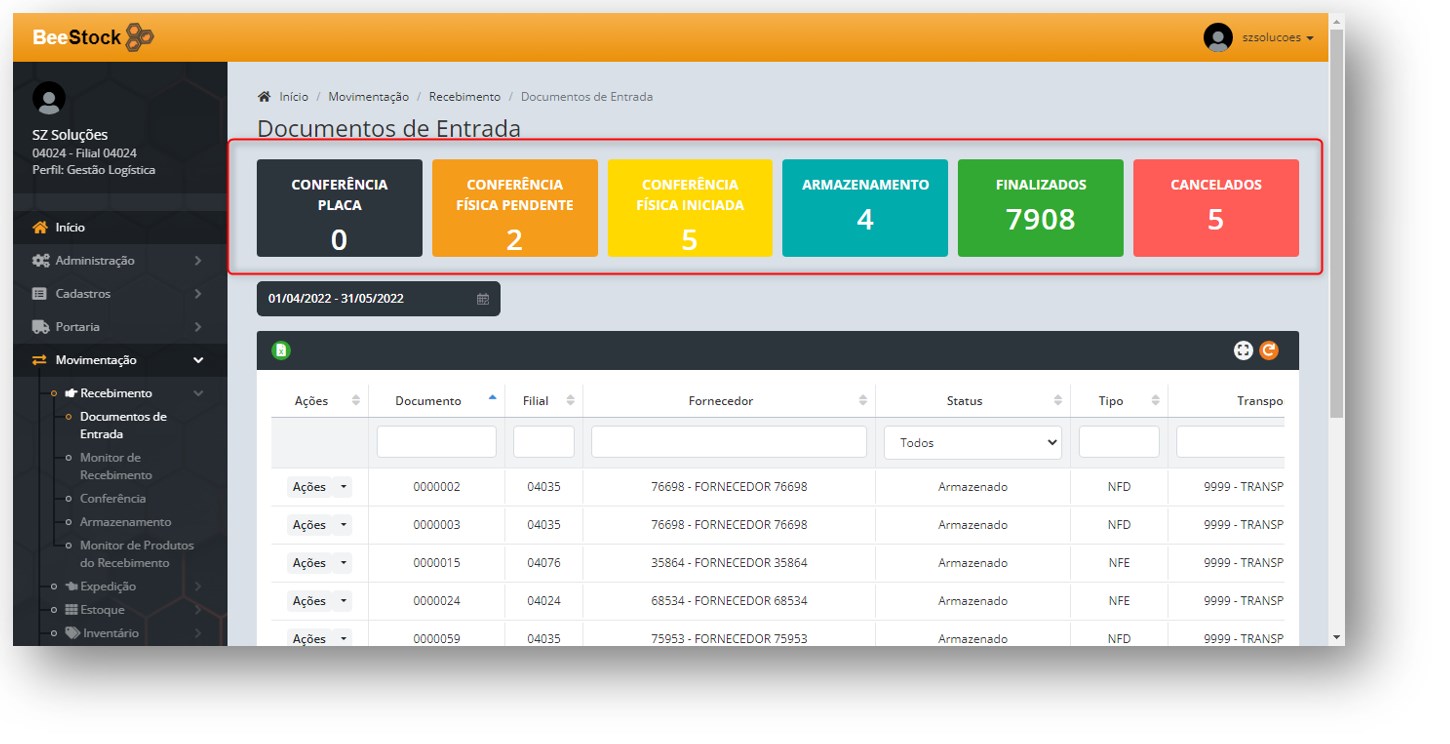

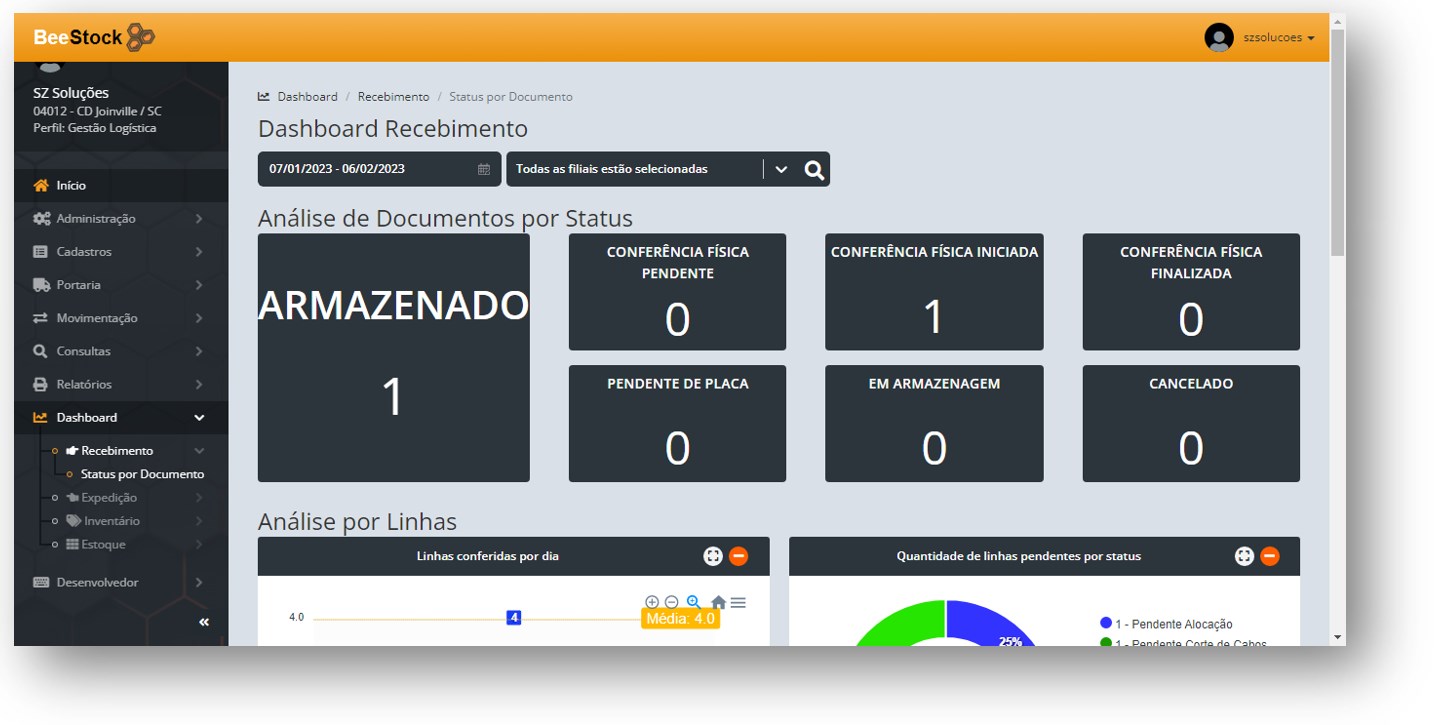

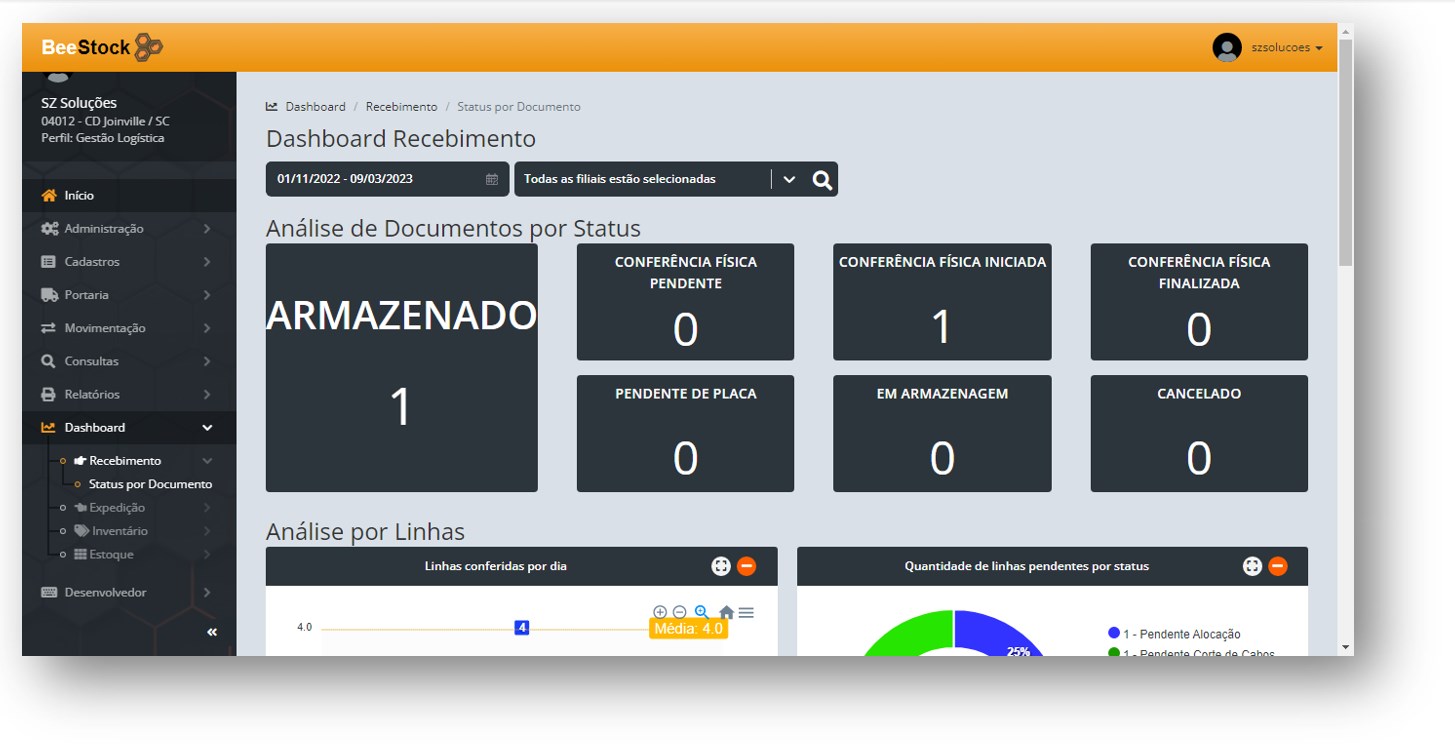

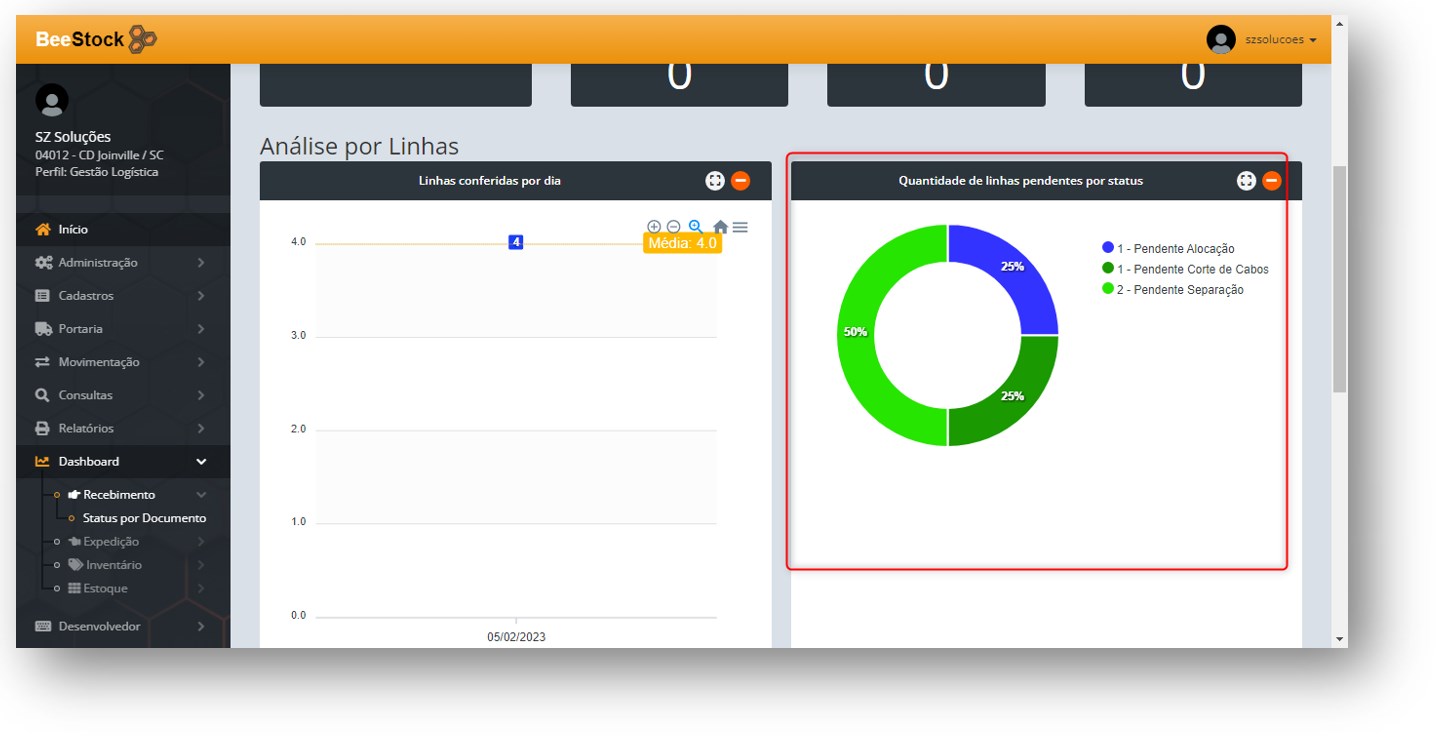

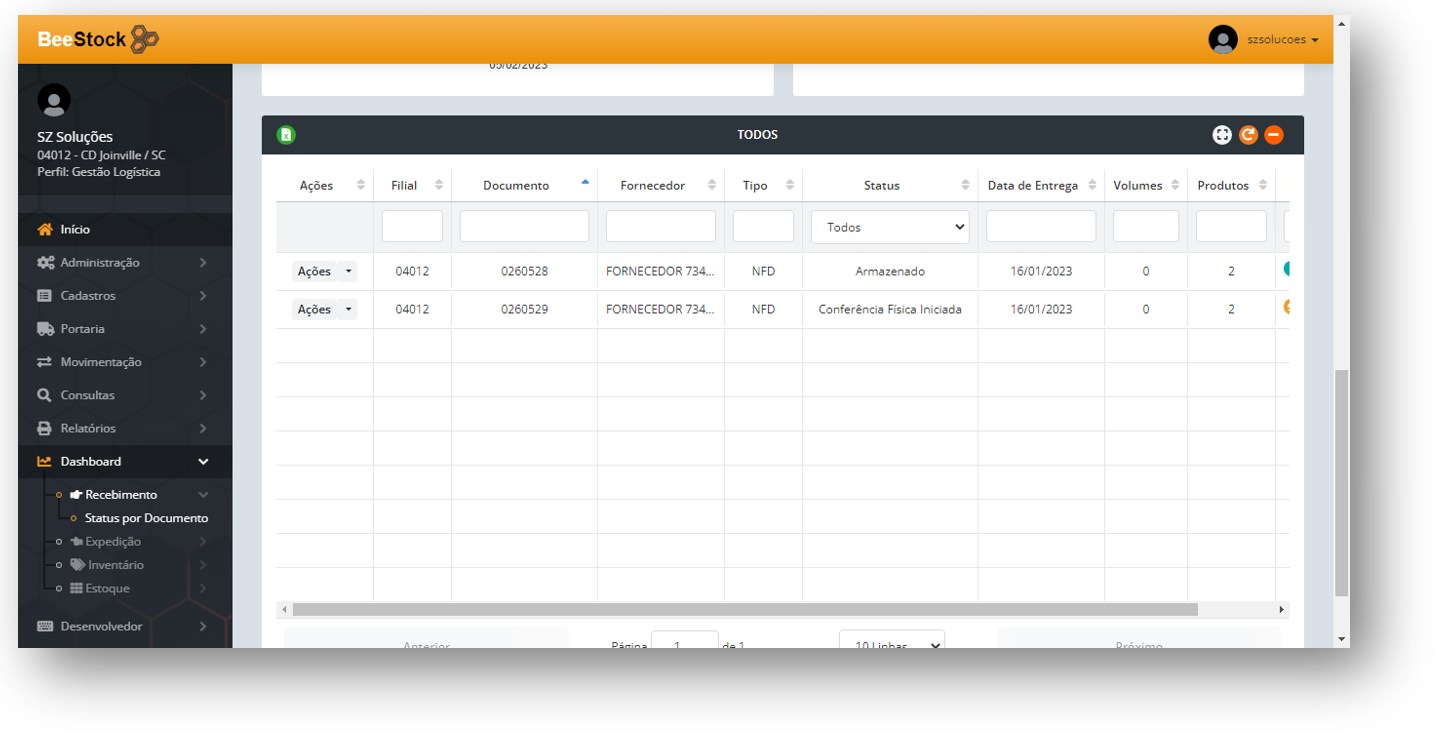

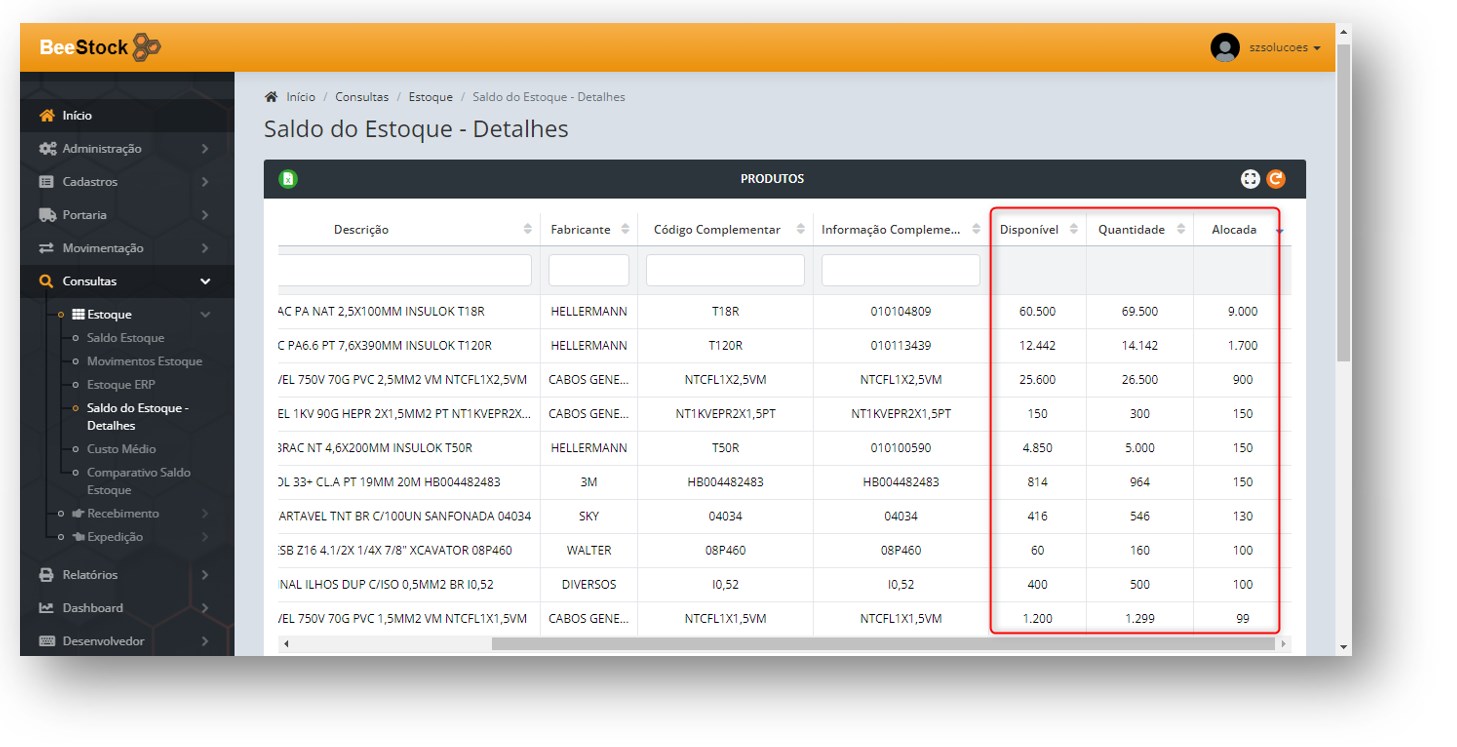

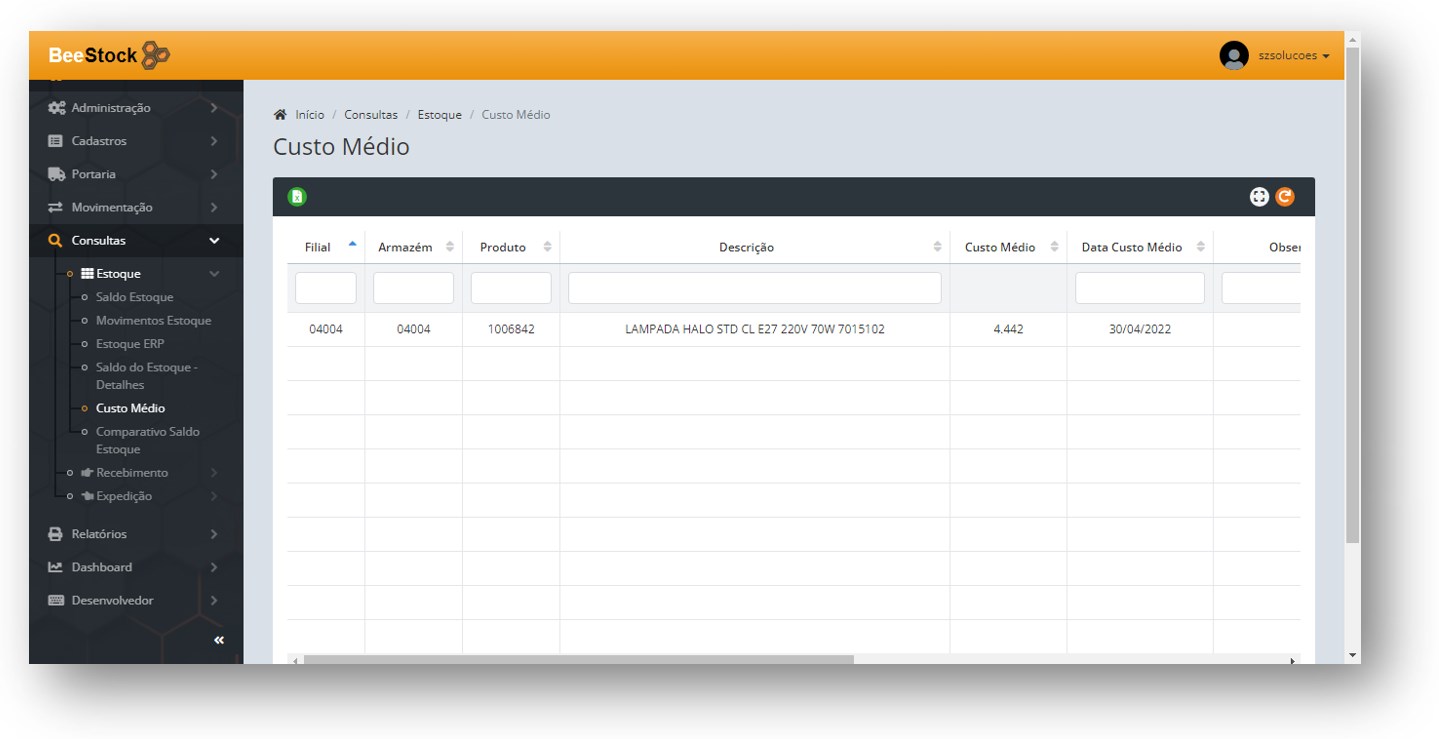

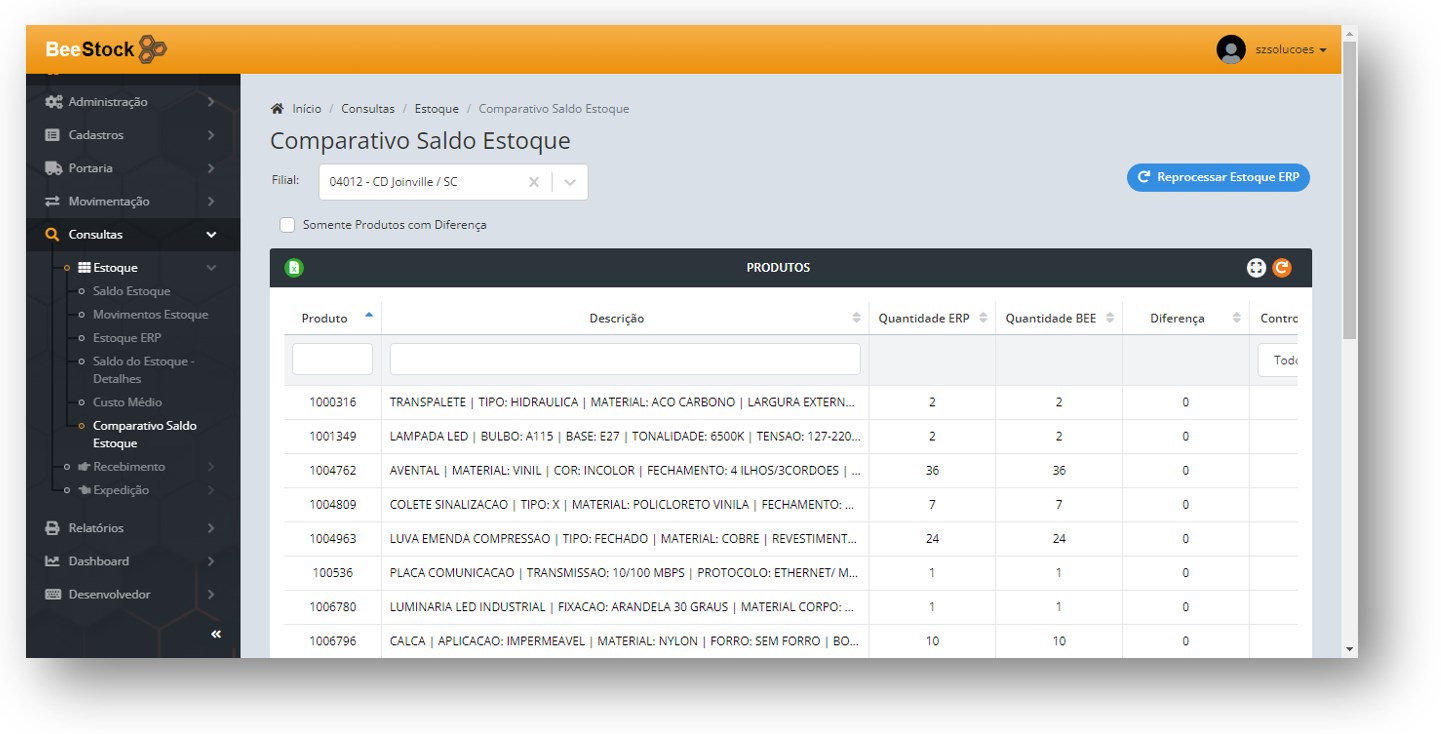

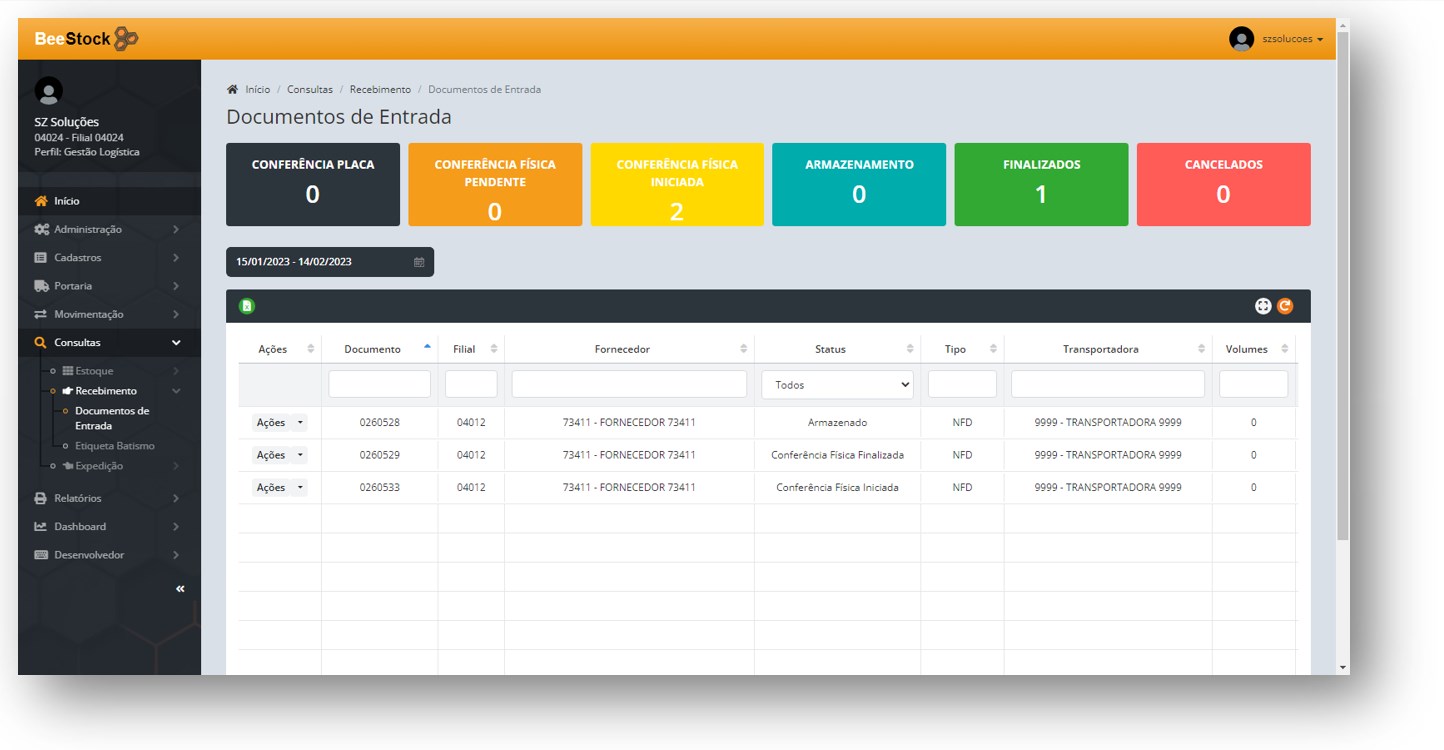

Inbound Documents

Located in the Movement > Receiving > Inbound Documents menu, this screen is used to list all inbound documents that have gone through BeeStock® in the defined date filter, as well as their respective statuses.

Access the Movement > Receiving > Inbound Documents menu.

The cards above show the number of documents in each status:

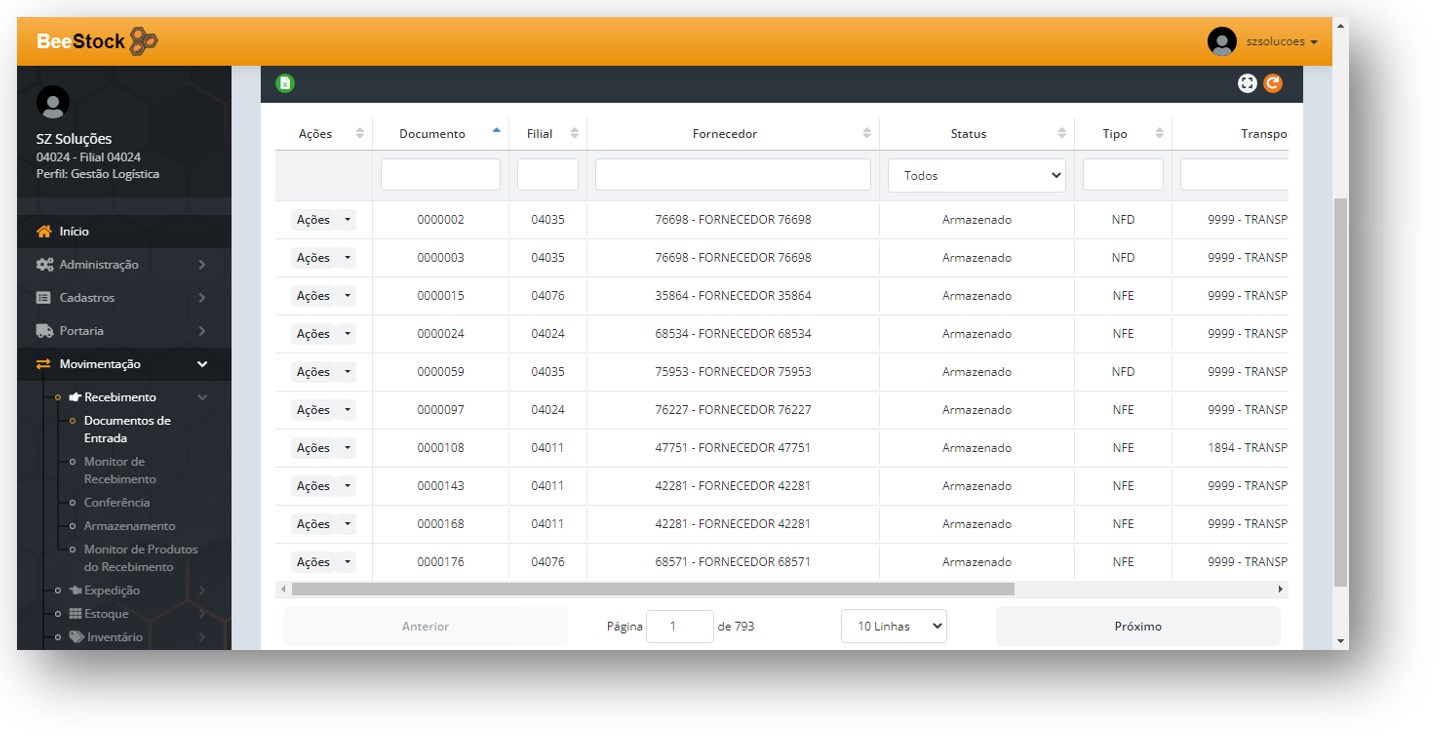

In the table below, we can see all documents within the date filter, and we can also filter by the columns:

Document

Branch

Supplier

Status

Type

Carrier

Volumes

Integration Date

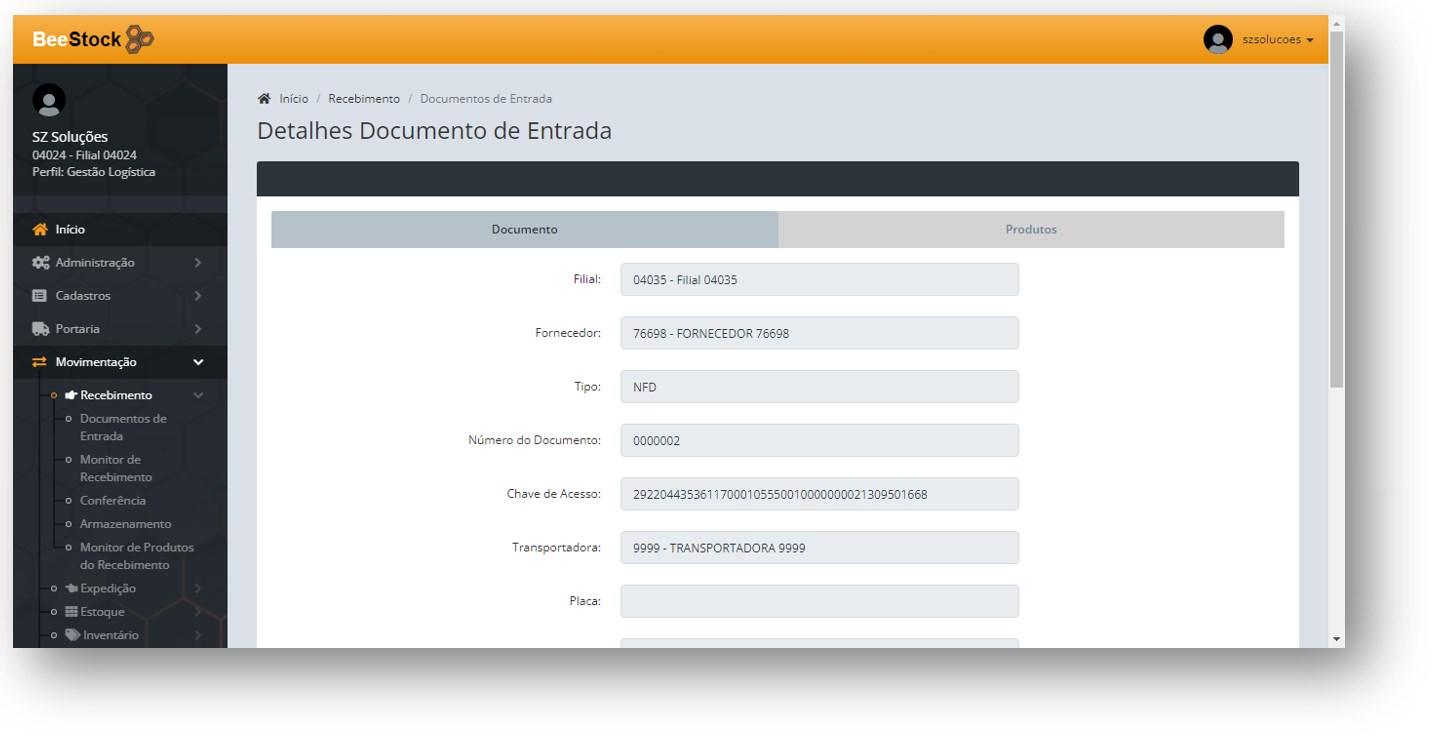

In the table, there is the Actions > Details button, where we can see more details of a specific document:

General tab.

Products tab.

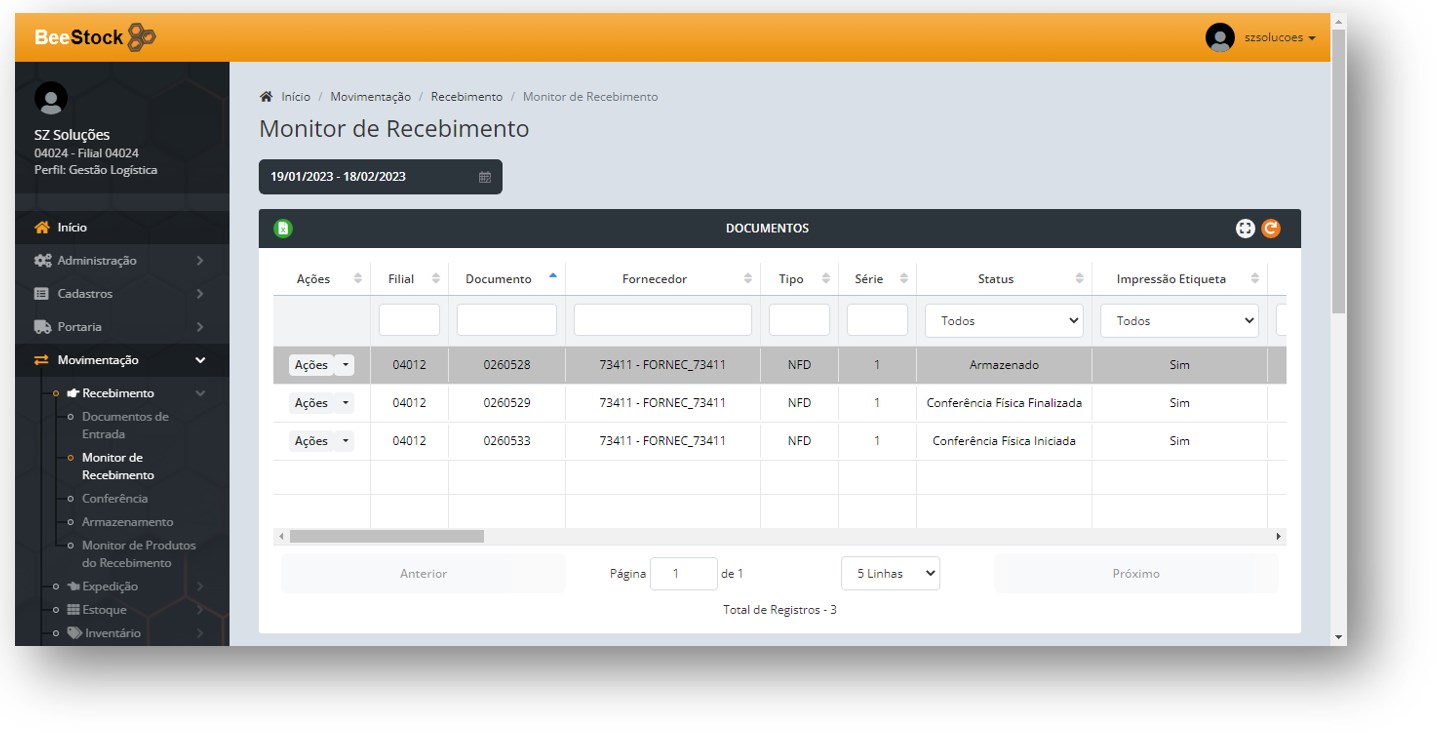

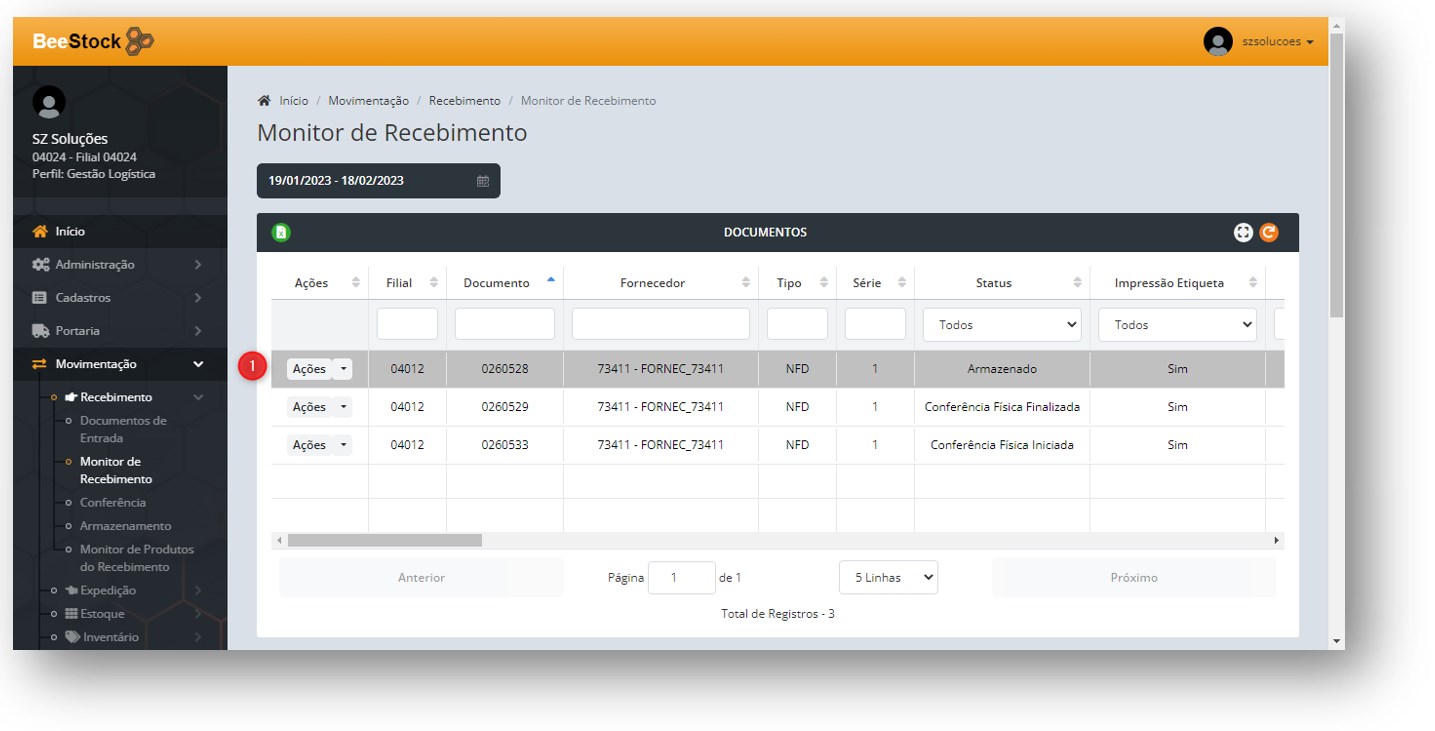

Receiving Monitor

Located in the Movement > Receiving > Receiving Monitor menu, it will be used to manage all inbound documents that have gone through BeeStock® in the defined date filter, as well as their respective statuses.

Access the Movement > Receiving > Receiving Monitor menu.

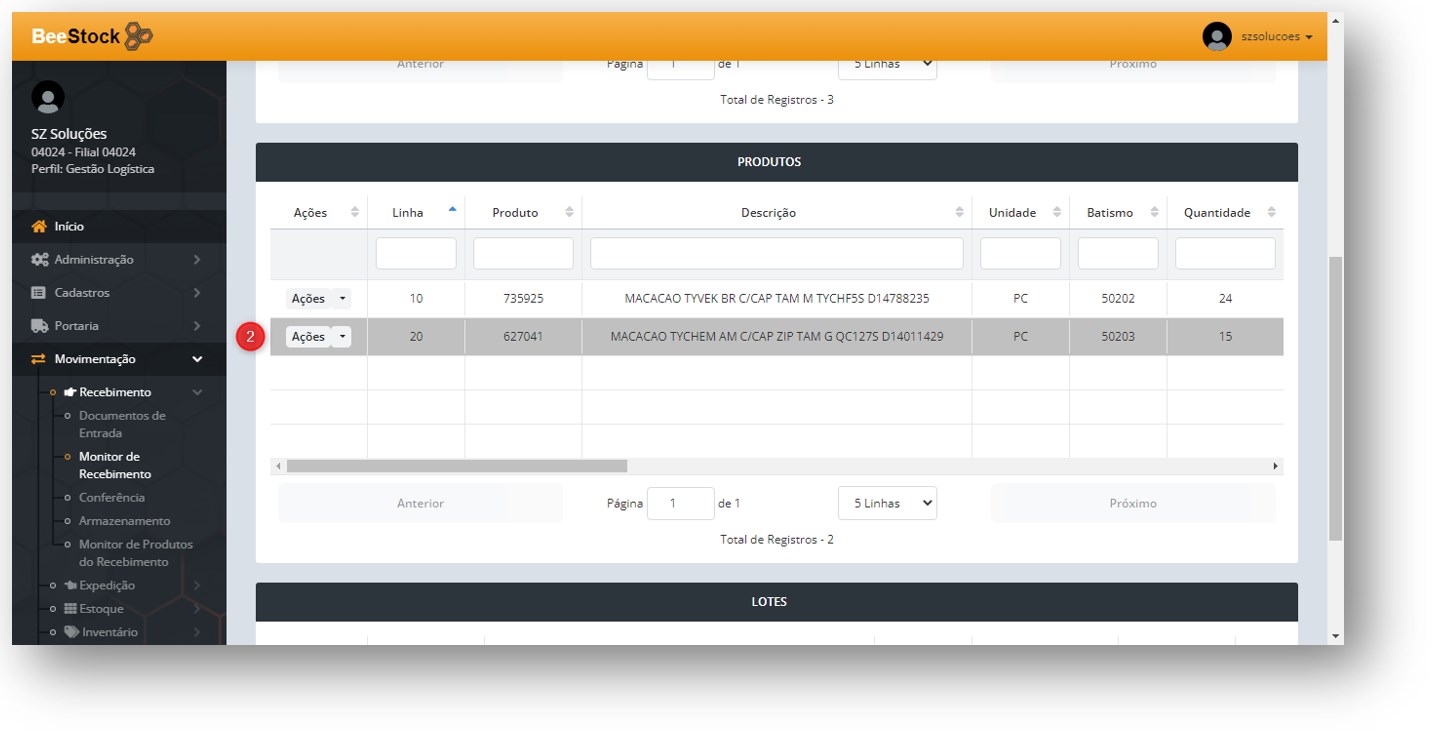

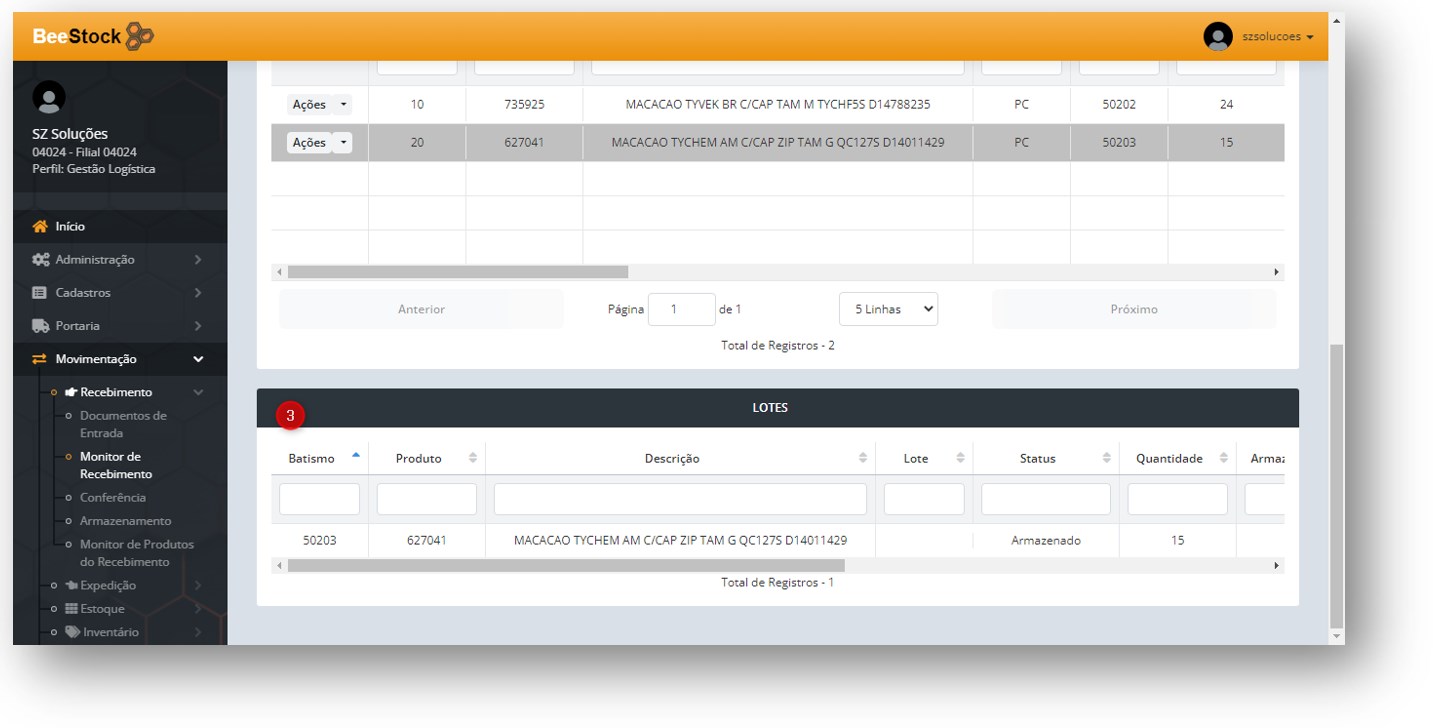

On the monitor, we have 3 grids:

Documents

Products

Batches

The grids will be filled according to the selection made in the upper grid, that is, when selecting a document in the document grid, the product grid will be filled with the products of the selected document. And it works the same way for the batch grid:

Document Grid.

Product Grid.

Batch Grid.

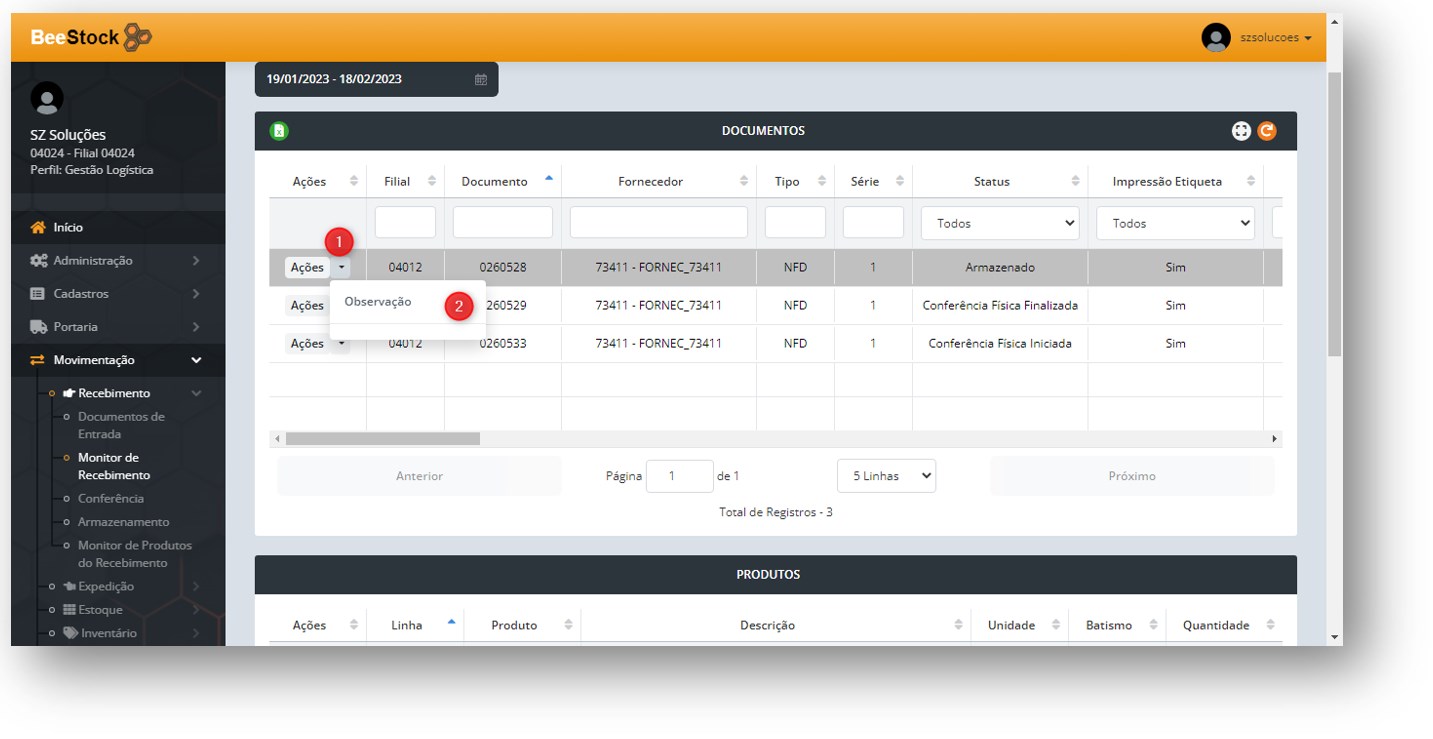

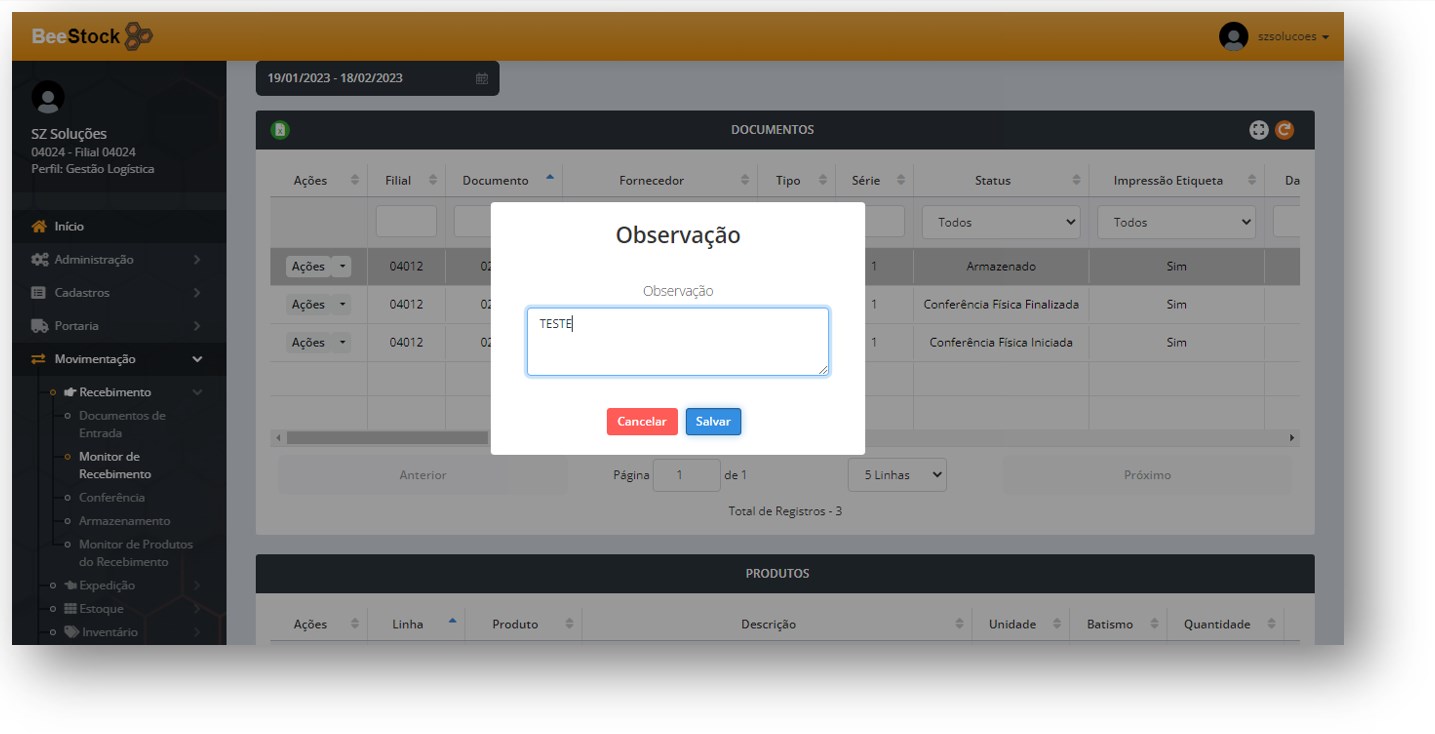

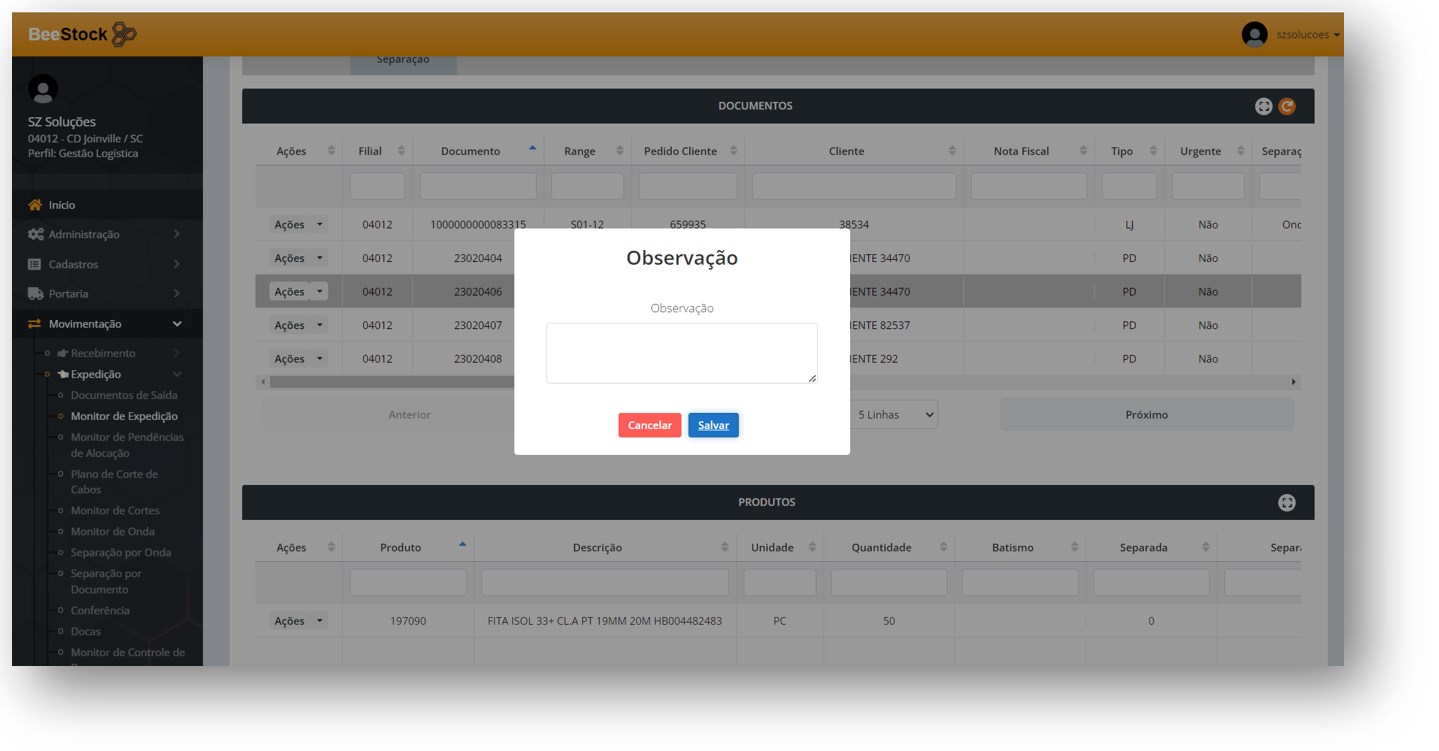

In the Document grid, there is the Actions > Observation button, where we can add an observation to the document:

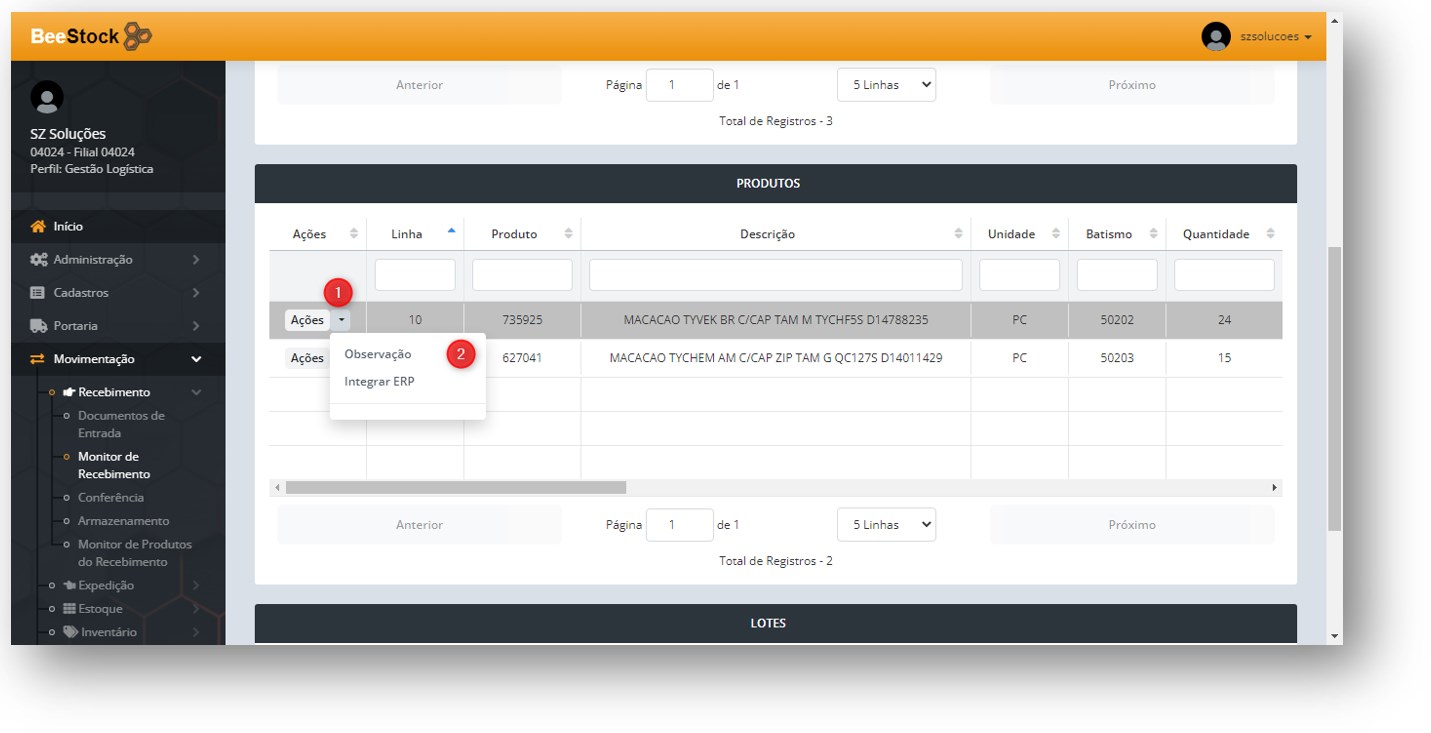

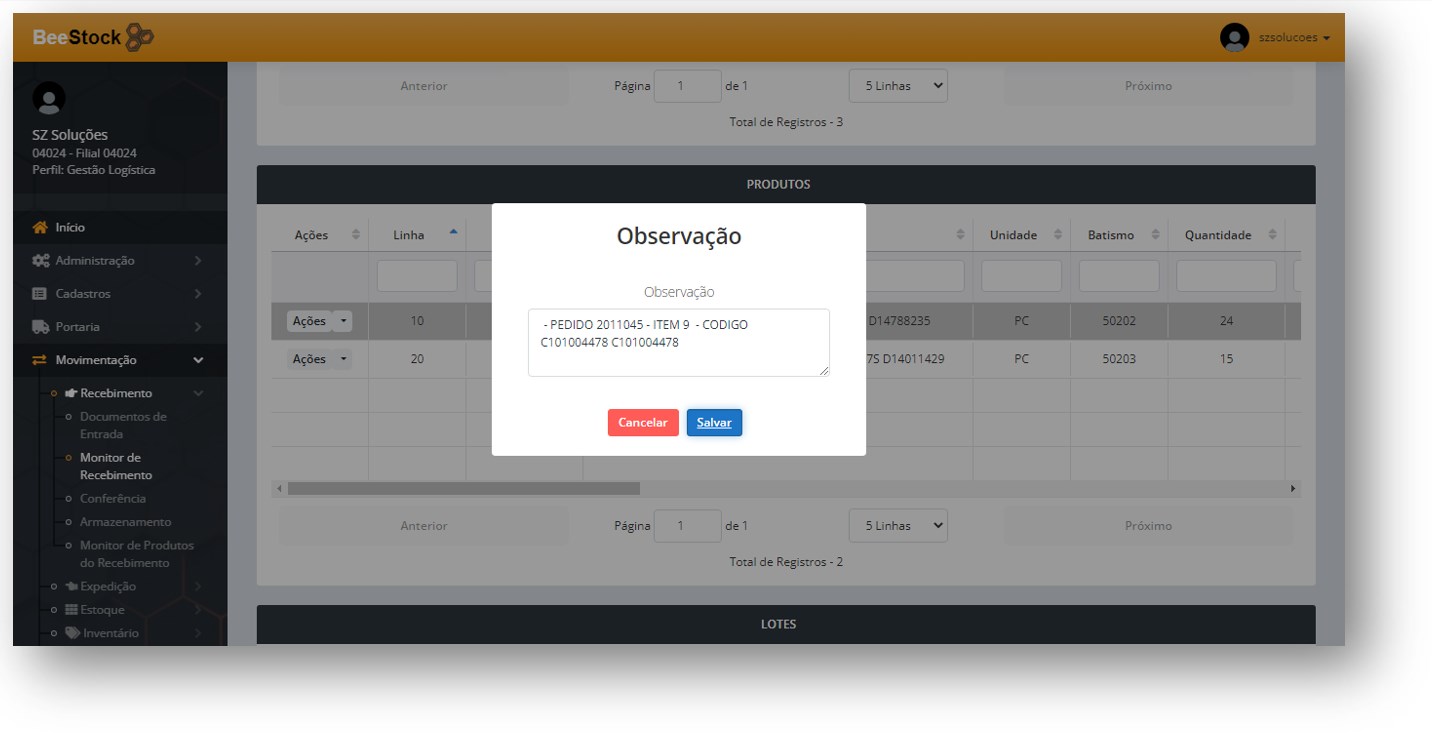

In the Product grid, there is the Actions > Observation button, where we can add an observation to the document:

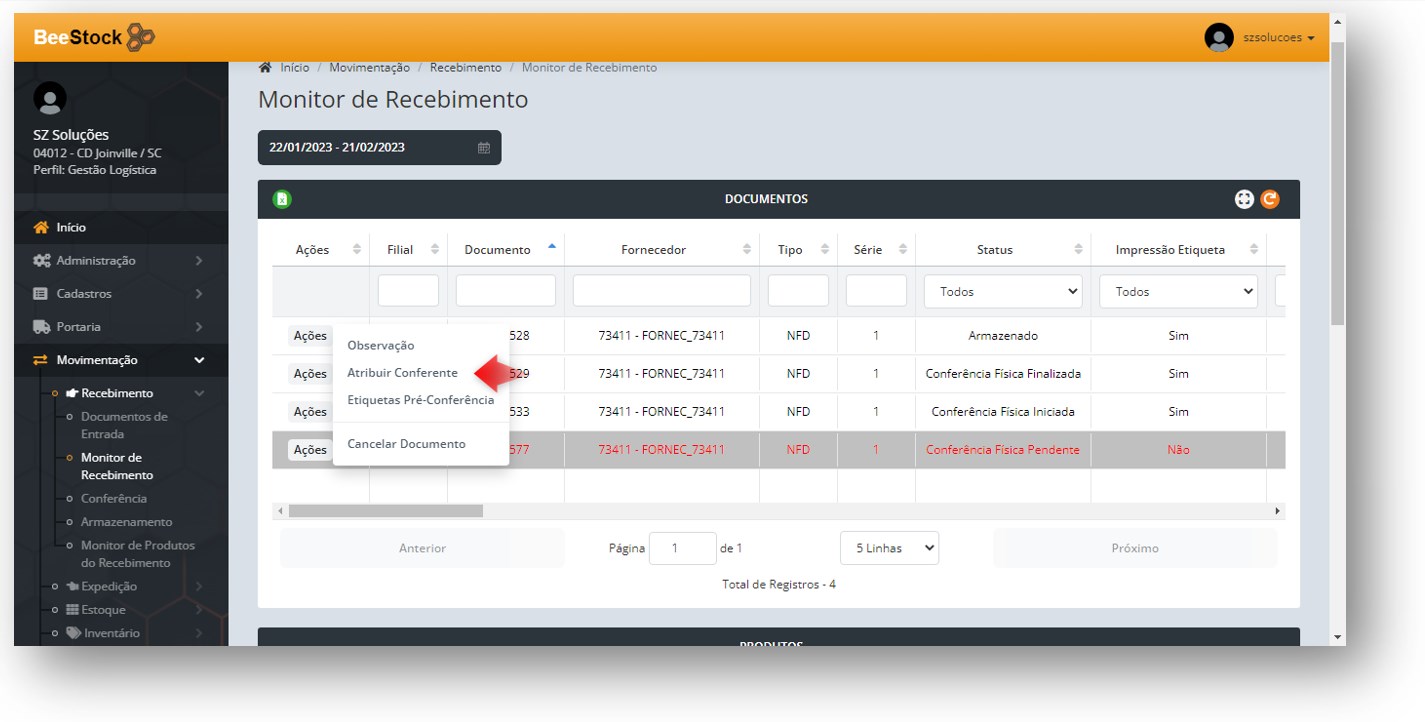

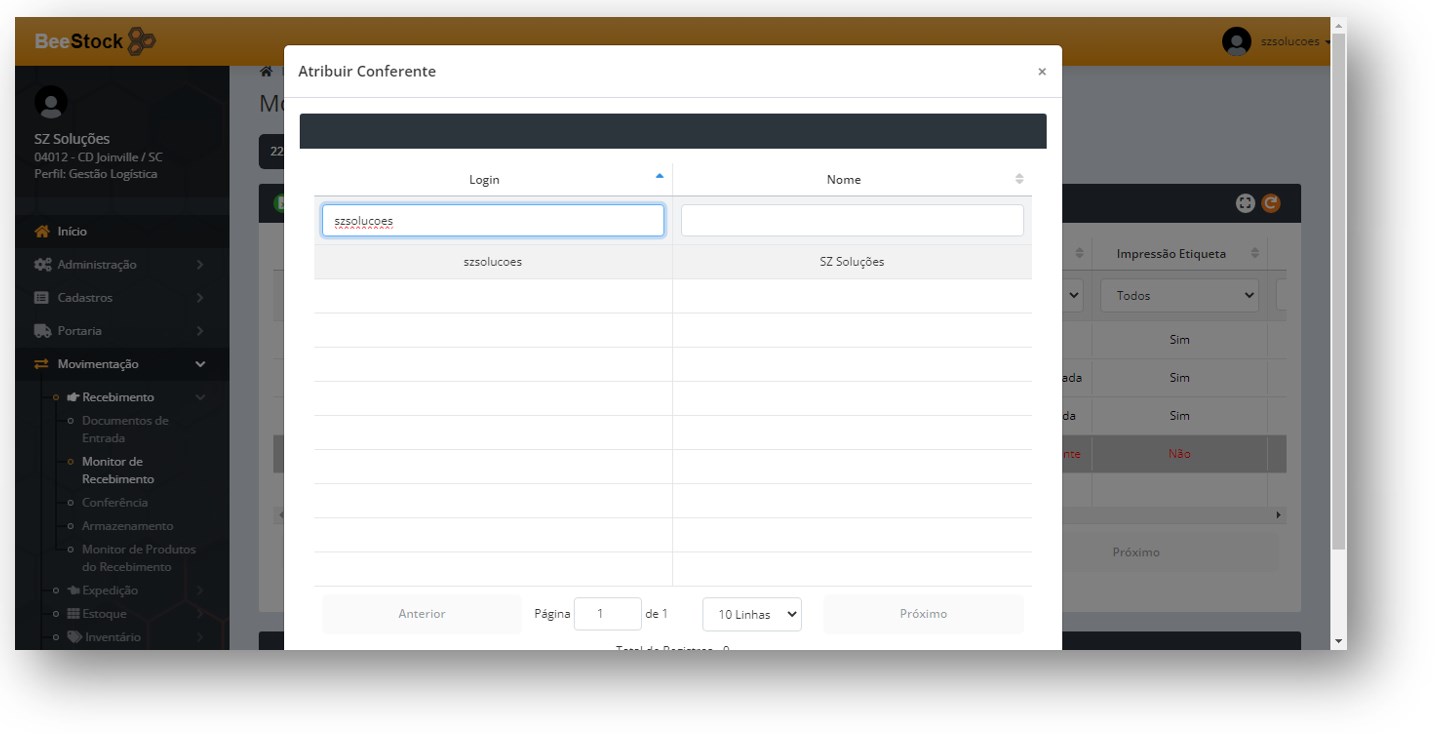

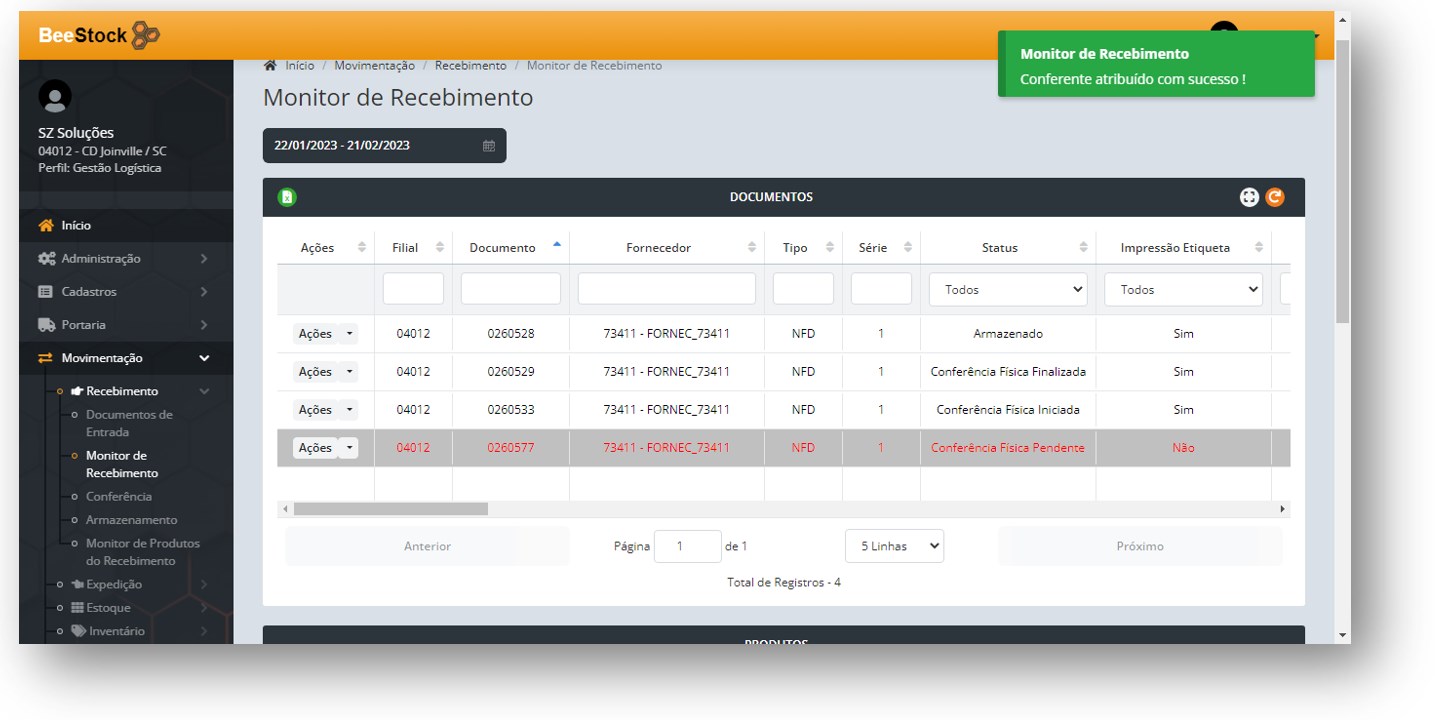

Also, in the Actions > Assign to Checker button, we can choose a checker, so only this user will be able to access the document:

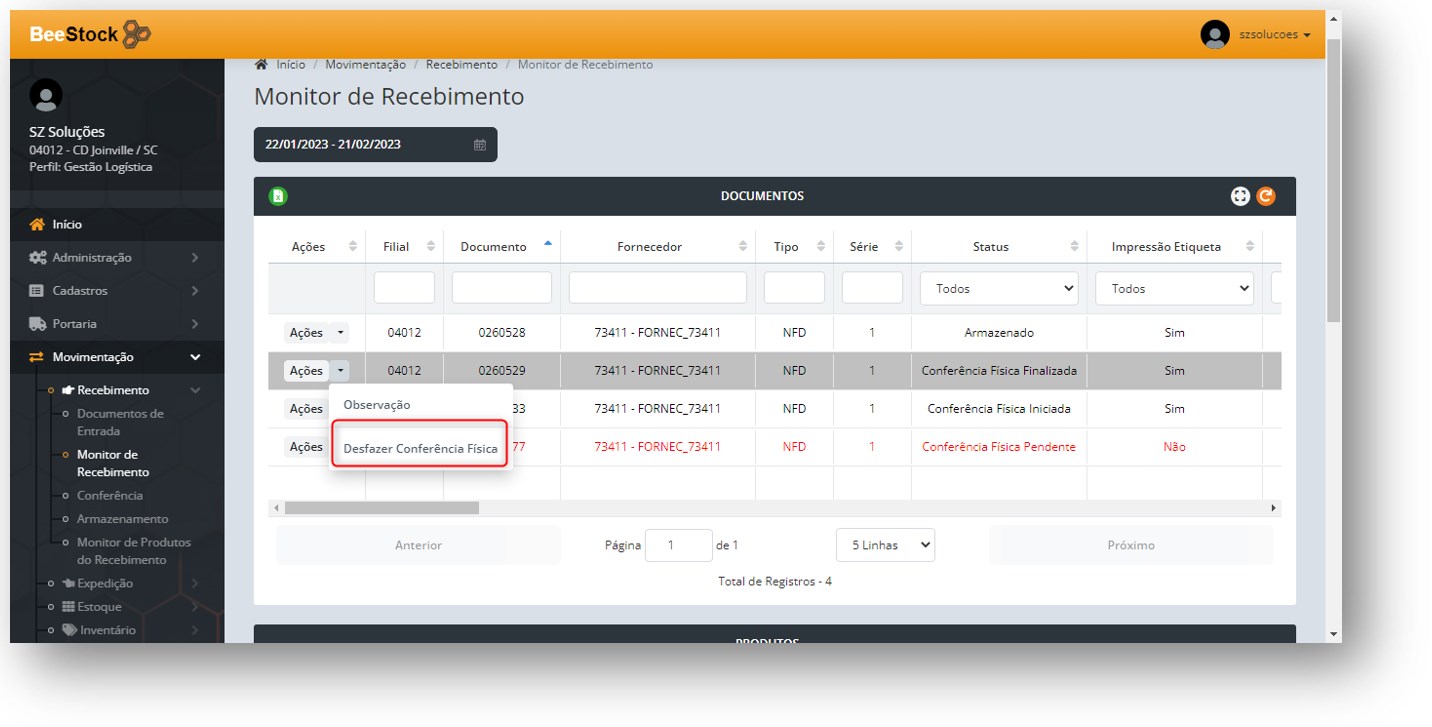

In a document with the status of Physical Check Started or Finished, we have the option to Undo the check in the Actions > Undo Physical Check button:

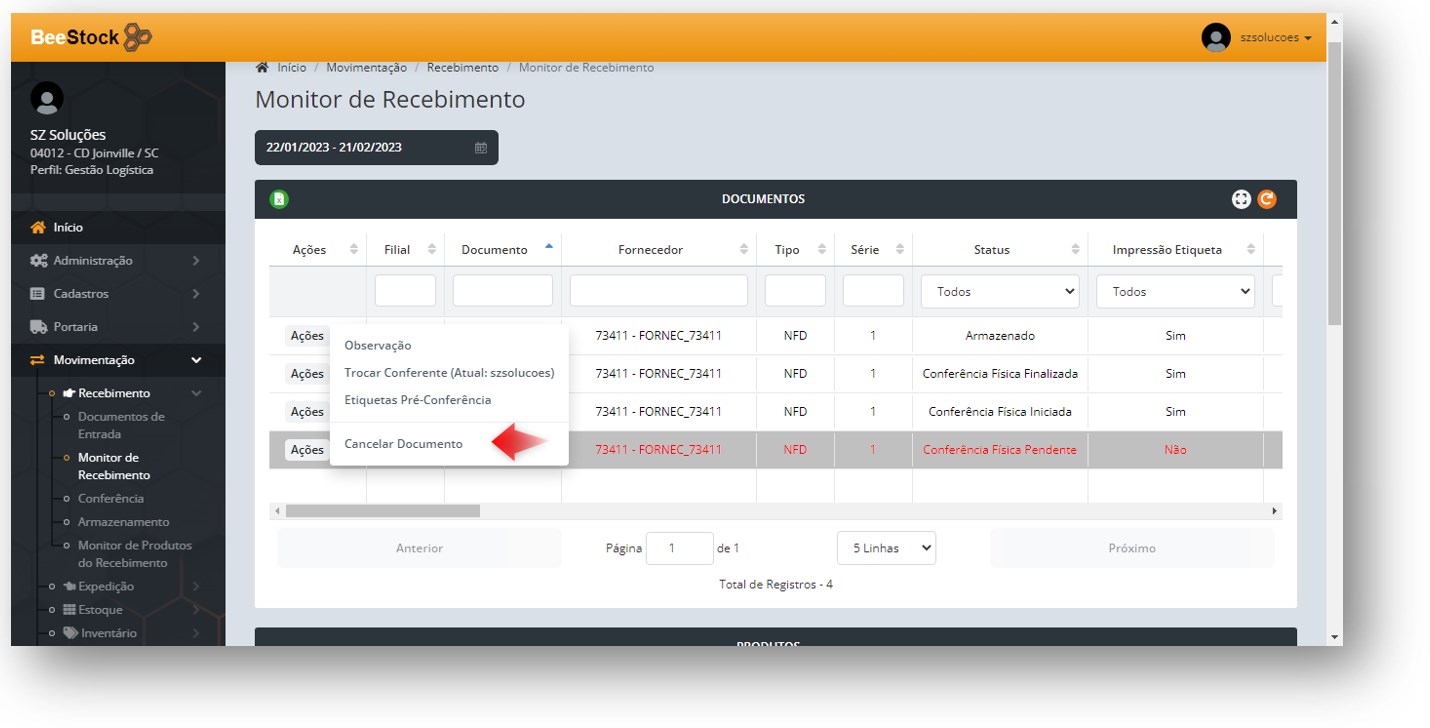

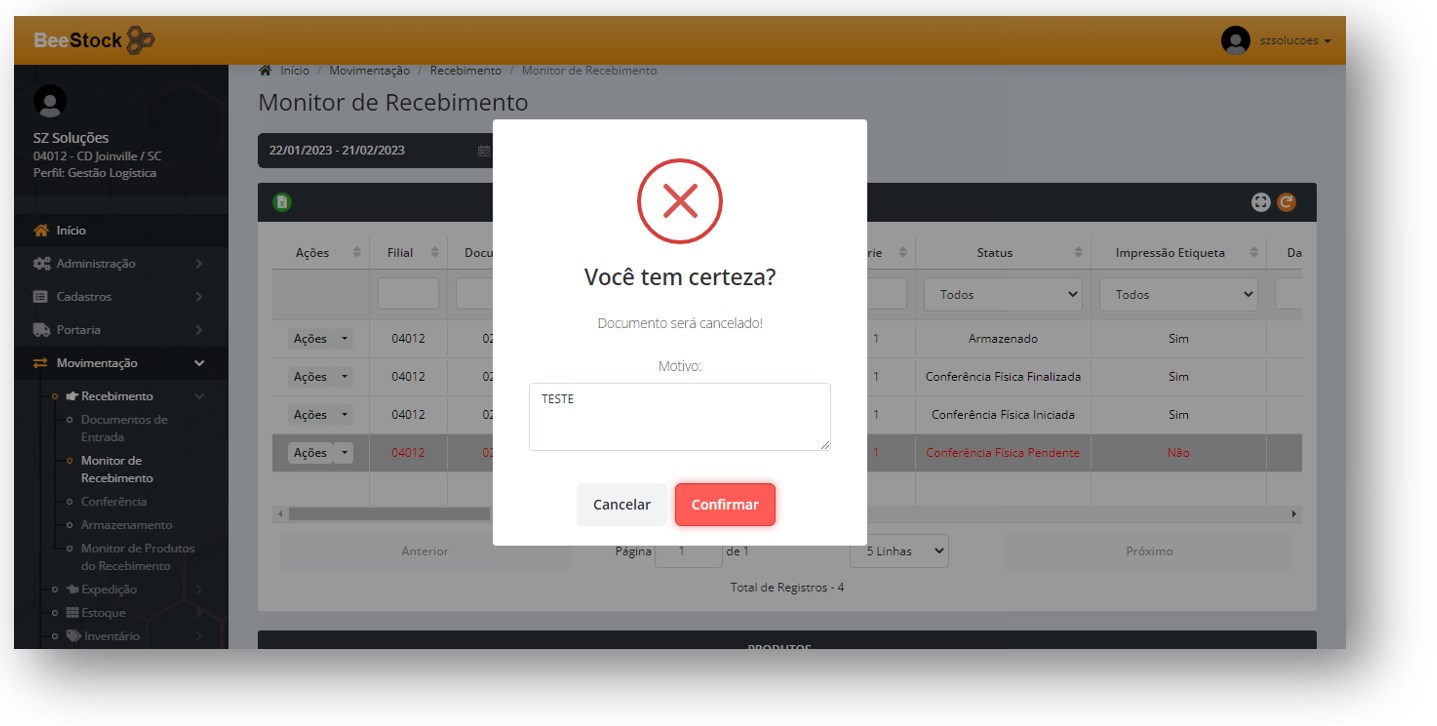

We also have the option to cancel the document in the Actions > Cancel Document button:

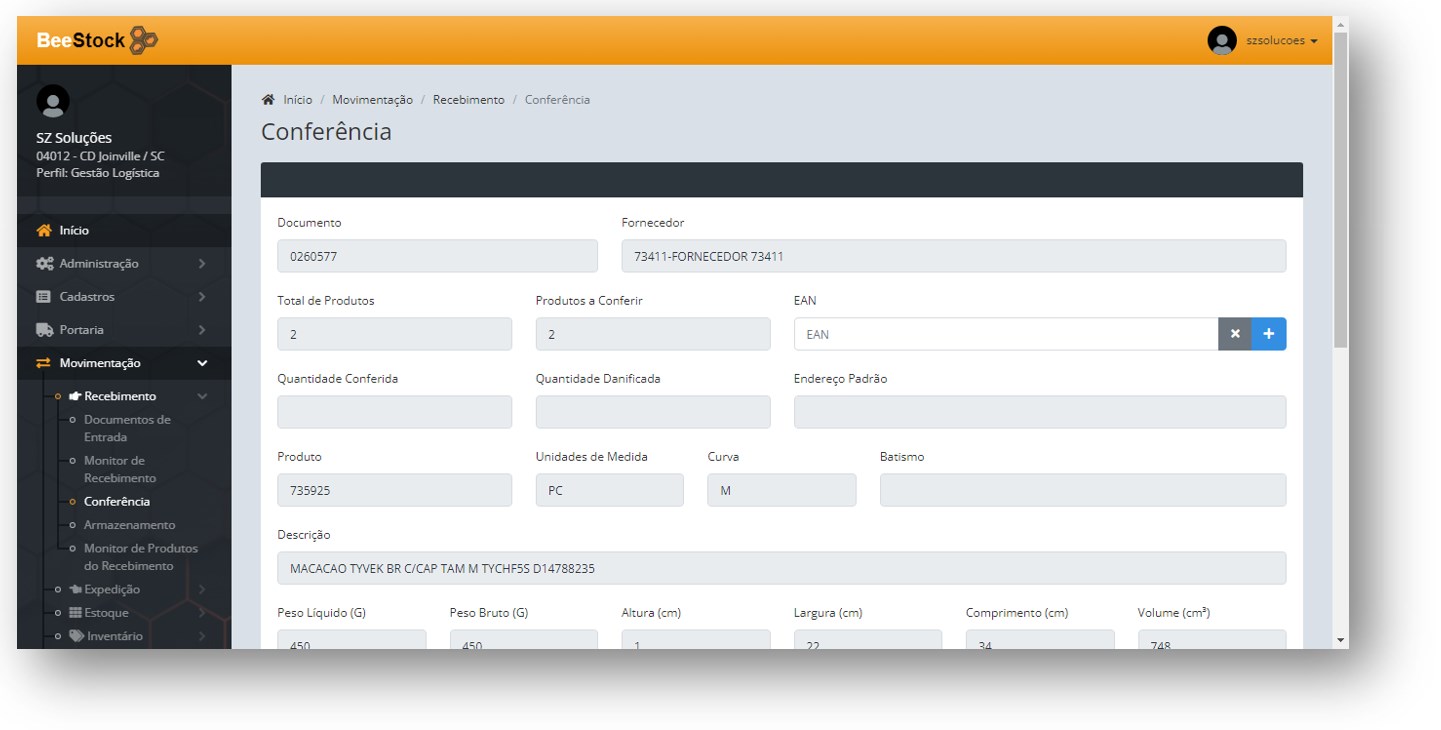

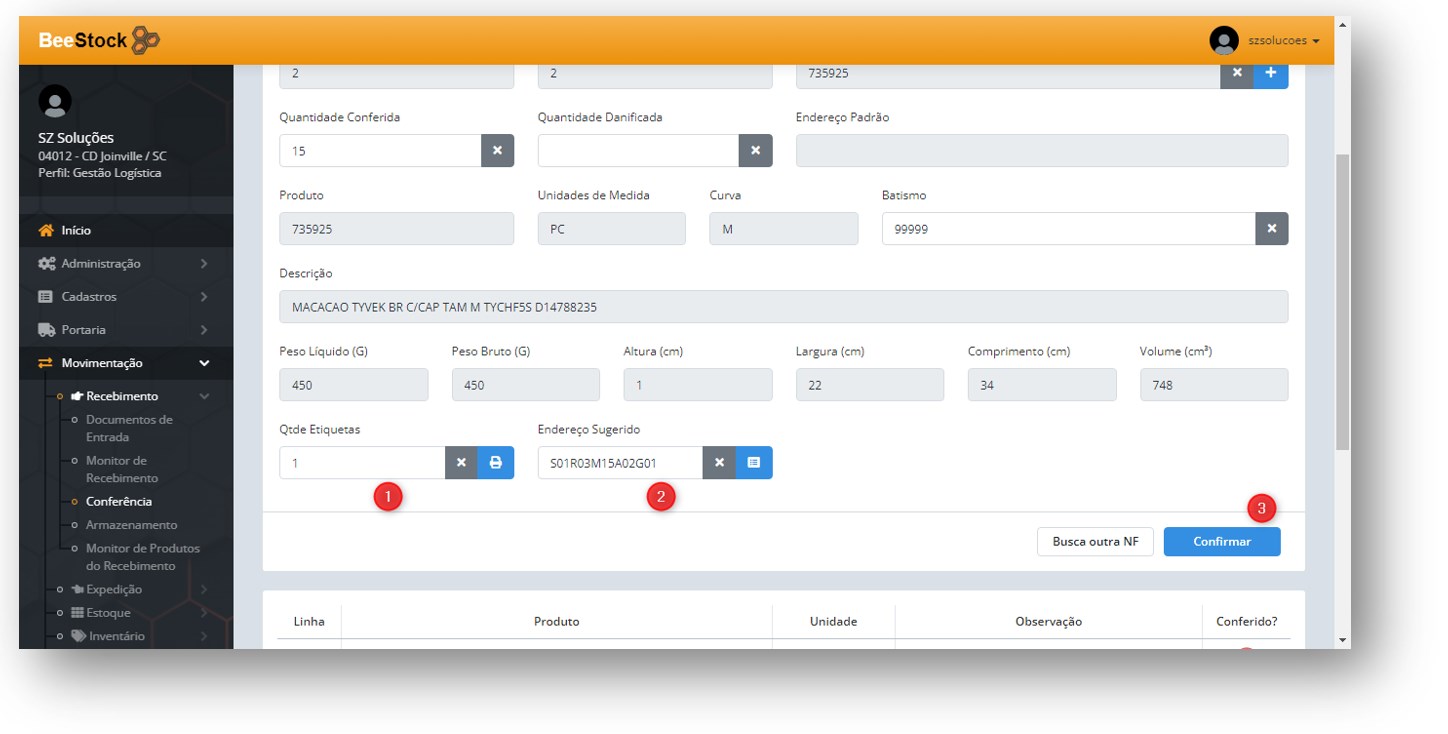

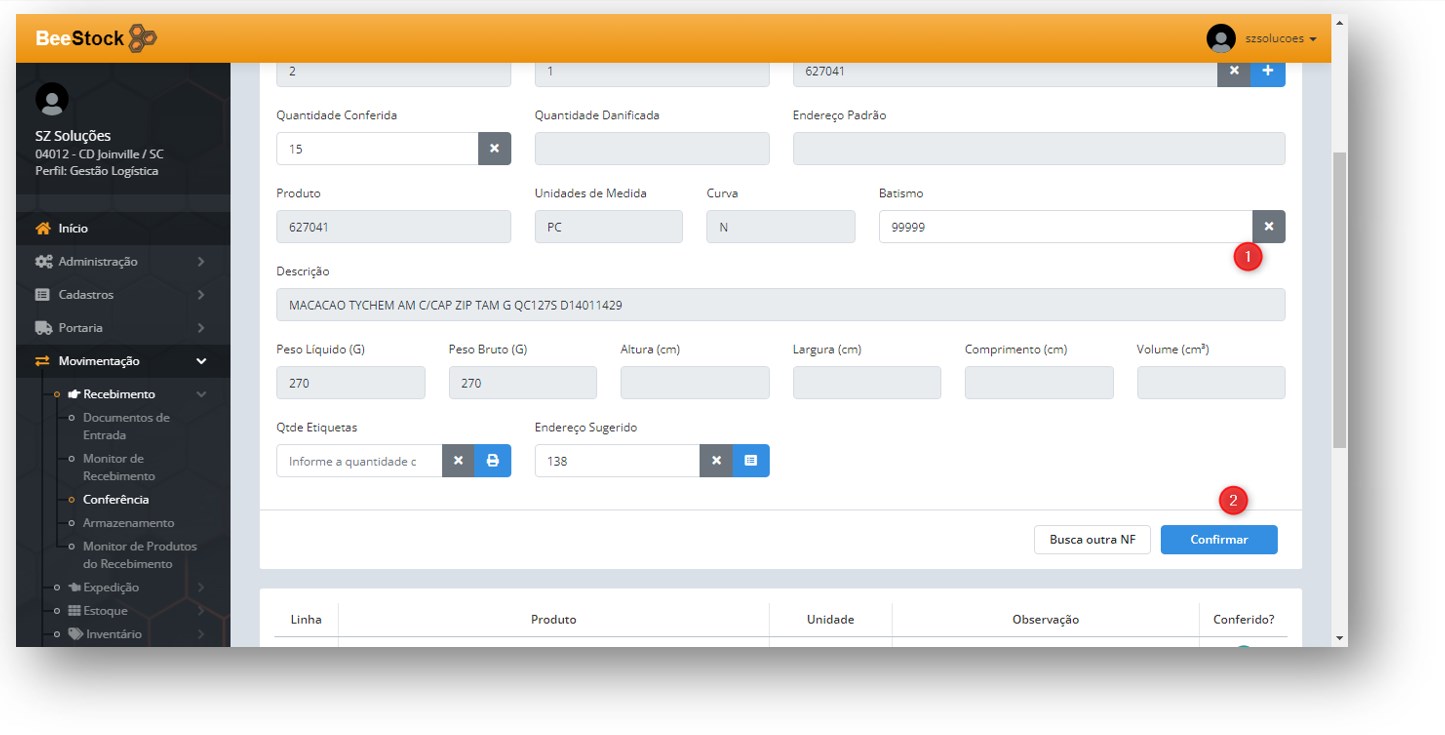

Inbound Check

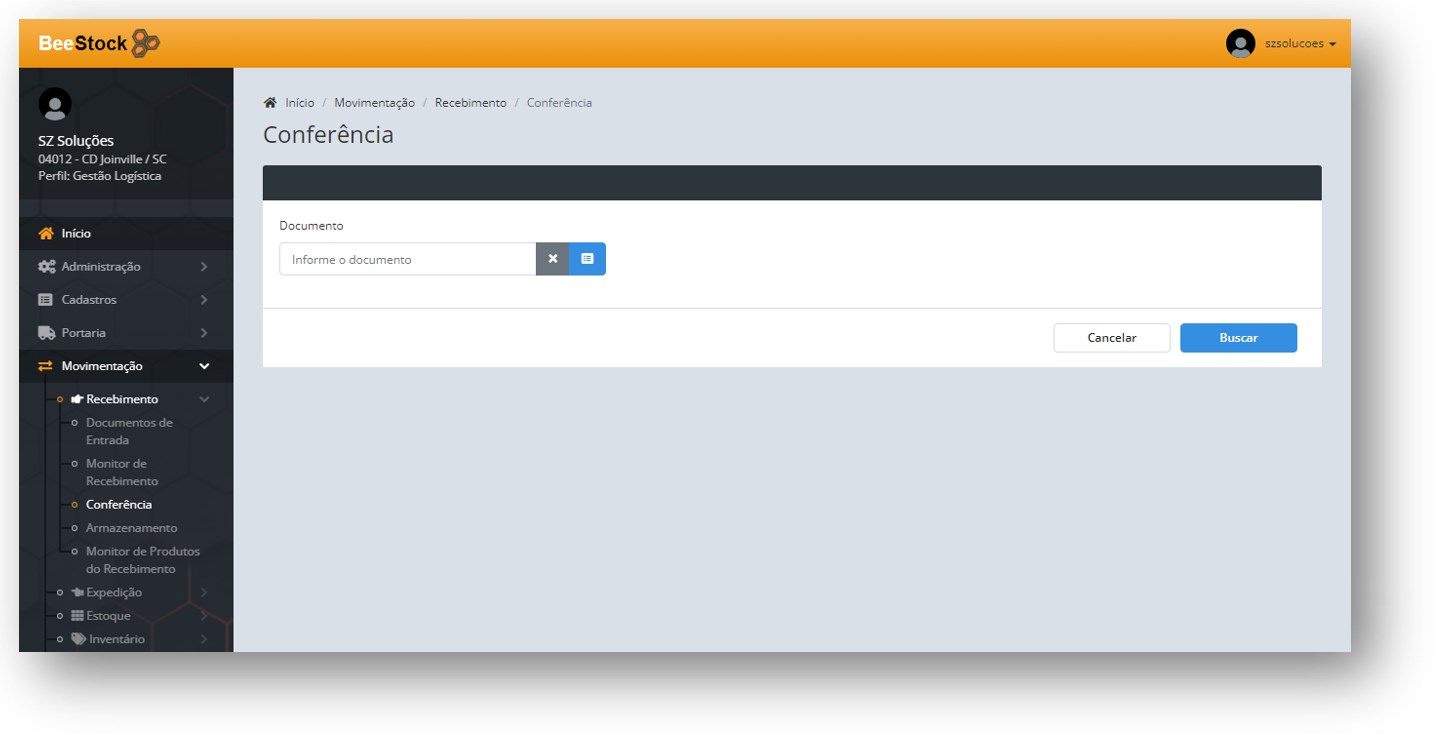

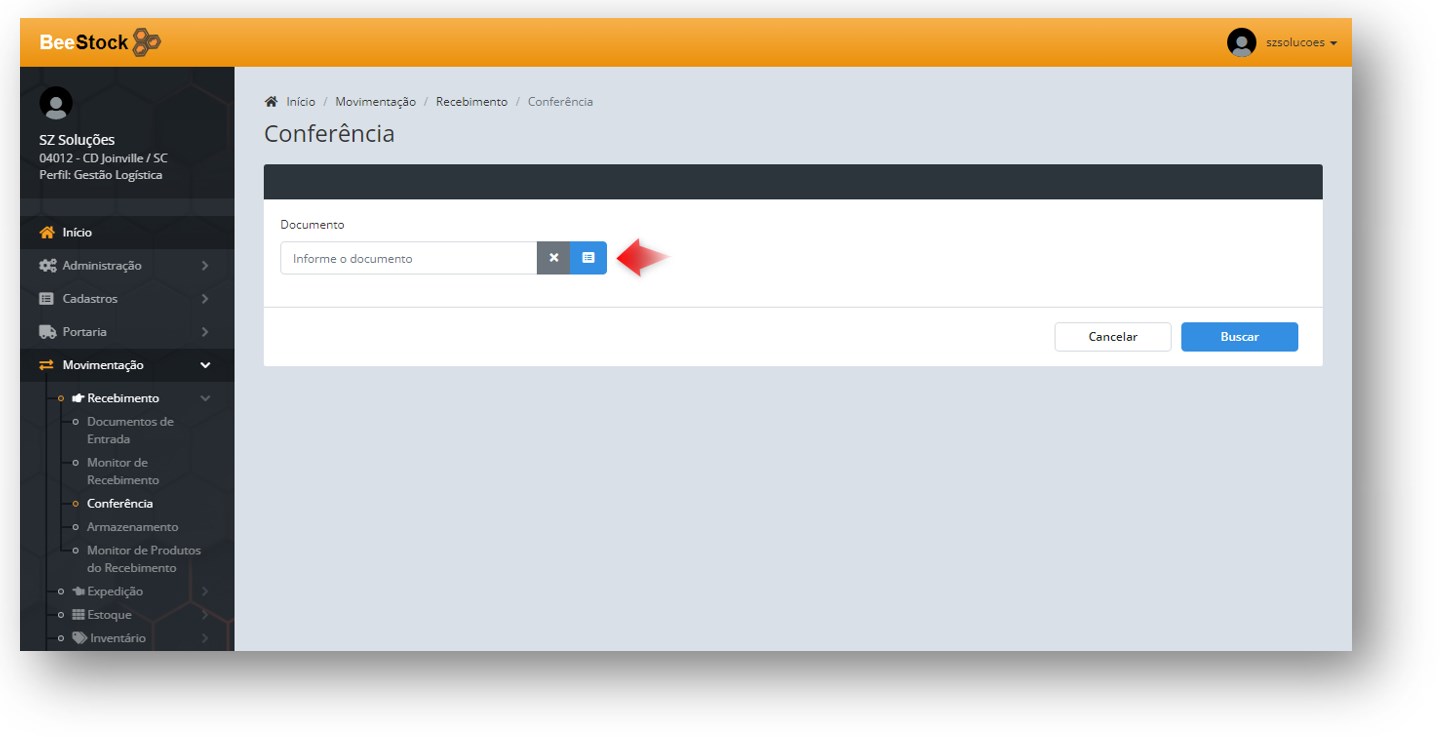

Located in the Movement > Receiving > Check menu, the screen is used to perform the check of products from an inbound document.

Access the Movement > Receiving > Check menu.

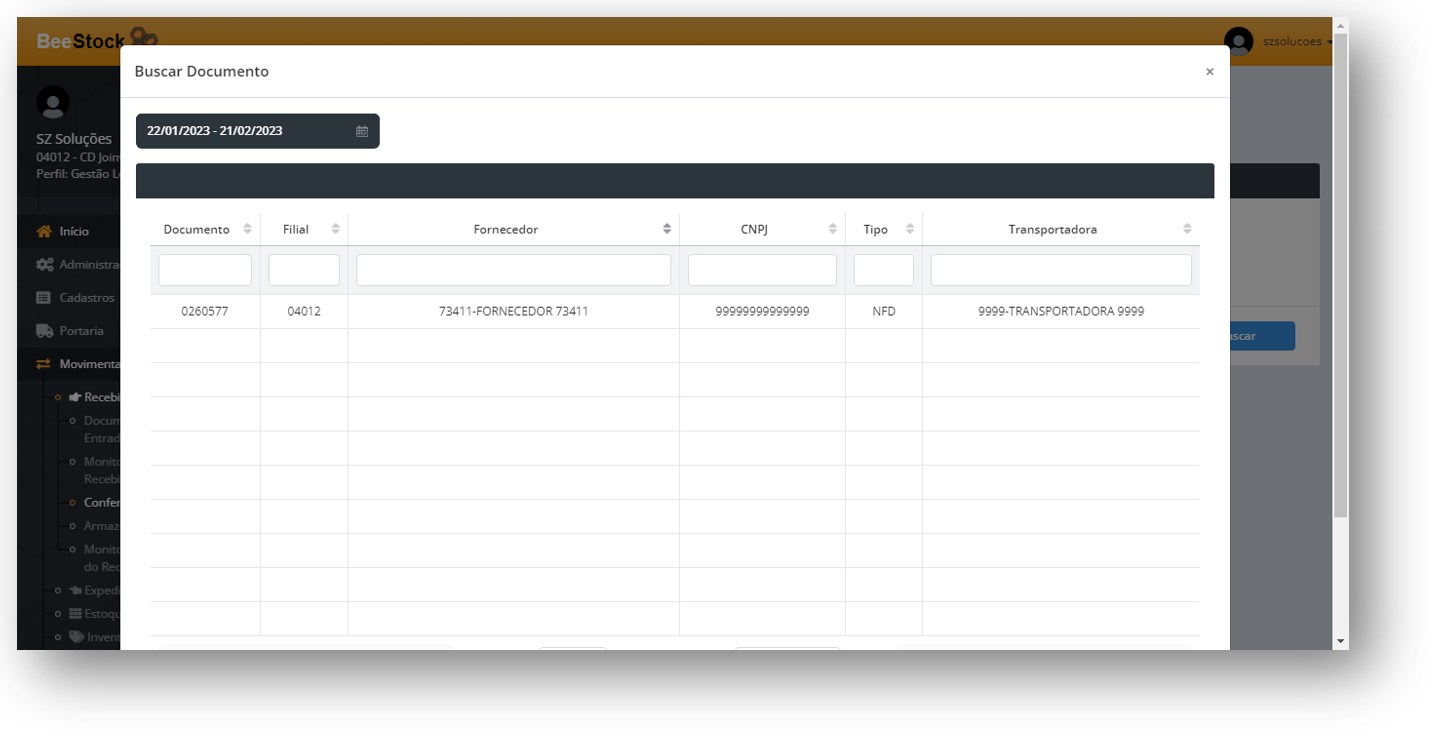

You can search directly by number or search the list of documents available for checking:

After selecting the document, we will go to the new screen:

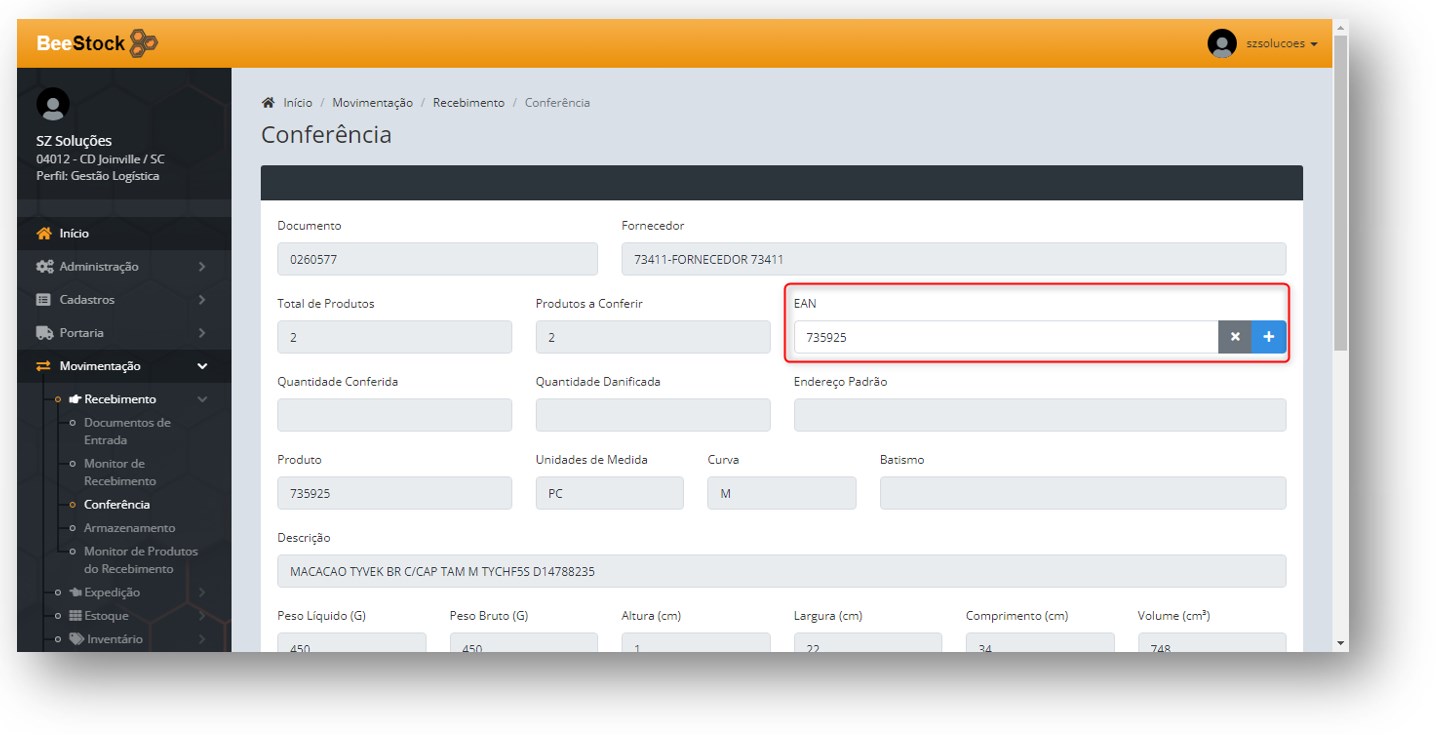

To start the check, we take the EAN of the first item, put it in the field and press the Enter key:

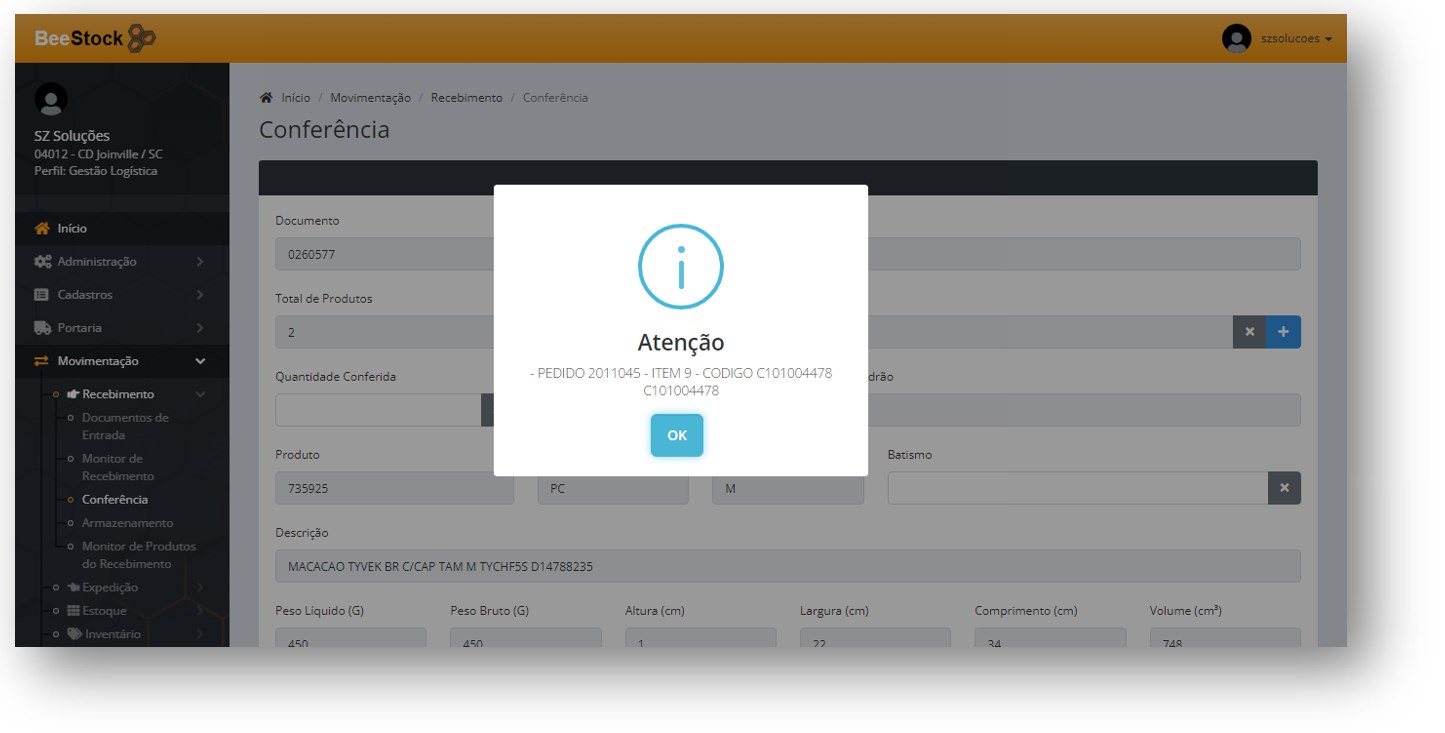

The observation of the product in question will be displayed.

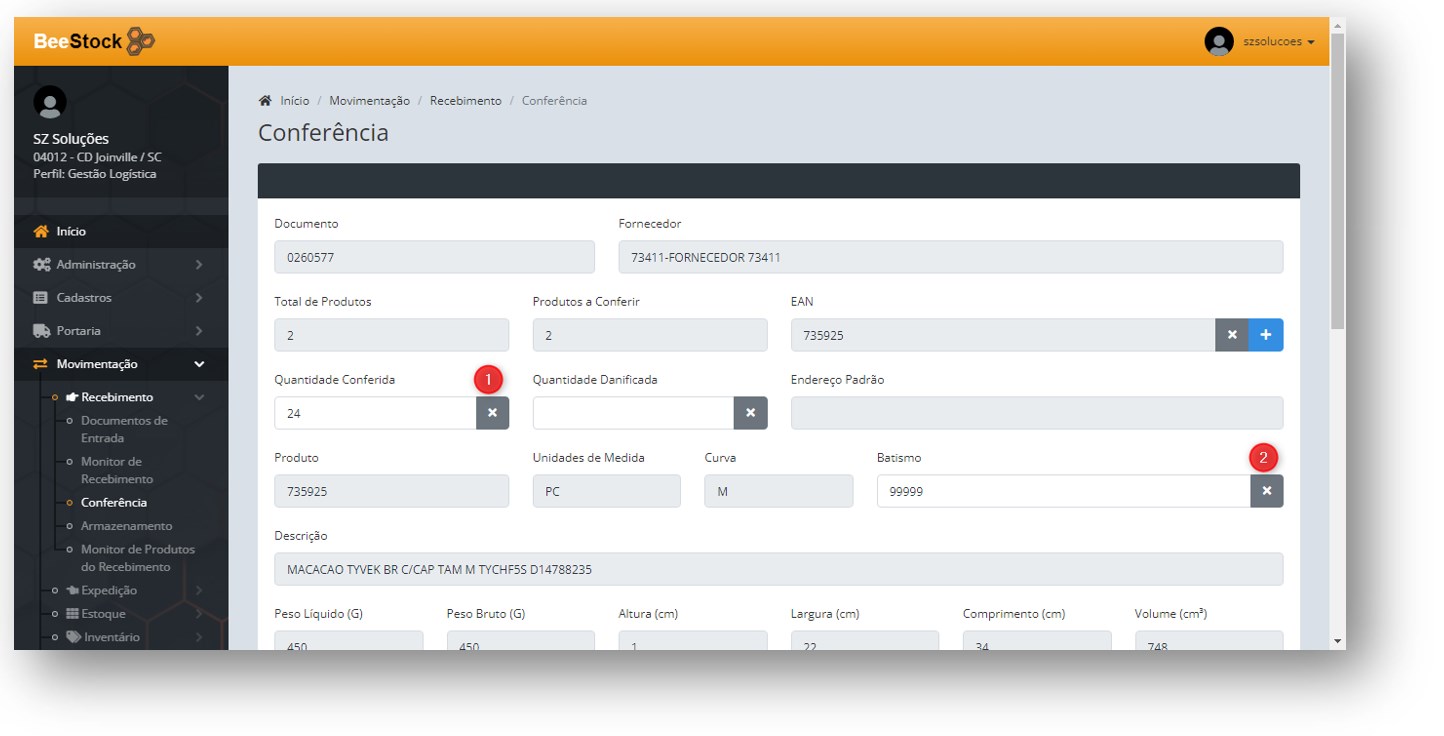

After that, we enter the quantity to be checked.

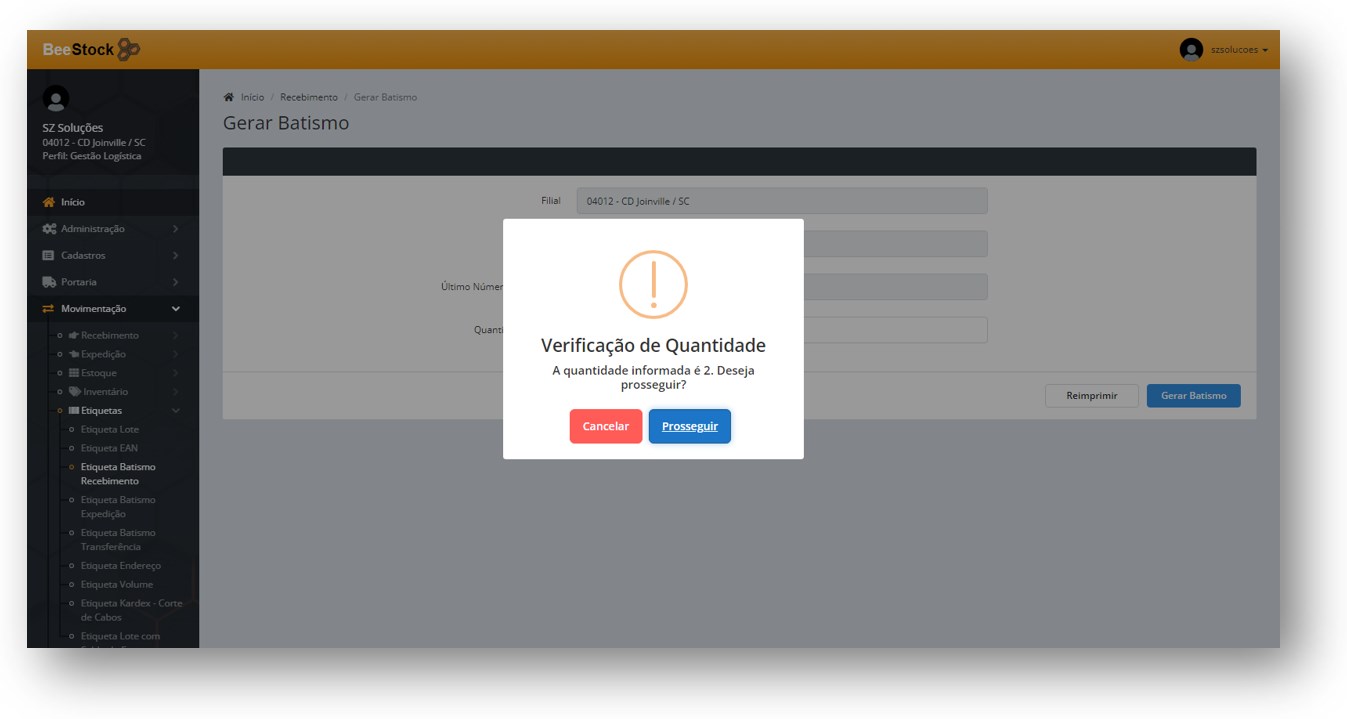

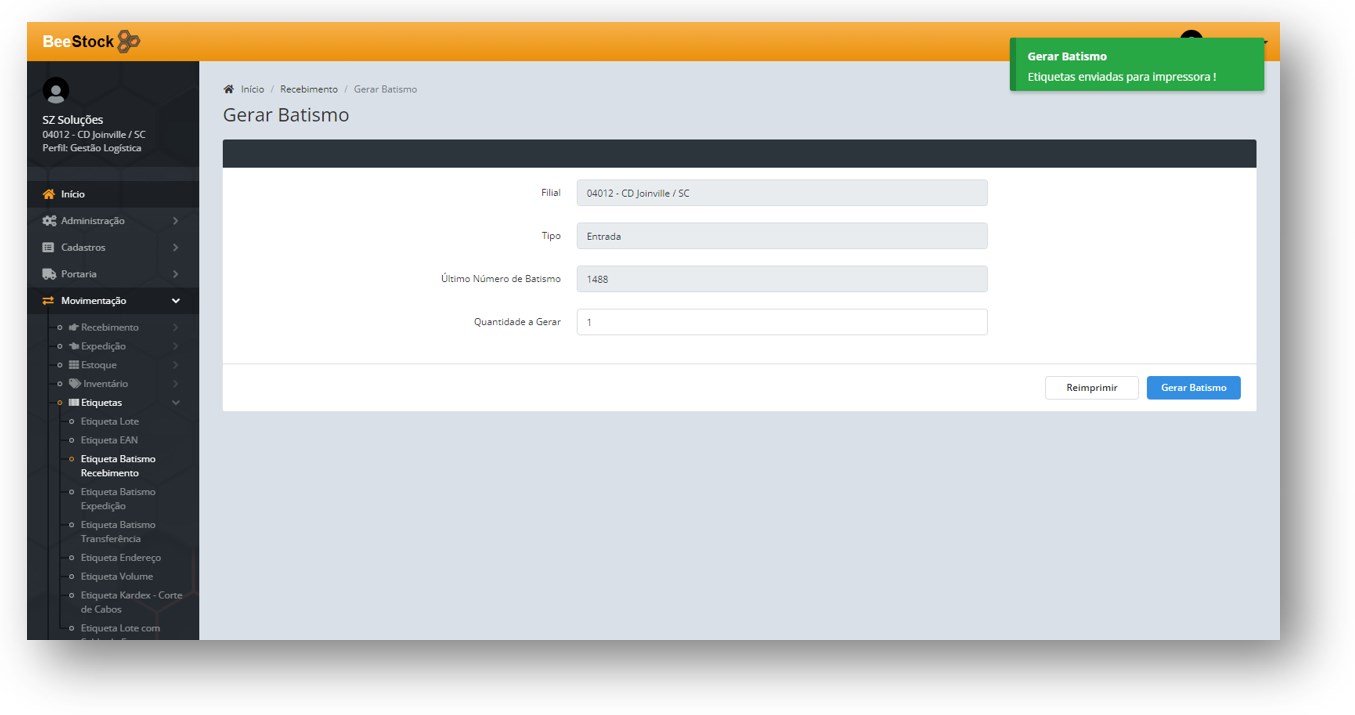

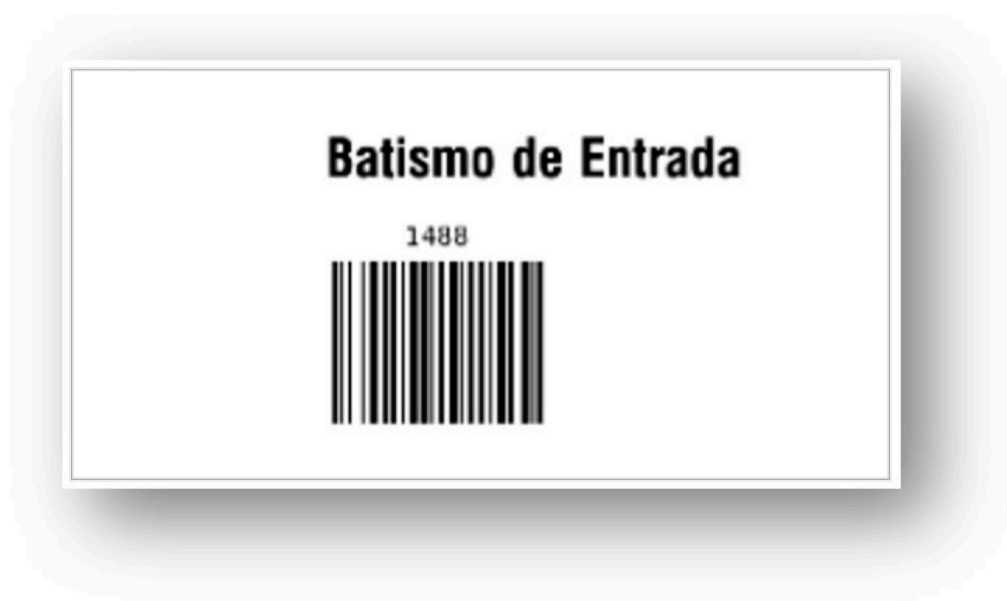

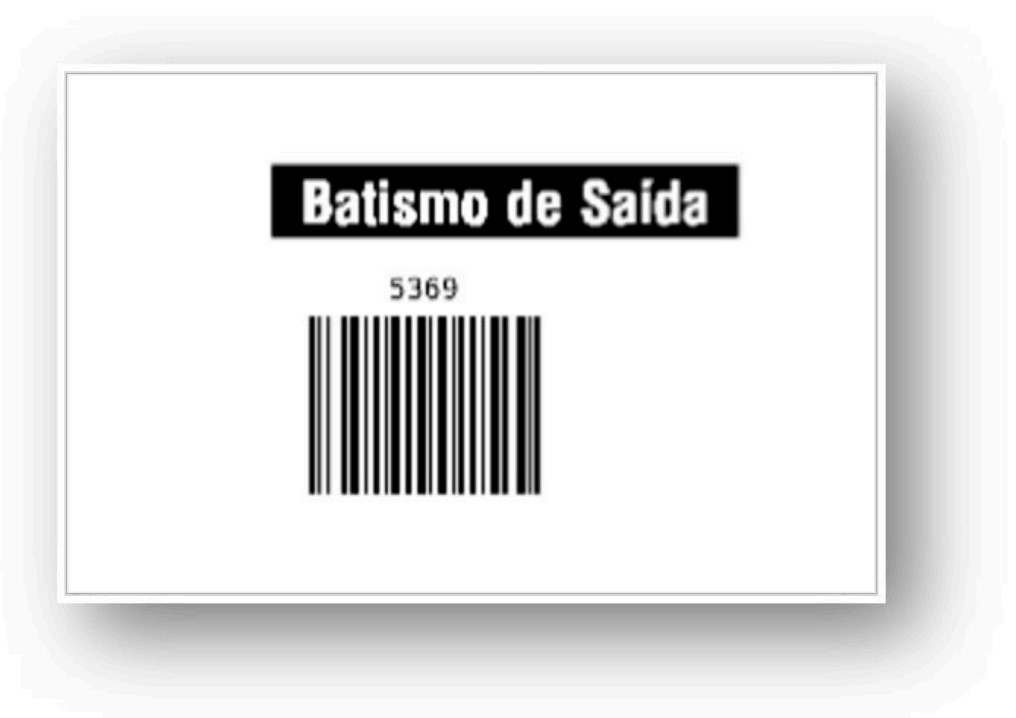

After the quantity, we must enter the Baptism number that will be used in the Storage:

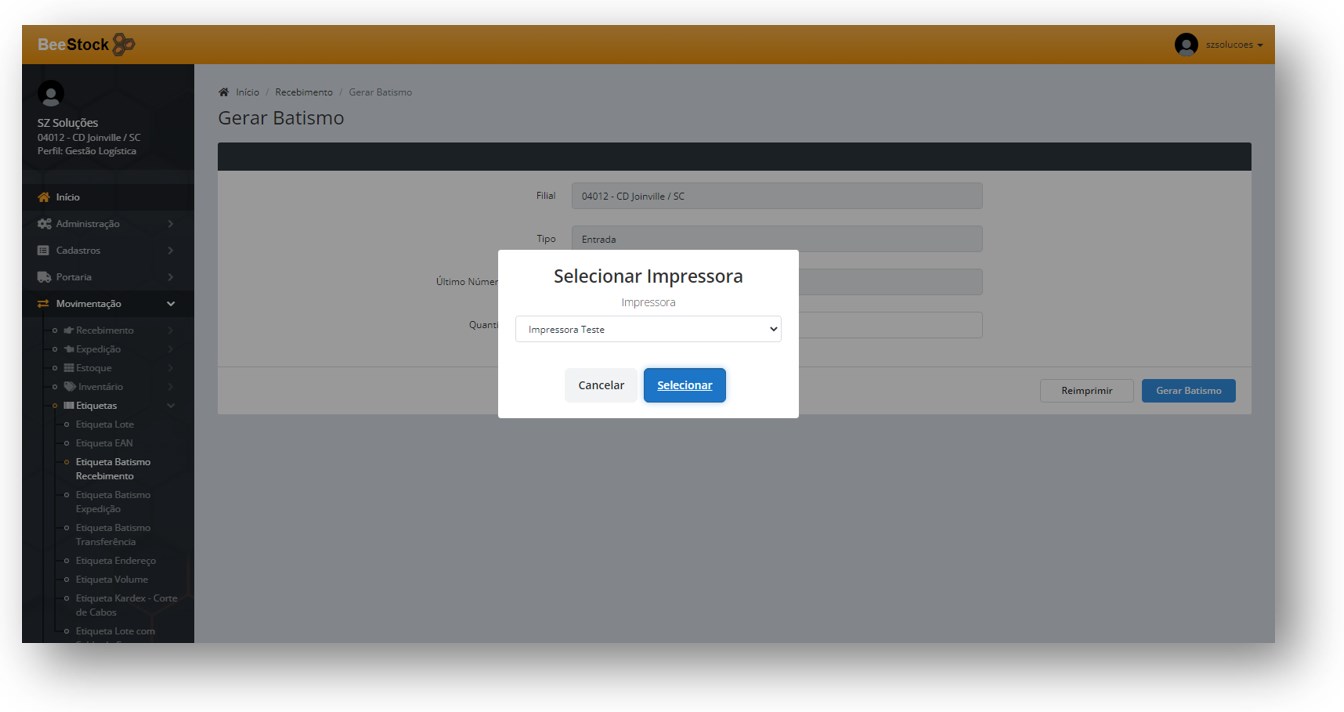

We have the option to enter the number of labels to be printed.

We check the suggested address; the suggested address can be changed as needed by the user, and it respects the business rule ordered in Branch Registration > Receiving tab.

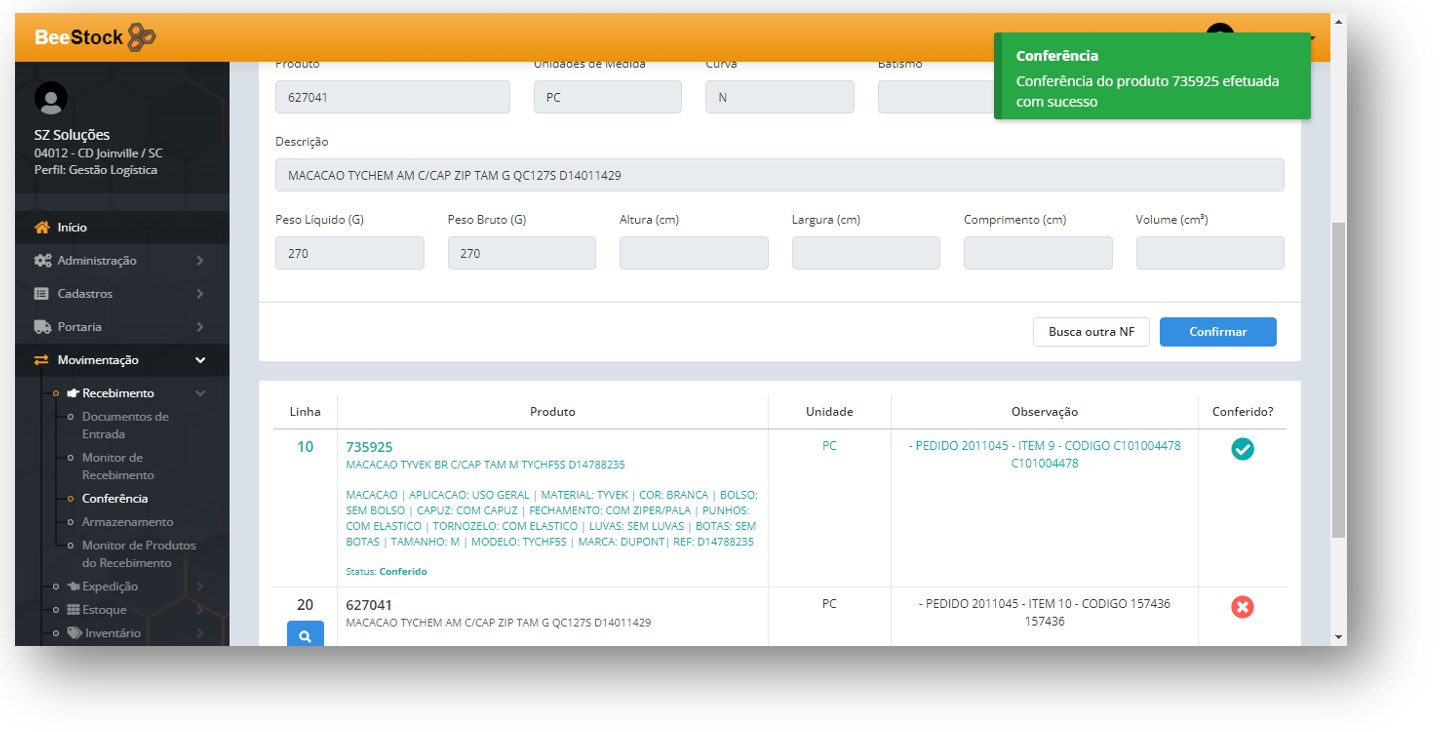

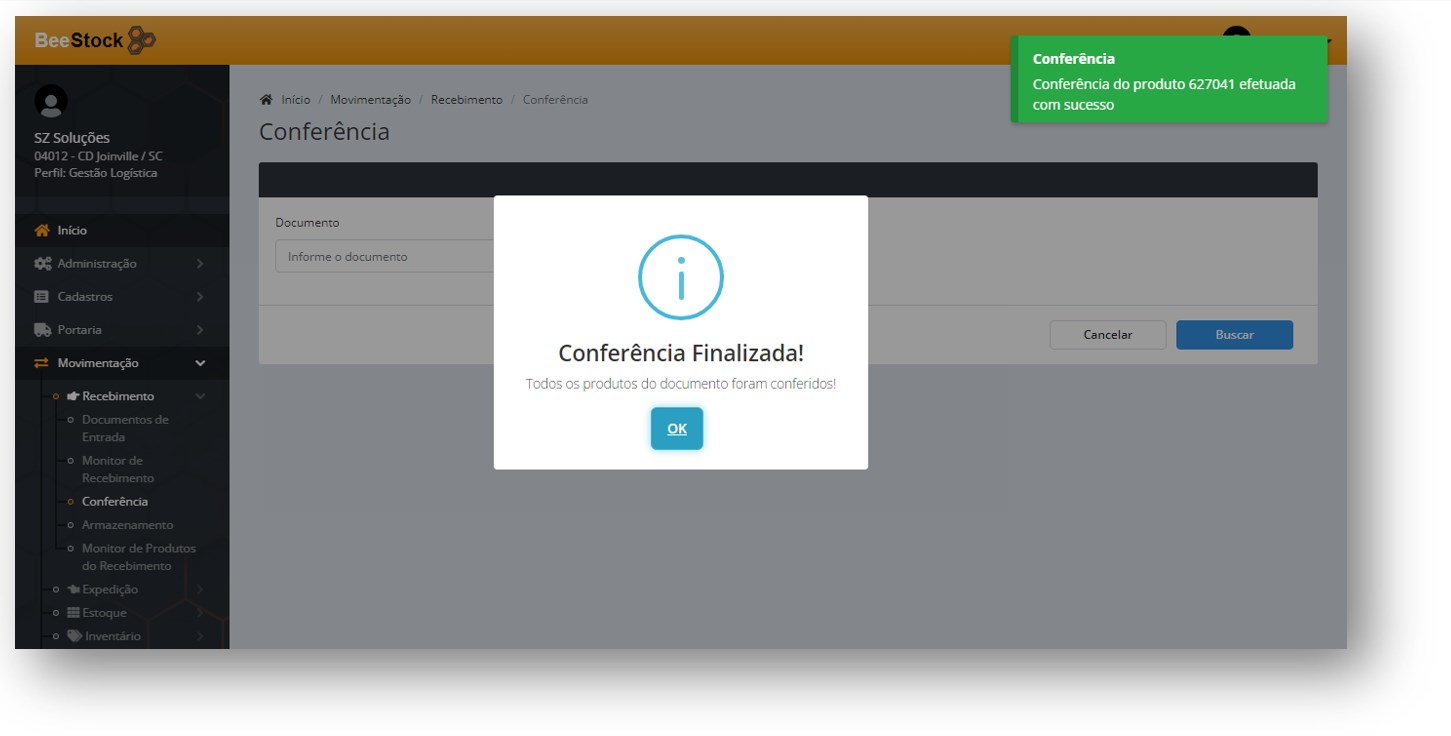

And then we click on Confirm:

After confirmation, the line of the checked product turns blue:

Then, just perform the same process for all items in the document.

When the item is controlled by expiration date, after entering the EAN and clicking on Confirm, we will go to the following screen:

After filling in all the information, click on Save:

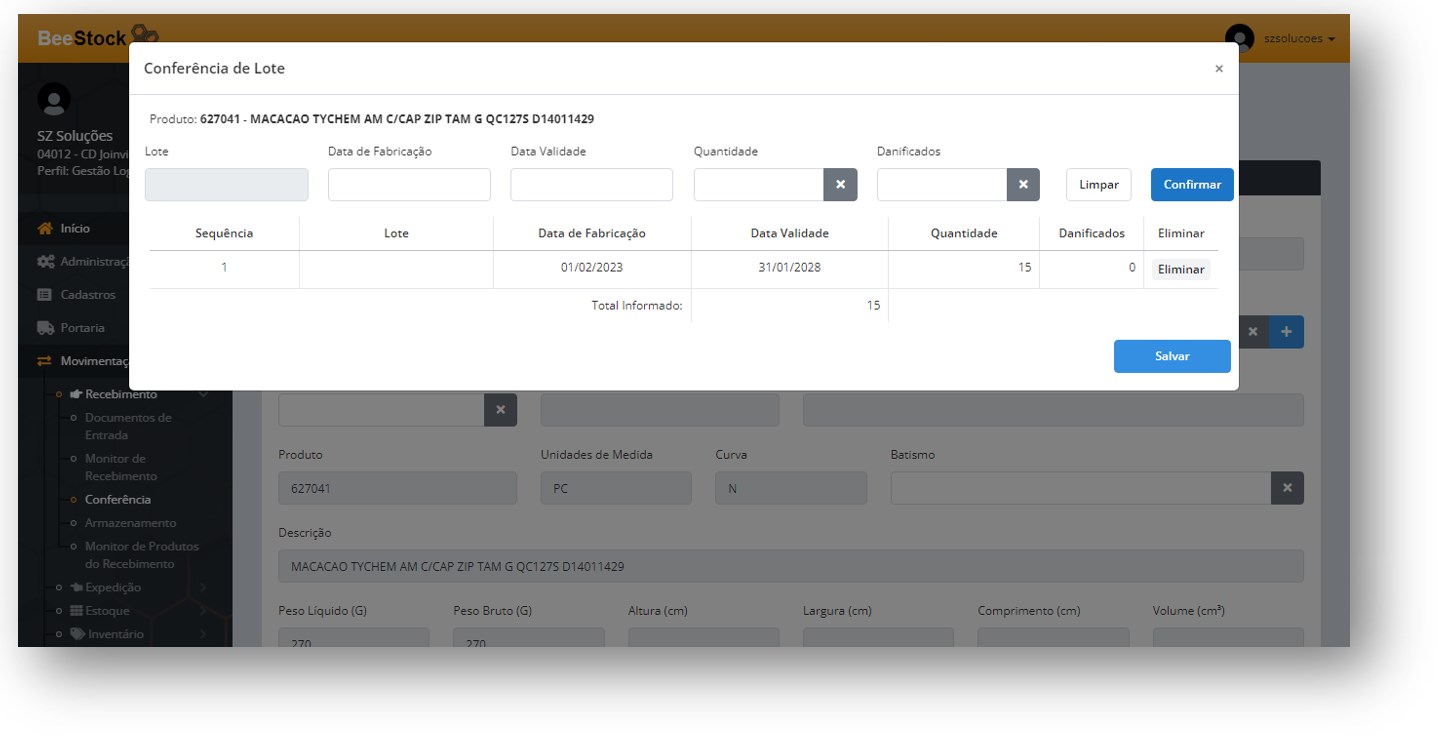

When filling in the Manufacturing Date, the information from the Product Registration (insert link), Inventory tab, Shelf Life: field is used to automatically calculate forward and suggest the expiration date.

And also, in reverse, if you enter the expiration date, it calculates based on the number of days from the product registration to suggest the manufacturing date.

Then, we enter the baptism and confirm:

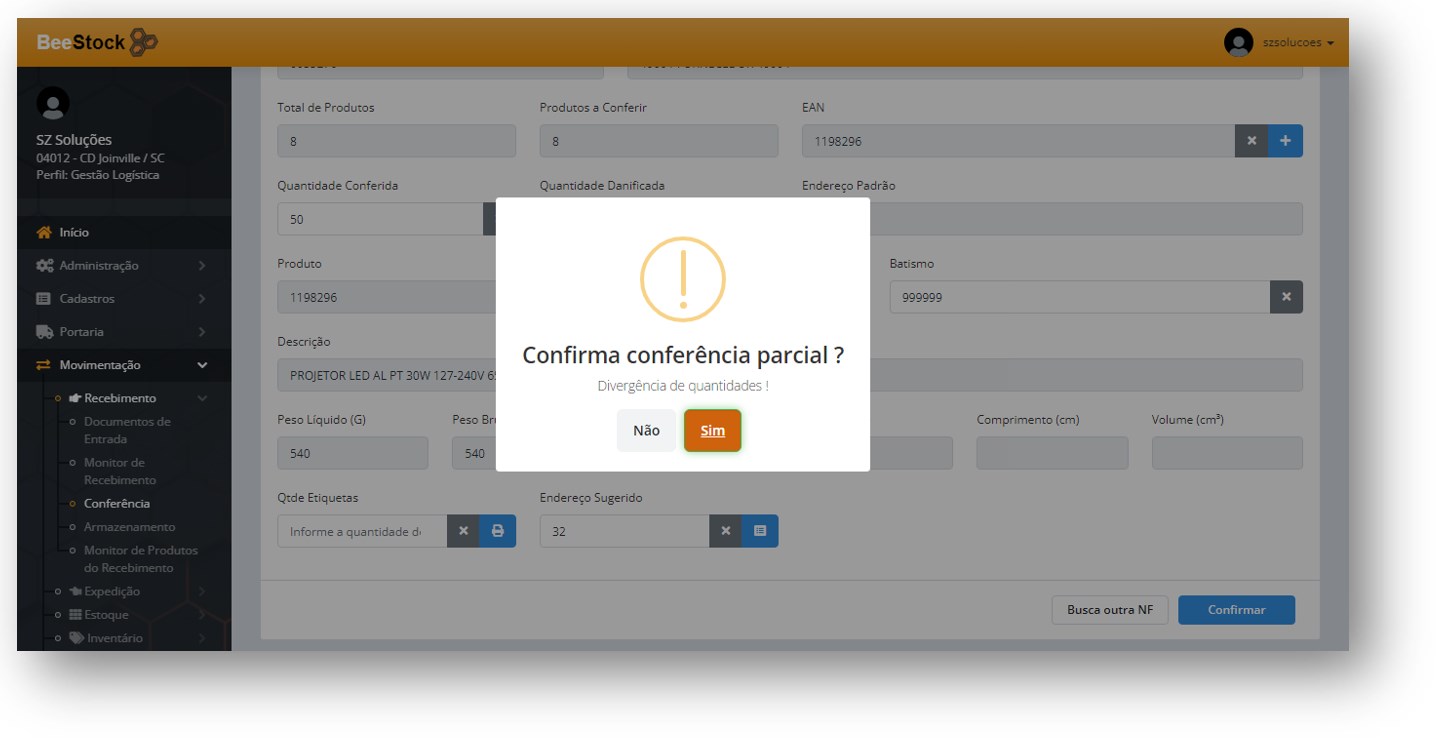

There is also the possibility to check a smaller quantity than the total, and when this is done, the following question appears:

Clicking on Yes, the partial check is performed, and we can check the rest later.

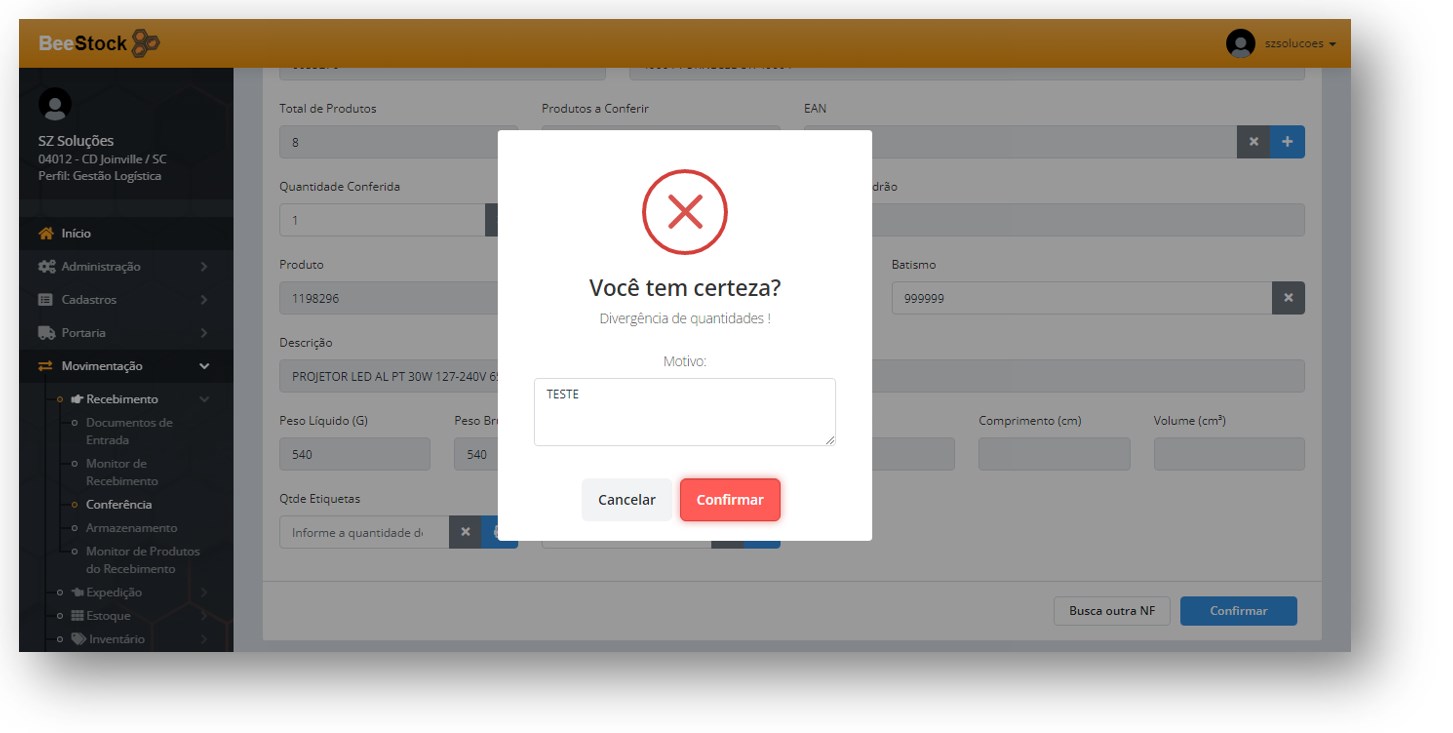

Clicking on No, it will be asked again if it is really a discrepancy:

Confirming the discrepancy, the product will be fully checked.

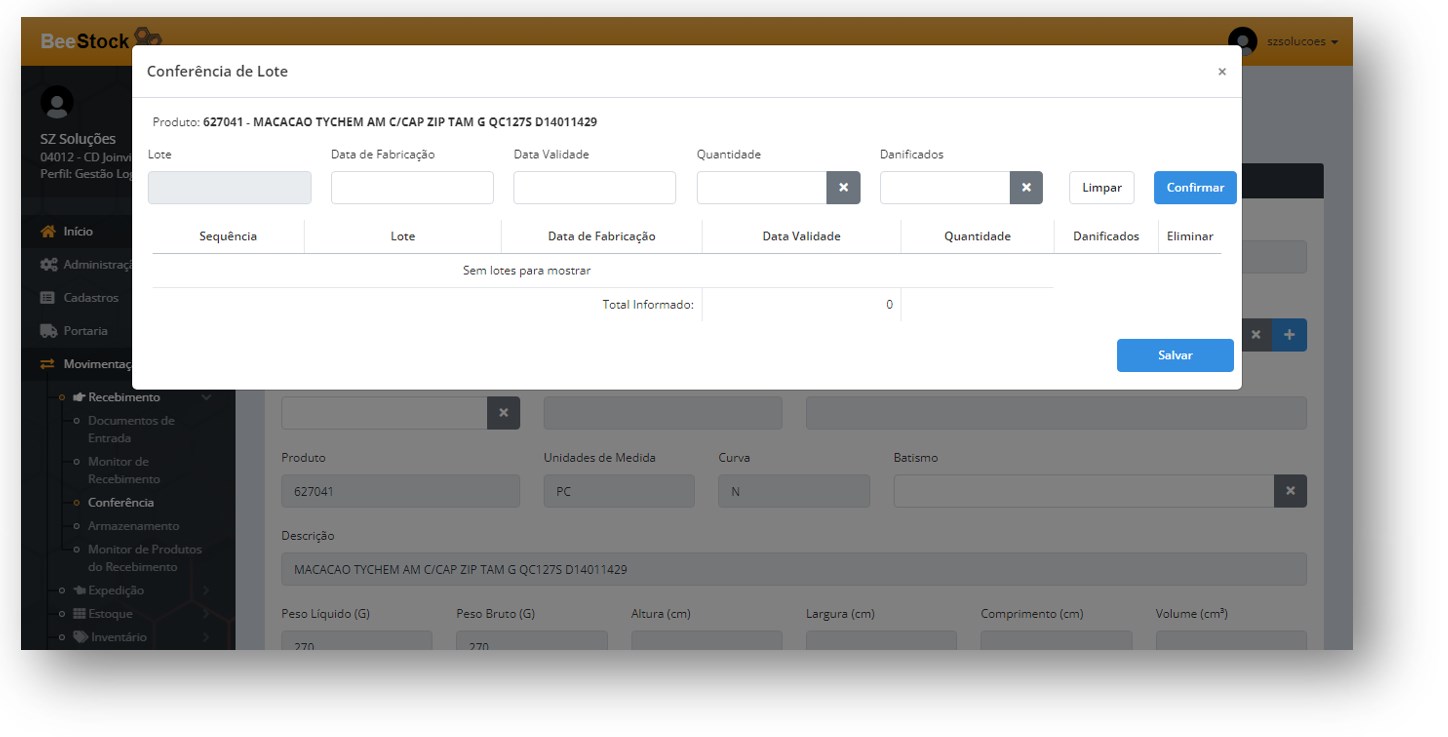

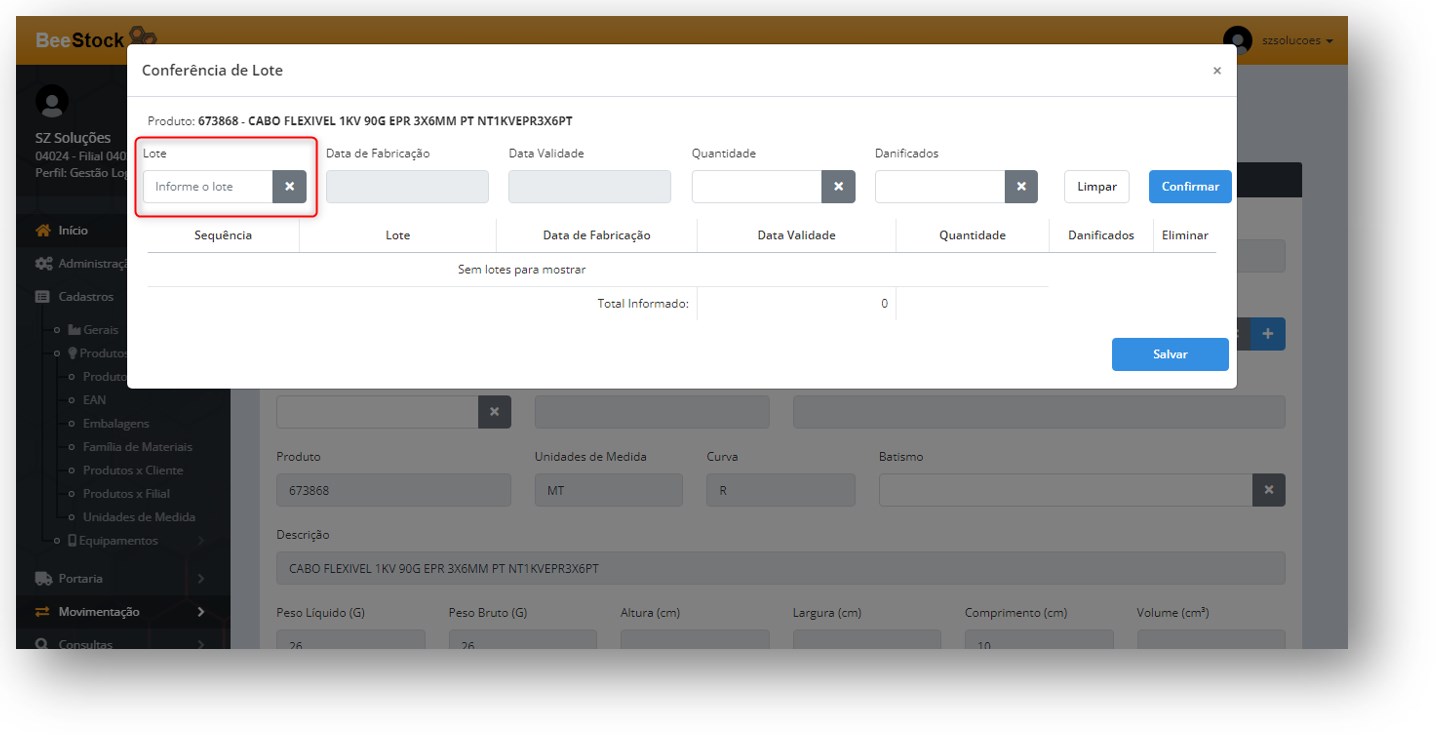

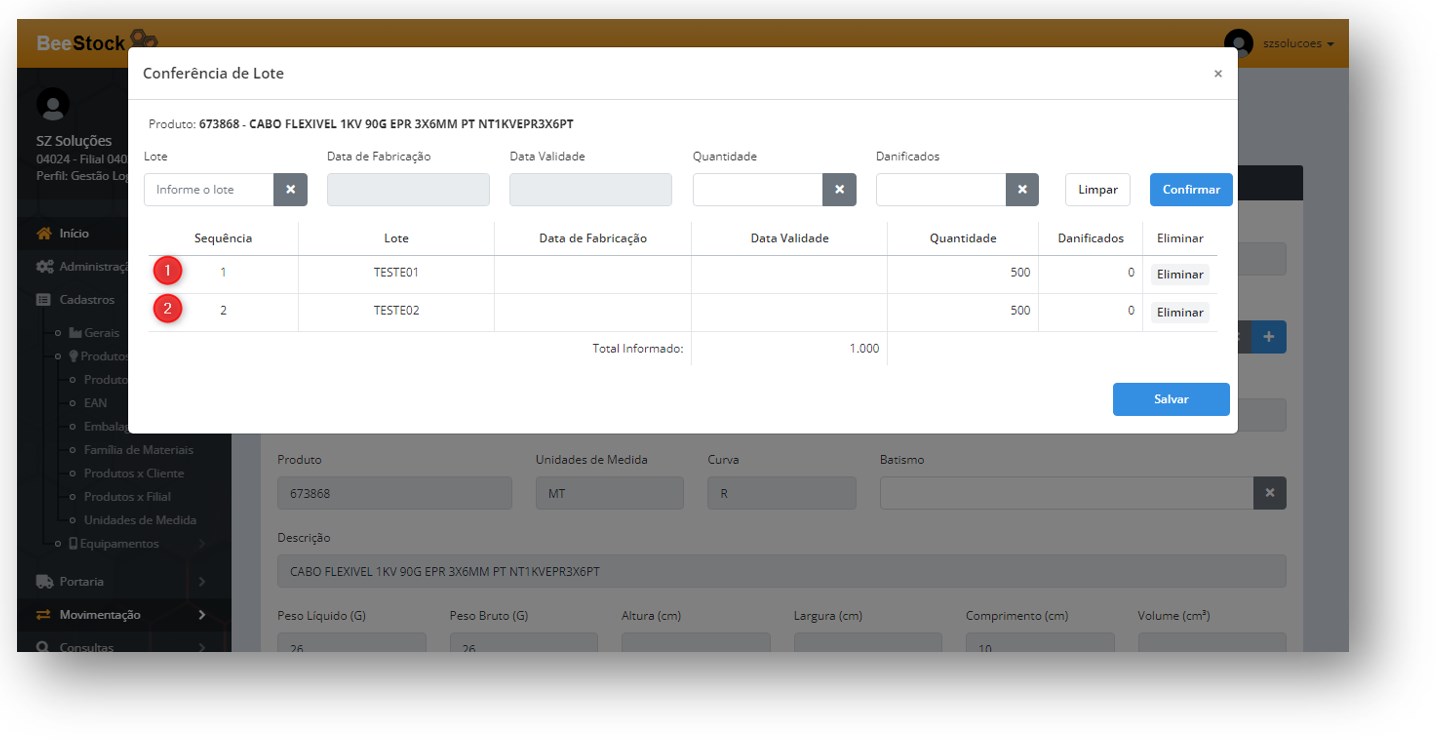

When the item is controlled by batch, after entering the EAN and clicking on Confirm, we will go to the following screen:

We can break the batch into more than one line:

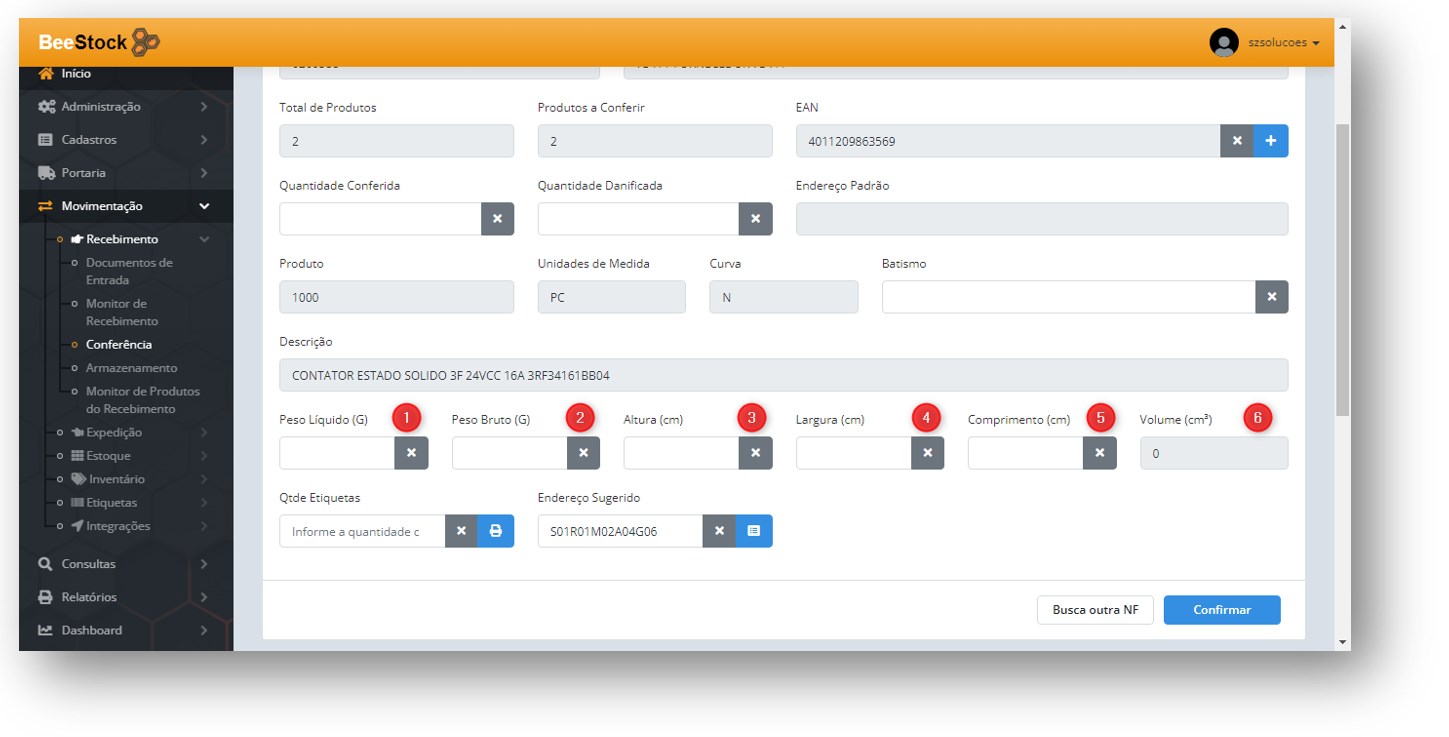

If the product does not have weight, height and width information registered, it will be requested to be filled in at the check, based on what was parameterized in the parameter Request Product Weights and Dimensions in the Physical Check on the Receiving tab of the Branch Registration.

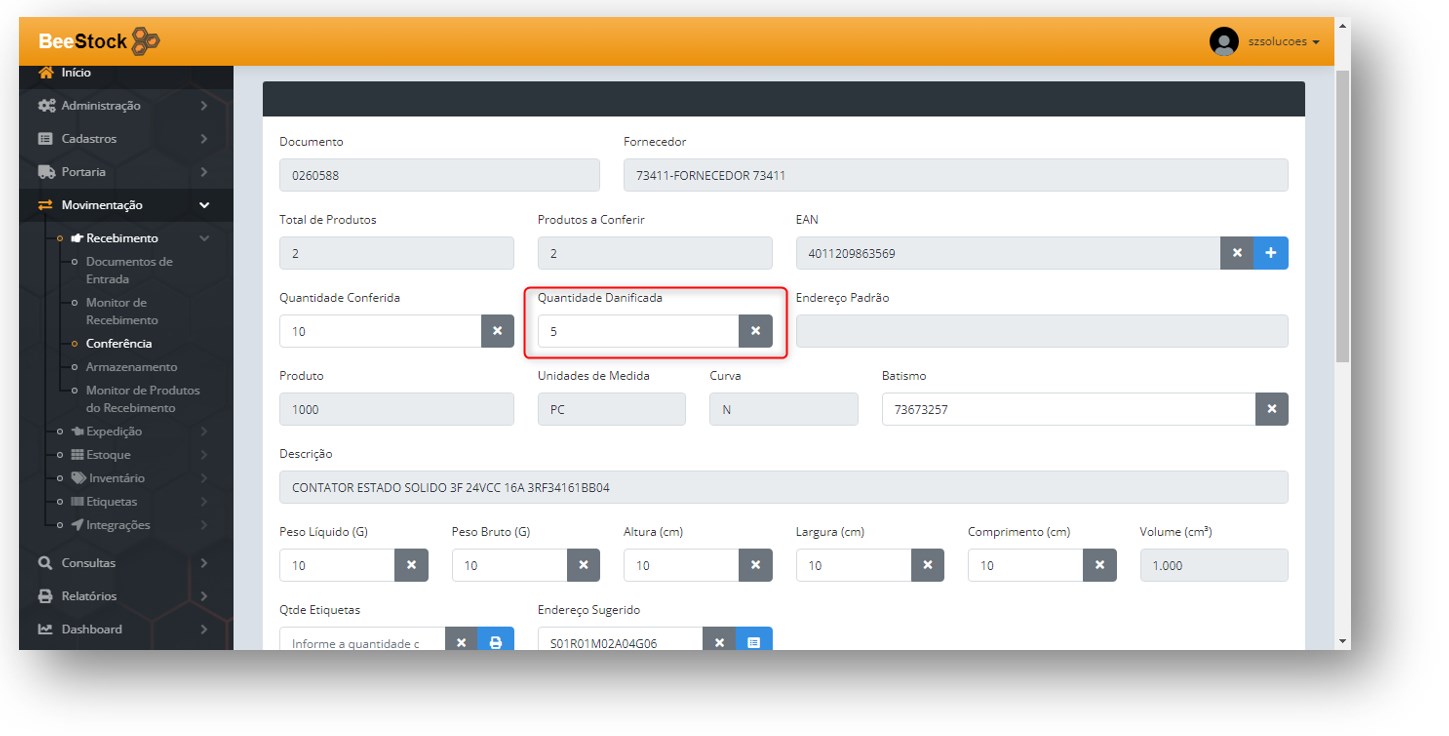

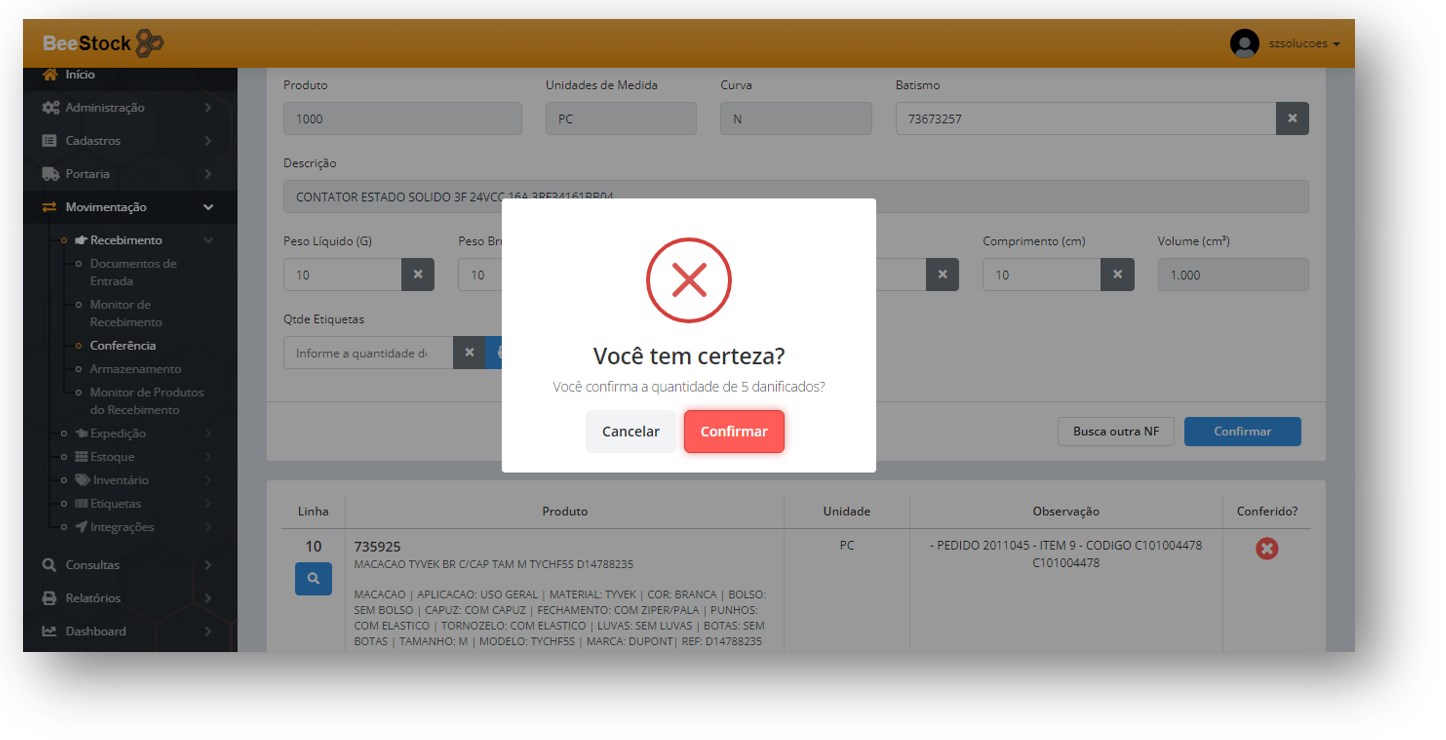

We also have the option to receive the product as damaged:

Confirming, the system will ask:

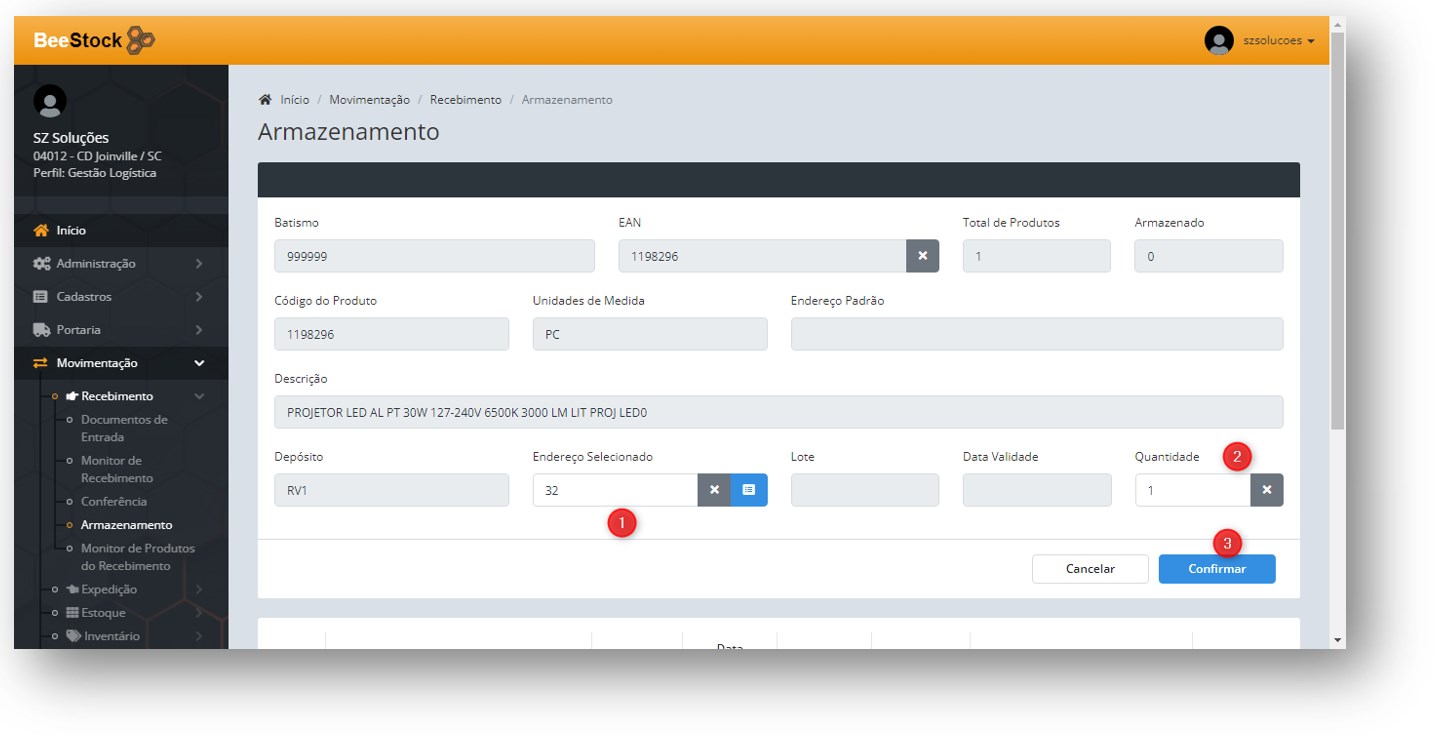

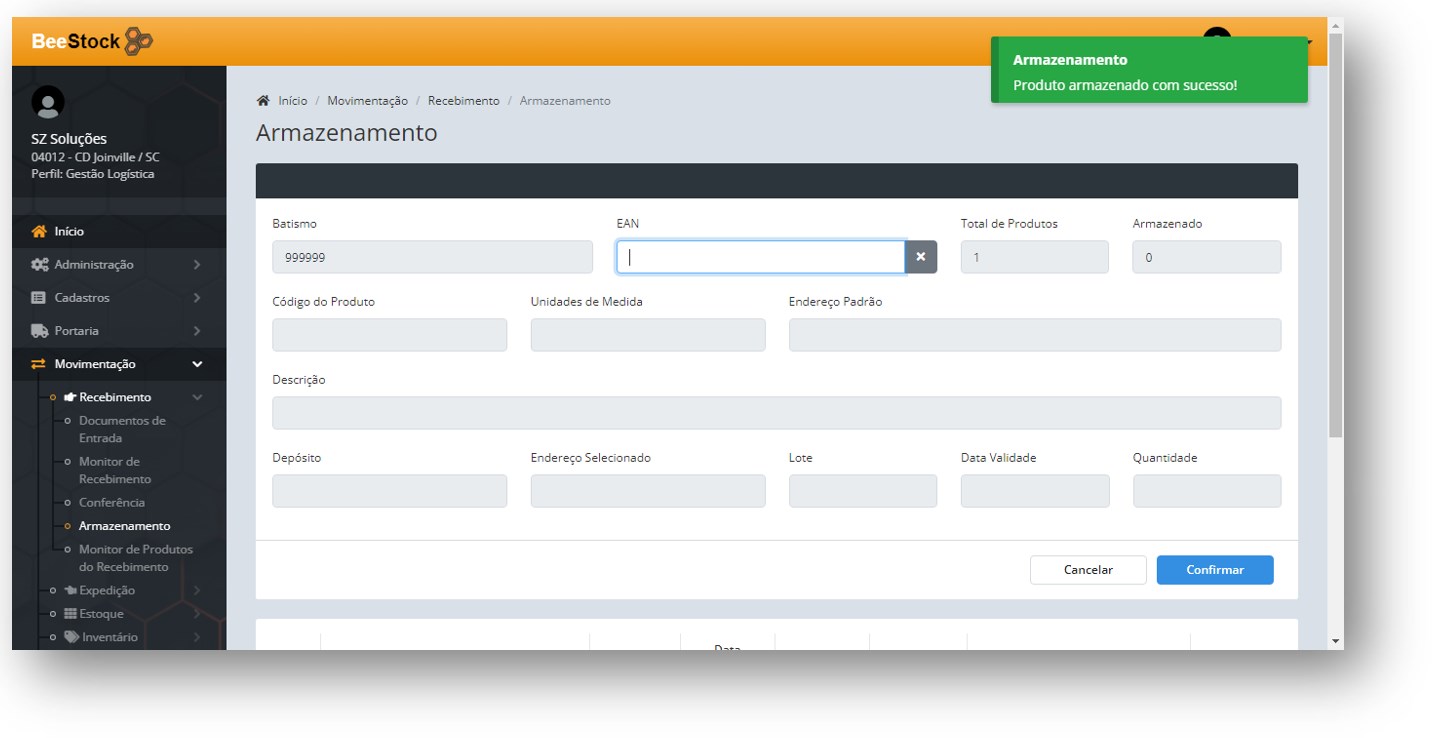

Storage

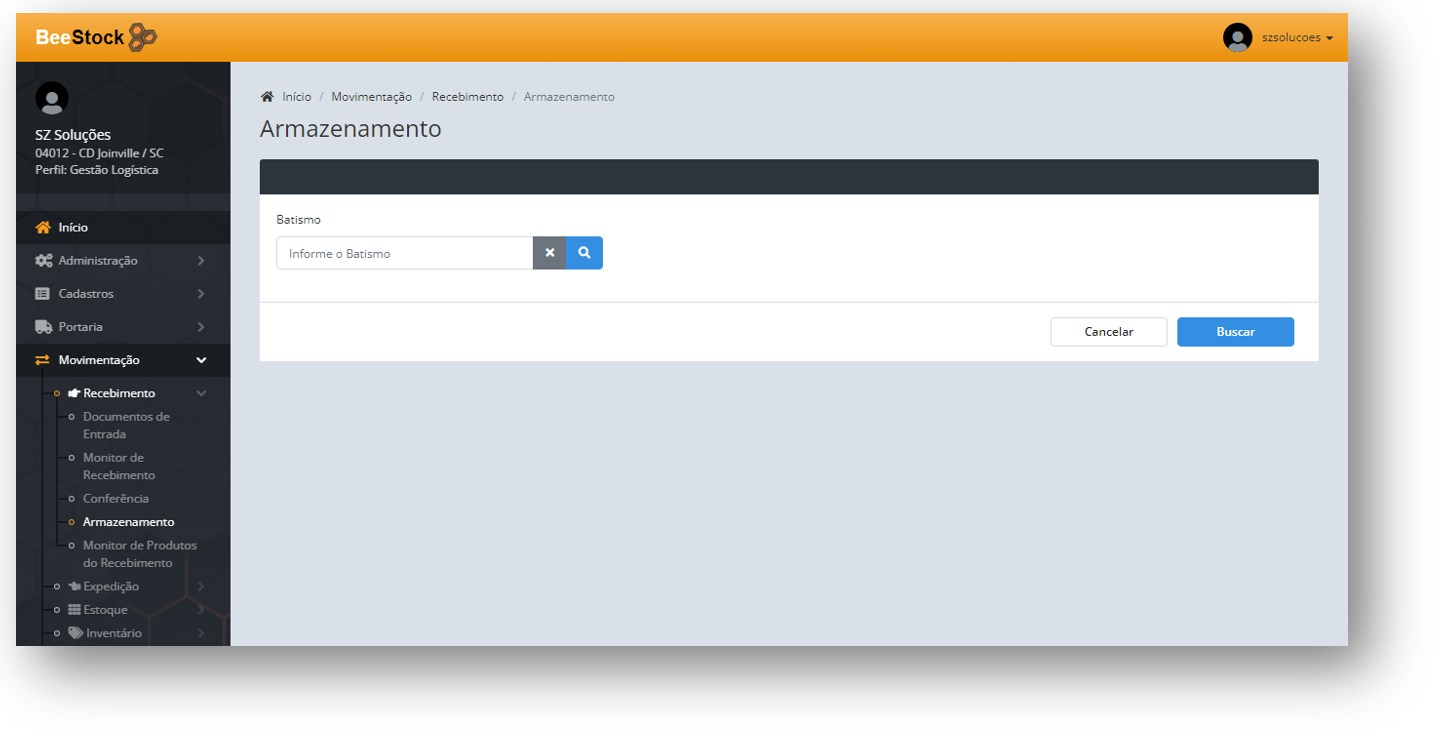

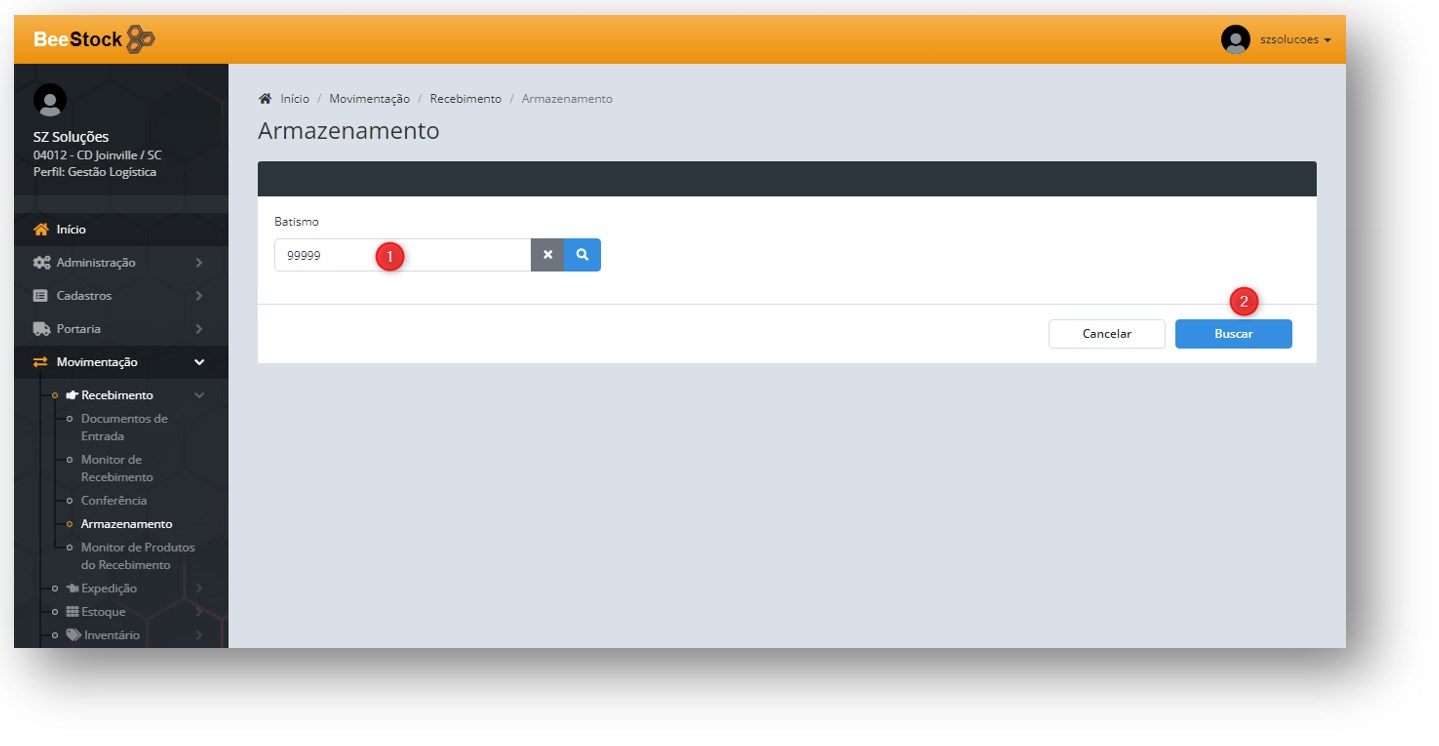

Located in the Movement > Receiving > Storage menu, the screen is used to perform the storage of products from an inbound document.

Access the Movement > Receiving > Storage menu.

We can enter the baptism number that will be used for storage:

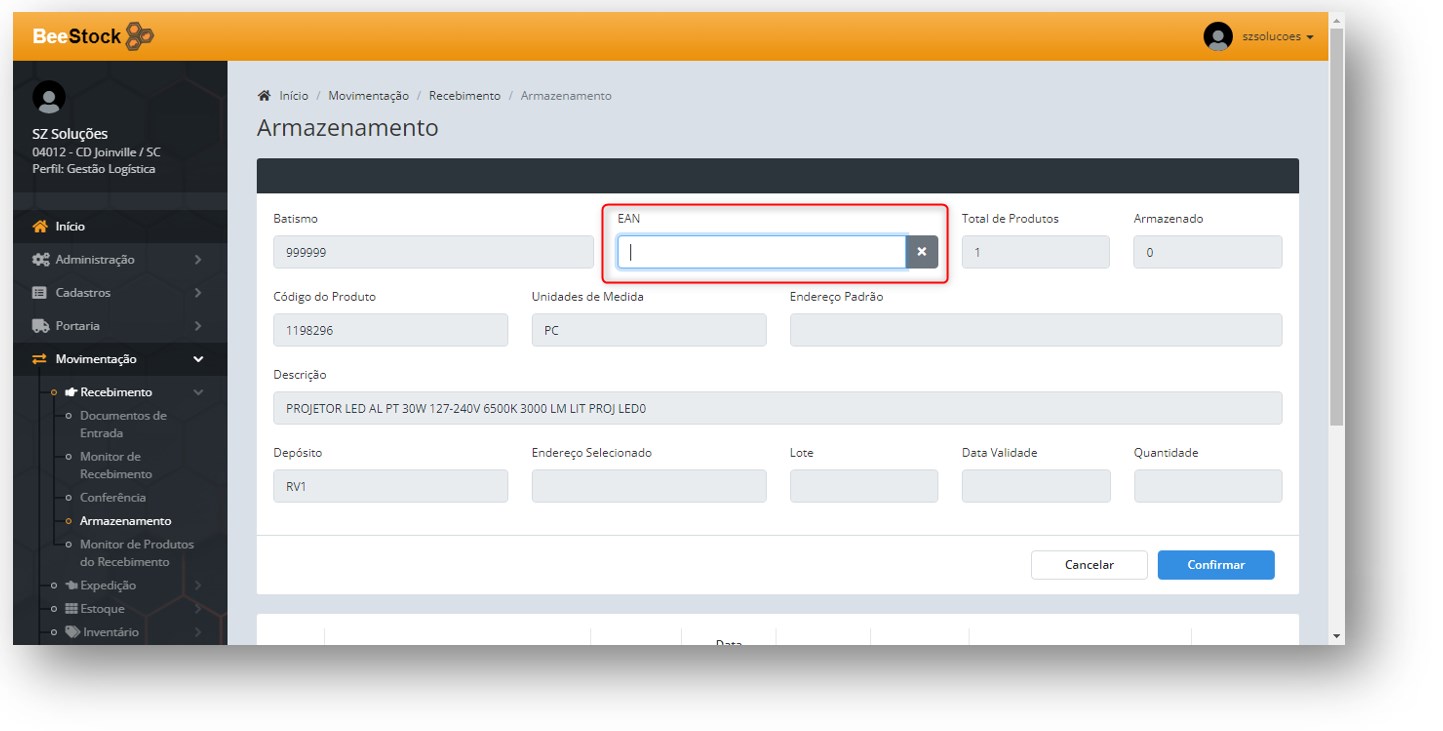

We enter the new screen and must enter the EAN of the product to be stored:

After the EAN, we must enter the address, quantity, and then confirm:

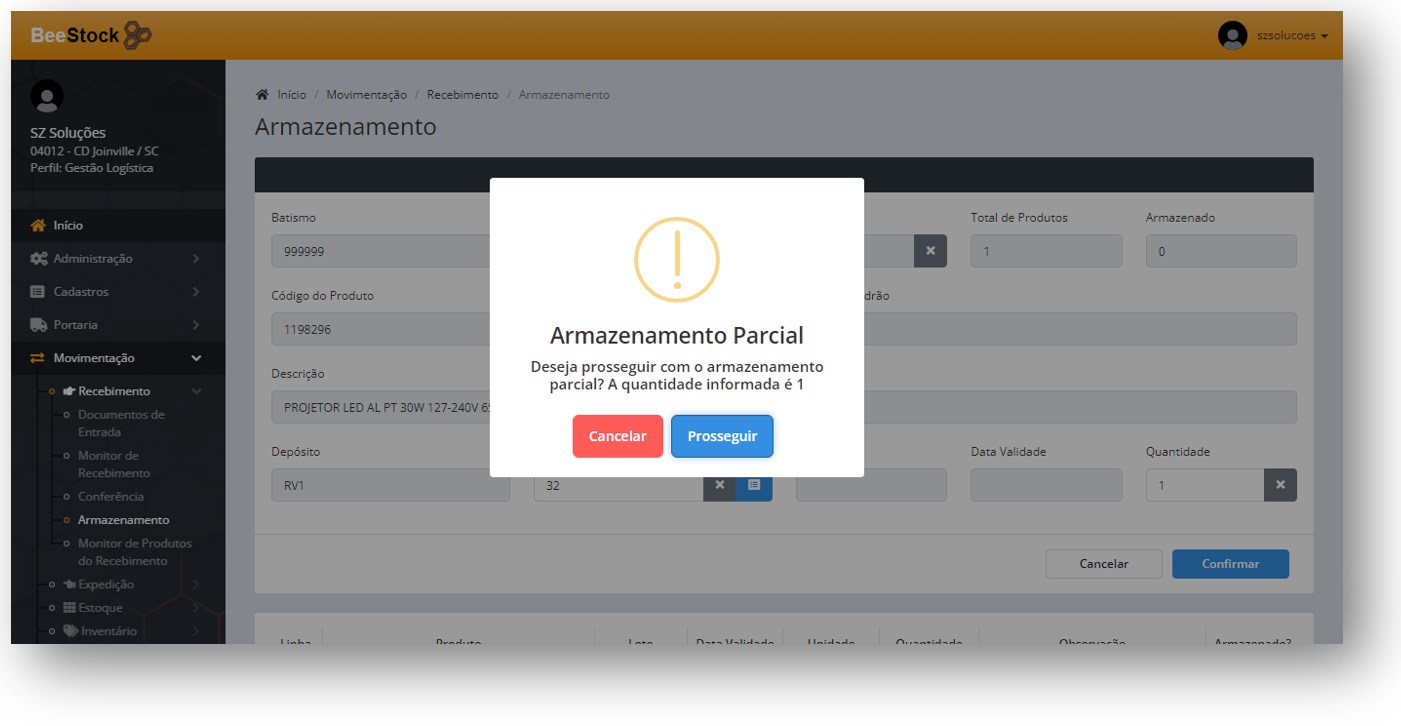

We can also store a partial quantity; when we try to store a partial quantity, we get the following message: By proceeding, the informed quantity will be stored and the rest will remain pending, allowing storage to be continued later.

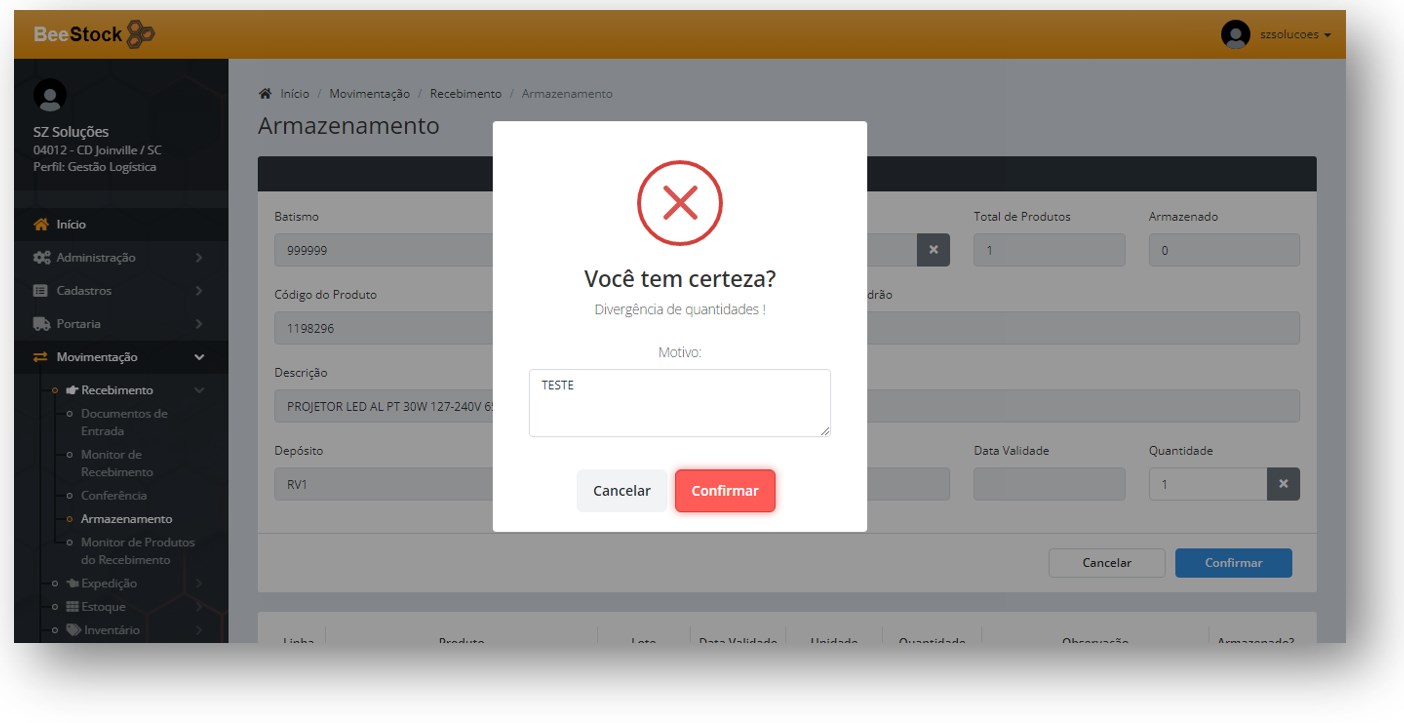

If we cancel, it will be asked if the discrepancy is confirmed:

If the discrepancy is confirmed, the remaining balance of the product will be sent to the discrepancy warehouse and the rest will be stored.

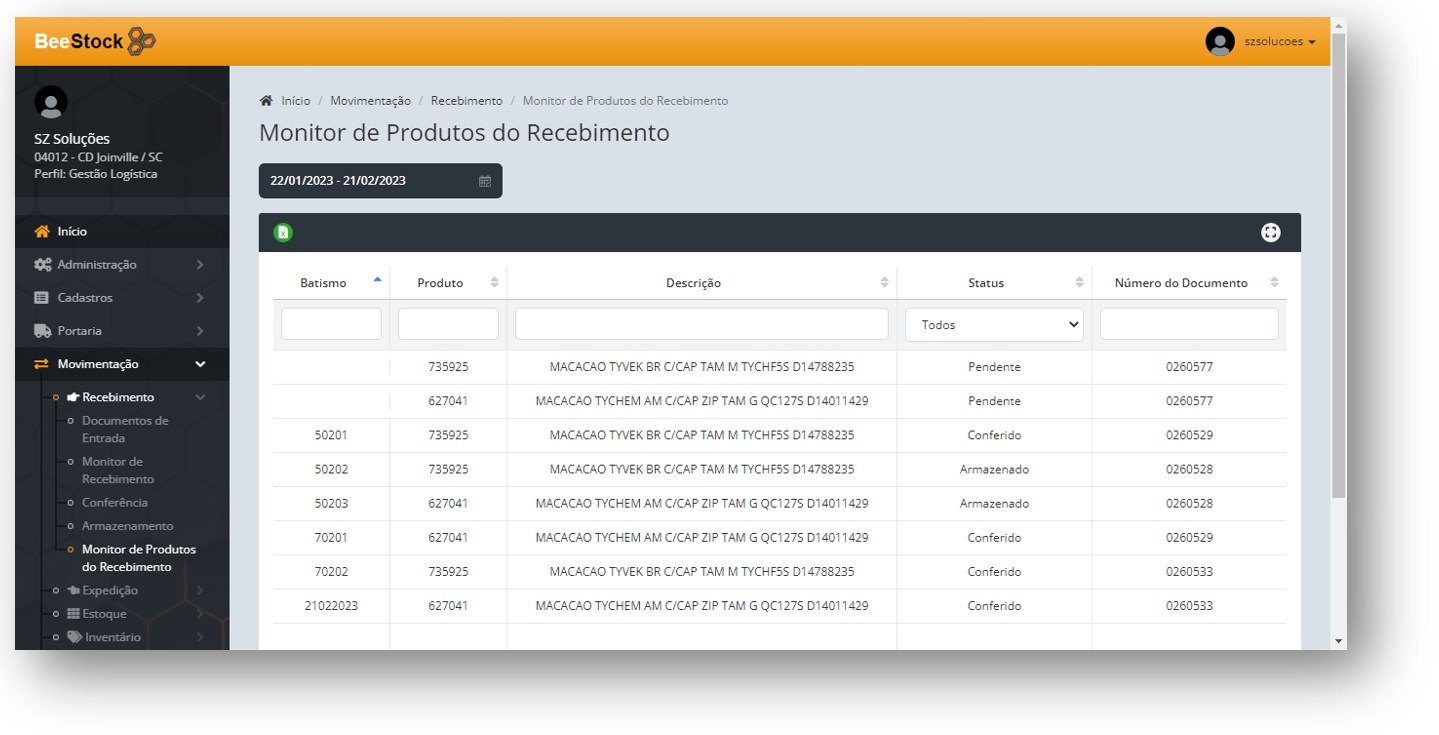

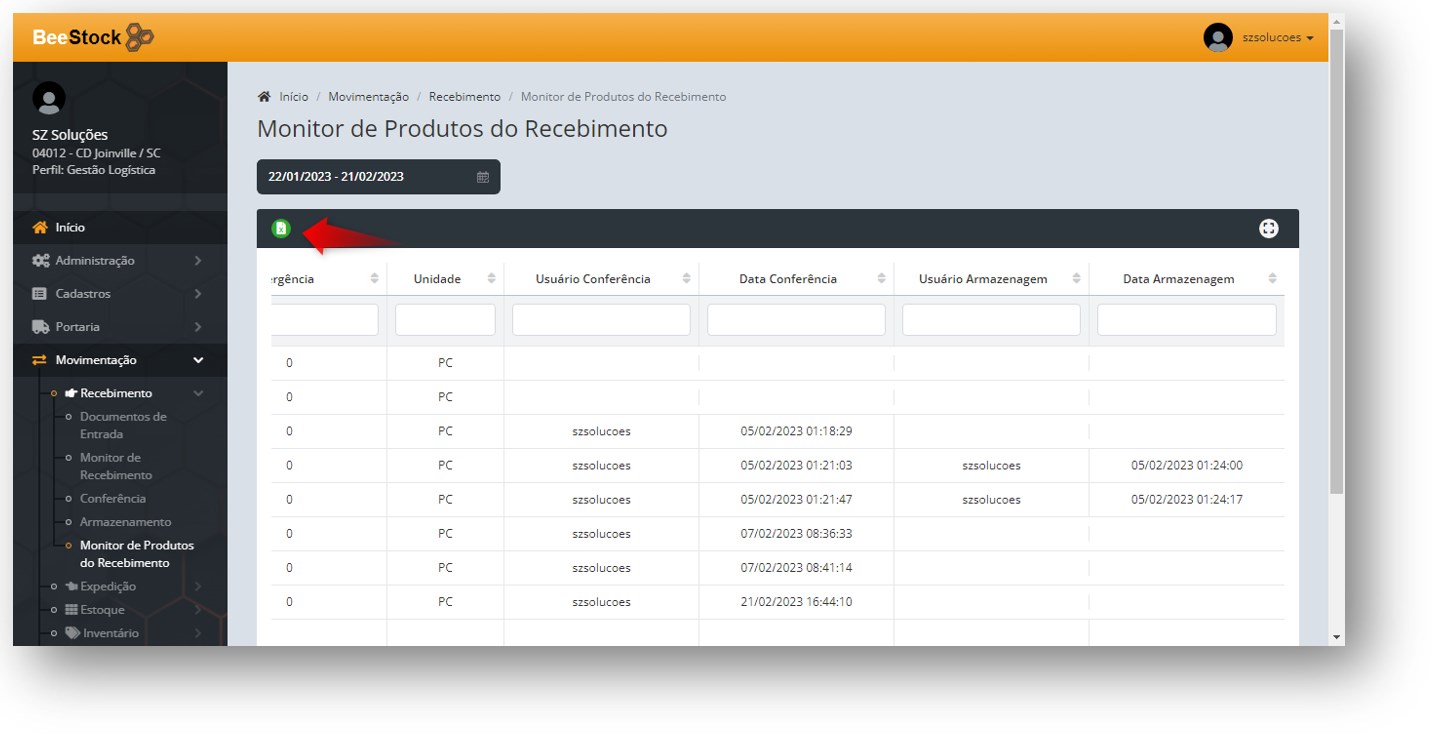

Receiving Products Monitor

Located in the Movement > Receiving > Receiving Products Monitor menu, the Receiving Products Monitor is used to view all products belonging to documents that are in receiving.

Access the Movement > Receiving > Receiving Products Monitor menu.

The Grid is filtered first and obligatorily by the filter at the beginning of the Inbound Document Date screen.

It is possible to filter the Grid by the columns:

Baptism

Product

Description

Status

Document Number

Supplier

Branch

Print Date

Creation Date

Quantity

Checked

Pending

Stored

Damaged

Discrepancy

Unit

Check User

Check Date

Storage User

Storage Date

We can also export the data on the screen to an Excel spreadsheet:

Receiving Flow - Collector

Located in the Inbound menu, the screens are used to perform the entire Inbound on Collector process.

Goods Inbound > GR Check.

Goods Inbound > Storage.

GR Check

Located in the Inbound > GR Check menu, the screen is used to perform the entire Inbound Check on Collector process.

We can enter the document number directly or search for the document by clicking on the magnifying glass:

Select the desired document.

After selecting the document, we will go to the screen:

To start the check, we take or scan the EAN of the first item:

After that, we enter the quantity to be checked.

After the quantity, we must enter the Baptism number that will be used in Storage:

We have the option to enter the number of labels to be printed.

We check the suggested address; the suggested address can be changed as needed by the user, and it respects the business rule ordered in Branch Registration > Receiving tab.

And then we click on Confirm:

Then, just perform the same process for all items in the document.

When the item is controlled by expiration date, after entering the EAN, we will go to the following screen:

After filling in all the information, click on Save:

When filling in the Manufacturing Date, the information from the Product Registration, Inventory tab, Shelf Life: field is used to automatically calculate forward and suggest the expiration date.

And also, in reverse, if you enter the expiration date, it calculates based on the number of days from the product registration to suggest the manufacturing date.

Then, we enter the baptism and confirm.

There is also the possibility to check a smaller quantity than the total, and when this is done, the following question appears:

Clicking on Yes, the partial check is performed, and we can check the rest later.

Clicking on No, it will be asked again if it is really a discrepancy:

Confirming the discrepancy, the product will be fully checked.

When the item is controlled by batch, after entering the EAN, we will go to the following screen.

We can break the batch into more than one line.

We also have the option to receive the product as damaged:

Confirming, the system will ask:

Storage

Located in the Inbound > Storage menu, the screen is used to perform the entire Storage on Collector process.

Access the Inbound > Storage menu.

We can enter the baptism number that will be used for storage:

The baptism will open and we must enter the EAN of the product to be stored:

After the EAN, we must enter the address, quantity, and then confirm:

We can also store a partial quantity; when we try to store a partial quantity, we get the following message:

If the discrepancy is confirmed, the product will be fully stored.

If we cancel, it will be asked if the partial storage is confirmed: By proceeding, the informed quantity will be stored and the rest will remain pending.

Picking Return Flow - Collector

Located in the Goods Receipt > Picking Return menu, this screen should be used to return the material balance to the origin address.

Access the Goods Receipt menu.

Access the Picking Return screen.

Click on the Magnifying Glass.

Locate in the list the document you want to return to picking (Previously generated through the Web menu Picking Return).

Confirm the requested fields by physically scanning the labels, ensuring that the physical and systemic storage of the material occur at the same time.

EAN

Address

Quantity

Click on Confirm

The message Item returned successfully! will be displayed.

You must perform the procedure for all items in the document for which you want to perform the picking return.

Remember that only after the picking return is performed, the balance becomes available again for new allocation at the origin address.

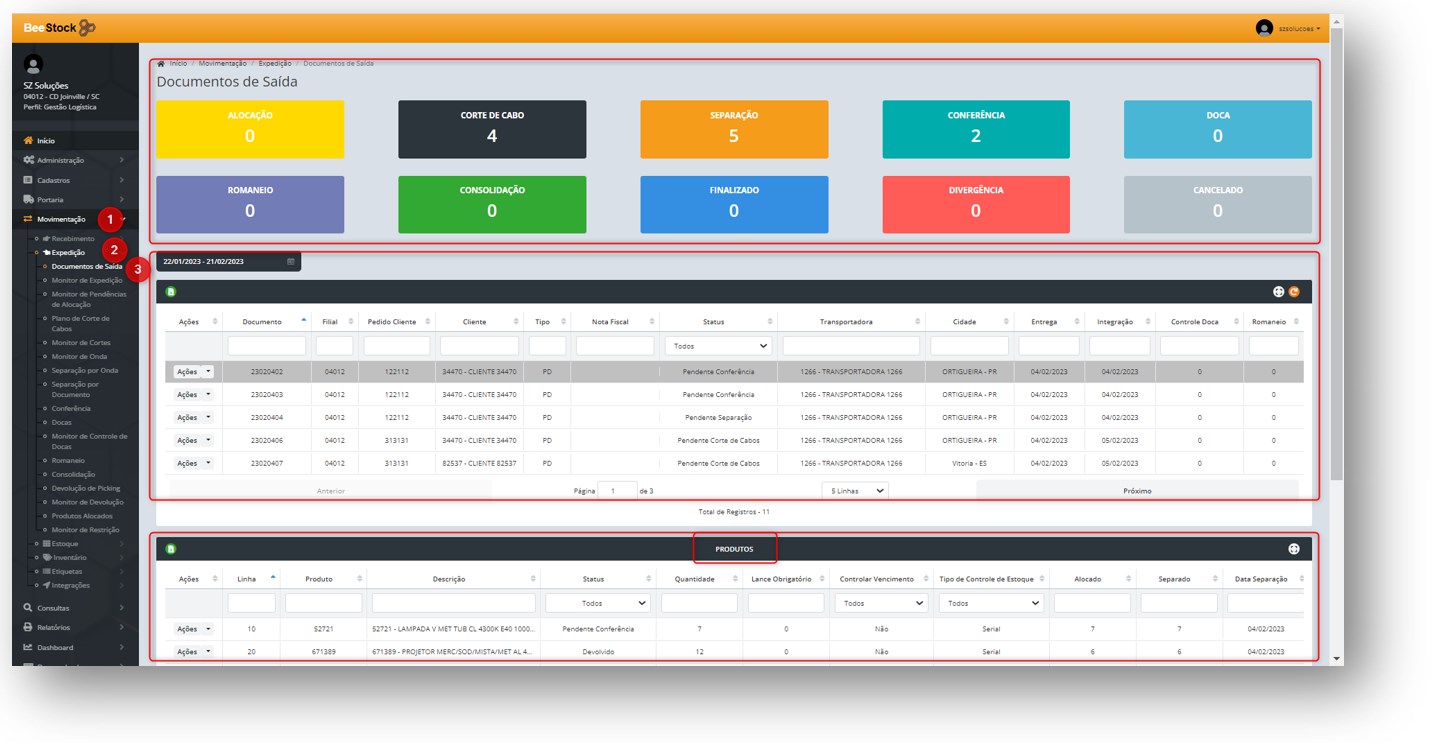

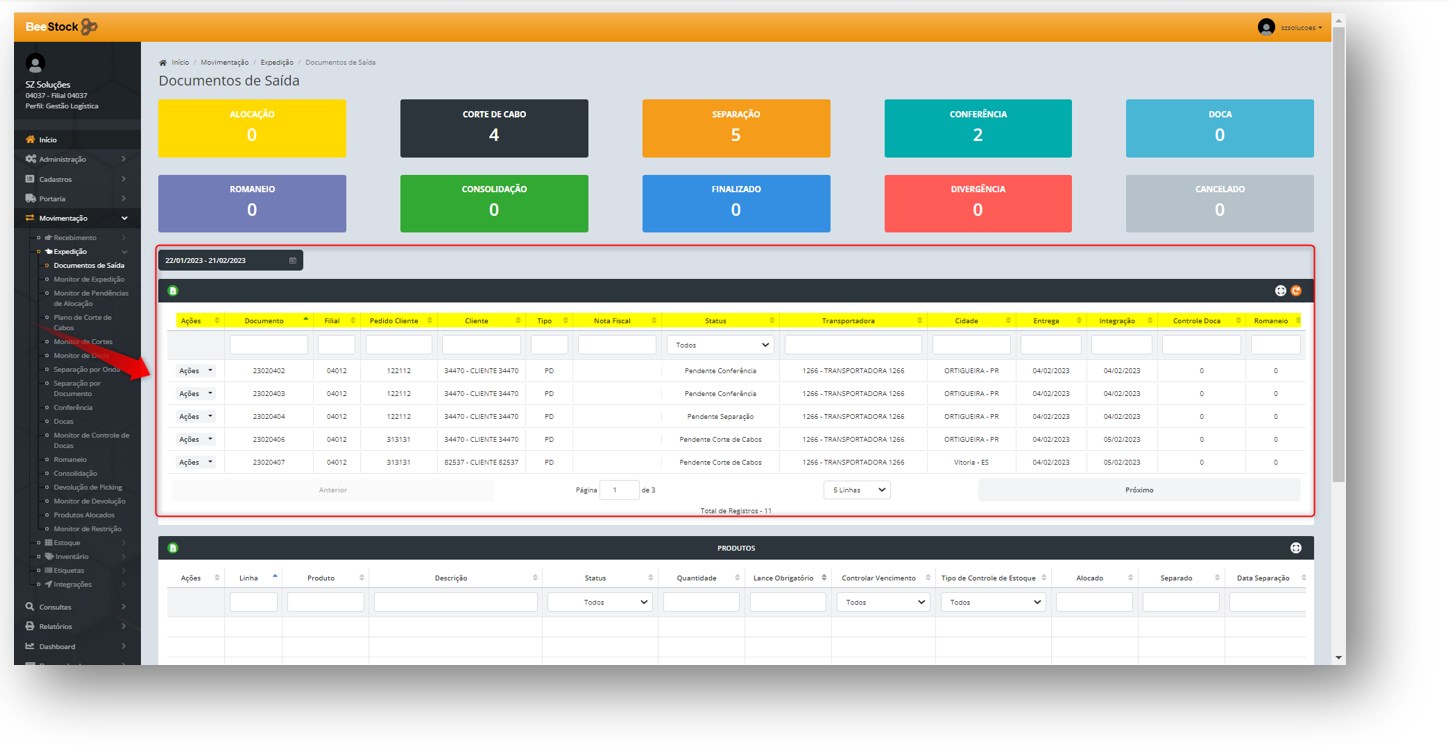

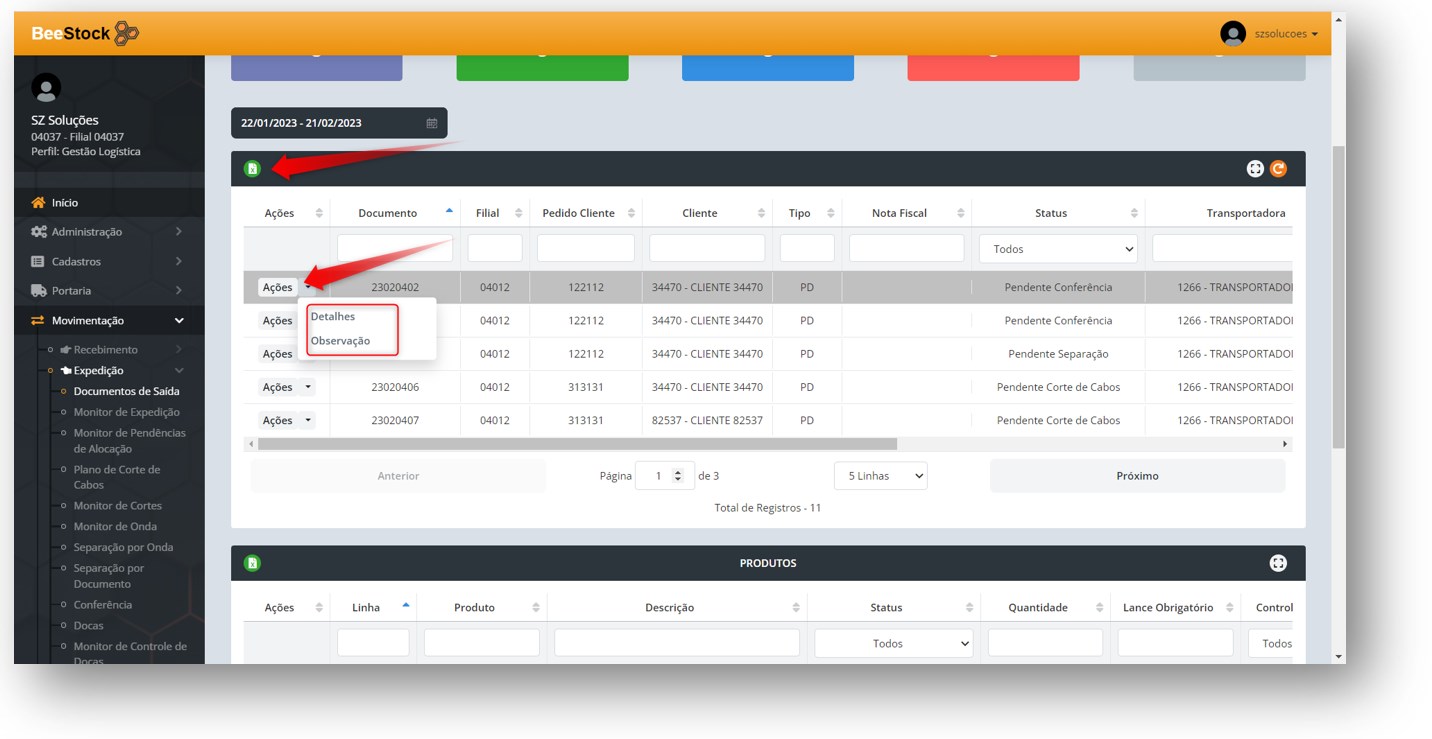

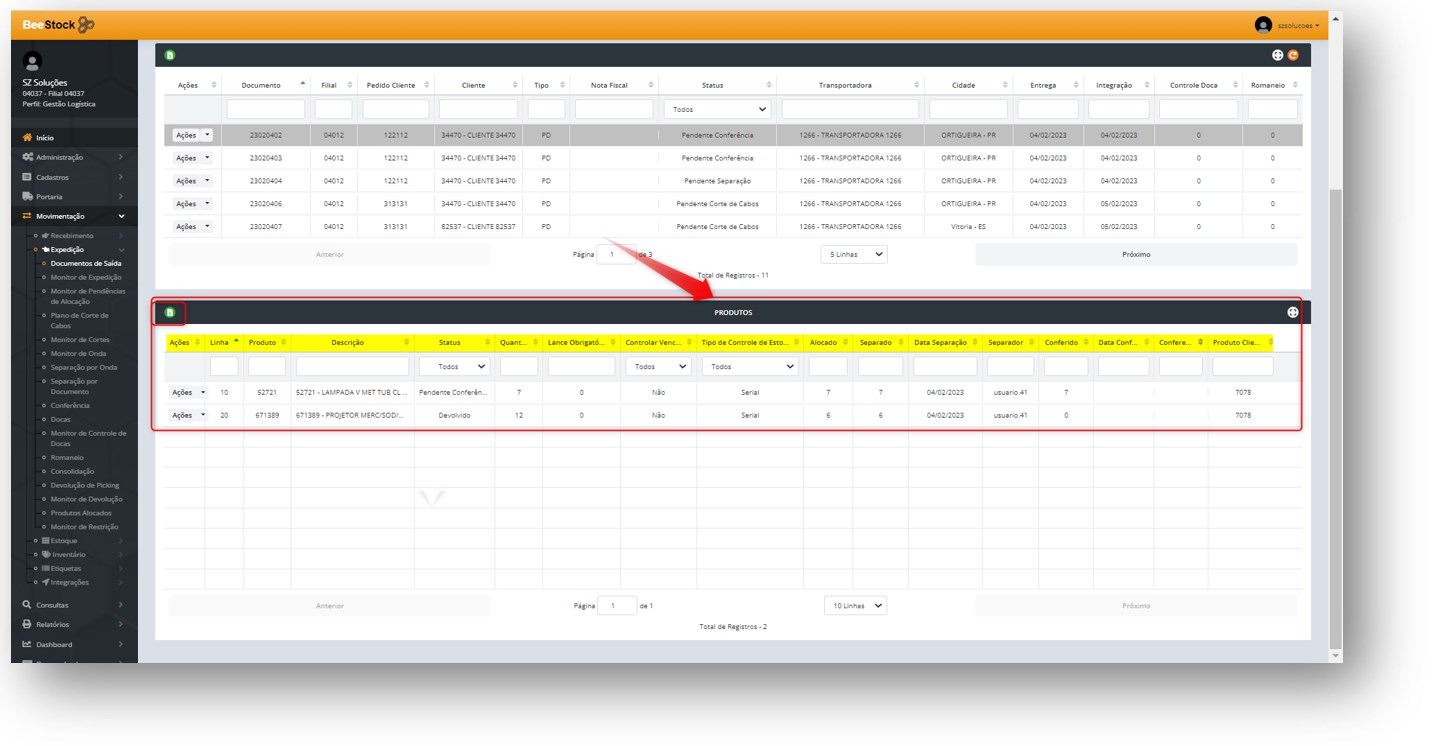

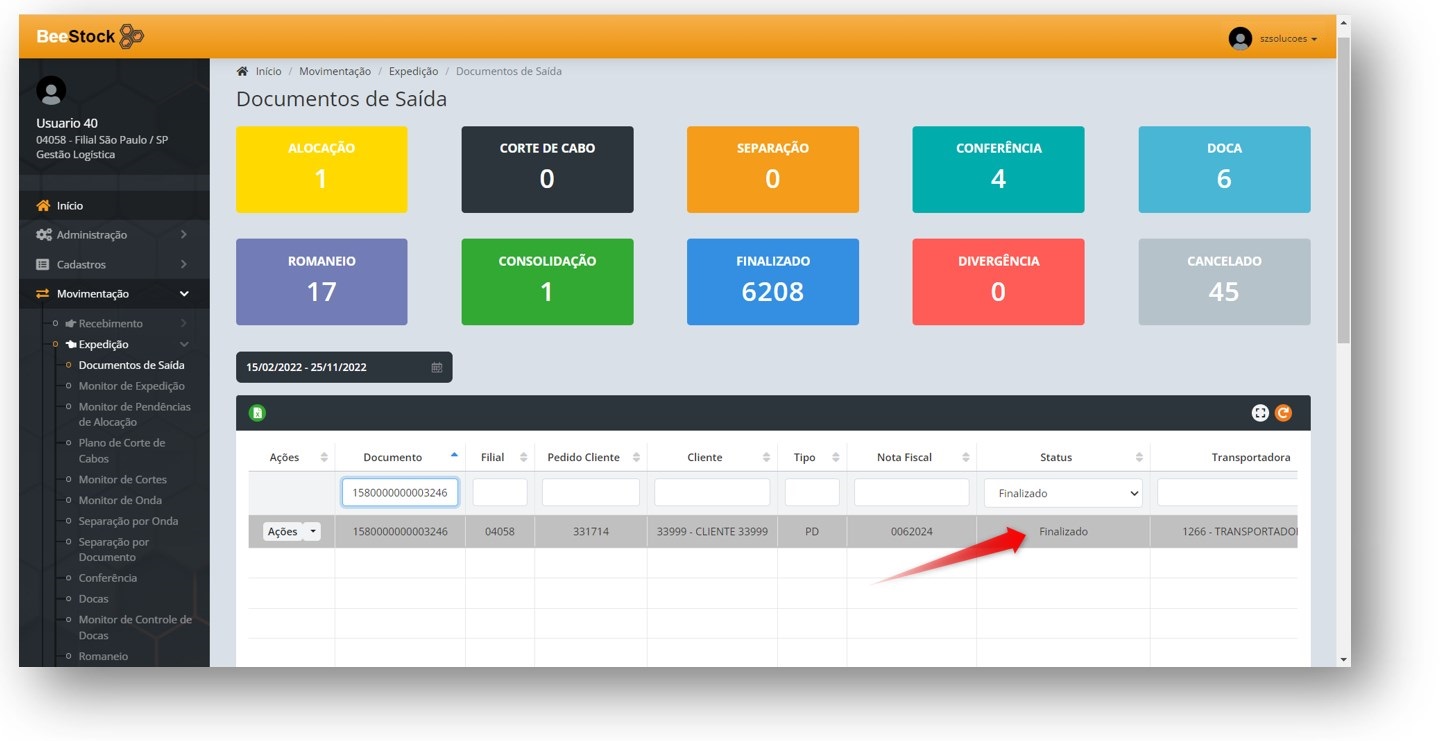

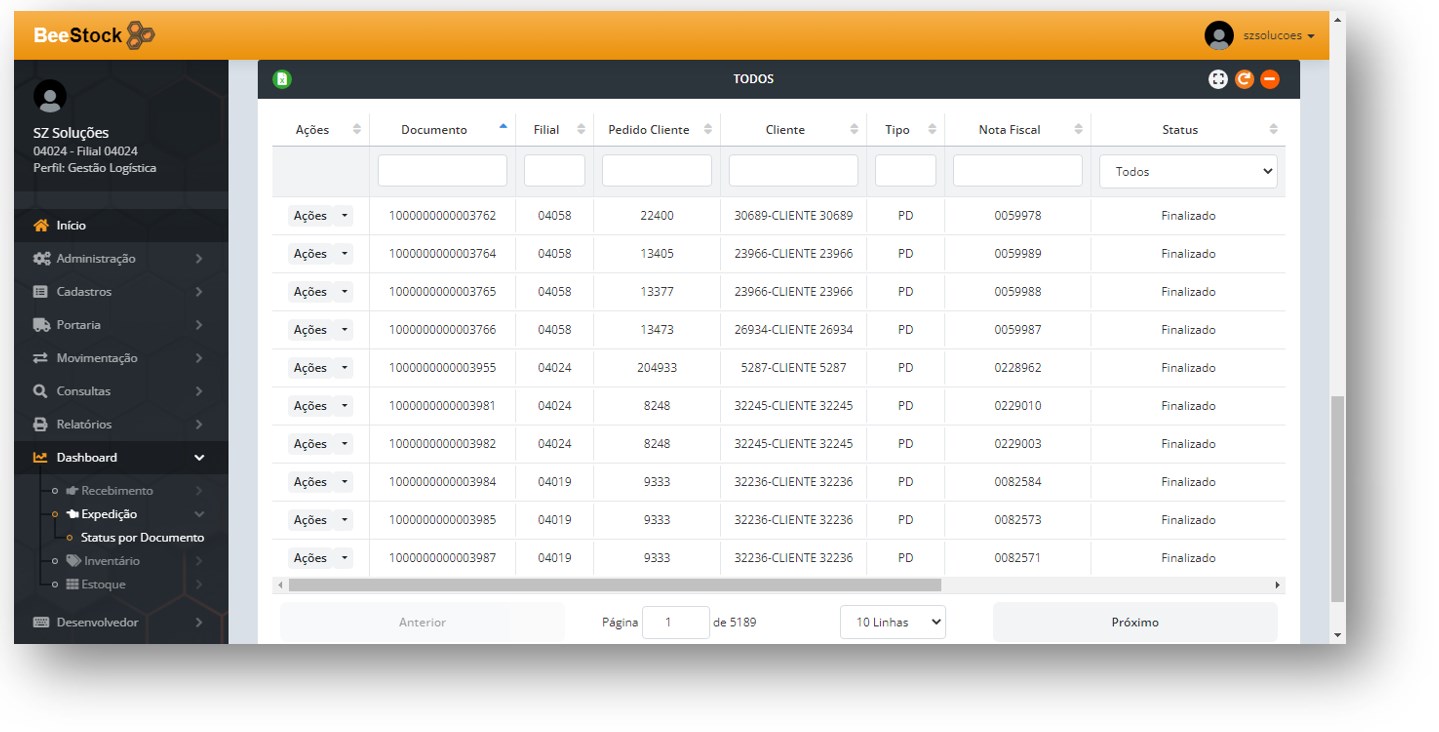

Outbound Documents

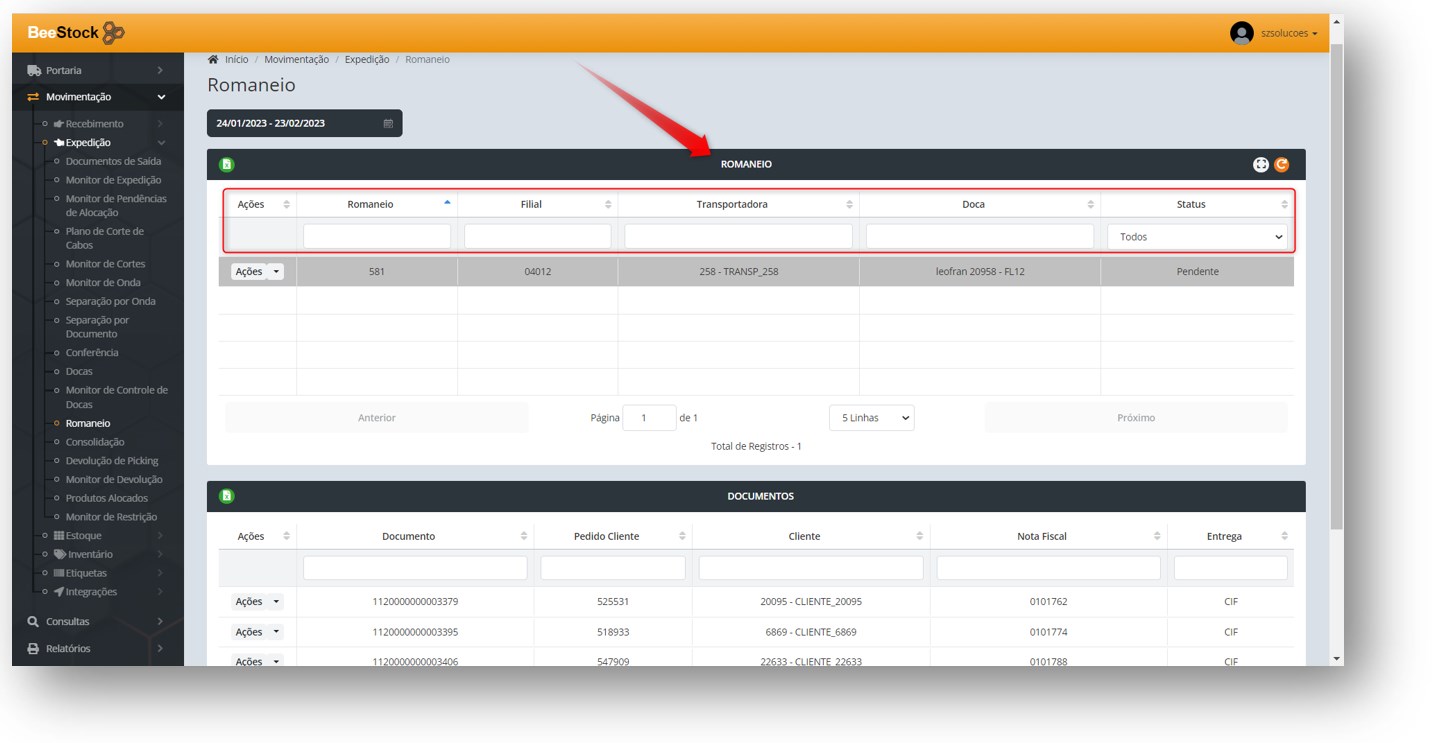

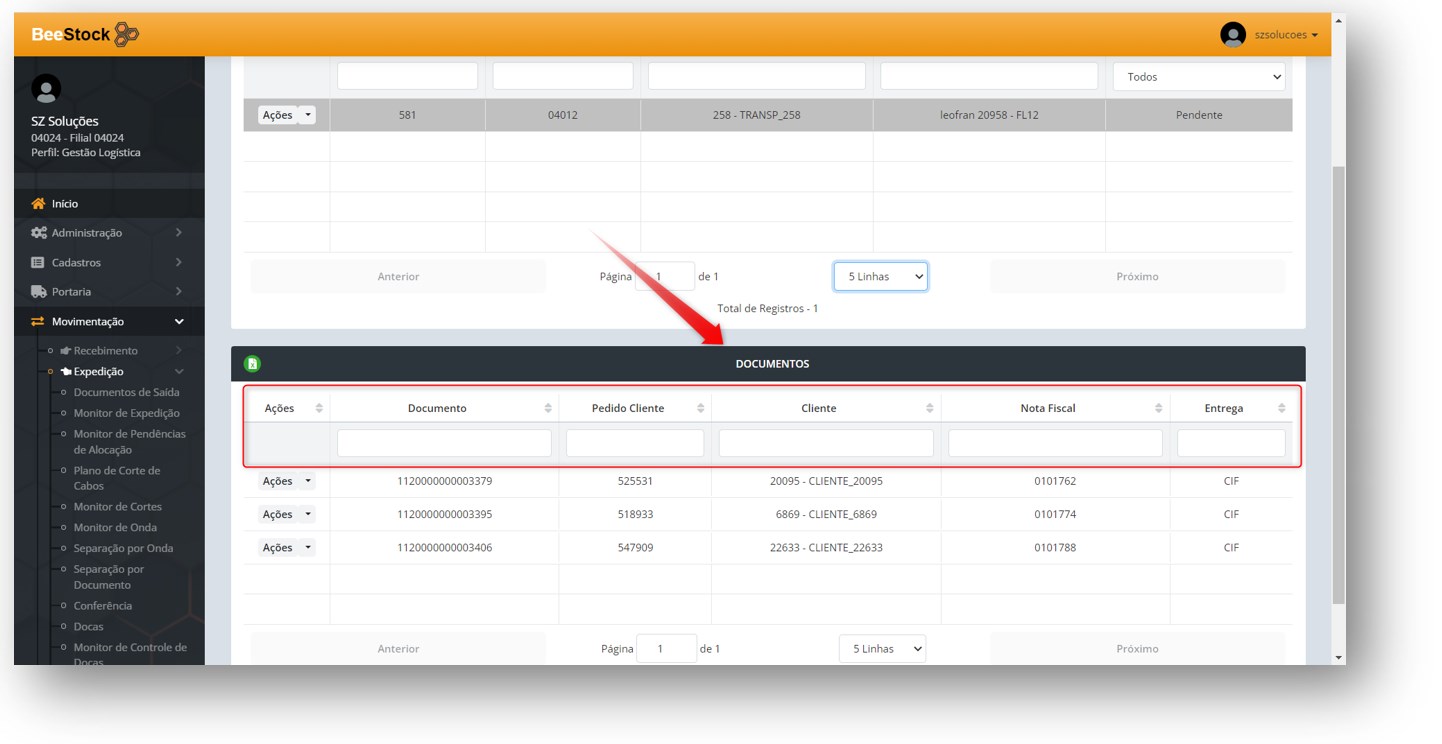

Located in Movement > Shipping > Outbound Documents, it gathers all outbound documents, regardless of their status in shipping.

An overview is presented at the top.

When selecting a document in the CENTRAL grid, the related products will be displayed in the PRODUCTS grid.

In the central grid, all documents for the period selected in the date range are presented, which can be filtered as needed.

Document

Branch

Customer Order

Customer

Type

Invoice

Status

Carrier

City

Delivery

Integration

Dock Control

Packing List

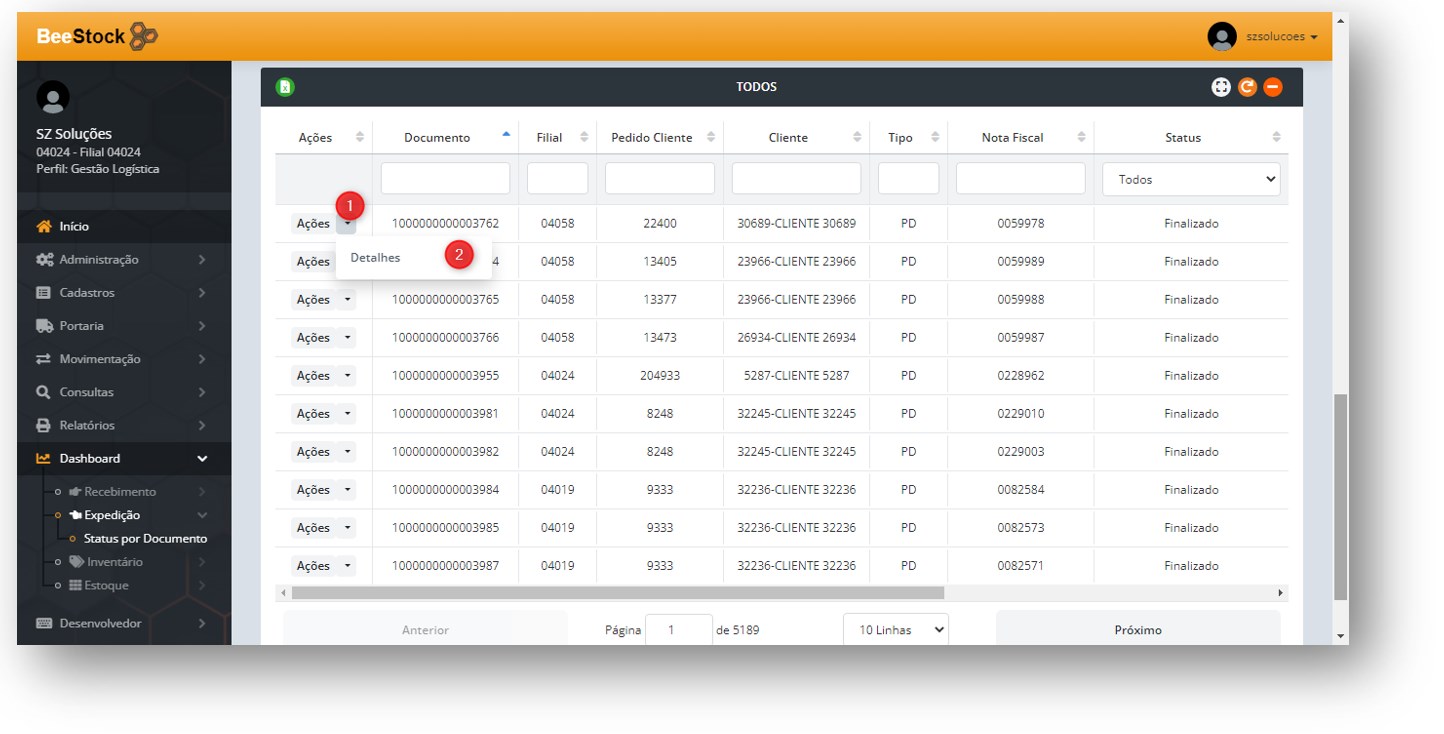

Still in the document view, the user has the option to export the records directly to an Excel spreadsheet, or in Actions, detail and view the observations of a selected document.

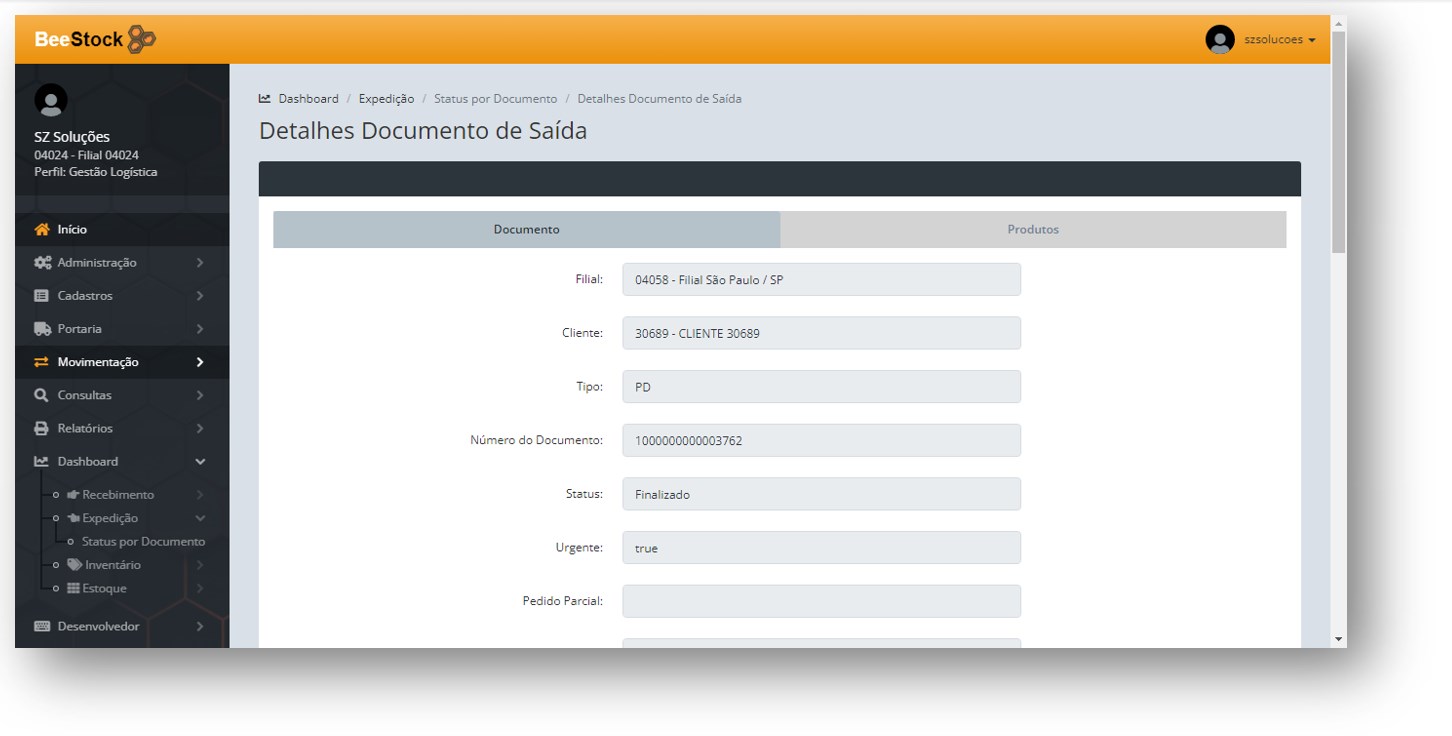

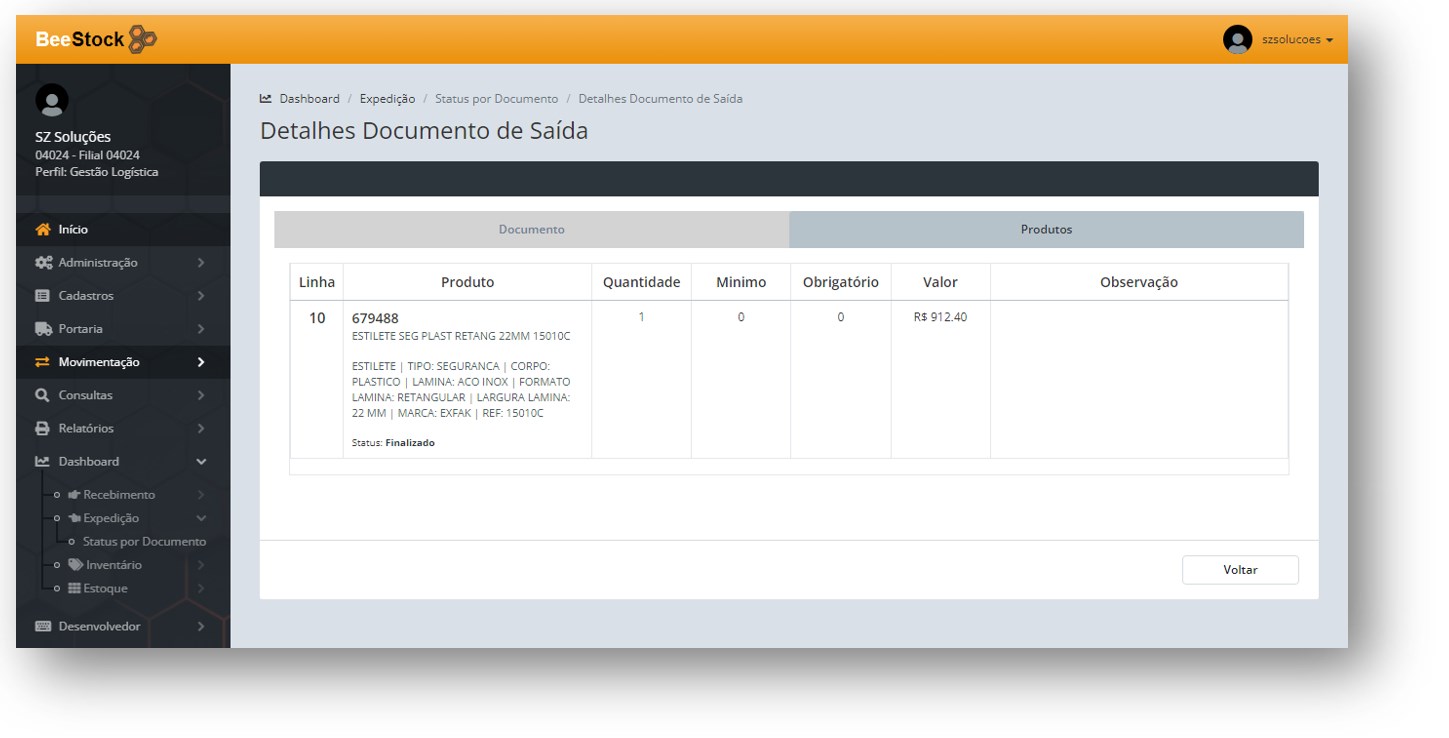

When selecting a document, the user will have the information of the products related to that document in Products at the bottom of the screen.

As in the document record, as shown in the image and description below, the user has various information about the products in Products, and can also use them to filter the desired product, as well as export the product records to an Excel spreadsheet.

Line

Product

Description

Status

Quantity

Required Batch

Control Expiration Date

Inventory Control Type

Allocated

Picked

Picking Dates

Picker

Checked

Check Date

Checker

Customer Product

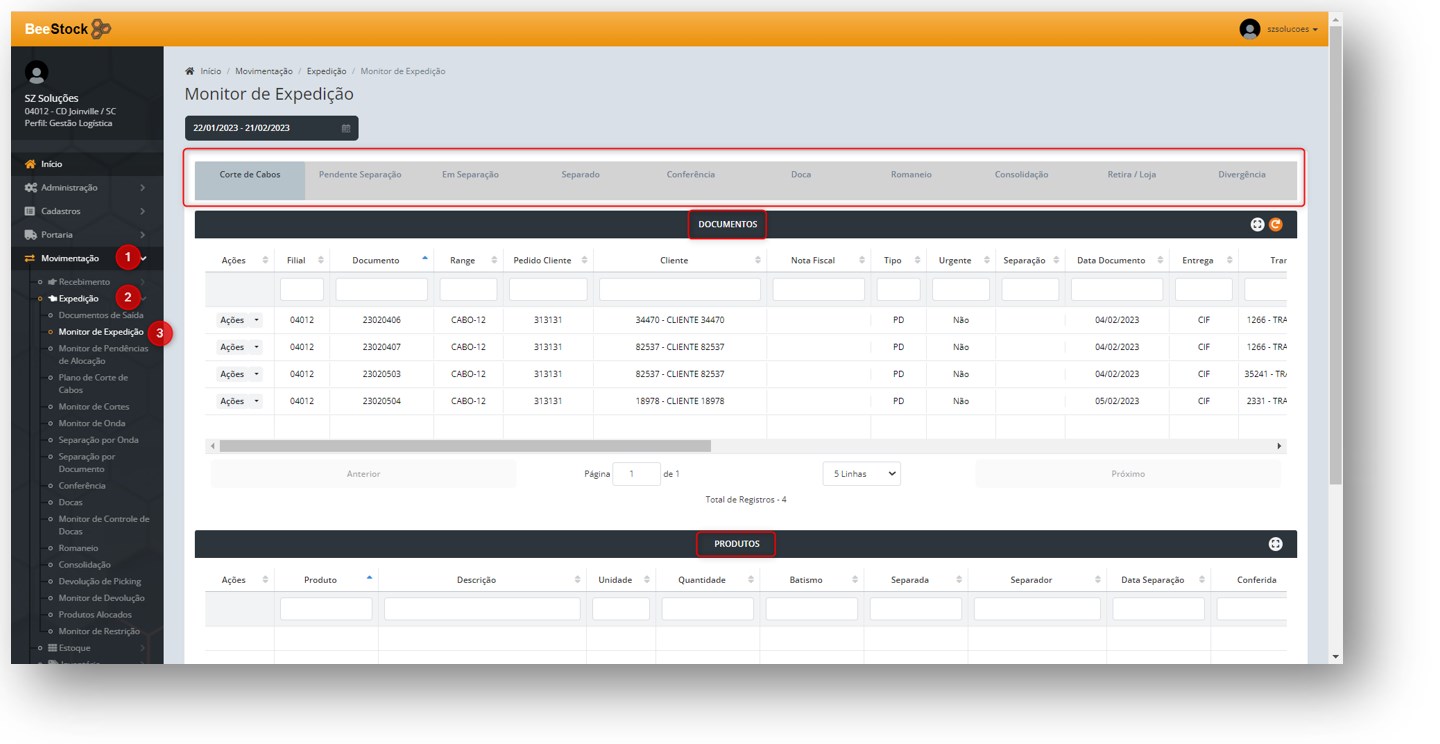

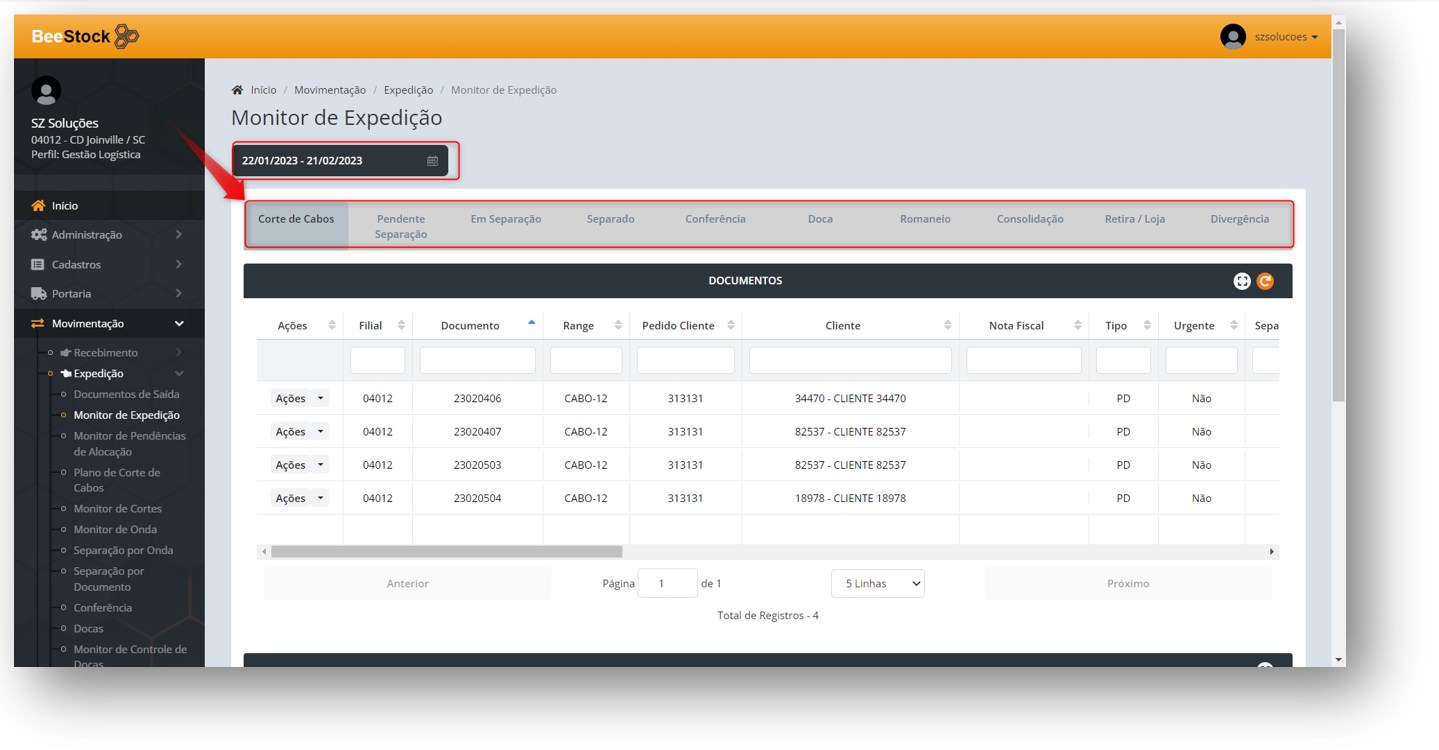

Shipping Monitor

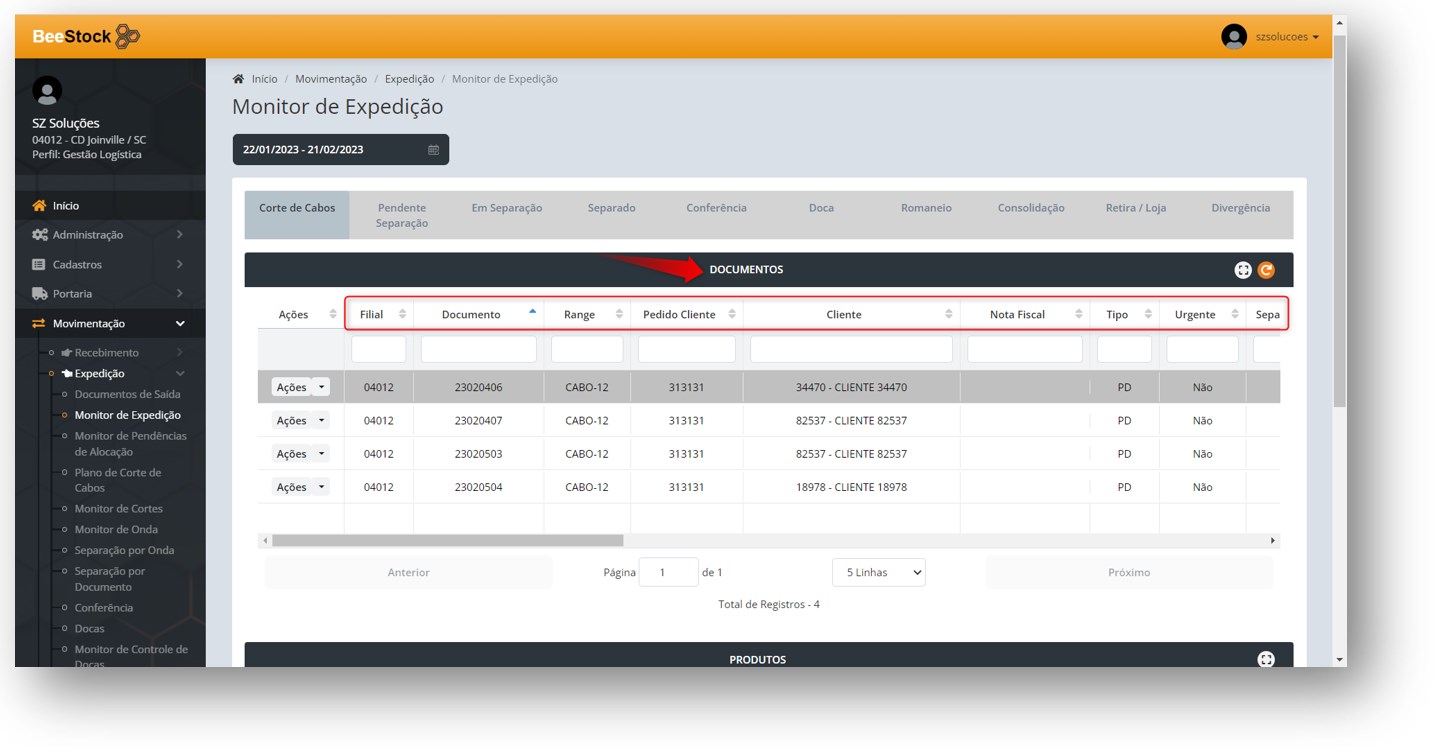

Located in Movement > Shipping > Shipping Monitor, in Documents all pending documents in the shipping process are gathered, separated by tabs, according to their status in shipping.

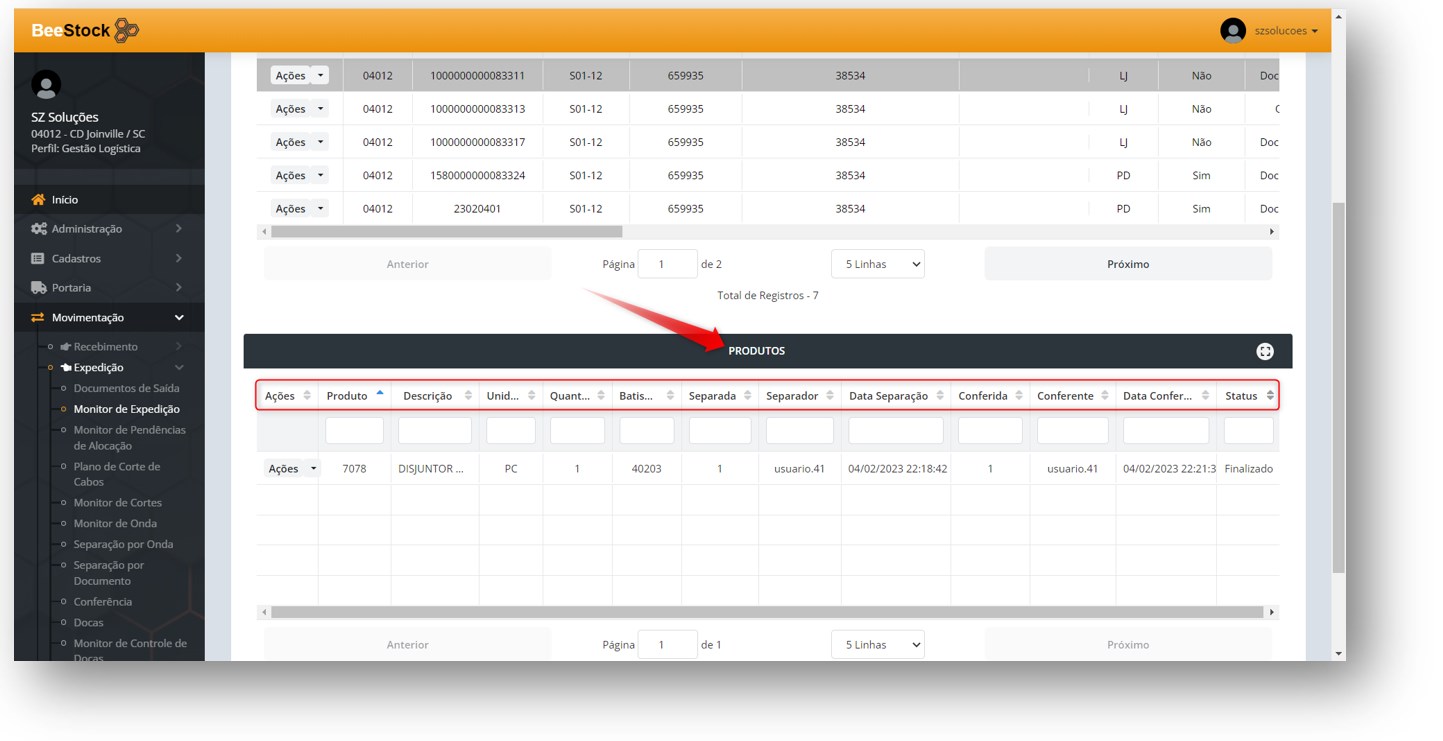

In Products, at the bottom of the page, the user has the view of the products of the selected document, linked to the information related to the stage of the shipping process in which the document is.

By filtering a period between desired dates, the user views the pending documents in each tab/status of the shipping process.

Description of the document tabs/status:

Cable Cutting

Pending Picking

In Picking

Picked

Checking

Dock

Packing List

Consolidation

Withdrawal/Store

Discrepancy

From the selection of the desired status, the user has the view of the following information related to the document:

Branch

Document

Range

Customer Order

Customer

Invoice

Type

Urgent

Picking

Document Date

Delivery

Carrier

Picked

Picking Date

Checker

Check Date

Consolidated

Consolidation Date

Salesperson

Observation

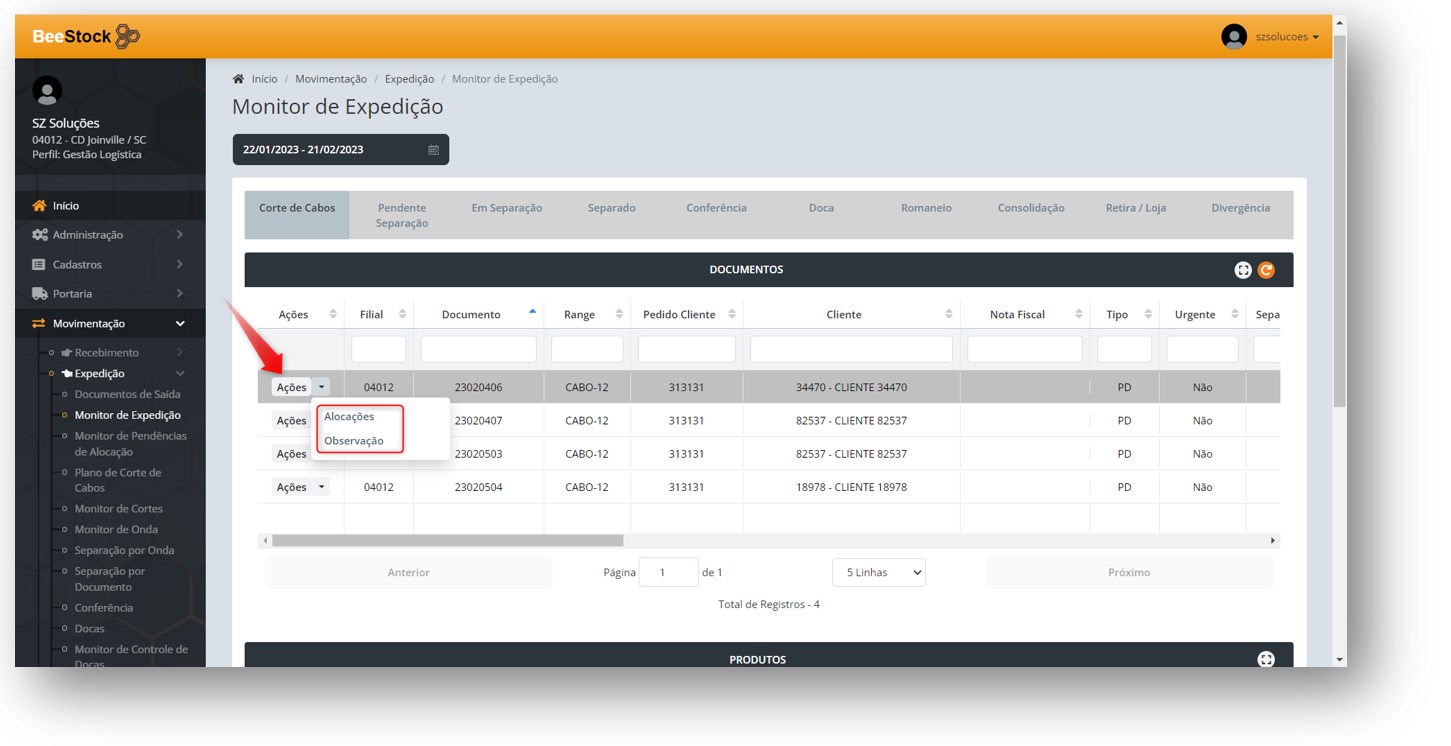

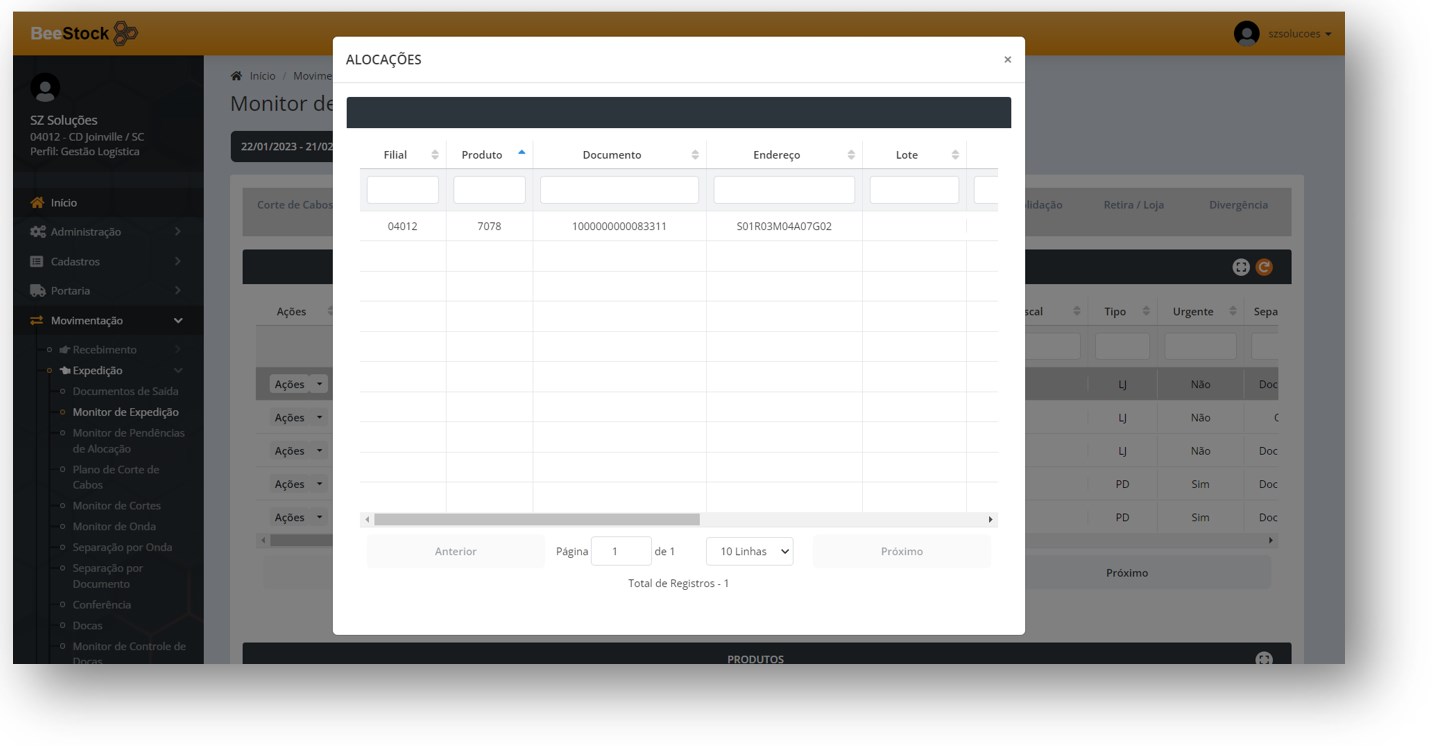

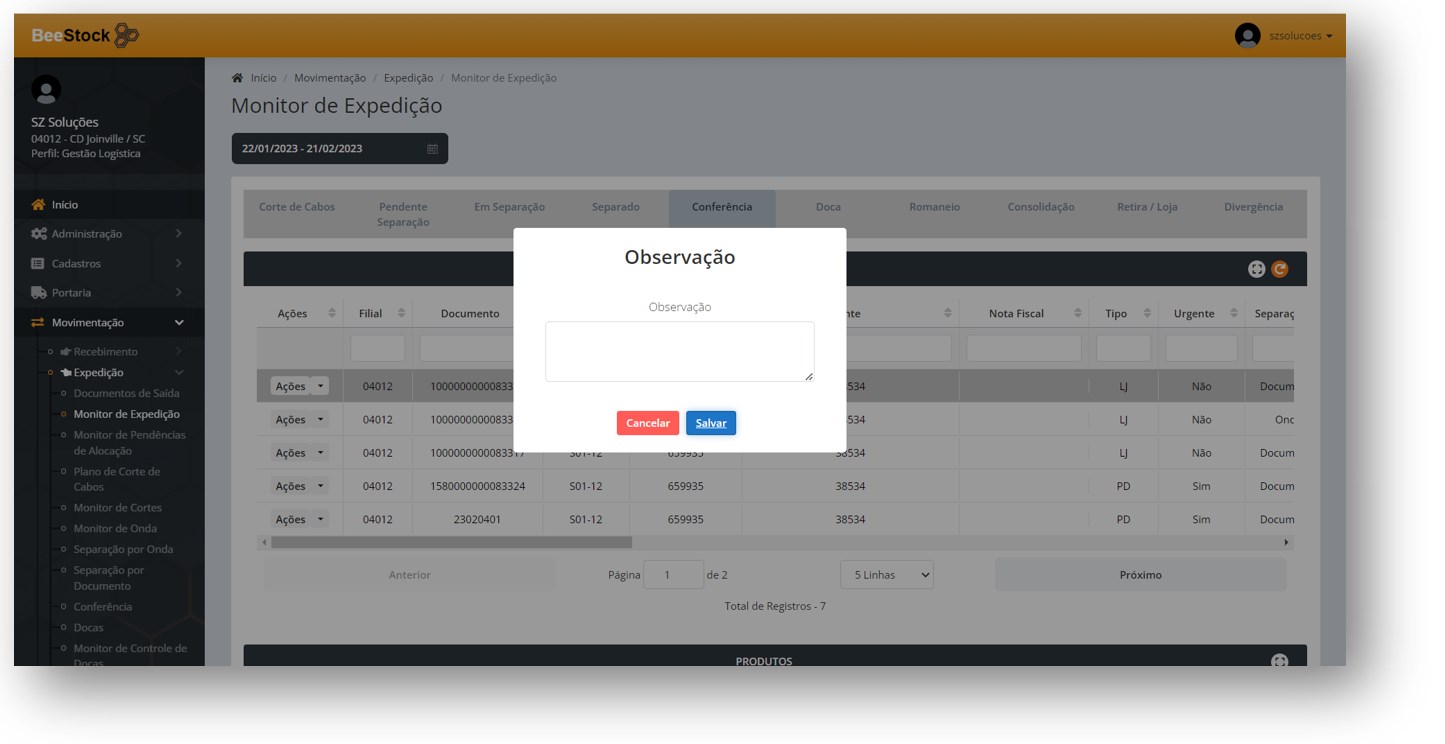

In the Documents grid, on the Cable Cutting tab, the user has the possibility to view the allocation of the product in stock in Actions > Allocations, and/or enter an observation on the document.

The screen below will be displayed:

Document observation screen when clicking on Actions > Observation.

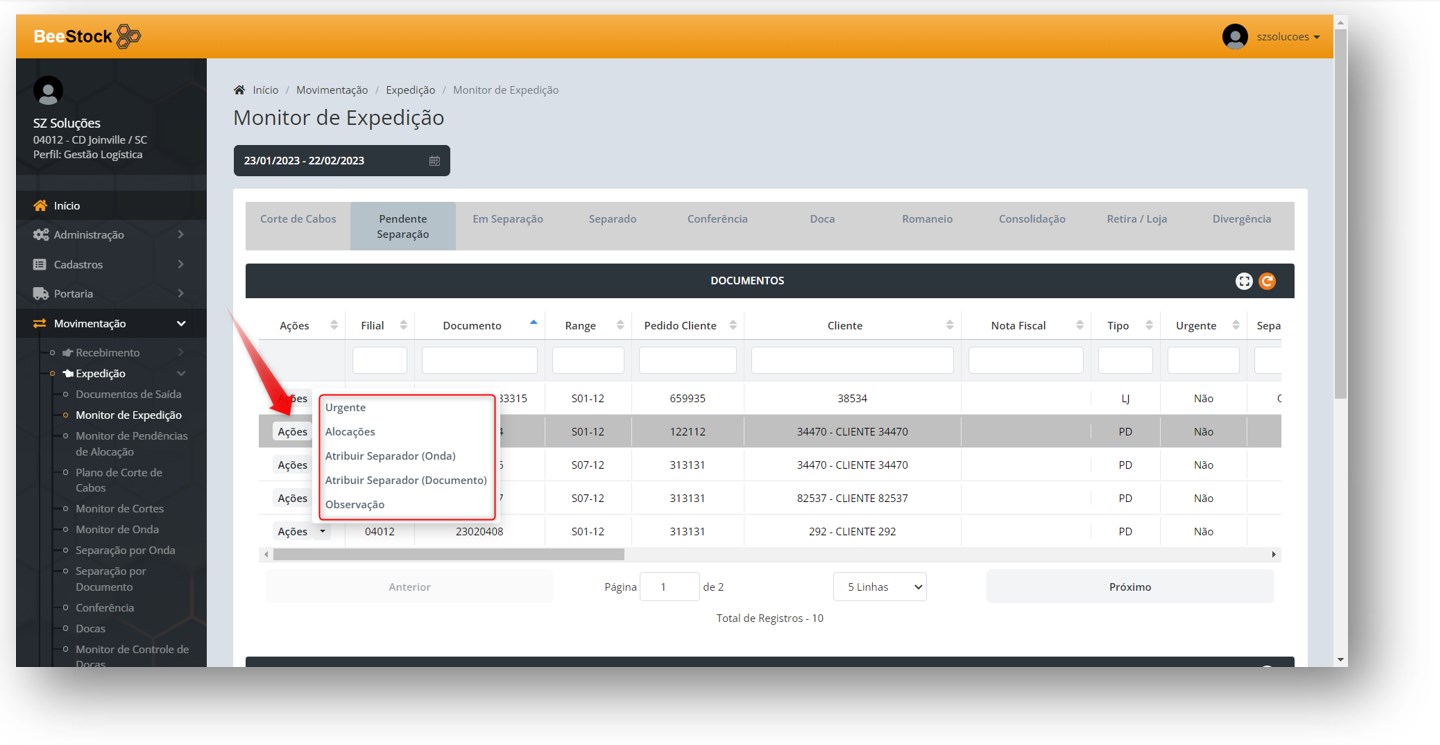

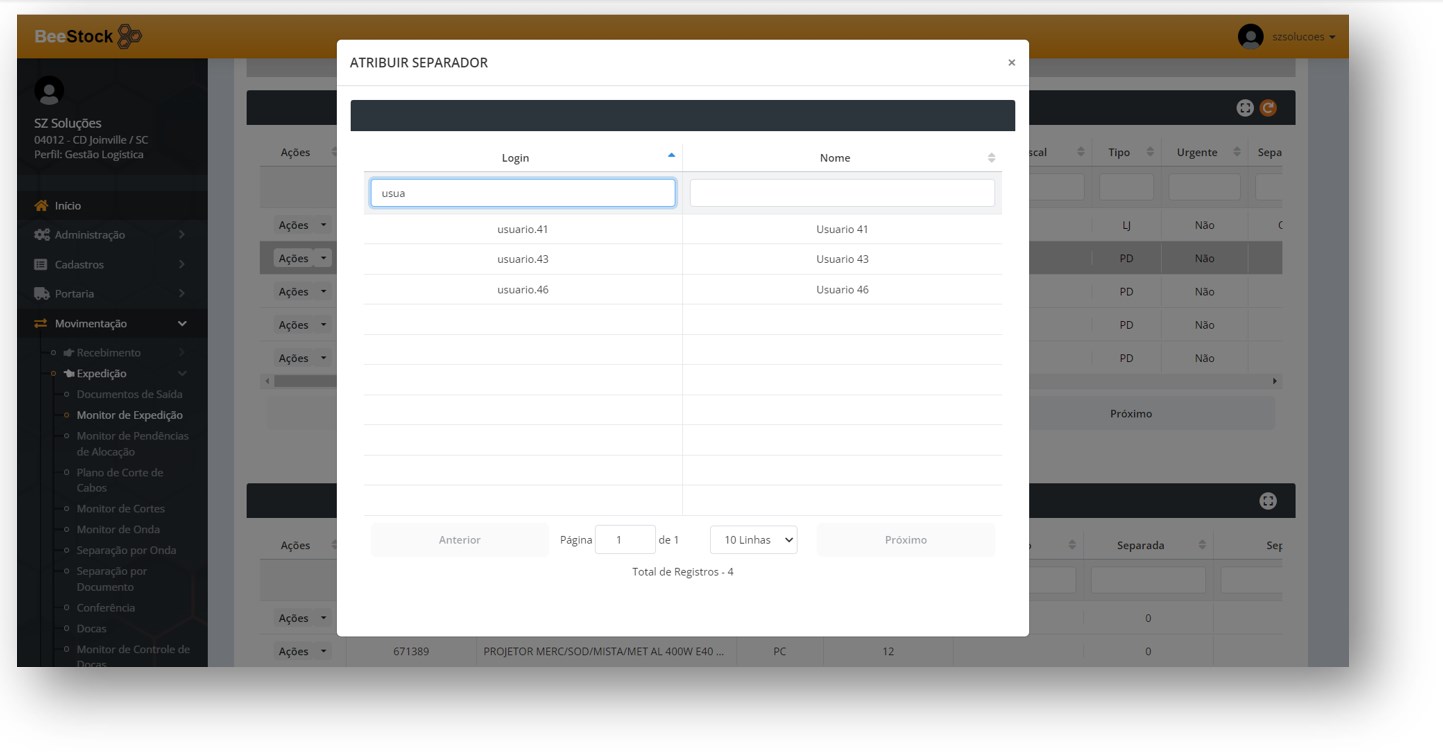

Still in the Documents grid, on the Pending Picking tab, by clicking on Actions, the user has the following functions available:

Urgent

Allocations

Assign Picker by Wave

Assign Picker by Document

Observations

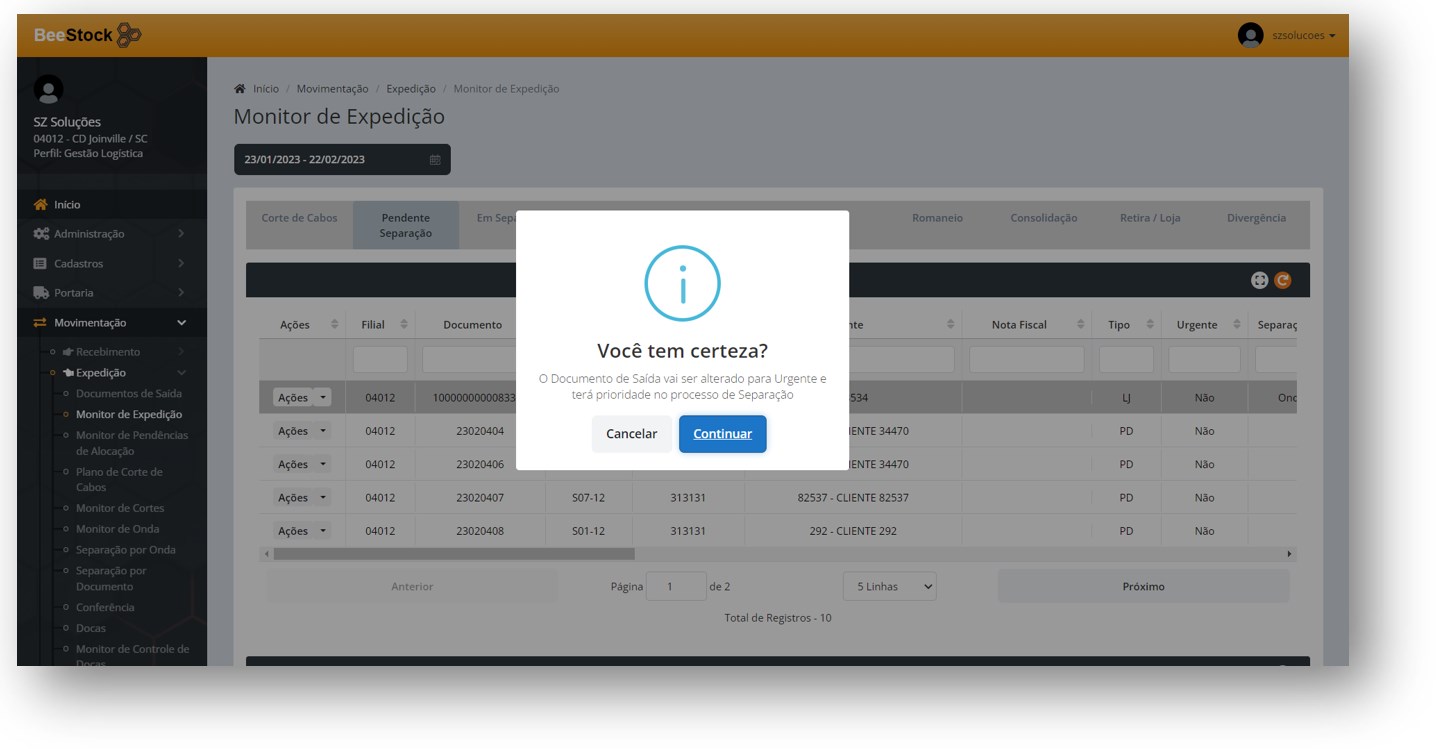

Urgent – When selecting the document as urgent, it is prioritized in the picking process, so that when searching for documents to start the shipping process, the user will first have access to the prioritized document.

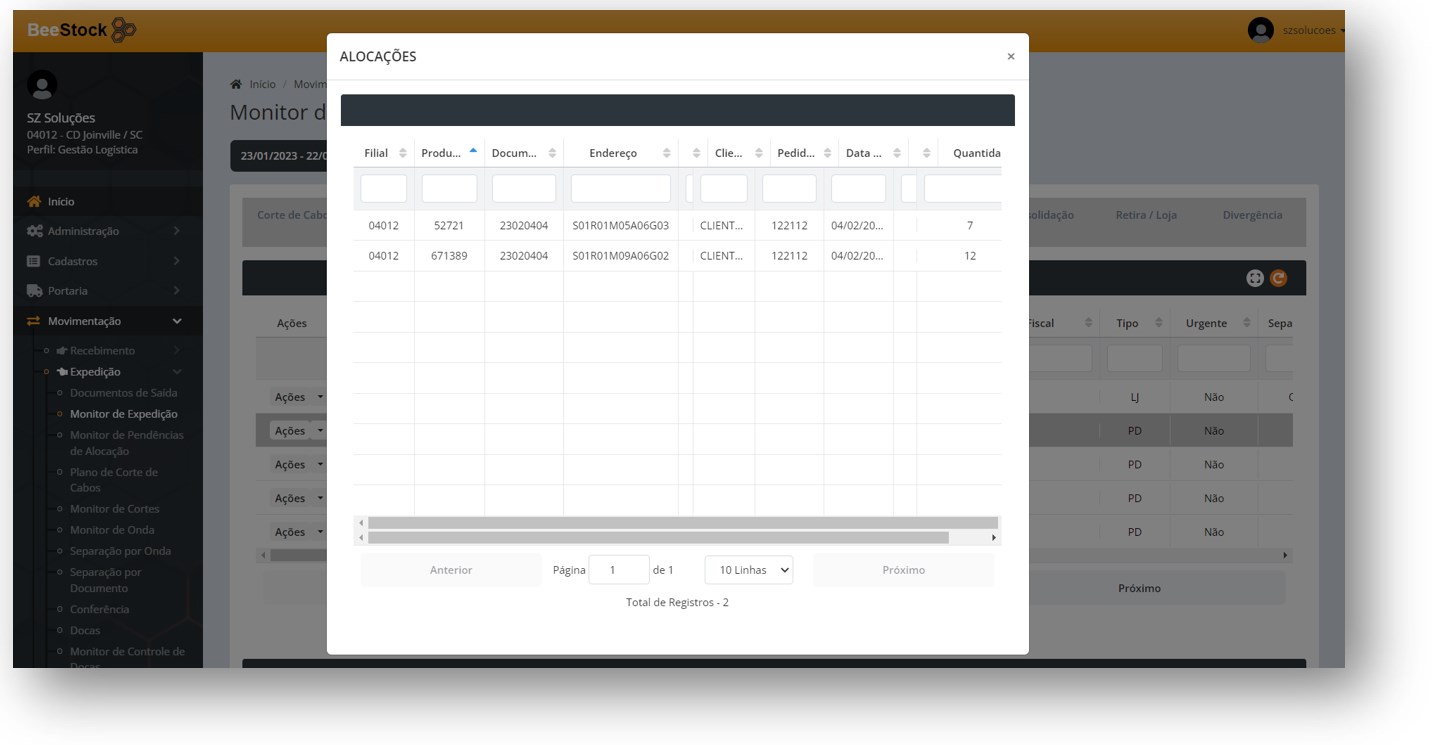

Allocations – Function that allows the user to verify the allocation of the products of the document in stock.

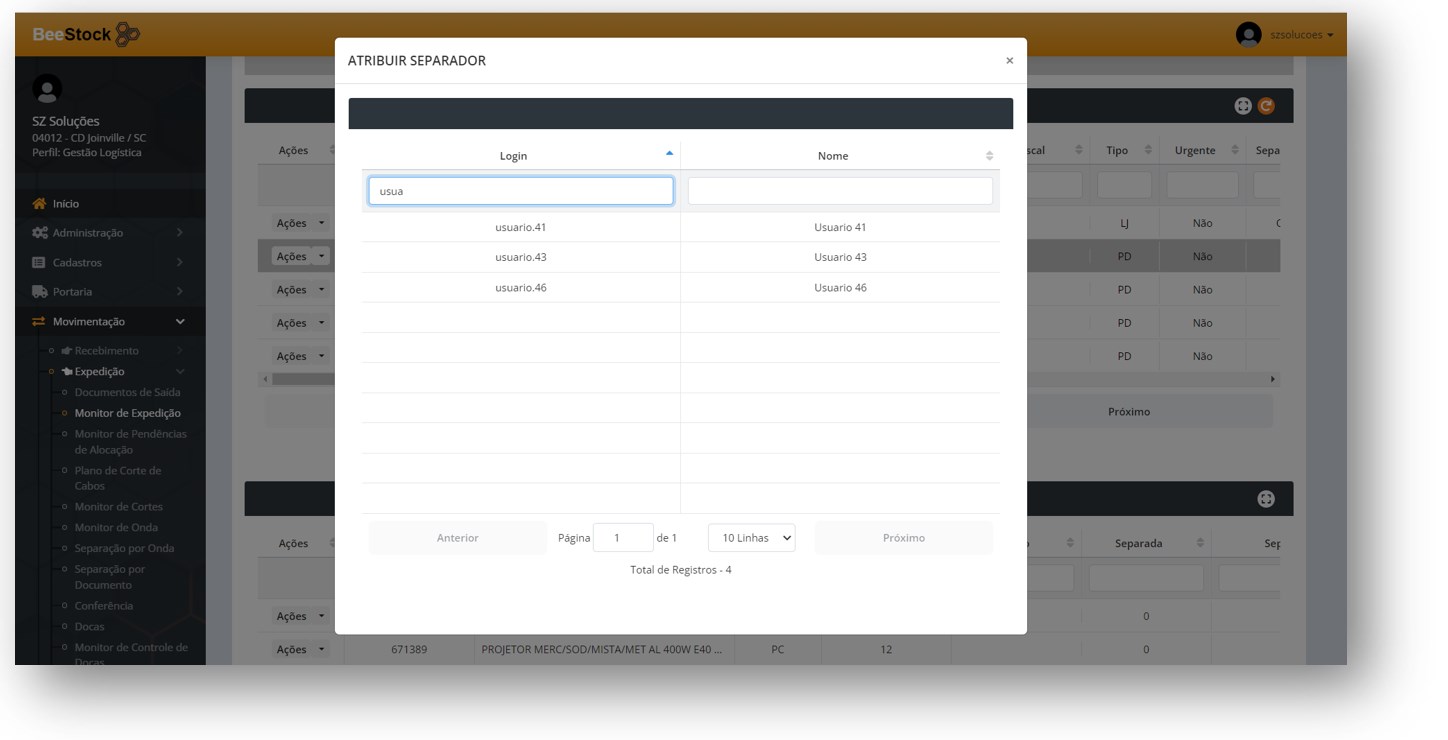

Assign Picker (Wave) – Assigns the sequence (product line) of the document to a specific user, so that only he will have access to this sequence in picking (in the same function it is possible to change the initially assigned picker, if necessary).

Assign Picker (Document) – Assigns the document to a specific user, so that only he will have access to pick the entire document (in the same function it is possible to change the initially assigned picker, if necessary).

Observation – Allows the insertion of an observation on the document, which will be presented to the picker when starting the picking.

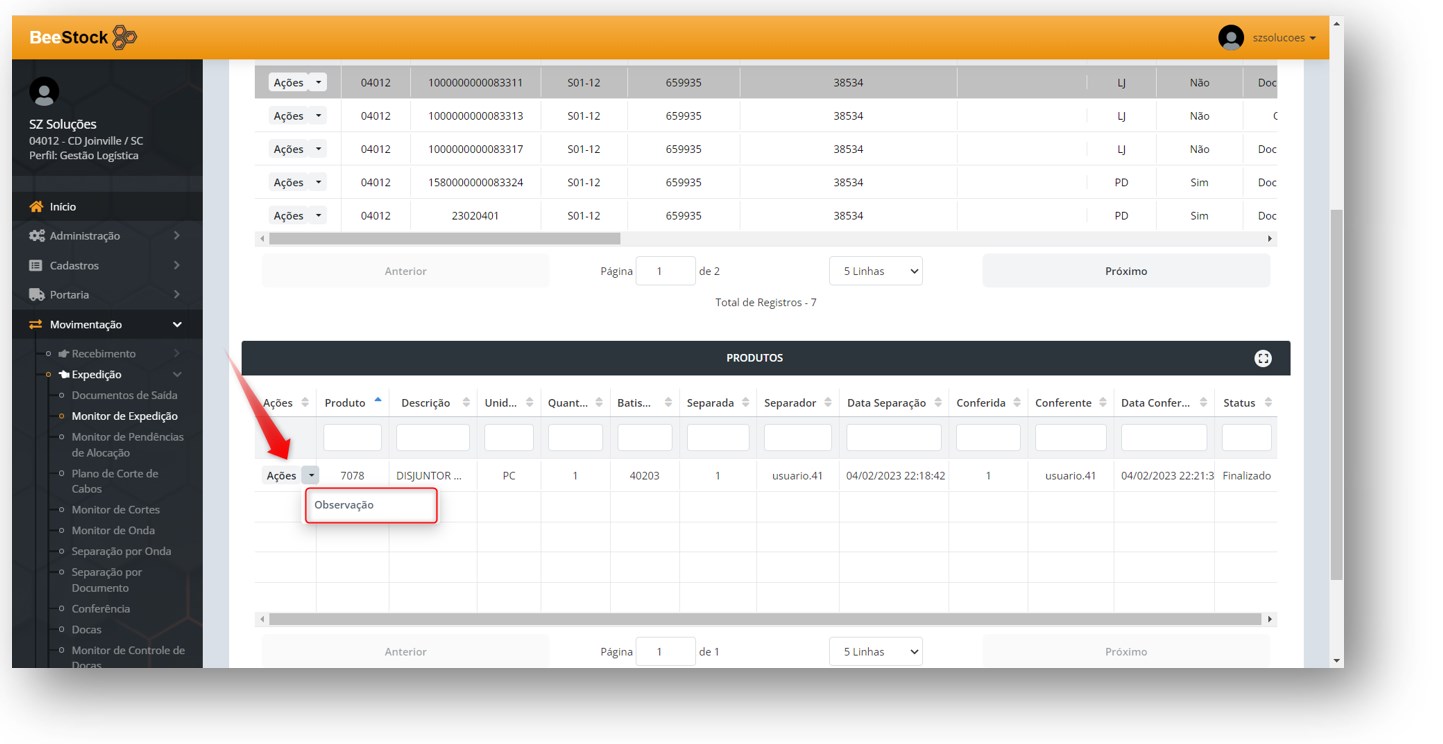

From the selection of a document, at the bottom of the screen in Products, the user has the view of the products linked to the document above for the range in question, with the related information according to the stage of the shipping process in which the document is.

Information related to the products according to the stage they are in the shipping process:

Product

Description

Unit of Measure

Quantity

Batch

Picked

Picker

Picking Date

Checked

Checker

Check Date

Status

Still in the product selection, as in the document selection, the user can enter an observation in Actions > Observation.

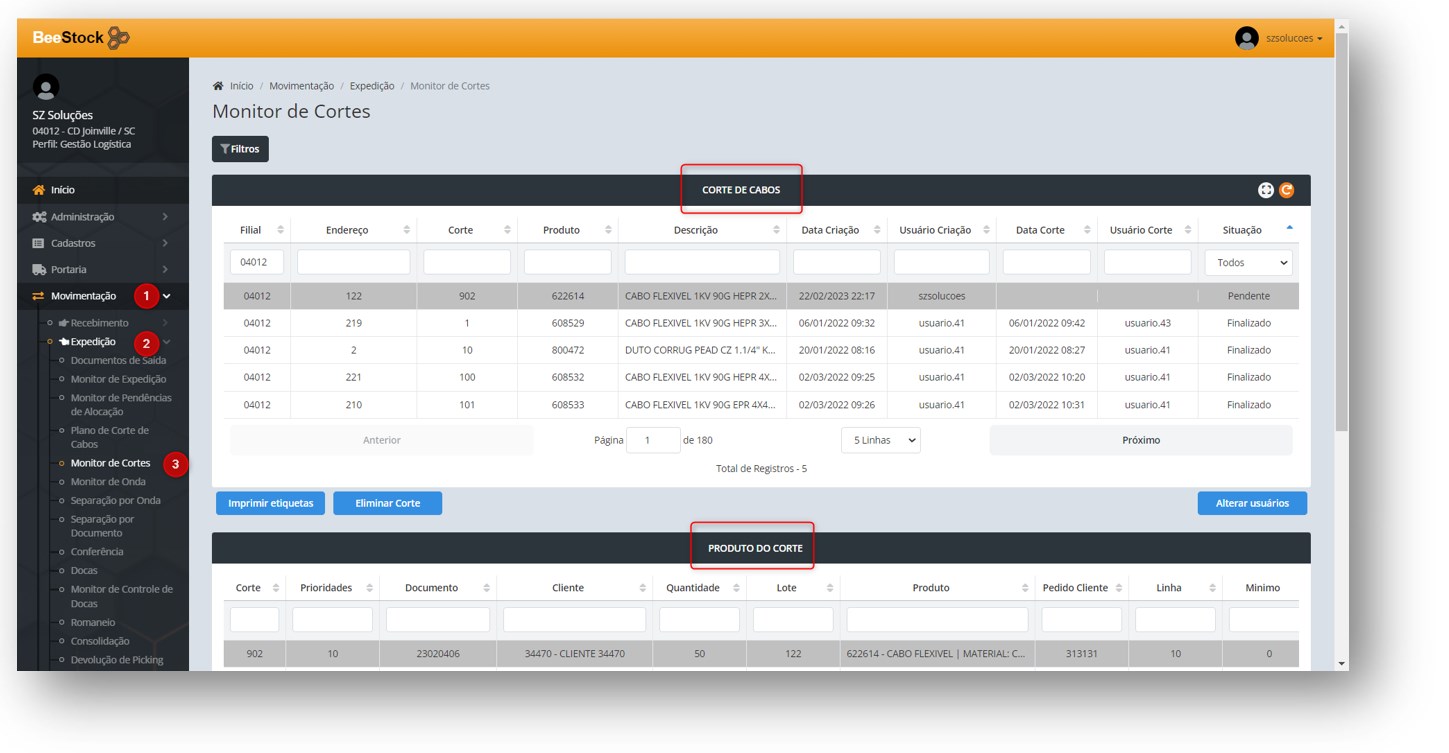

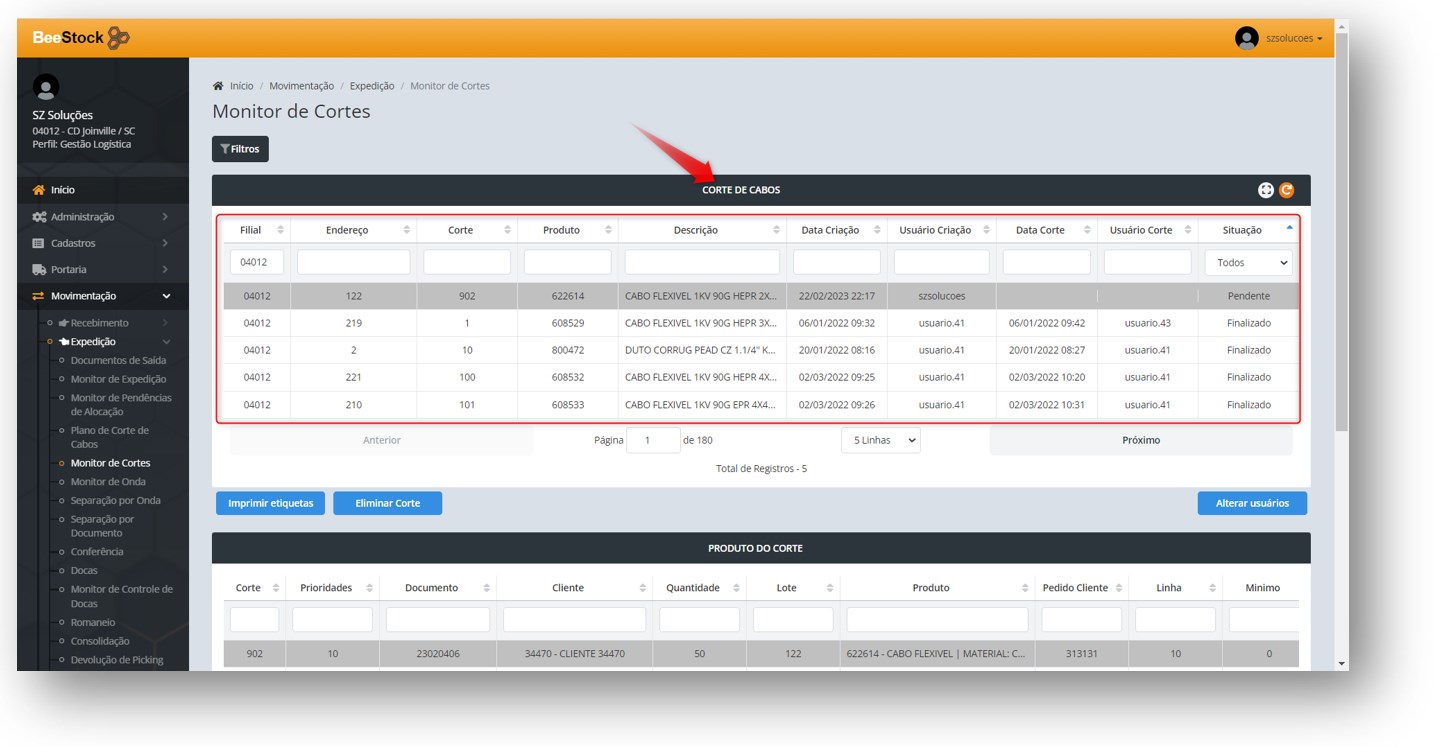

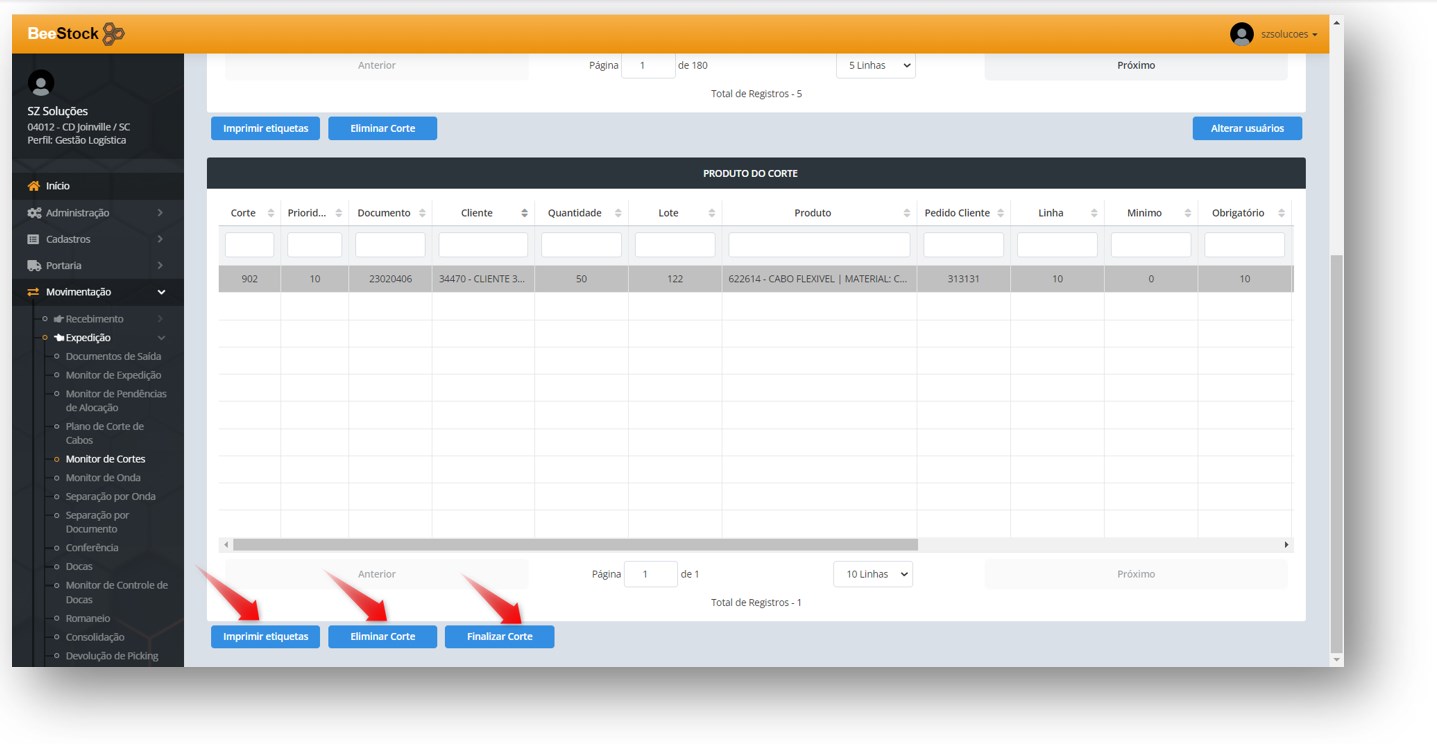

Cutting Monitor

Located in Movement > Shipping > Cutting Monitor, it has the function of performing the cable cutting in the system so that it is physically carried out or assigning the cutting to a user to be finalized via collector.

The screen is divided into two frames:

Cable Cutting

Cutting Products

Cable Cutting tab – where all the cuts already finished, canceled, and pending are presented.

From this screen, the user will have the following information:

Branch

Address (Address where the product is allocated)

Cut (Cutting sequence)

Product

Creation Date (Date the cutting plan was created)

Creation User (User responsible for the cutting plan)

Cutting Date (Date the cutting was performed)

Cutting User (User who performed the cutting)

Status (Pending, Finished, or Canceled)

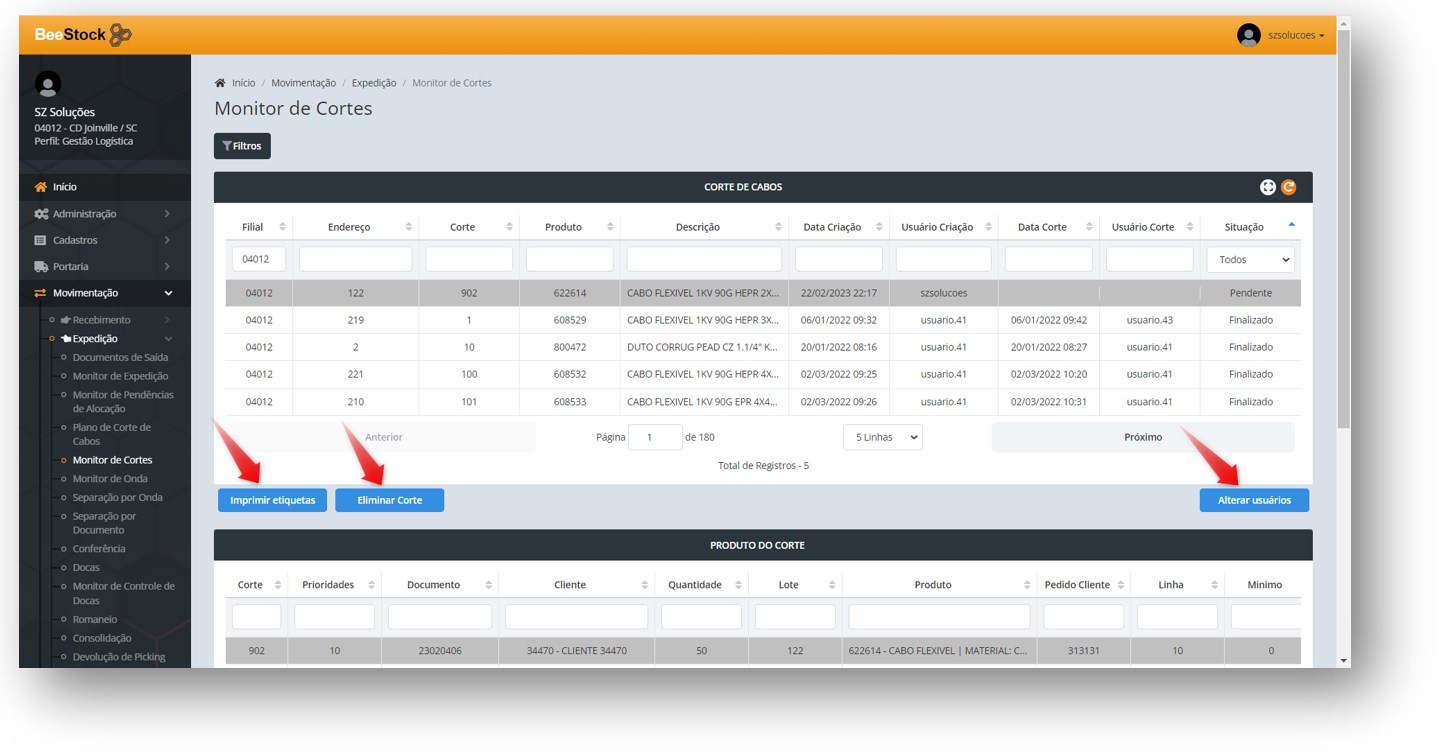

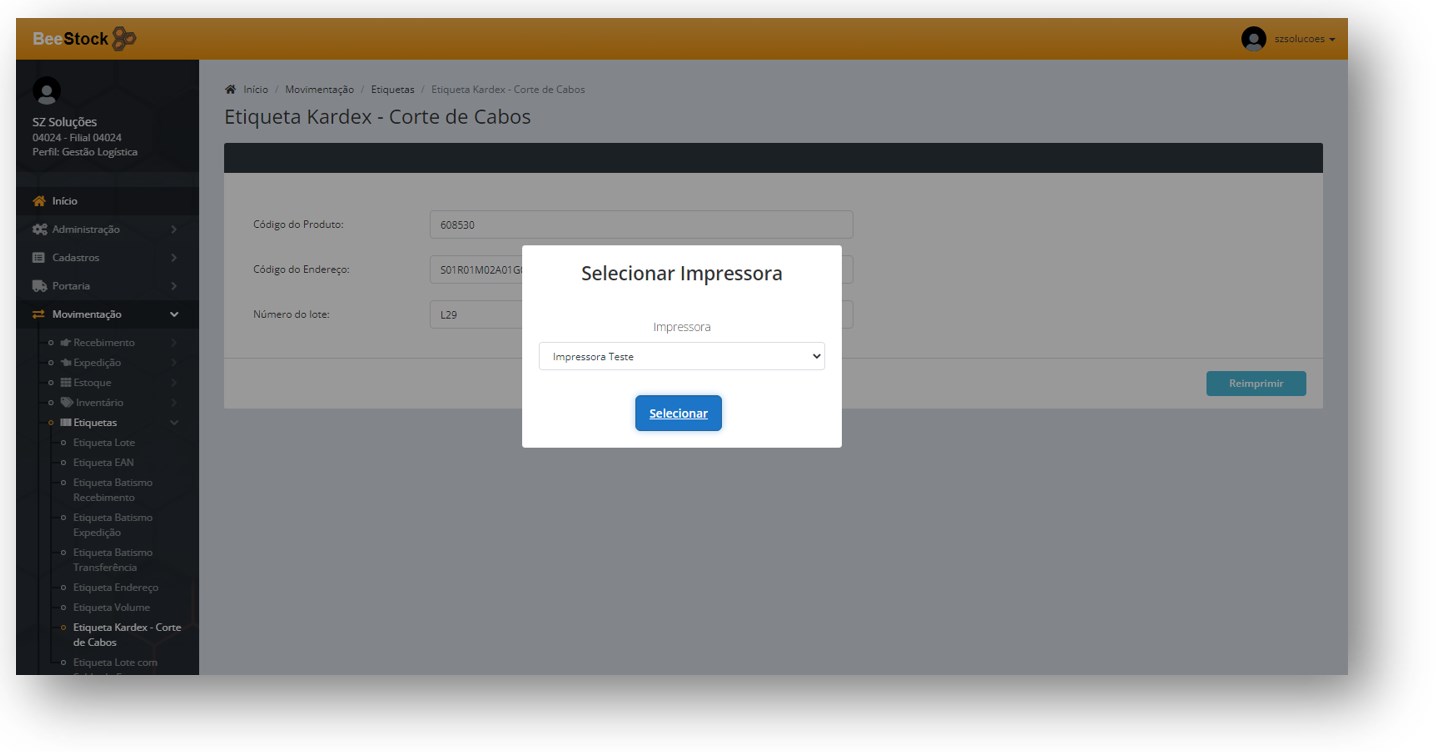

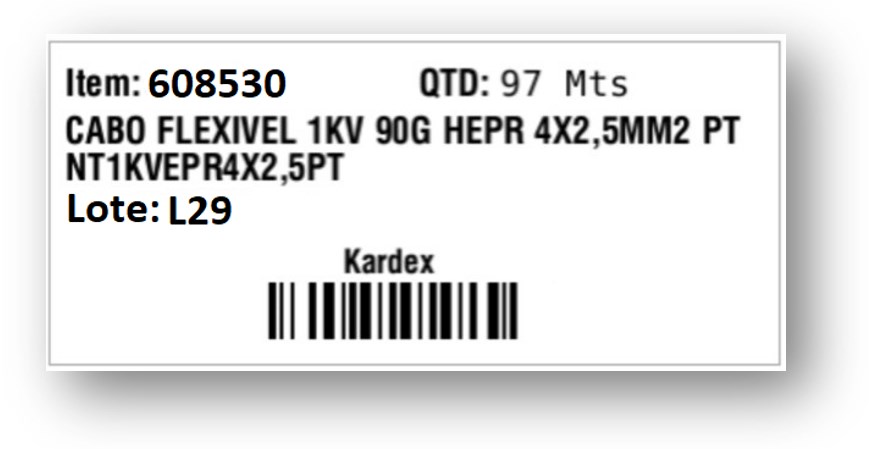

In the Cable Cutting tab, the user will have the possibility to Print Labels, Delete Cut, and Change Users.

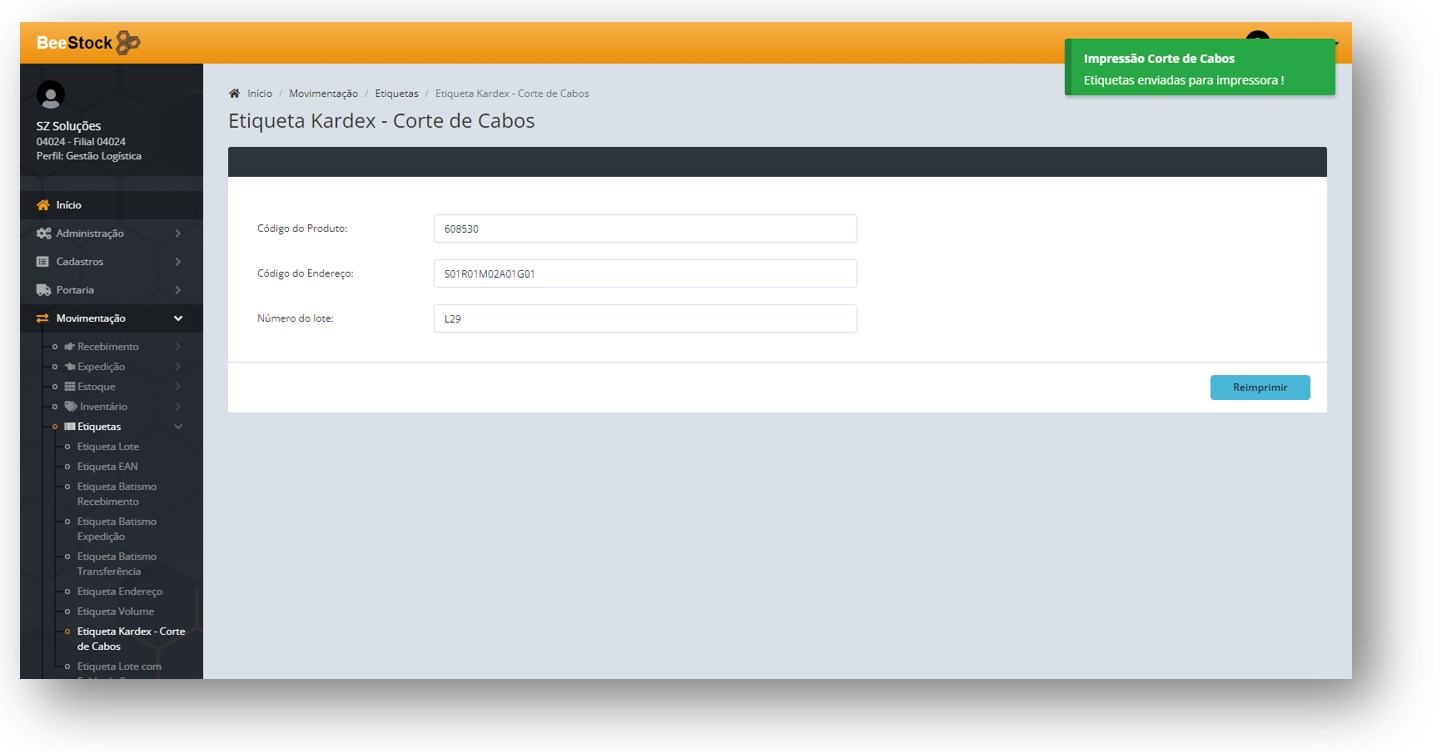

Print Labels – Prints the label with the information of the document, product, and cut quantity, and also prints a label to attach to the reel with the remaining balance after cutting.

Delete Cut – Allows the deletion of a cable cut that is still pending.

Change Users – Allows assigning to a user so that they can perform the pending cut via collector.

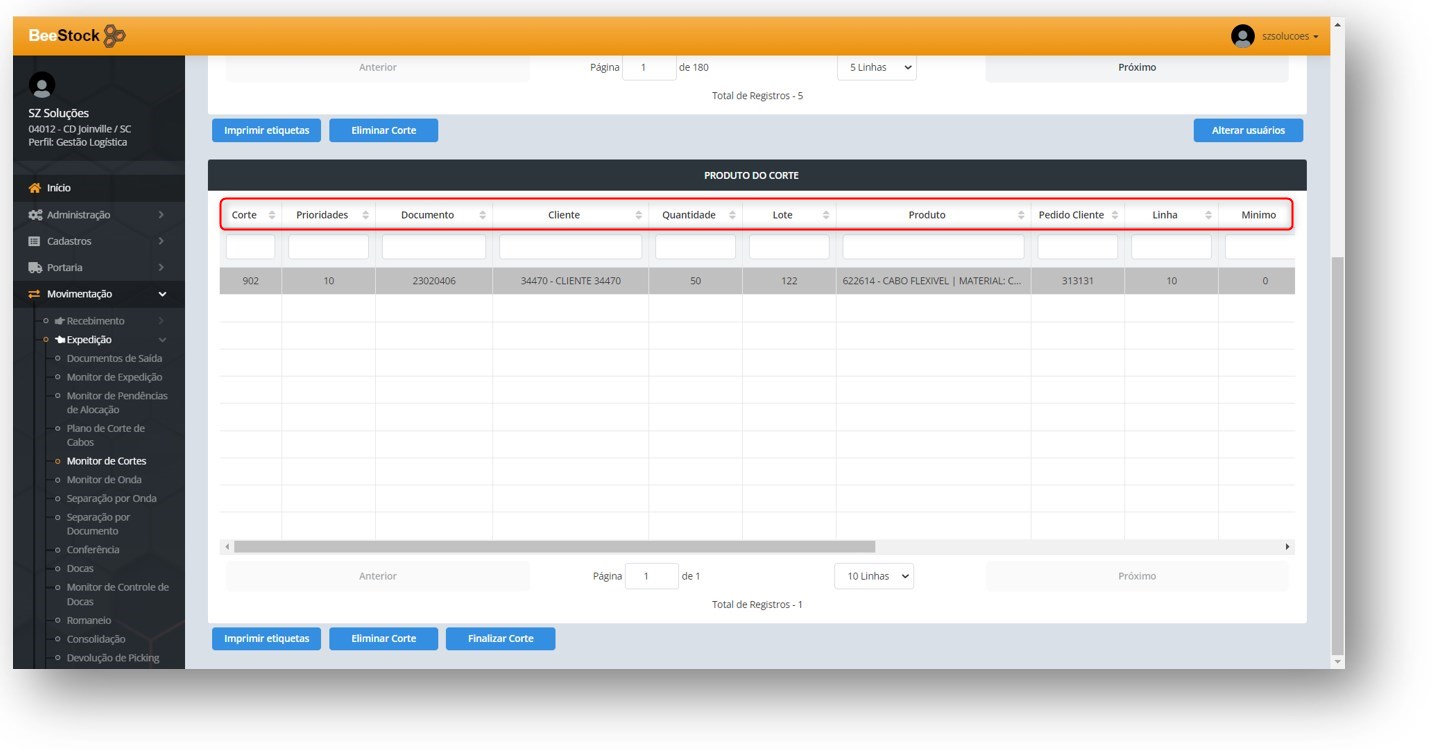

The Cutting Products tab provides information about the product to be cut related to stock.

Cut

Priorities

Document (Documents available for the cutting plan of the selected product)

Customer (Customer linked to the sales order)

Quantity

Batch

Product

Customer Order (Sales order linked to the document)

Line (Order sequence)

Minimum (Minimum length of cable that can be cut, in meters)

Required (Required length of cable that must be cut, in meters)

Status (Pending, Finished, or Canceled)

Creation Date (Date the cutting plan was created)

Creation User (User responsible for the cutting plan)

Cutting Date (Date the cutting was performed)

Cutting User (User who performed the cutting)

Transfer (Destination branch of the transfer, if applicable)

In the Cutting Products tab, the user also has the possibility to Print Labels, Delete Cut, and Finalize Cut.

Print Labels – Prints the label with the information of the document, product, and cut quantity, and also prints a label to attach to the reel with the remaining balance after cutting.

Delete Cut – Allows the deletion of a cable cut that is still pending.

Finalize Cut – Finalizes the cut in the system so that it can be physically carried out, changing the cut status to Finished.

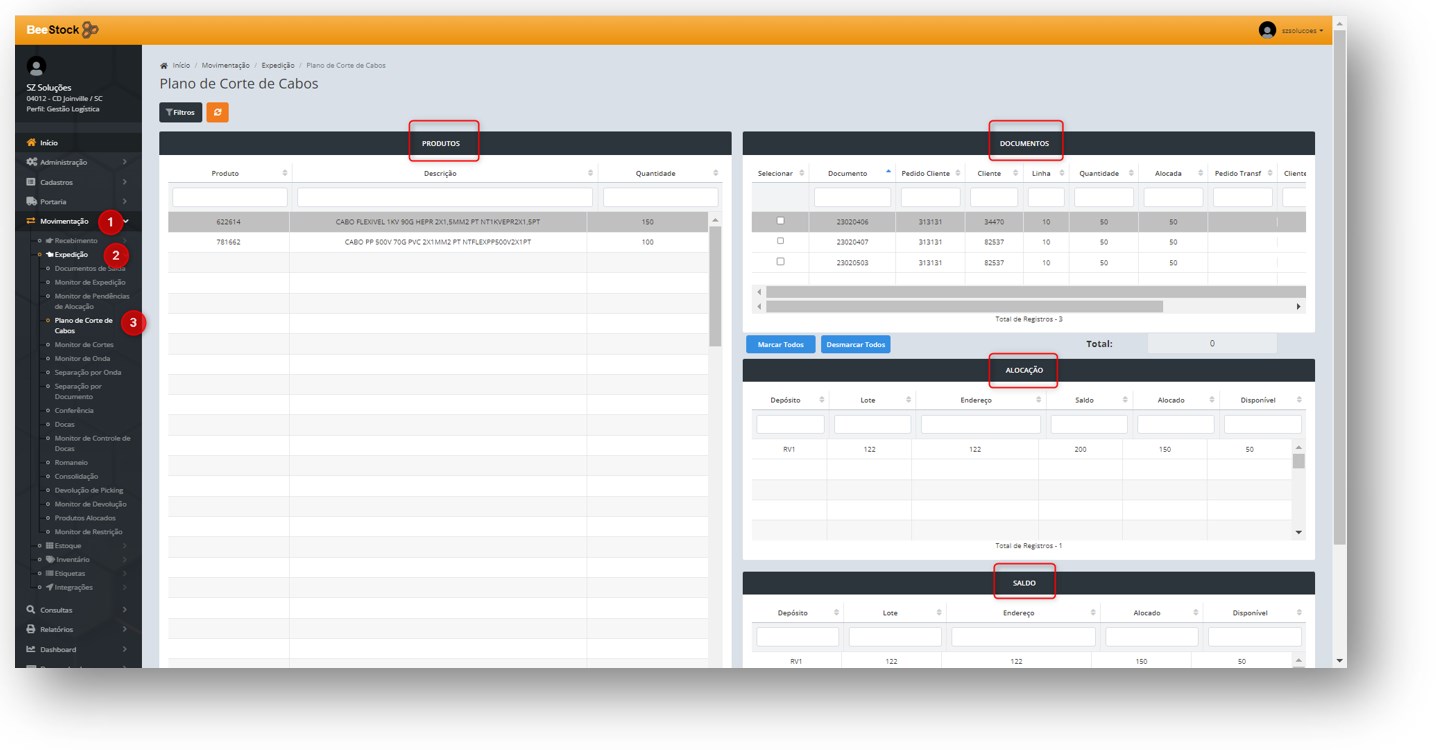

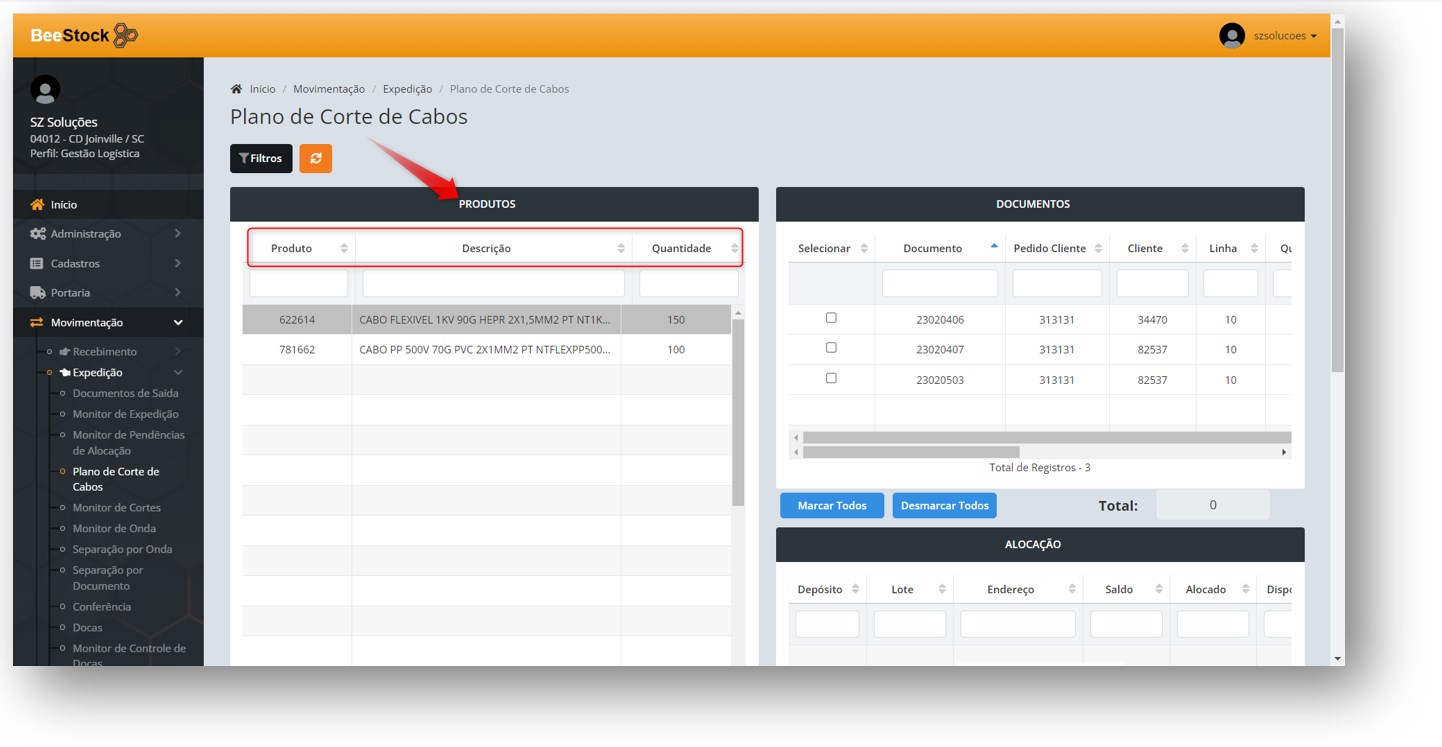

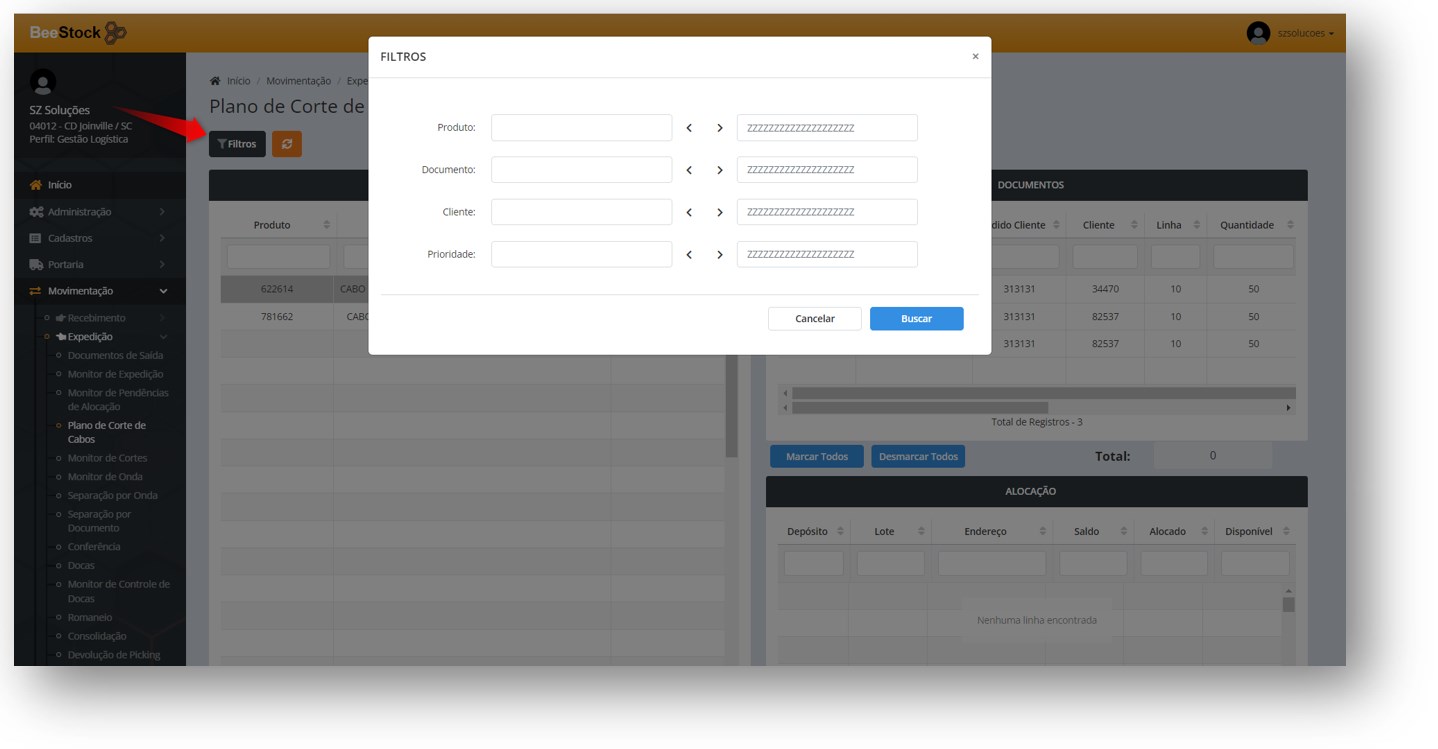

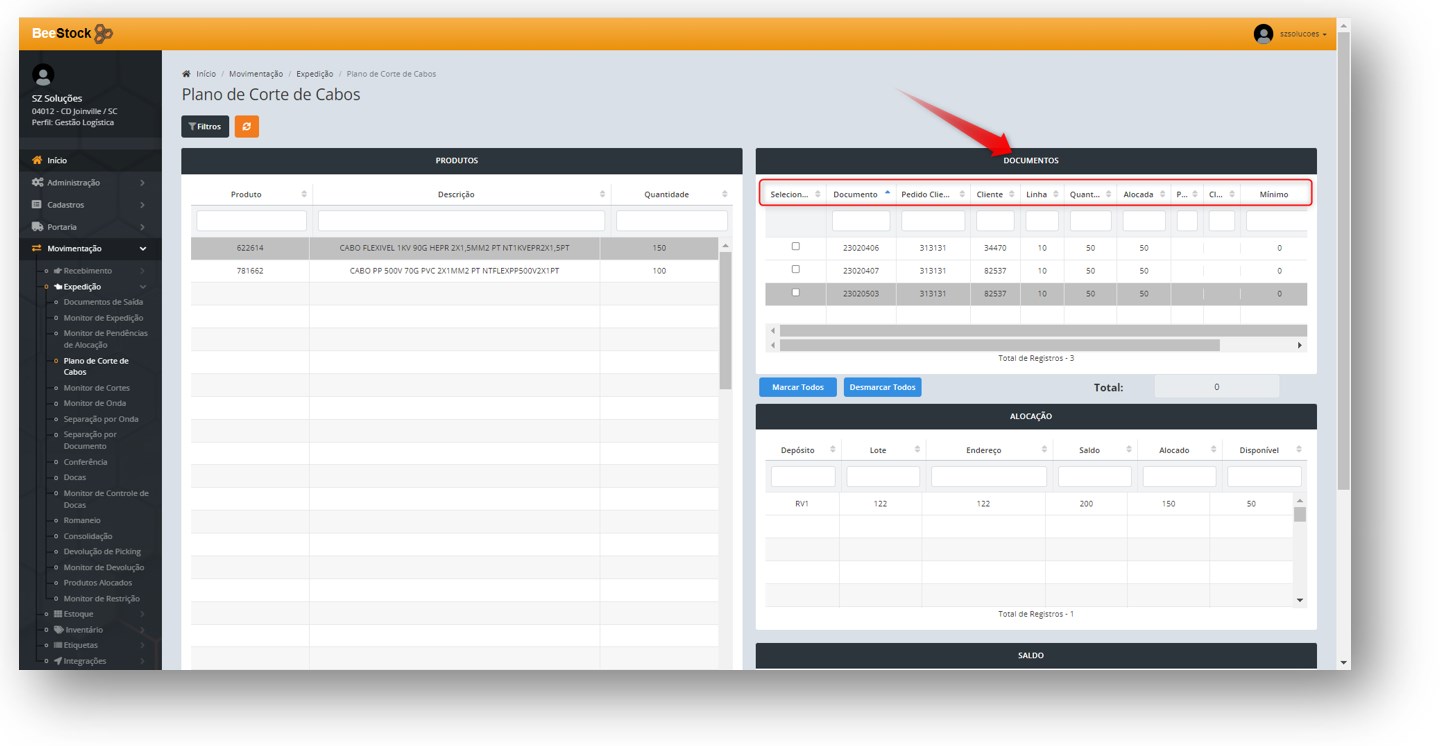

Cable Cutting Plan

Located in Movement > Shipping > Cable Cutting Plan, it has the function of optimizing the cable cutting so that the cable reels available in stock are used more effectively.

It is divided into four main frames:

Products

Documents

Allocation

Balance

Products tab – where all products pending cable cutting are presented, with the product code, description, and quantity to be cut. When selecting a product, the user should pay attention to the next tab, Documents, to start the cable cutting plan.

Still in the Products tab, the user has the option to use the filter to view only the products in a desired range.

Documents tab – When selecting a product, all documents with pending cutting for that specific product are displayed. In this tab, the user can select one or more documents at a time to start the cutting.

The following document information is presented in the Documents tab for the user to view before proceeding with the cable cutting plan:

Document (Documents available for the cutting plan of the selected product)

Customer Order (Sales order linked to the document)

Customer (Customer linked to the sales order)

Line (Order sequence)

Quantity

Allocated (Allocated quantity)

Transfer Order (Transfer order linked to the document)

Transfer Customer (Destination branch of the transfer)

Minimum (Minimum length of cable that can be cut, in meters)

Required (Required length of cable that must be cut, in meters)

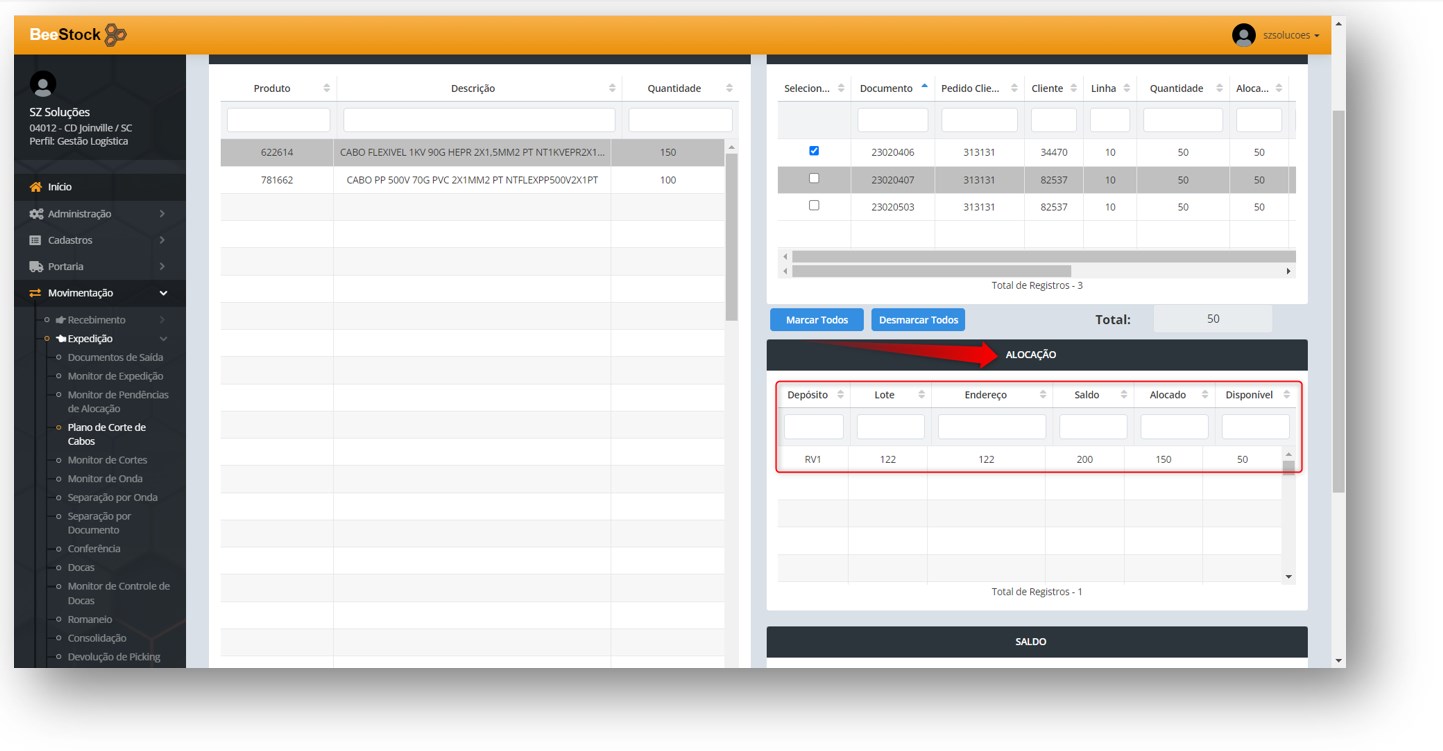

When selecting the desired documents for the cutting plan, in Allocation, the user has a complete view of the product allocations in stock.

Warehouse (Warehouse where the product is located)

Batch (Product batch at the address)

Address

Balance (Total product in stock)

Allocated (Total allocated balance for products pending cable cutting)

Available (Total balance that is available in stock to meet new demands for the product)

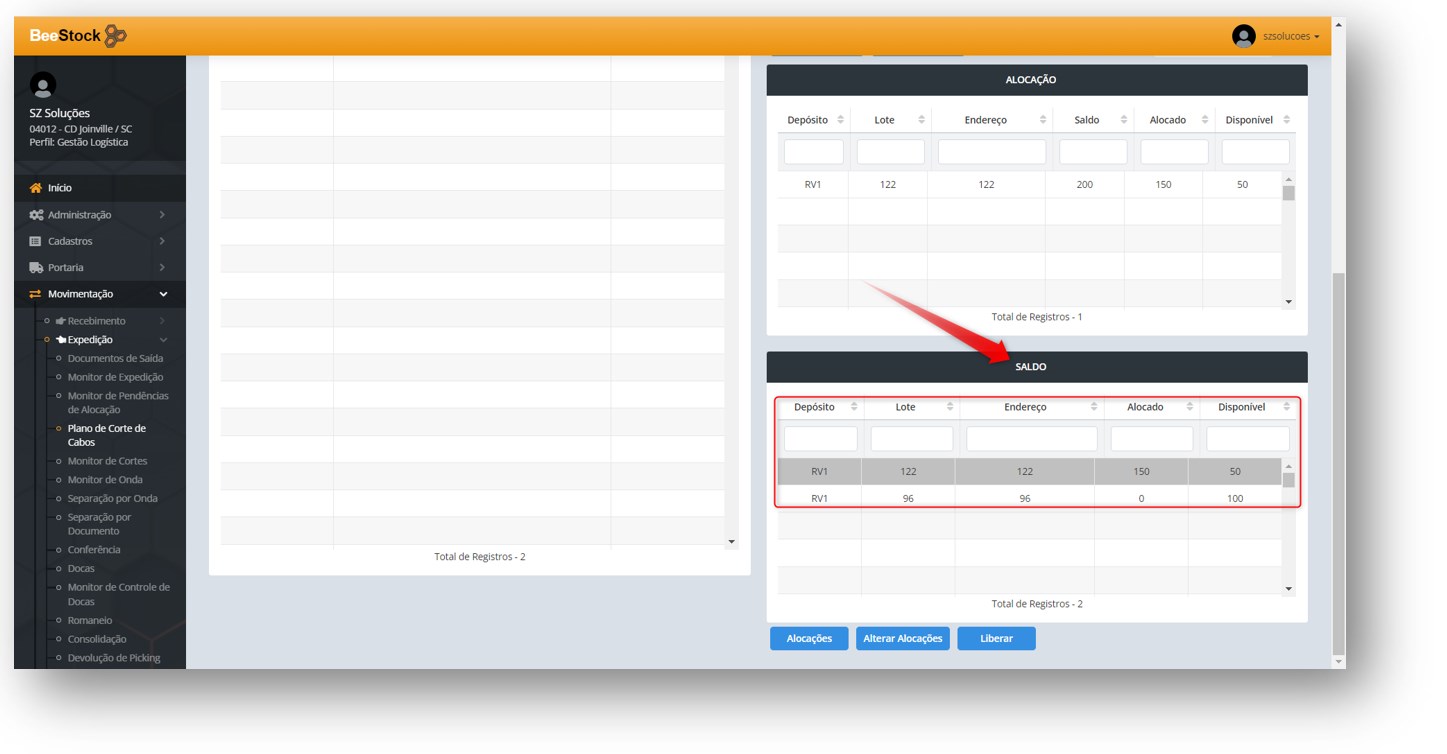

In the Balance tab, the user can:

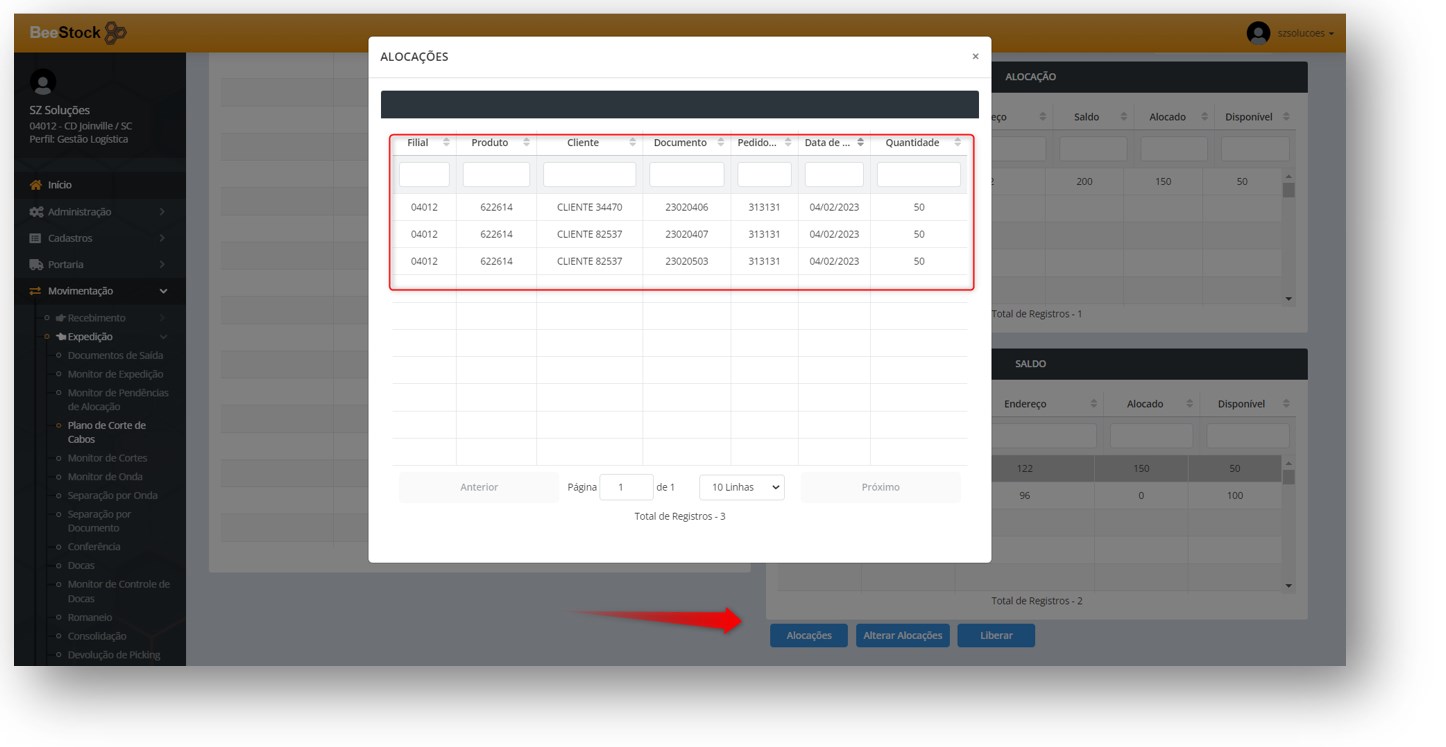

In Allocations, view by documents.

Change the Allocation.

Release the cutting plan according to the allocation suggested by the system.

Allocations – When clicking on Allocations, the user has the view of all documents allocated in stock and their respective quantities, comparing with the information presented in the Allocated column of the Balance tab, as shown in the previous image.

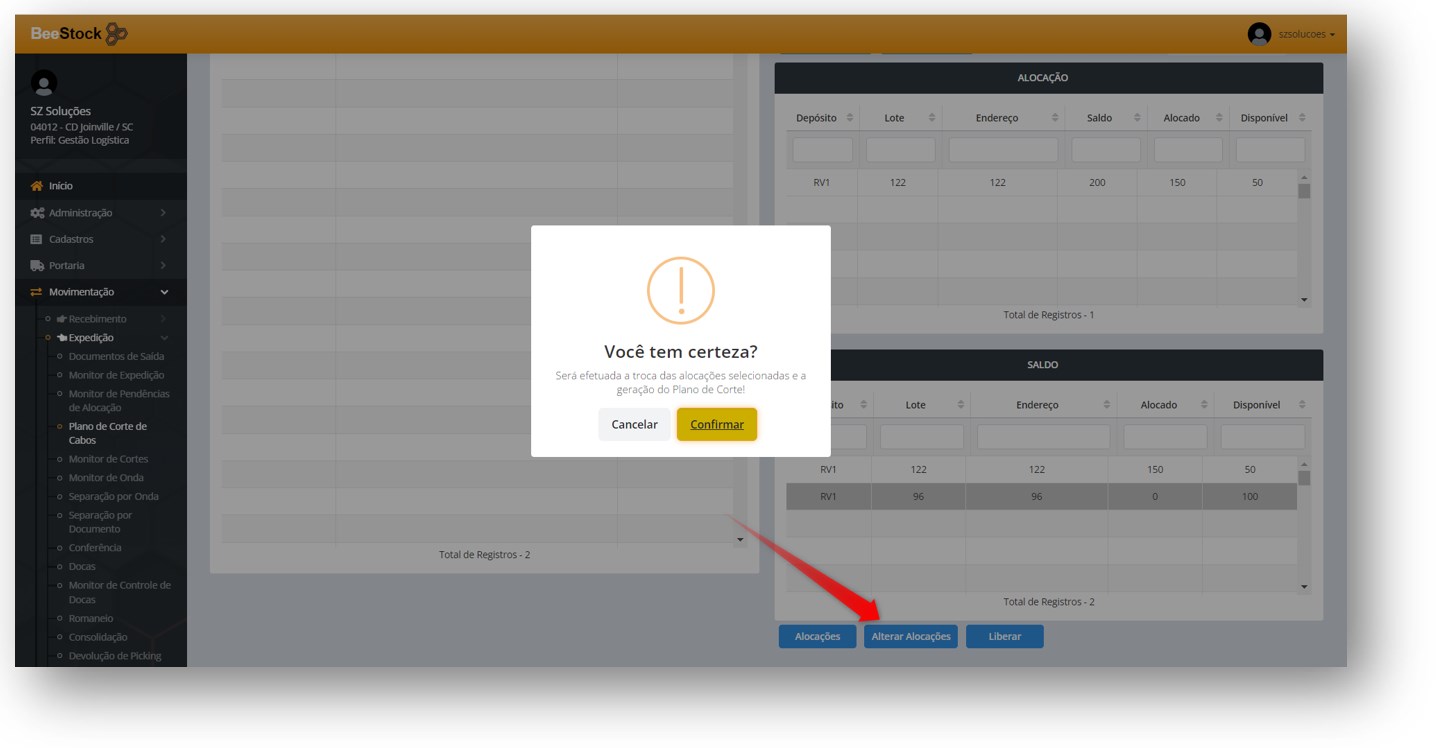

Change Allocation – From this option, the user can select a line with a different address from the one suggested by the system and make the allocation change. At this moment, the cutting plan will be released so that the cable cutting can be performed via collector.

Release – By clicking on Release, the user agrees with the system’s allocation suggestion and releases the product so that the cable cutting can be performed via collector.

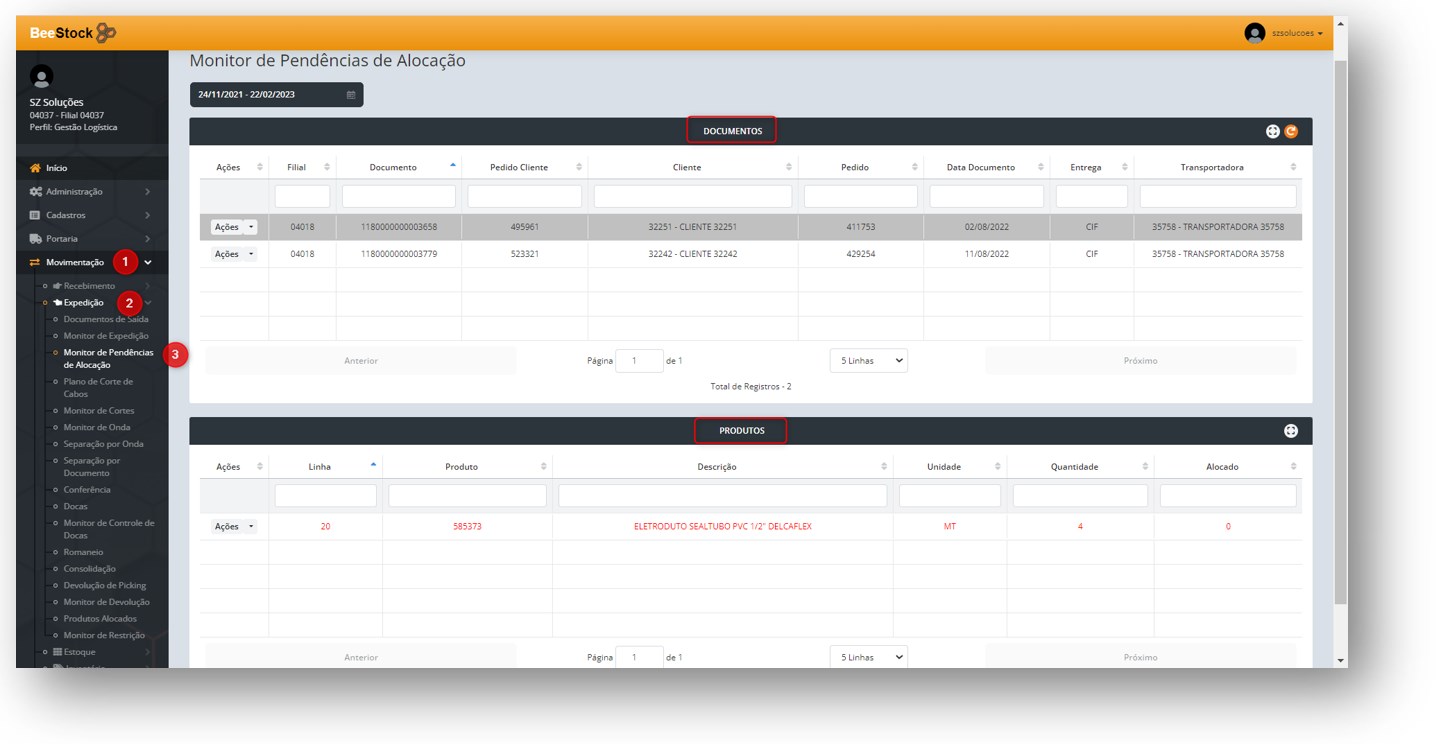

Allocation Pending Monitor

Located in Movement > Shipping > Allocation Pending Monitor, it gathers the documents that for some reason do not have available balance (expired, damaged, missing products, etc.) in BeeStock® to fully fulfill them.

The screen is divided into two grids:

Documents, in the central part.

Products, at the bottom.

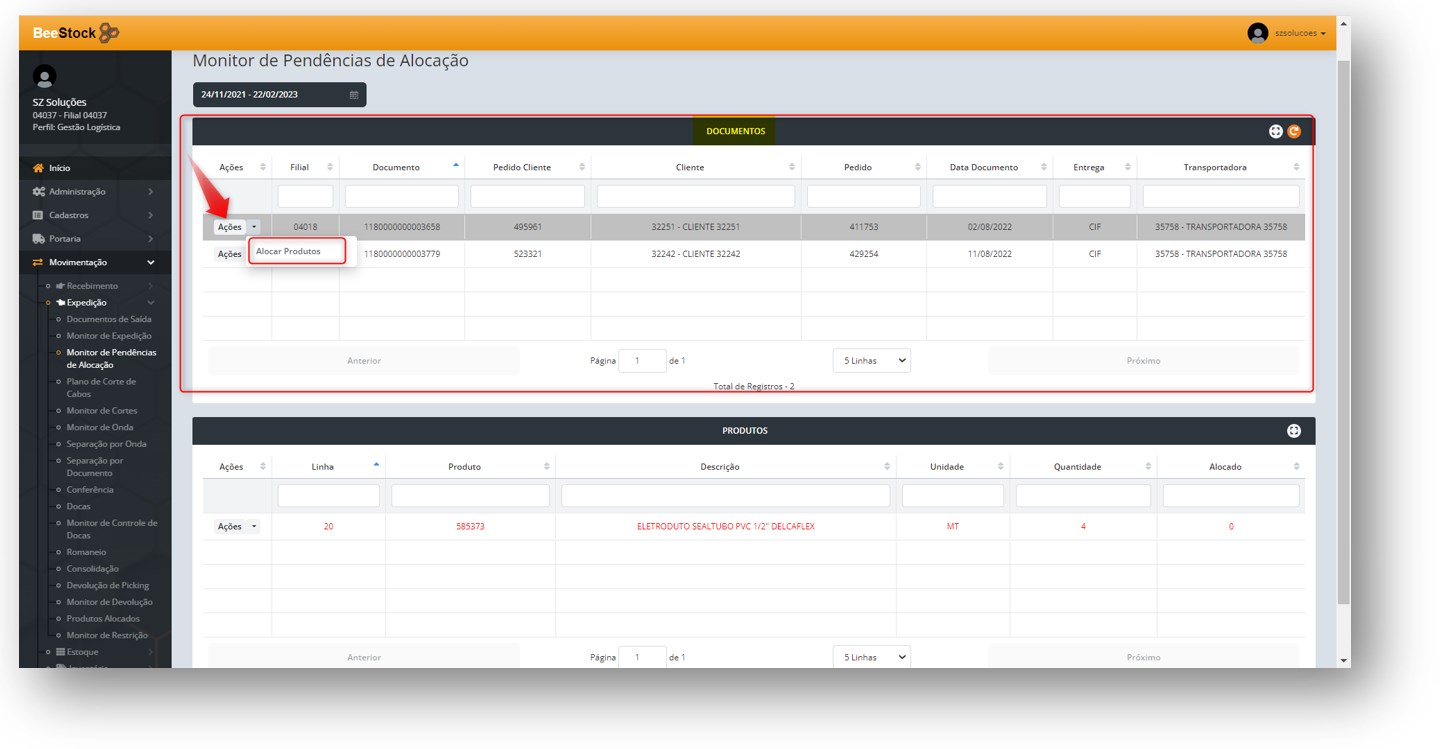

Documents – When selecting a document, in Actions > Allocate Products, the user can allocate all the products of the document, if they already have available balance. This way, all products of the document that have available balance and are pending allocation will be released, changing the document status to Pending Picking or Pending Cable Cutting.

The Documents tab presents the following information:

Branch

Document

Customer Order

Customer

Order

Document Date

Delivery (CIF, FOB, Forwarding, etc.)

Carrier

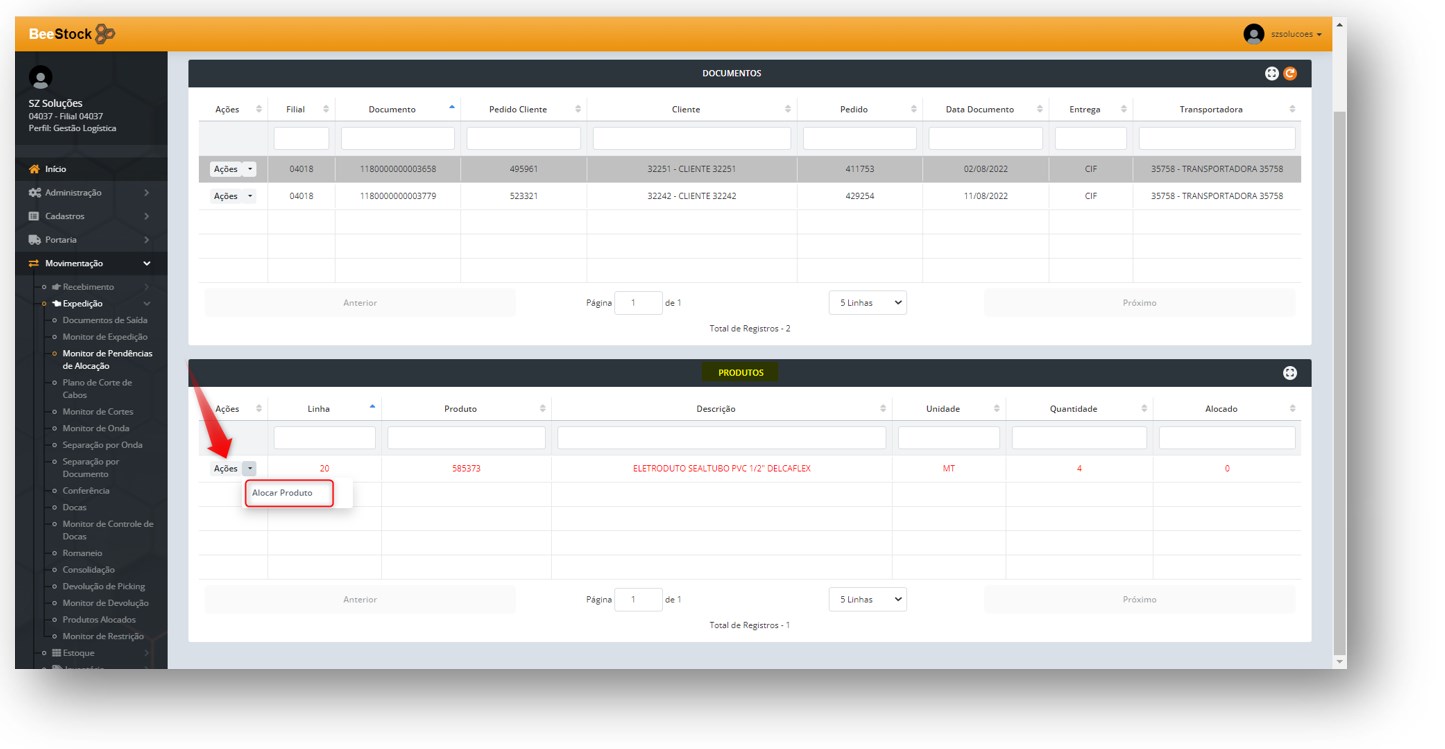

Products – When selecting a document, the products of that document are presented below in Products, with only the products pending allocation appearing in red.

Unlike in Documents, in Products, the user has the option to release the pending status of only one product at a time, and as long as not all sequences of the document are released, the document will remain pending allocation.

The Products tab presents the following information:

Line

Product

Description

Unit

Quantity

Allocated (Quantity of balance allocated for the product)

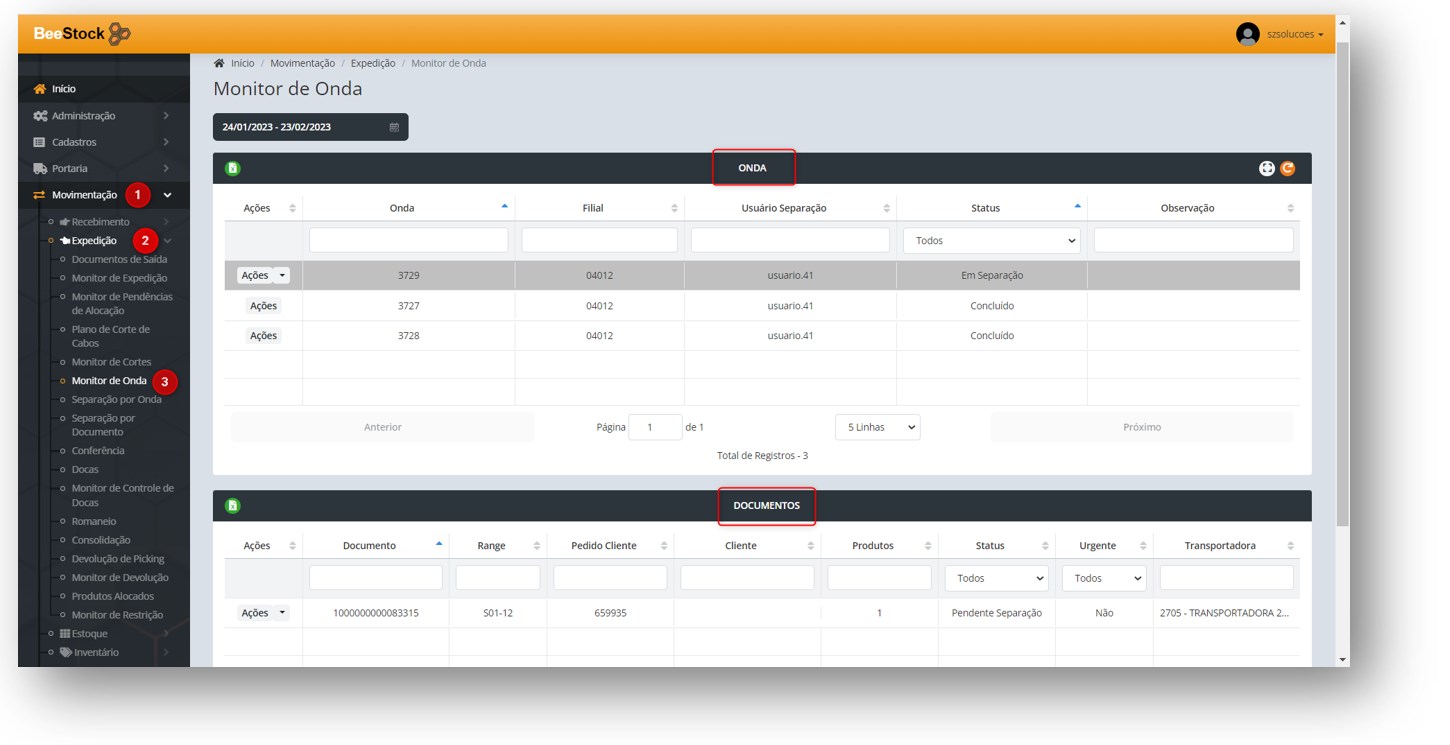

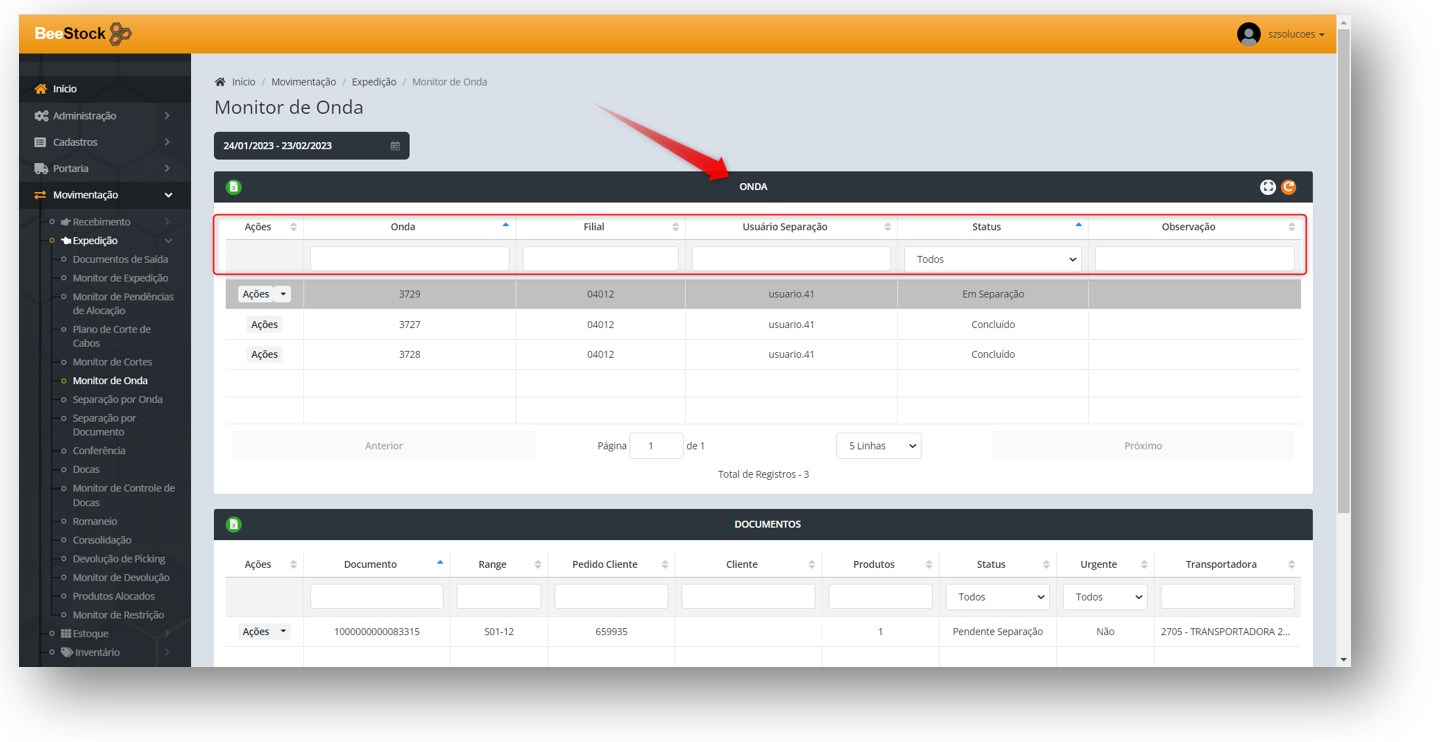

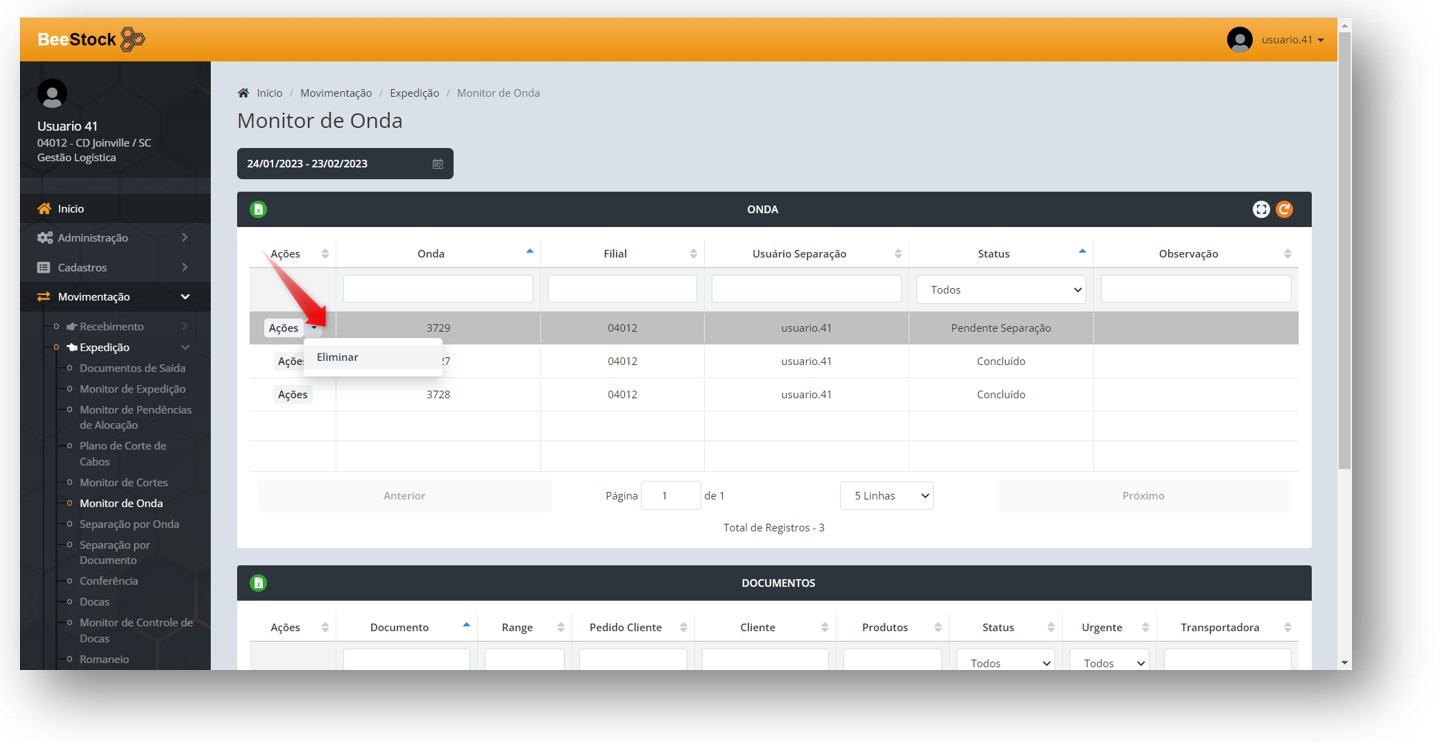

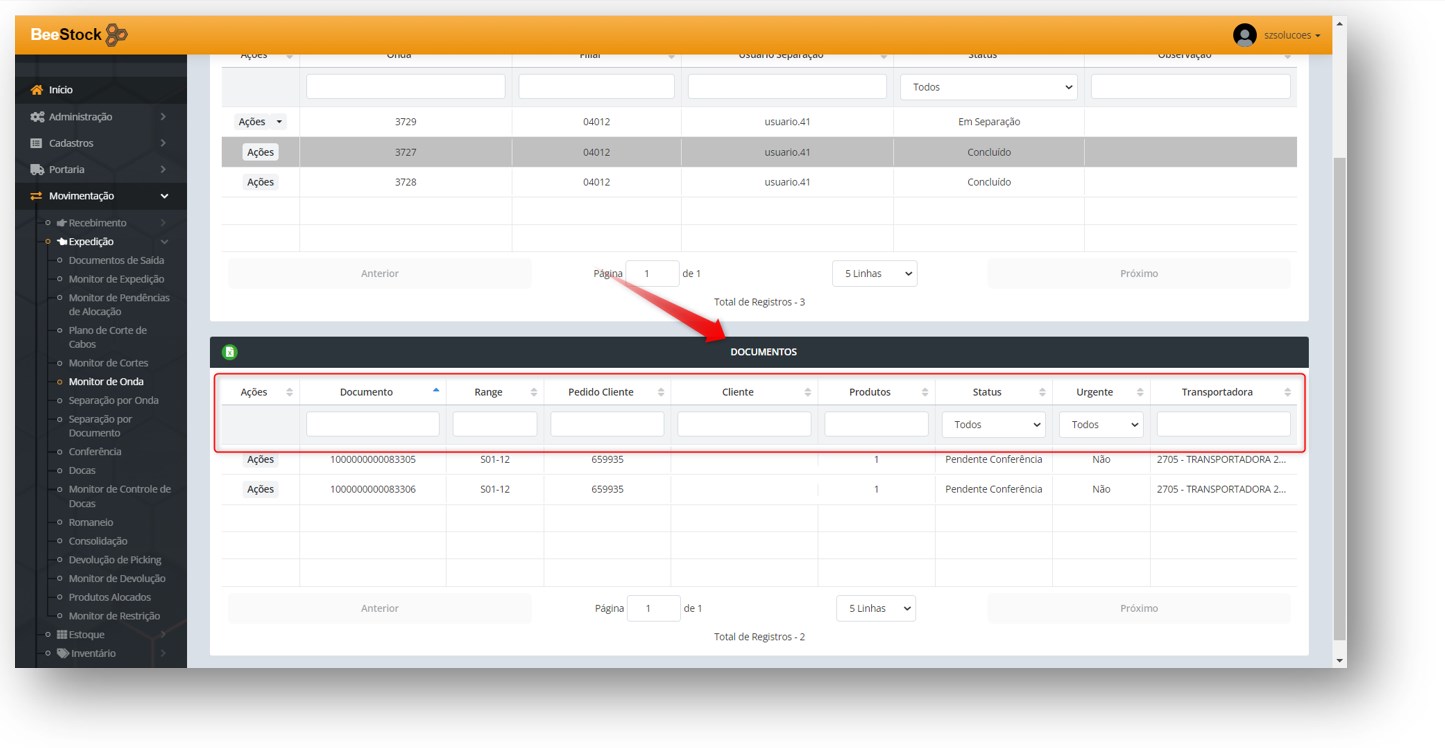

Wave Monitor

Located in Movement > Shipping > Wave Monitor, it is the place where all picking wave records are stored.

It is divided into two main frames:

Wave

Documents

Wave tab – Records of all statuses are displayed.

Pending

In Picking

Completed

The following fields will be displayed:

Wave (Numerical sequence of the wave record)

Branch

Picking User (User to whom the picking wave is assigned)

Status (In Picking, Pending Picking, or Completed)

Creation Date (Date the cutting plan was created)

Observation

In Actions > Delete, the user has the possibility to delete a wave that has not yet been completed. In this case, the products become available again to be picked in a new wave.

Documents tab – All documents available in that wave will be displayed, divided by the following information:

Document

Range (Name that identifies a group of addresses in stock)

Customer Order

Customer

Products

Status (Status of the product within the wave)

Urgent (If the product has priority)

Carrier

Picking by Wave

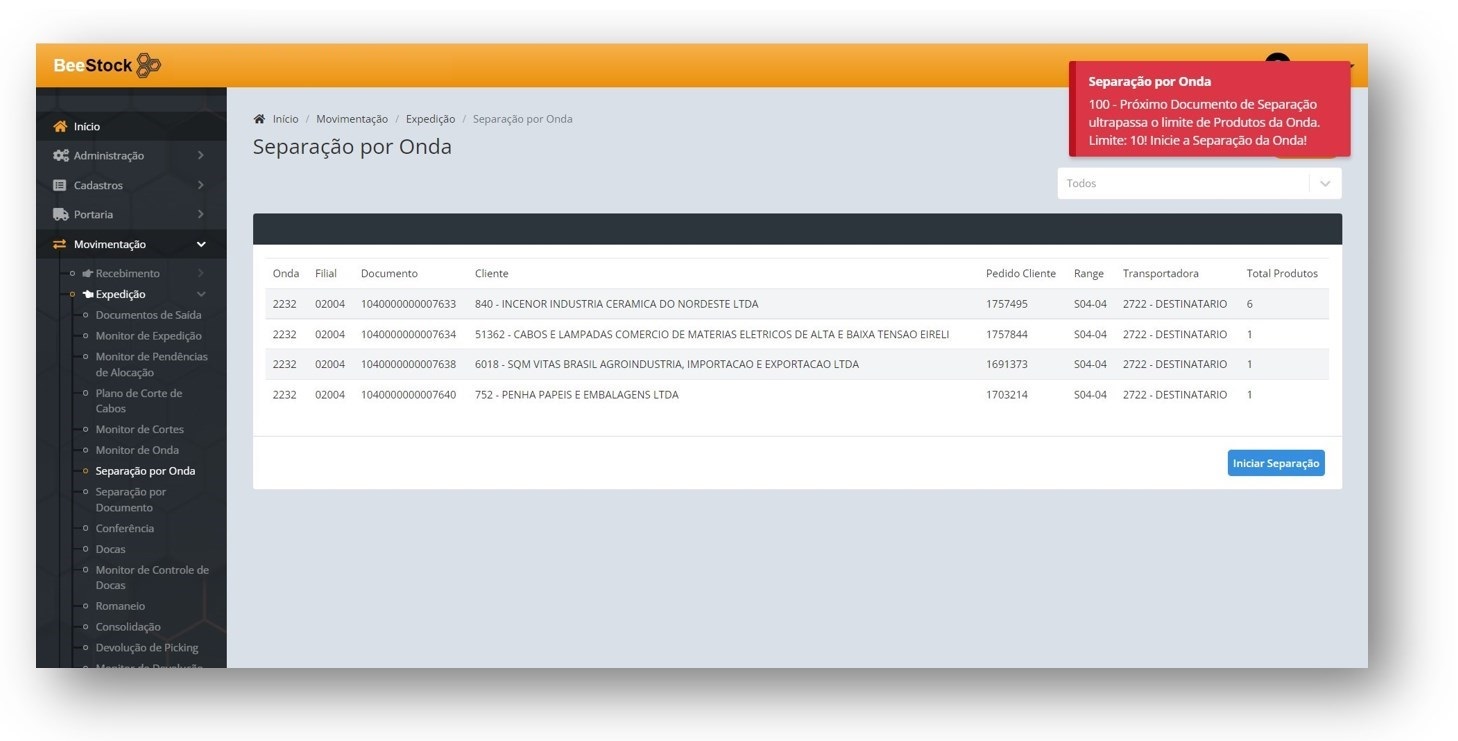

Located in the Shipping > Movement > Picking by Wave menu, in this screen it is possible to pick products in batches of documents by wave, also segregated by sector/area.

To start the process:

Click the orange +Search button until the desired documents and products are loaded into the grid.

Or until the Products per Wave Limit configured in Branch Registration is reached.

Click Start Picking.

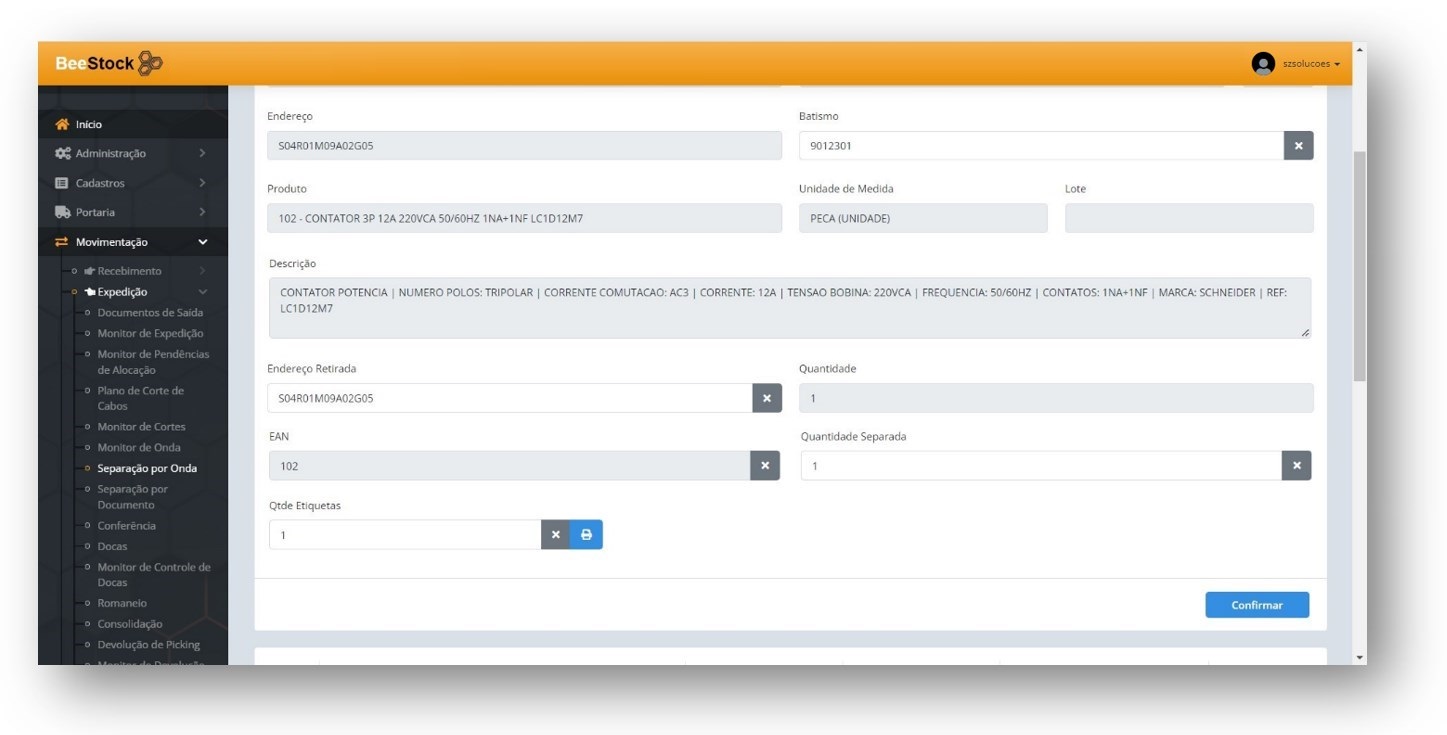

The Picking by Wave screen will be loaded.

Enter the Picking Address.

Enter the EAN barcode of the product being physically picked.

Confirm the Picked Quantity (The quantity can be total or partial).

If you want to print additional labels, in the Qty Labels field, enter the number of labels you want to print and click the Printer icon.

Click Confirm.

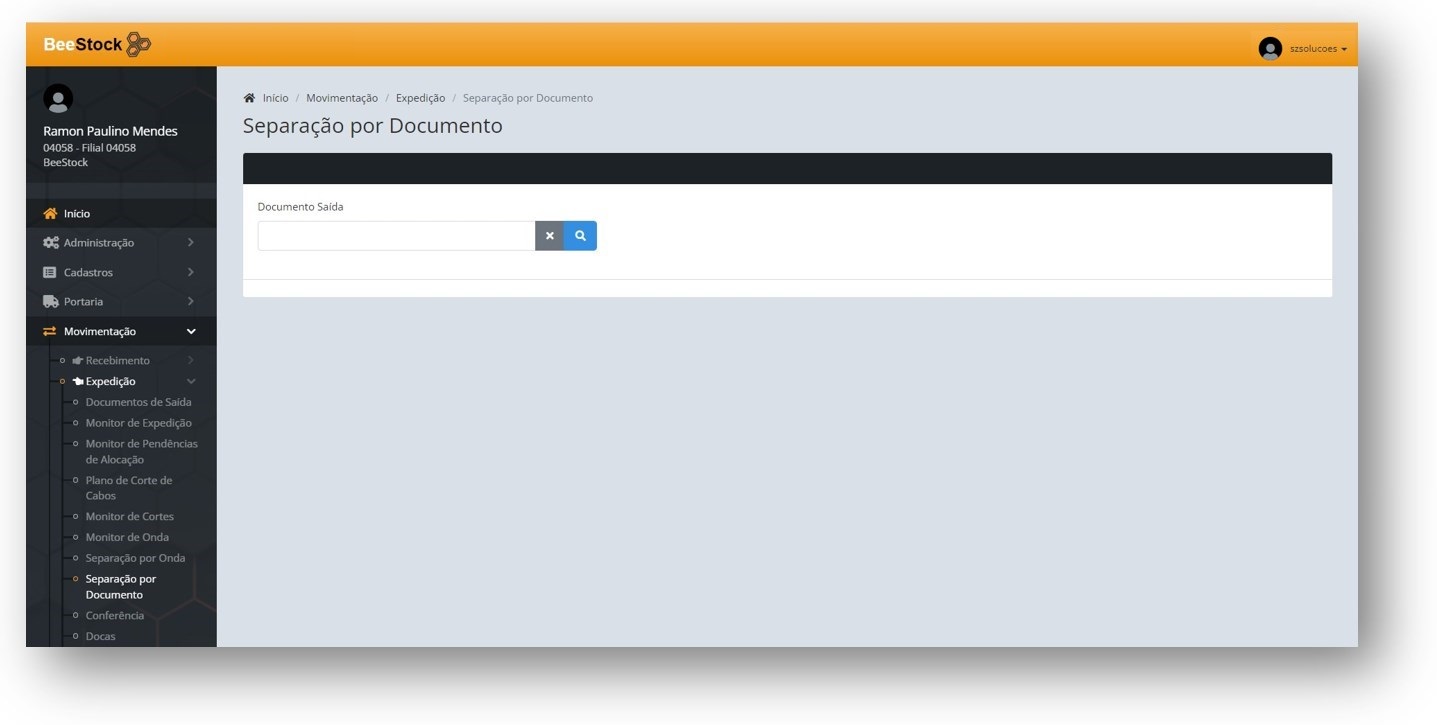

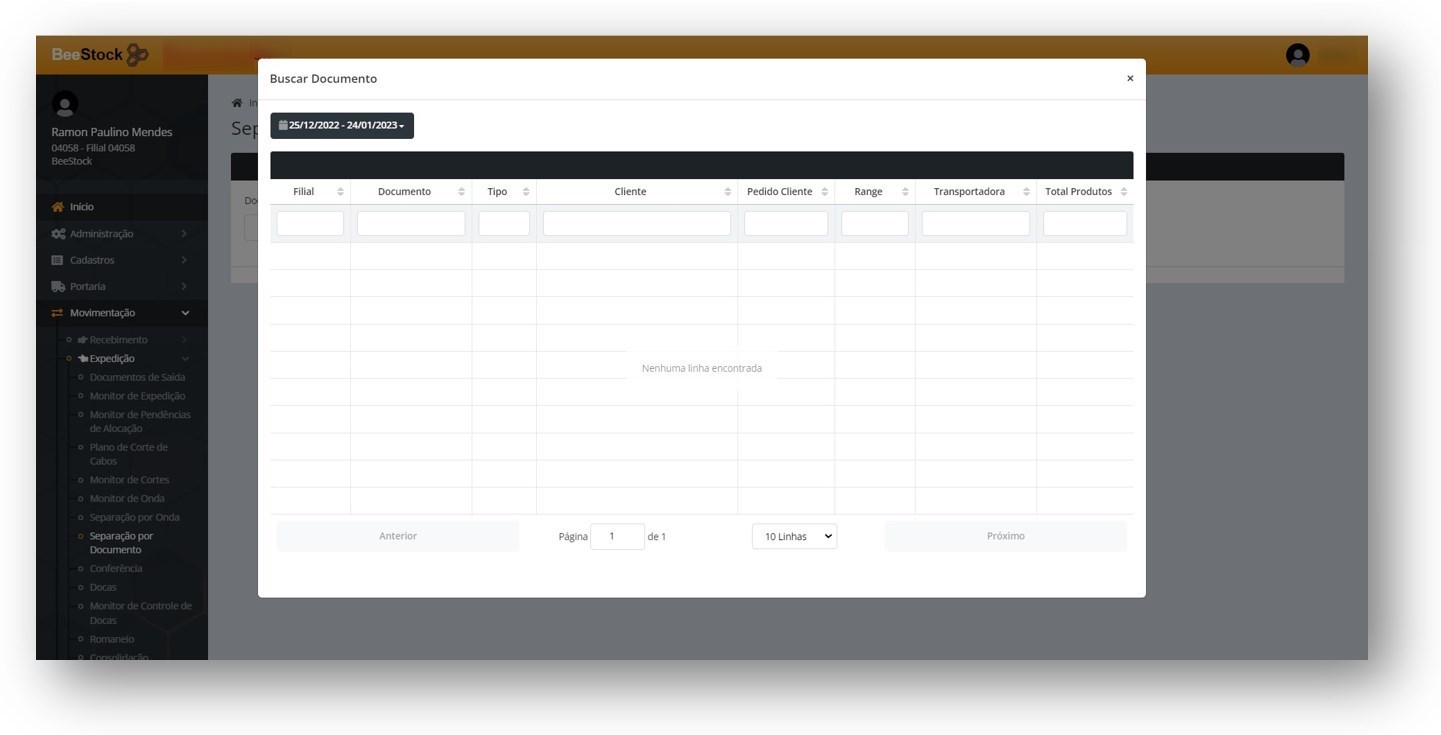

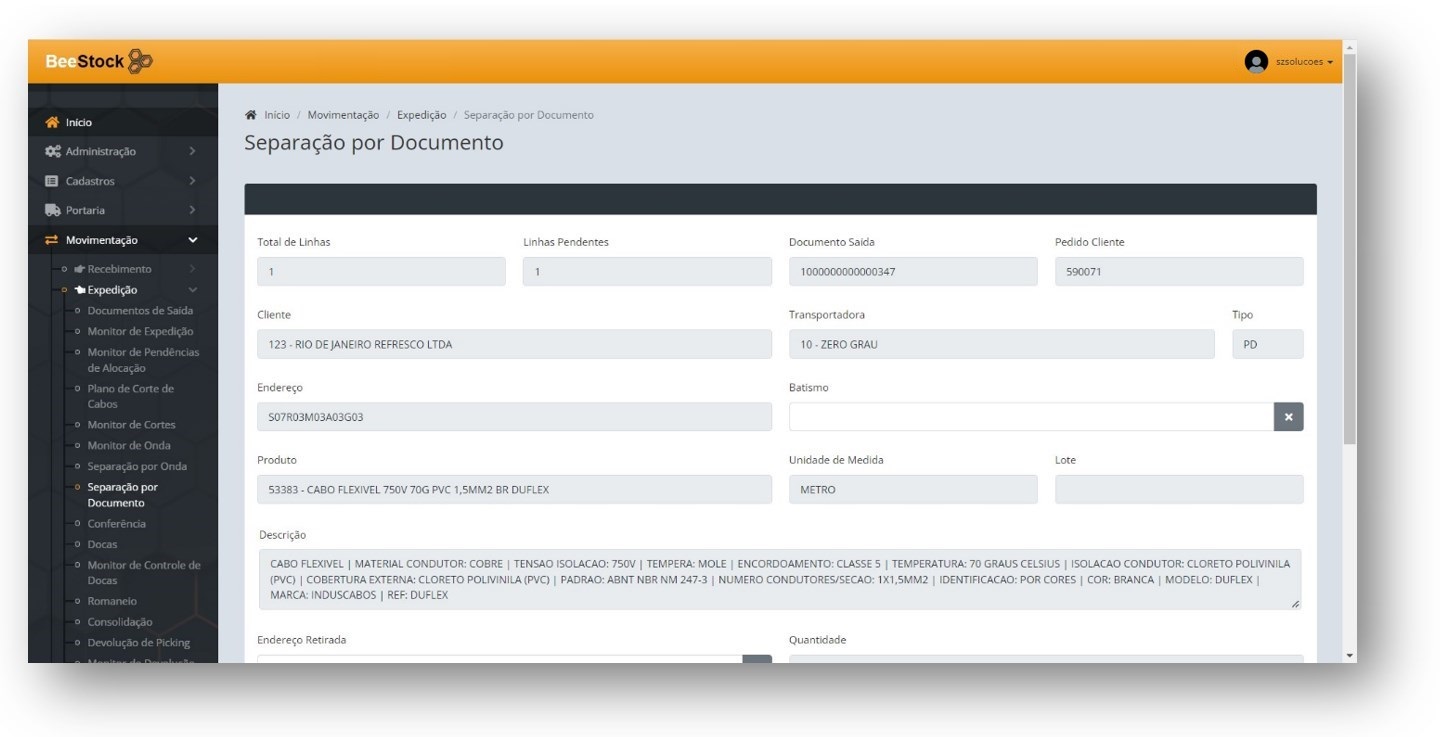

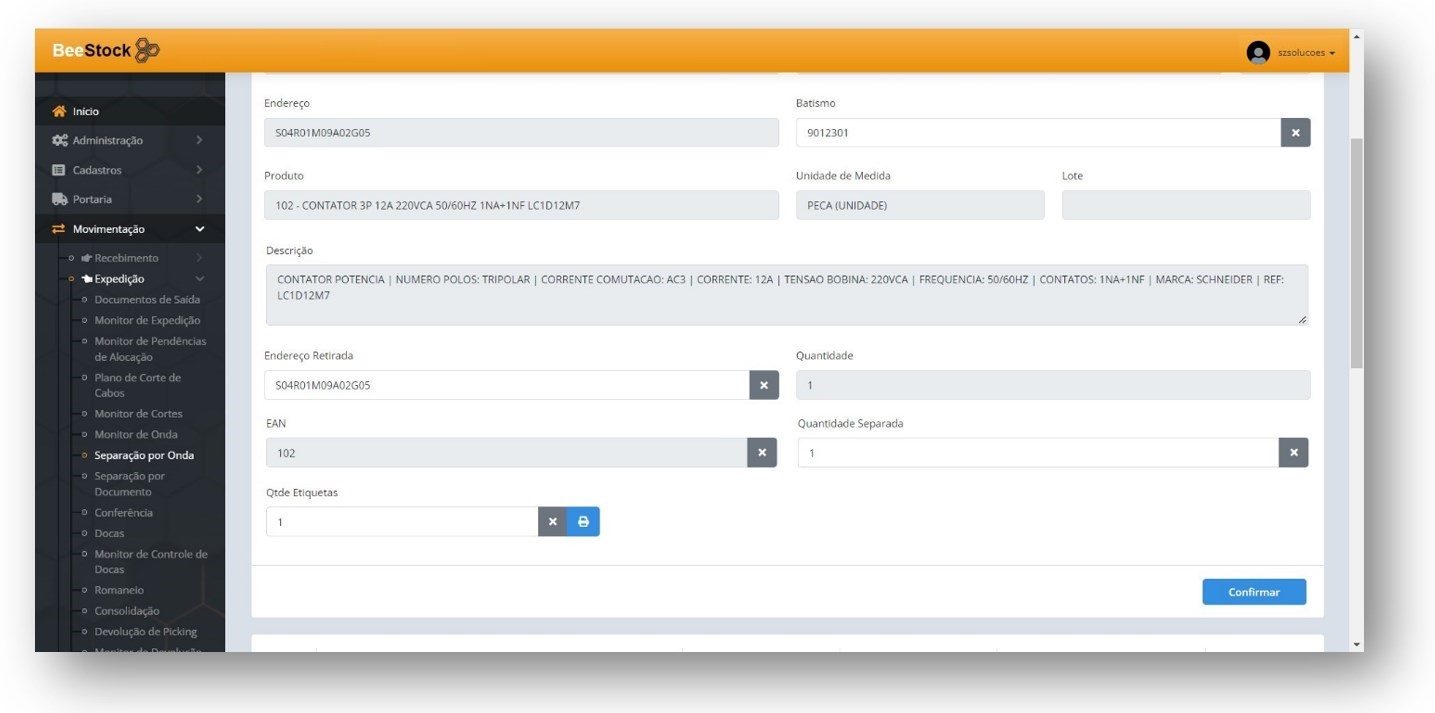

Picking by Document

Located in the Shipping > Movement > Picking by Document menu, picking by document allows you to pick all the items in the document, directing all the items to be picked to the user.

To start the process:

Enter the desired document number or click the Magnifying Glass button to list the documents available for picking.

Select the desired document to start picking.

The picking by document screen will be loaded.

Enter the Picking Address.

Enter the EAN barcode of the product being physically picked.

Confirm the Picked Quantity (The quantity can be total or partial).

Click Confirm.

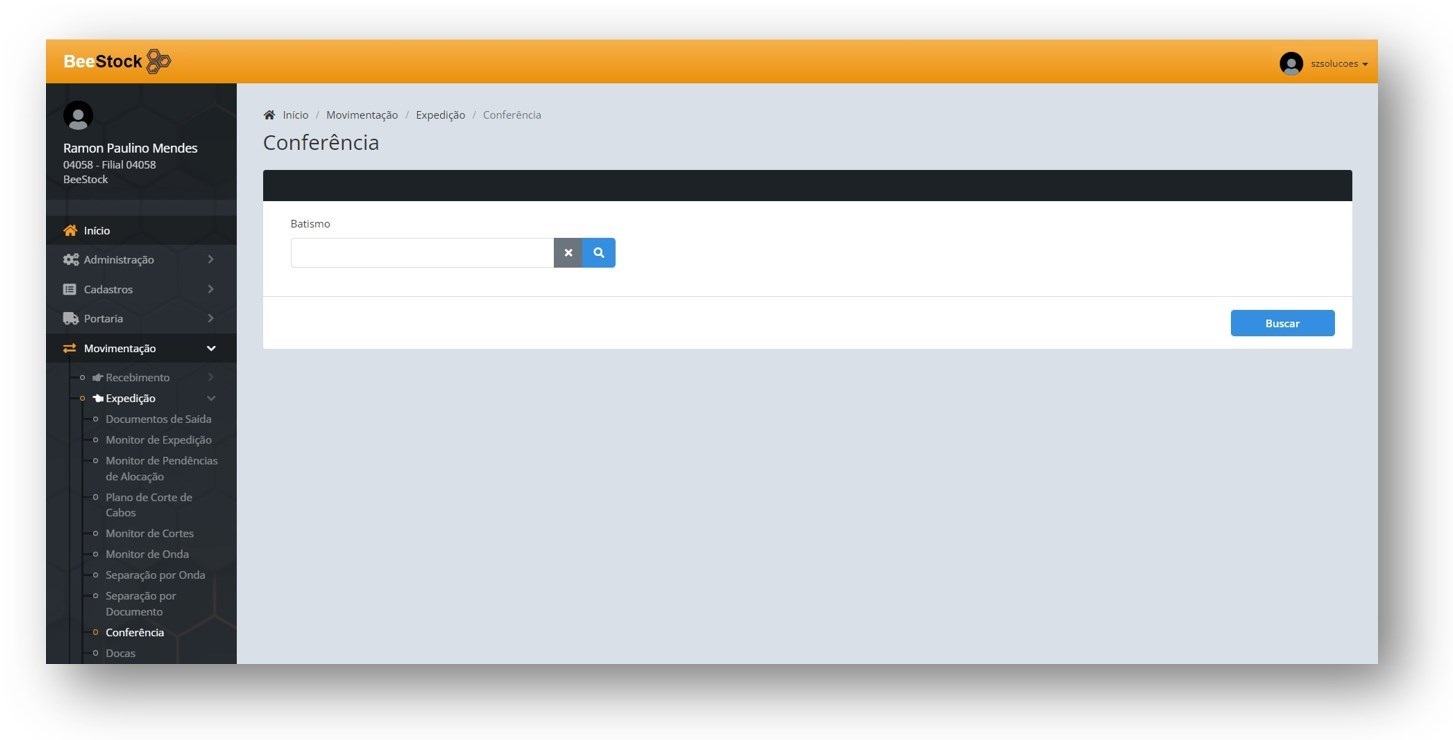

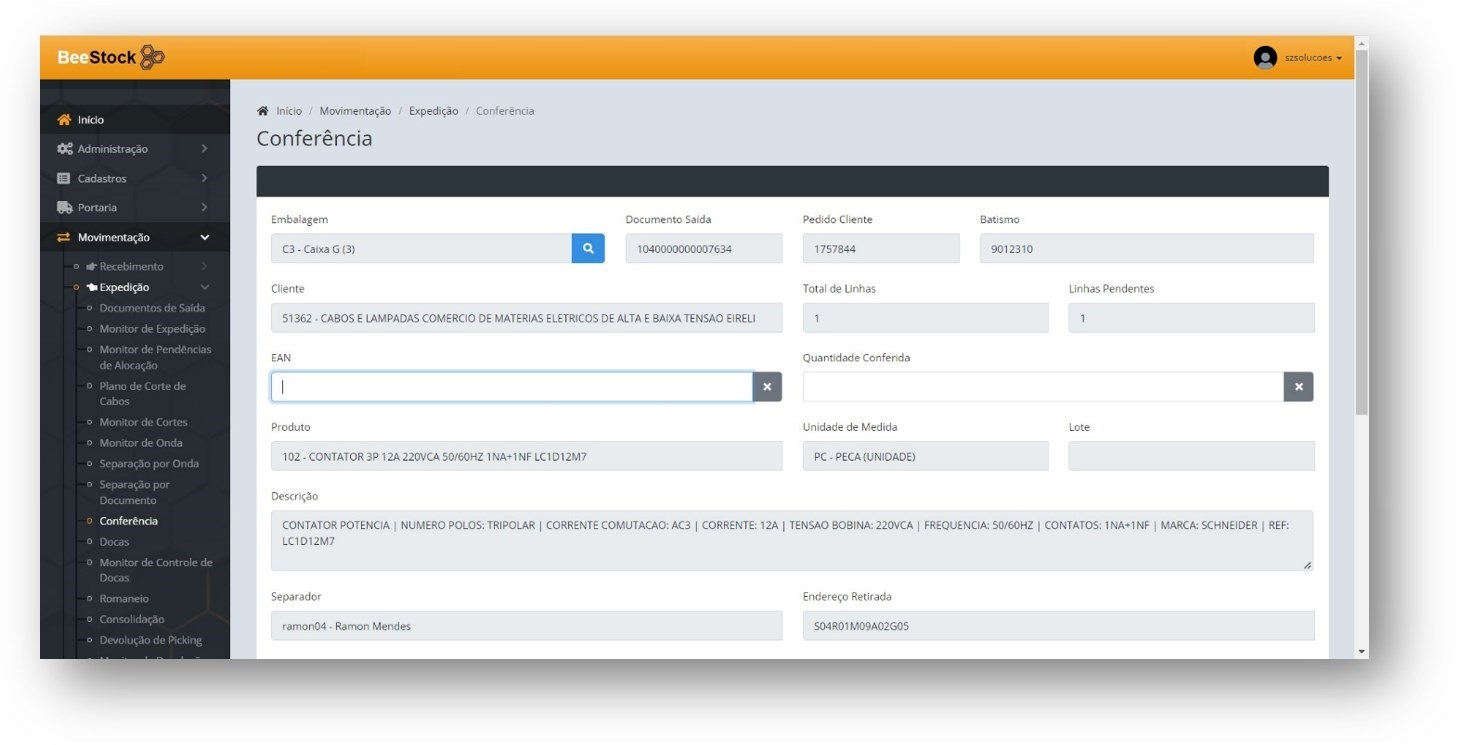

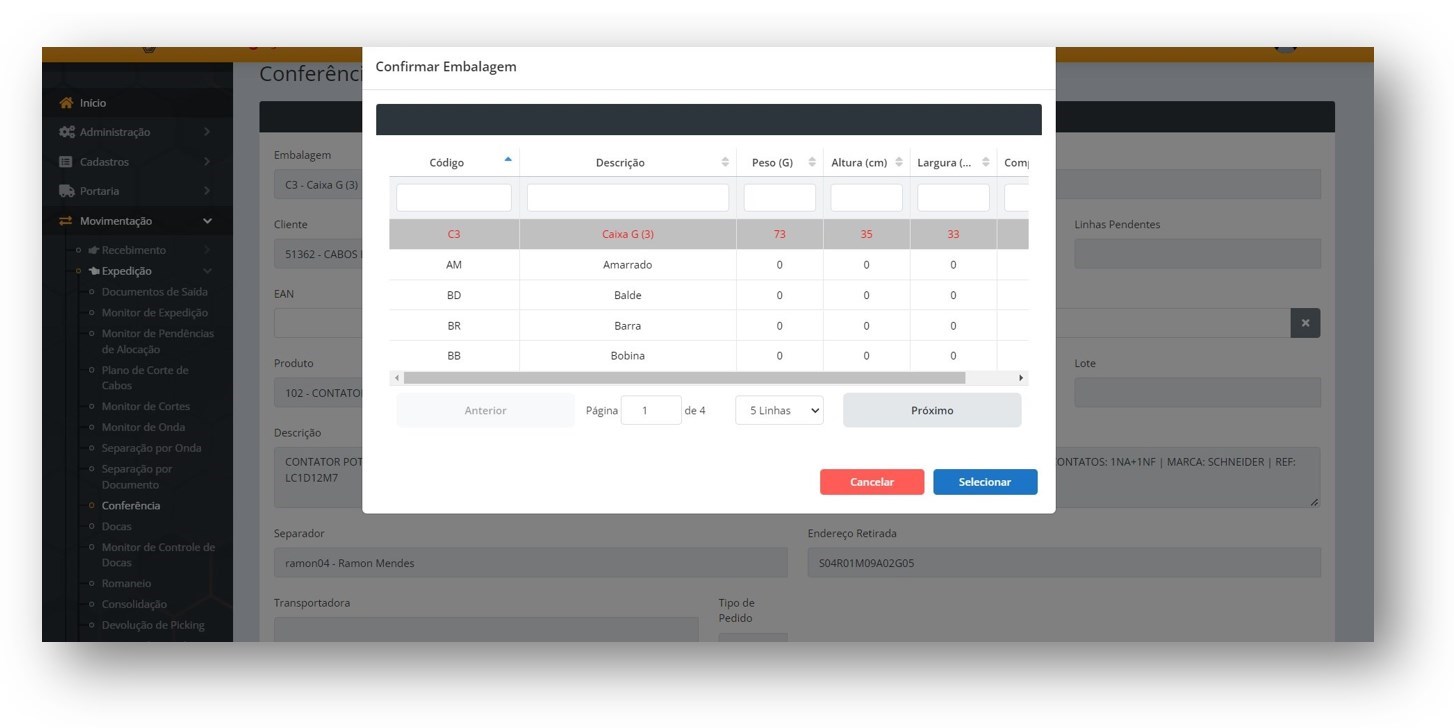

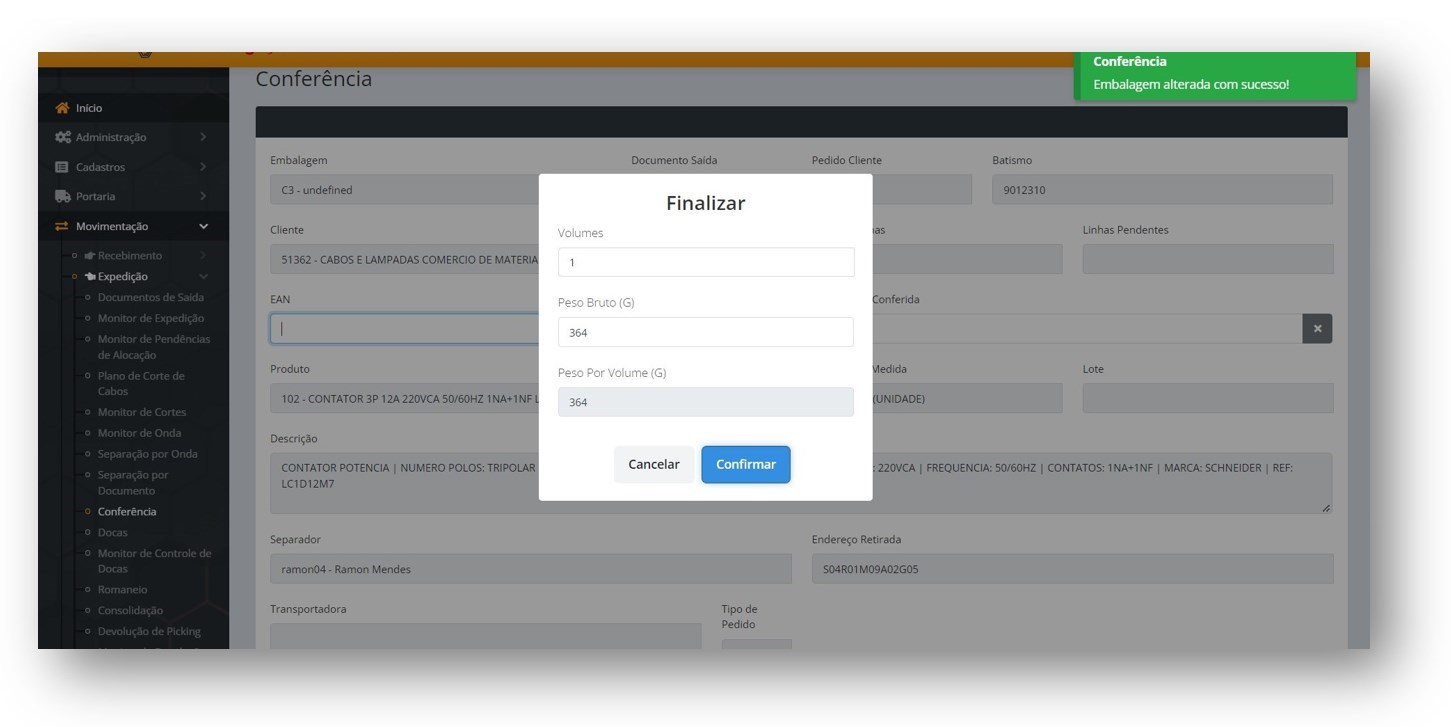

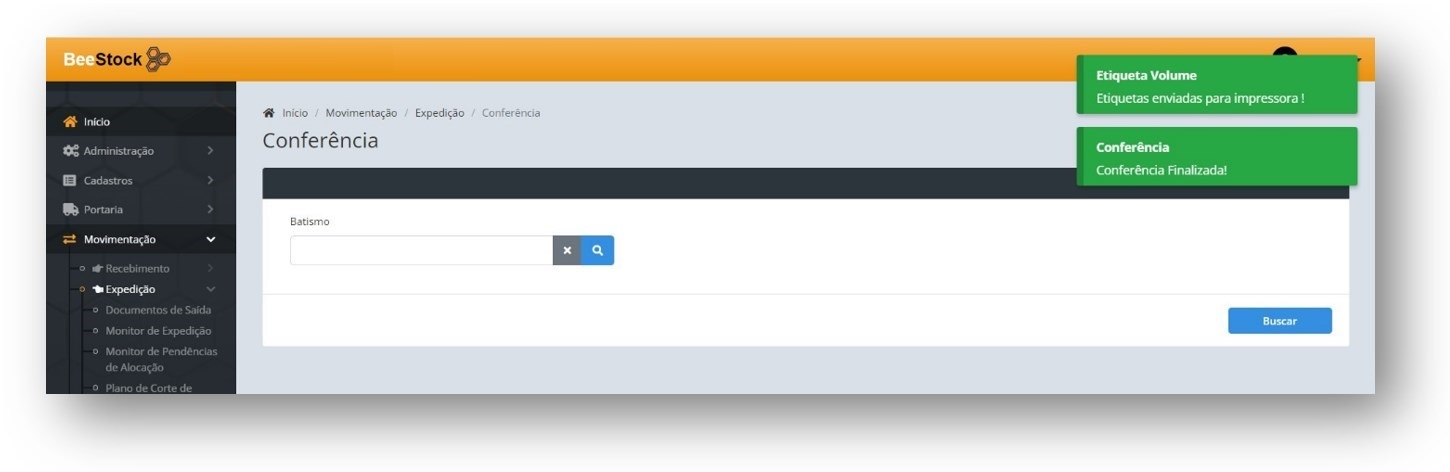

Outbound Checking

Located in the Movement > Shipping > Checking menu, it is used to check the materials previously picked in their respective batches, in order to ensure the correct shipping of the products.

To start the process:

Access the Movement > Shipping menu.

Enter the batch number and confirm the information on the screen.

Enter the product to be checked and confirm the quantity.

Perform the physical check of the products.

The message Checking completed will be displayed.

When you want to finish the package, click Finish.

Select the desired package and click Select.

The message Package changed successfully will be displayed.

Confirm the quantity of packages and the weight, and click Confirm.

Select the desired printer and the message Checking Completed, Labels sent to printer! will be displayed.

Repeat the procedure until the checking of all items in the document is complete.

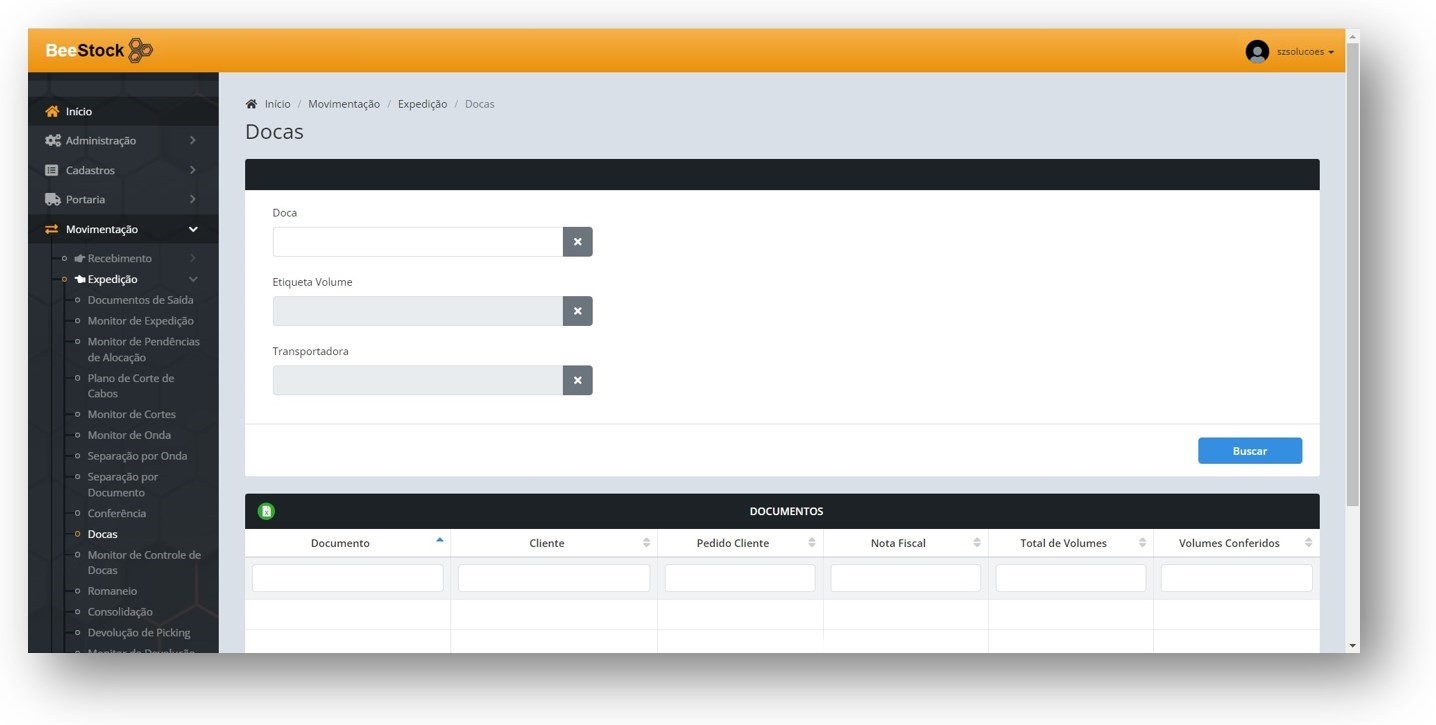

Docks

Located in the Movement > Shipping > Docks menu, it is used to stage the material, inserting the packages and associating them with a specific carrier’s group, so that all packages of all documents are shipped together later.

To perform the Dock process, follow these steps:

Access the Movement > Shipping > Docks menu.

Enter the Dock name and click Confirm.

Scan the barcode of the package label attached to the physical package.

The message Completed successfully will be displayed.

Repeat the process for all packages you want to insert.

When finished, click the orange Finish button.

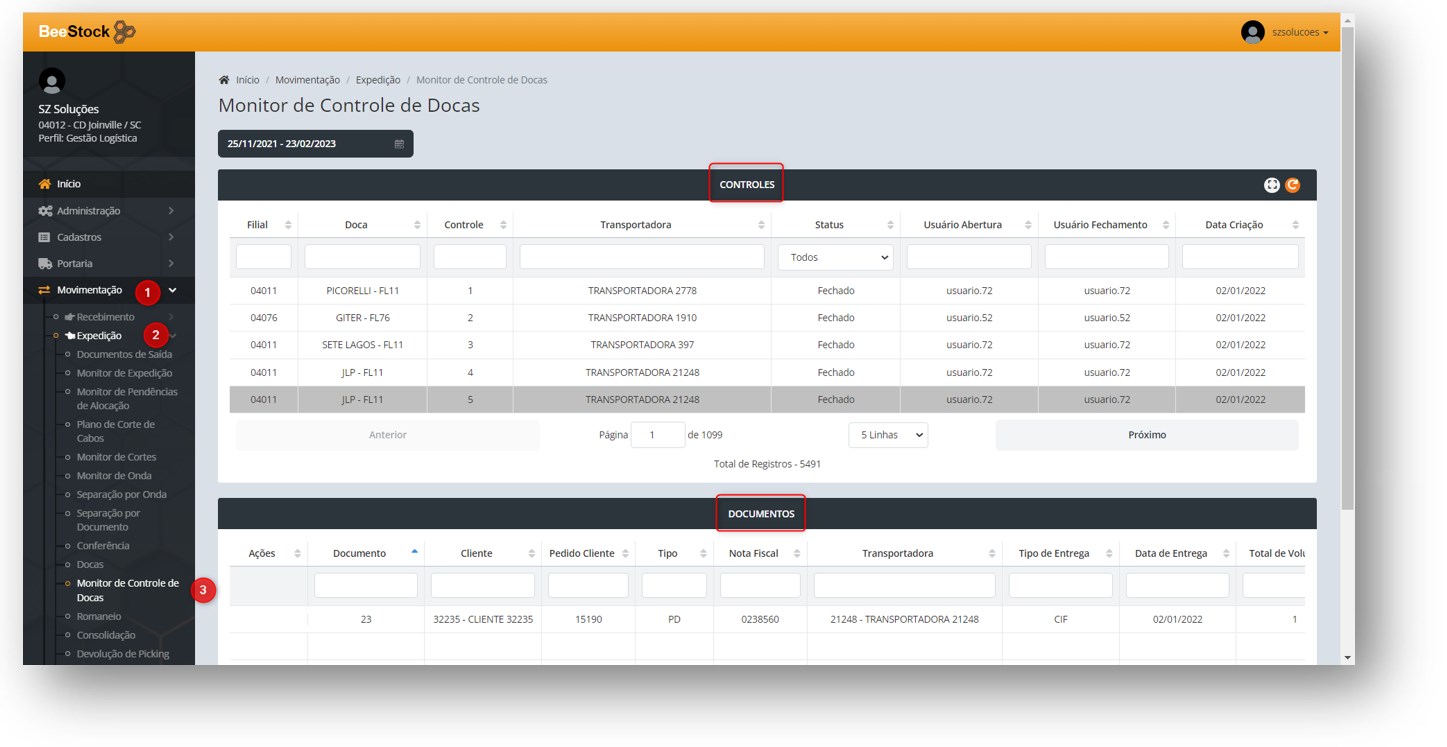

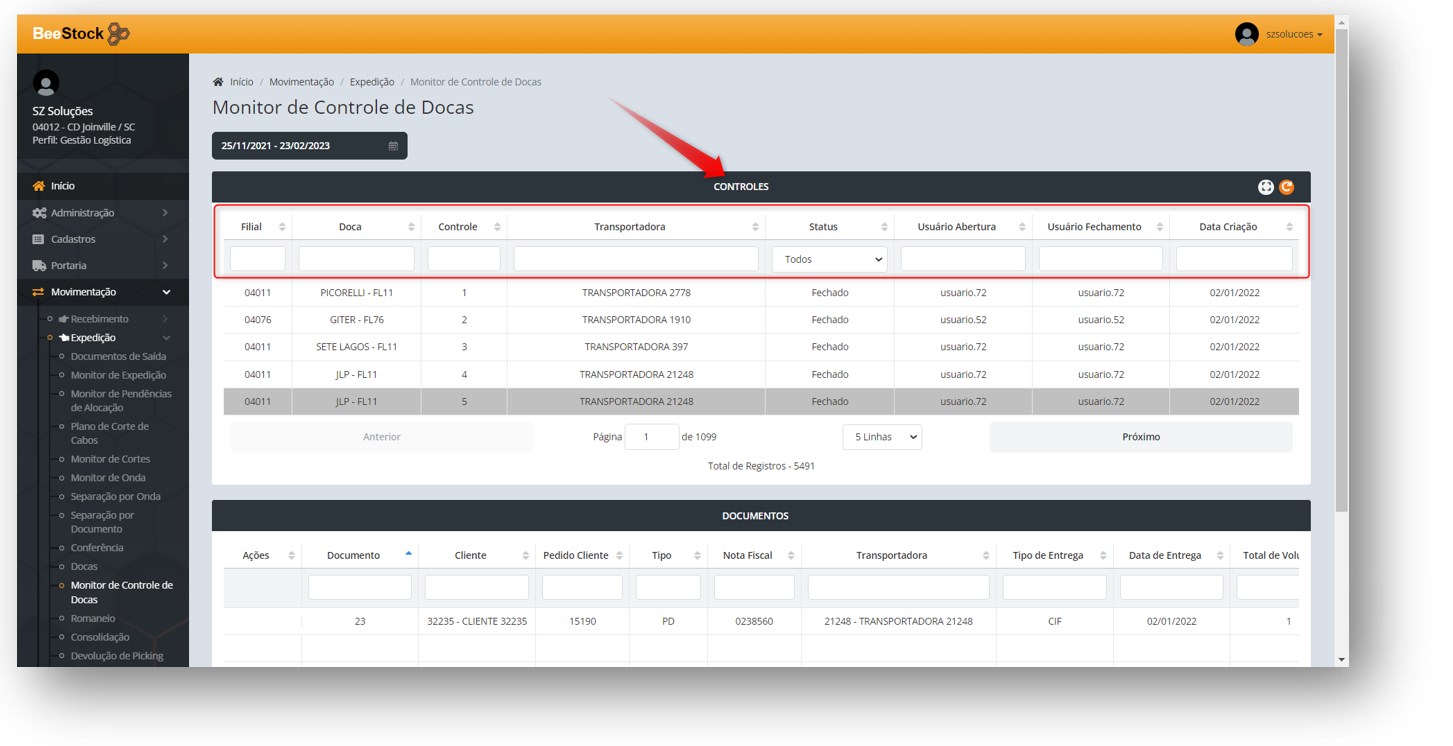

Dock Control Monitor

Located in Movement > Shipping > Dock Control Monitor, it is the place where all dock records are stored, both open and closed.

The screen is divided into two main frames:

Controls

Documents

Controls tab – where all dock controls are recorded, both open and closed.

Branch

Dock

Control (Numerical sequence that identifies the opening and closing of a dock)

Carrier

Status

Opening User (User who registered the dock opening)

Closing User (User who registered the dock closing)

Creation Date (Date of the dock control creation)

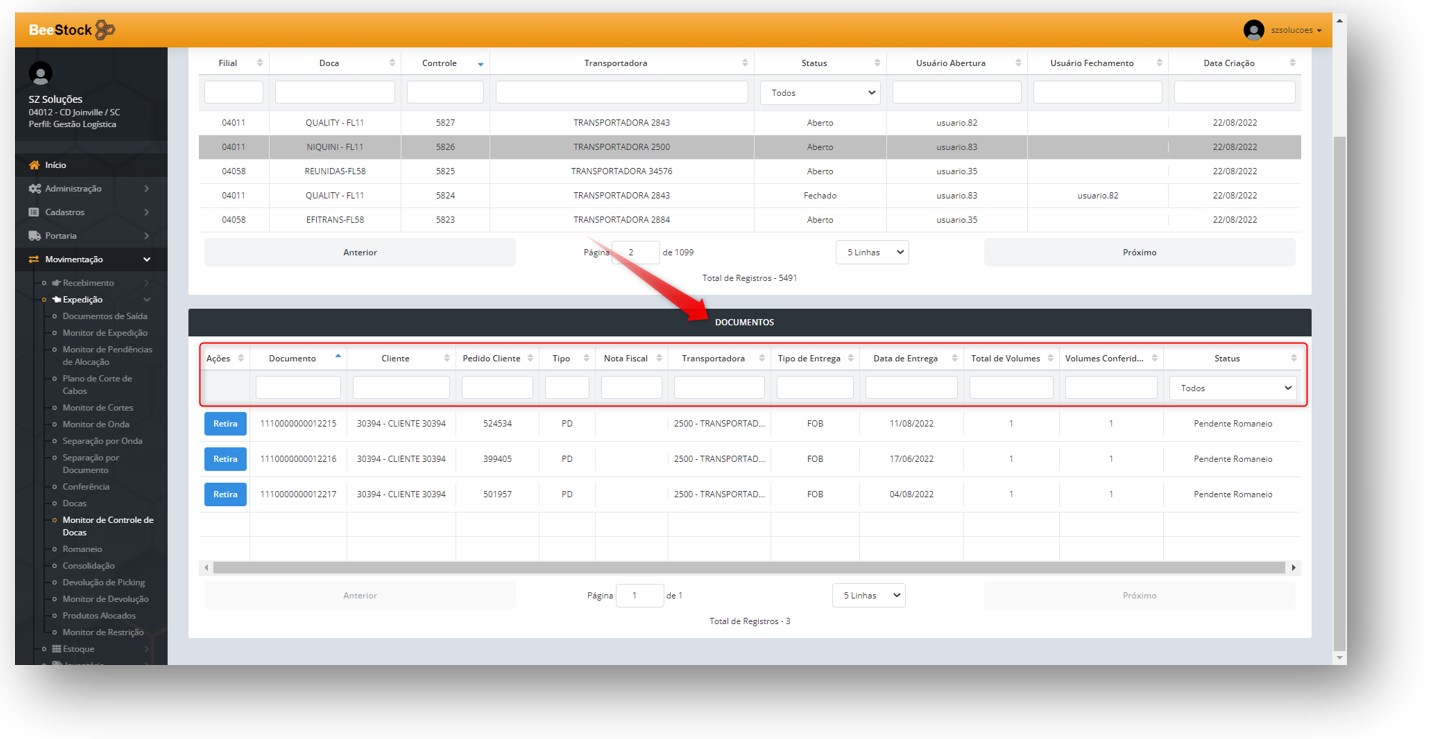

In the Documents tab, all documents available on that dock will be presented, divided by the following information:

Actions (Only when the dock status is open, the user has the possibility, in the Withdraw button, to withdraw documents that may not follow the packing list with the carrier)

Document

Customer

Customer Order

Type

Invoice

Carrier

Delivery Type (CIF, FOB, Forwarding, etc.)

Delivery Dates

Total Packages (Total number of packages in the document)

Checked Packages (Total number of packages in the document that have been checked)

Status (Status of the document within the dock)

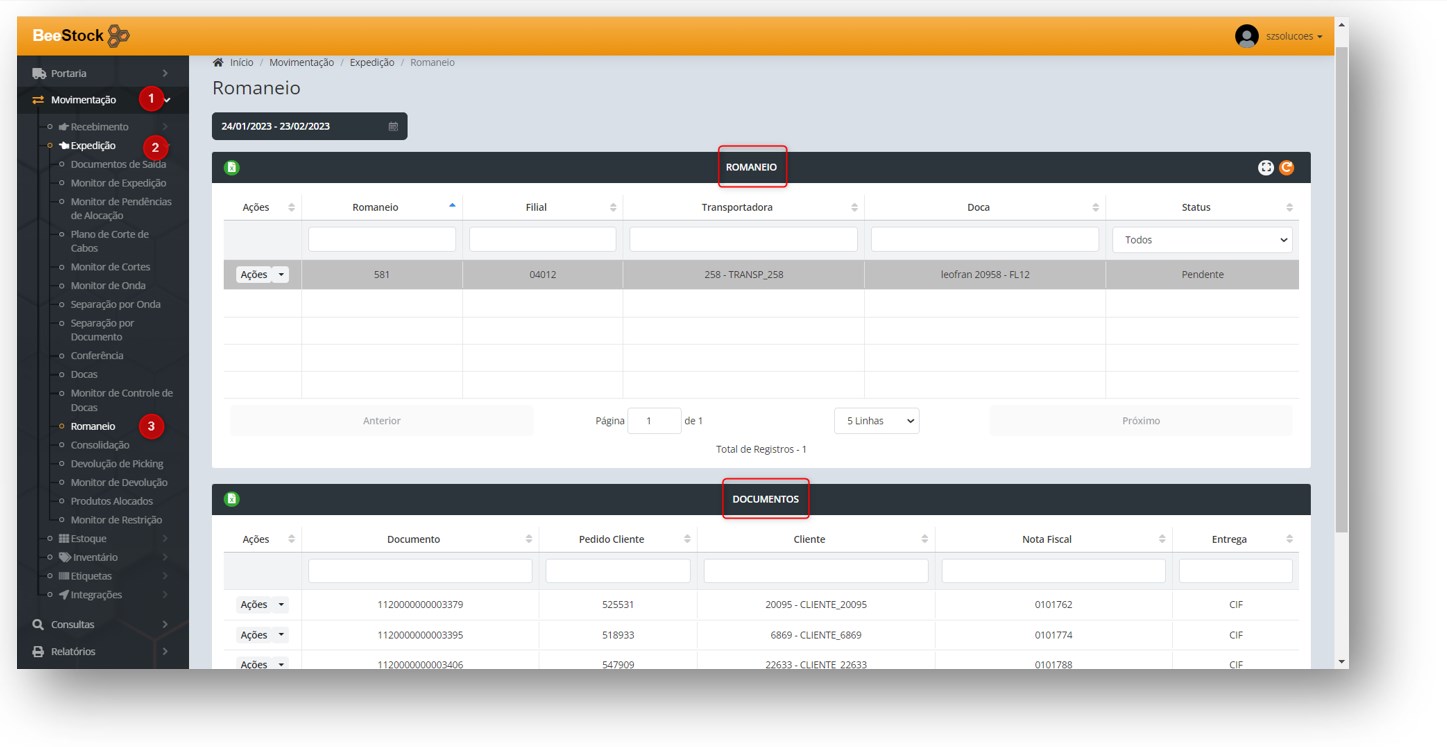

Packing List

Located in Movement > Shipping > Packing List, it is the place where all generated packing list records are stored.

The screen is divided into two main frames:

Packing List

Documents

The generation and registration on the Packing List screen occurs automatically after the dock is closed, as well as its integration with the ERP.

Packing List tab – where all generated records are stored.

Packing List

Branch

Carrier

Dock

Status

In the Documents tab, the user has a view of all documents that are included in that packing list, divided by the following information:

Document

Customer Order

Customer

Invoice

Delivery

Consolidation - Collector

Located in the Collector, in the Goods Issue > Consolidation menu.

The Consolidation screen aims to ensure the delivery of the correct packages to the carrier, basically checking if the package check label matches the consolidation label (Invoices) of the package to be shipped, thus ensuring the delivery of the correct material to the carrier.

To perform the consolidation process, follow these steps:

Enter the package label information in the Package Label field. The consolidation label will be printed automatically.

After that, the Document, Pending (with the number of pending packages), and the sequence and package information at the bottom will be filled in automatically.

Scan the barcode of the printed label in the Consolidation Label field.

The message Completed successfully will be displayed.

Repeat the process until all packages in the document are consolidated.

Once all packages are consolidated, the document status in the web system will change to Finished.

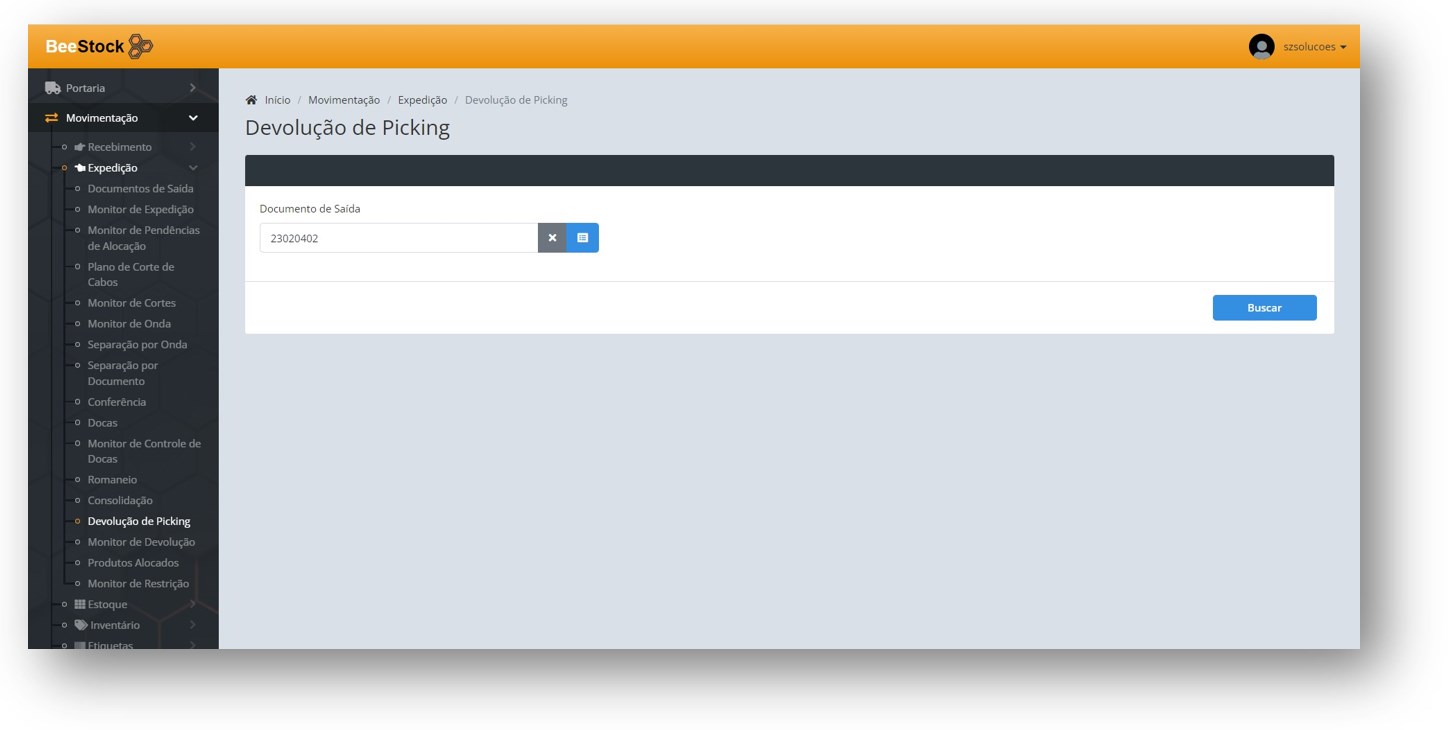

Picking Return

Located in the Movement > Shipping > Picking Return menu, this screen is used to generate picking returns, aiming to return the material balance to the origin address, reversing the picking.

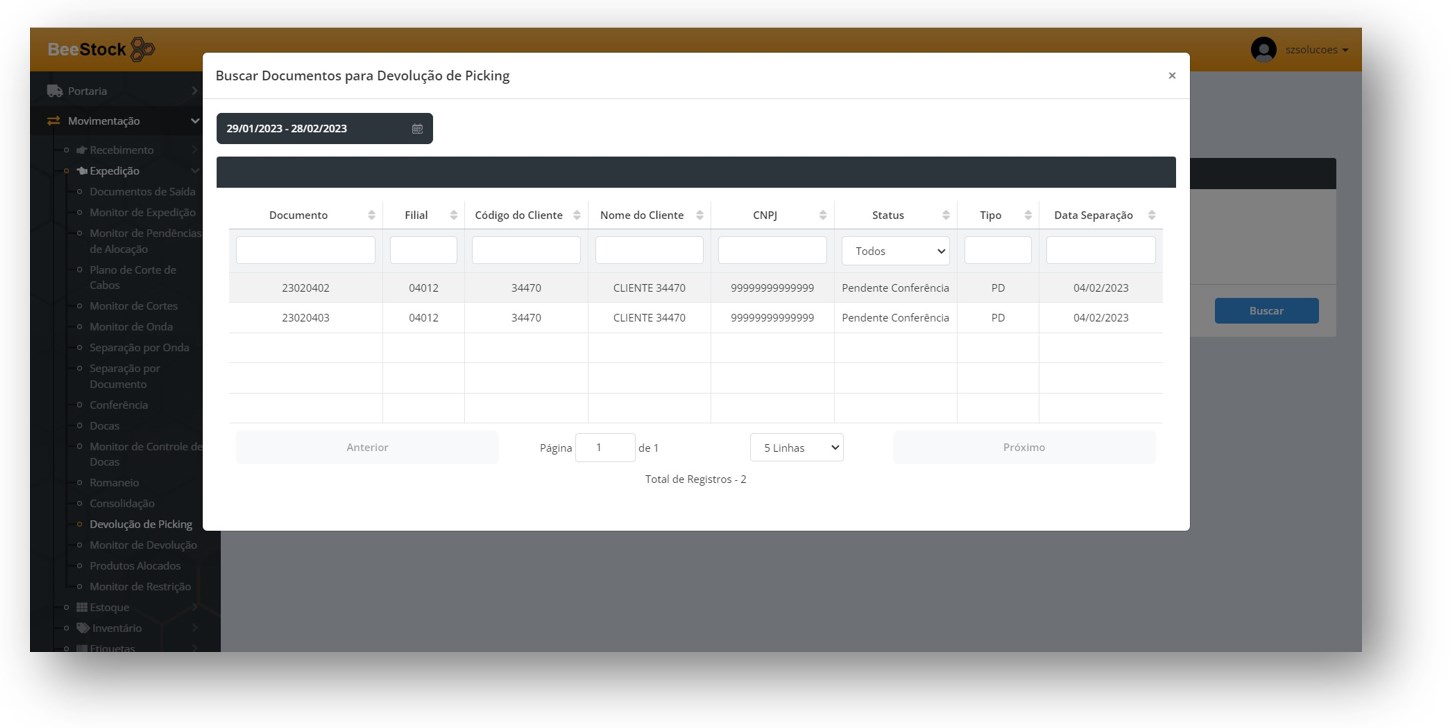

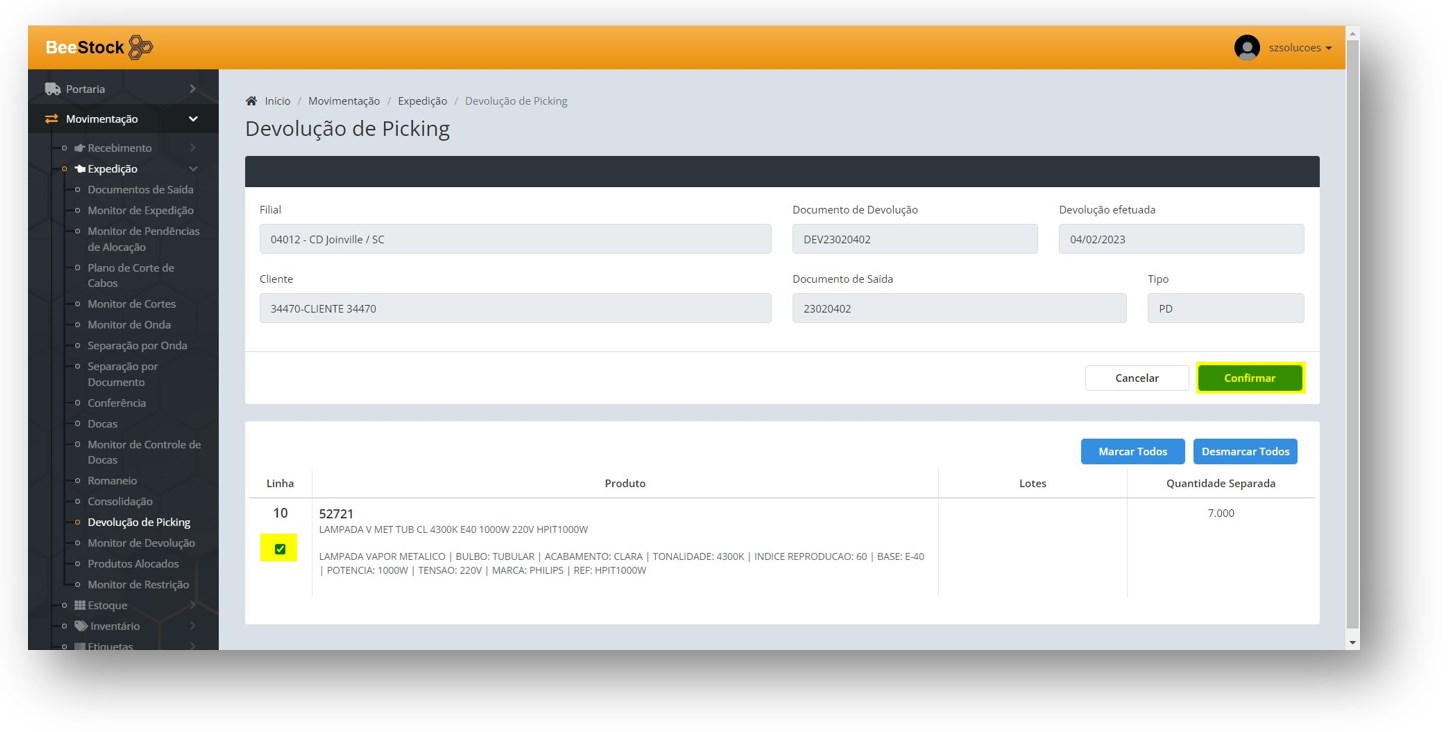

To perform a picking return, access the screen and:

Manually enter the Outbound Document for which you want to perform the picking return.

Click Search.

Or you can also:

Search the list of documents by clicking the blue button.

Click on the desired document.

When clicking Search or selecting a document from the list, select the items for which you want to generate the picking return document and click Confirm.

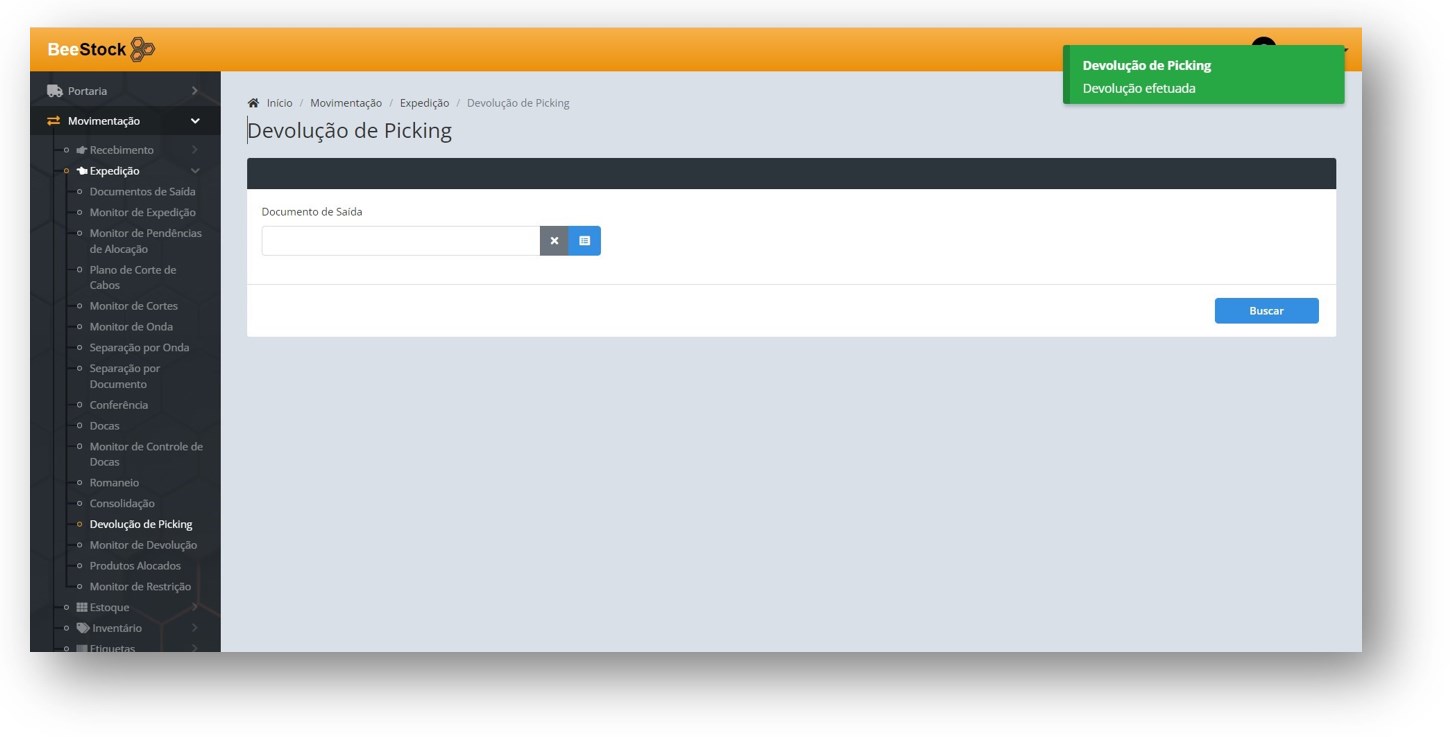

The message Return performed will be displayed, indicating that the return document was generated successfully and the physical return can be performed via collector.

The return document will start with RET followed by the original outbound document number.

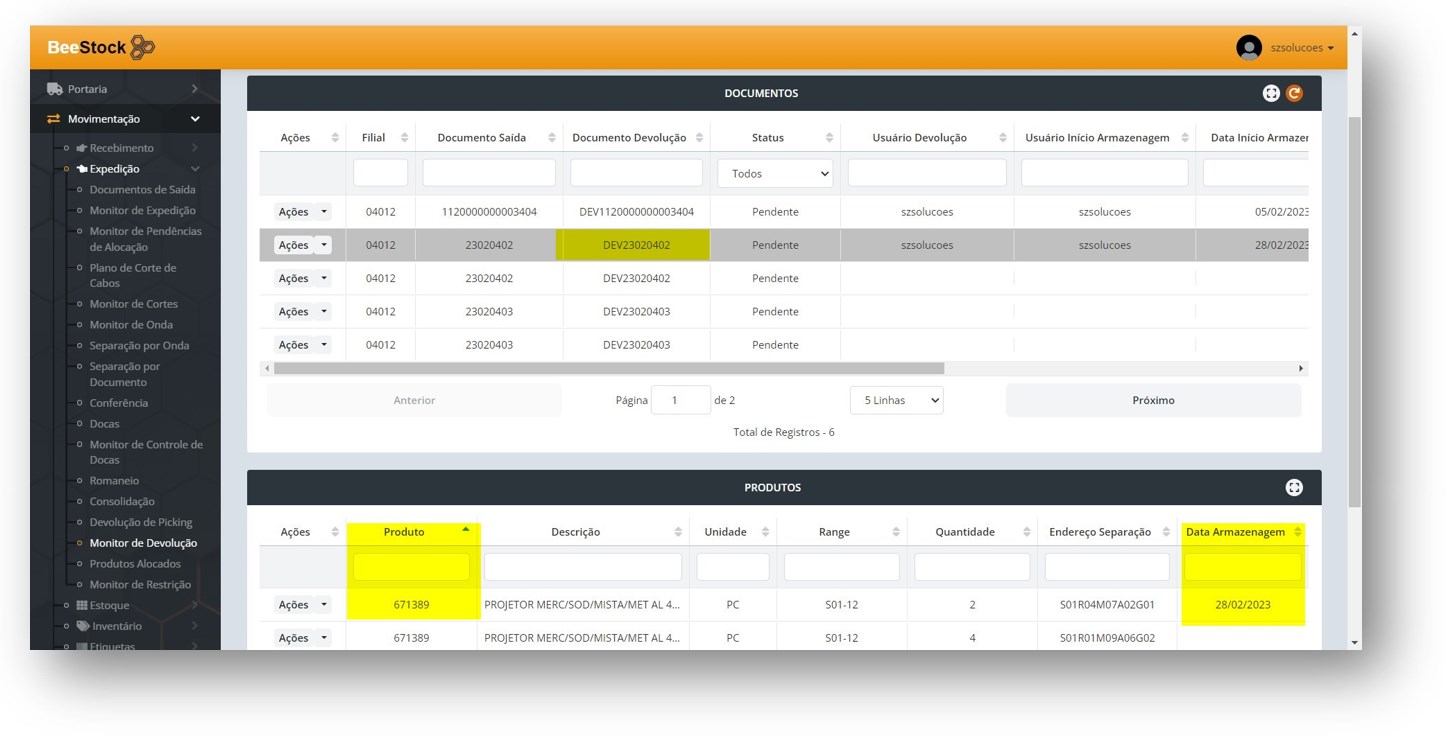

Return Monitor

Located in the Movement > Shipping > Return Monitor menu, this screen displays all generated return documents and their respective statuses.

In the top DOCUMENTS grid, select the desired document, and in the bottom PRODUCTS grid, all items included in this document will be loaded, containing: \

Pay attention to Storage Date, which indicates that the product in question has been stored at the address and is available again for allocation.

Date filter

Branch

Outbound Document

Return Document

Status

Return User

Storage Start User

Storage Start Date

Storage End User

Storage End Date

And in the bottom grid:

Product

Description

Unit

Range

Quantity

Picking Address

Storage Date

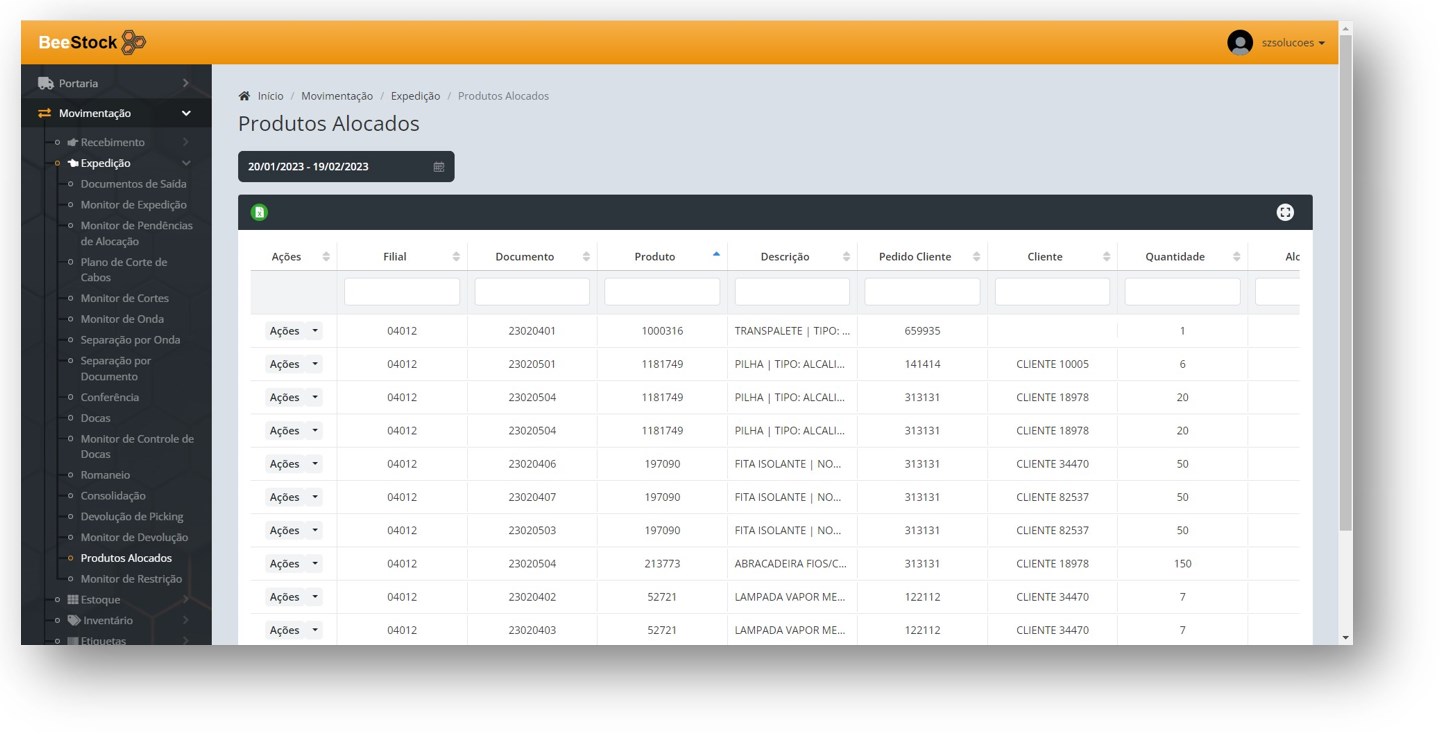

Allocated Products

Located in the Movement > Shipping > Allocated Products menu, this screen allows you to view, by product, where it is allocated in the different outbound documents, providing another option to view allocated balance by Product.

• The screen contains the following filters:

Date range filters

Filters for each column

• Fields:

Branch

Document

Product

Description

Customer Order

Customer

Quantity

Allocated

Picked

Delivery Date

Inventory Control

Expiration Date

Batch

Creation Date

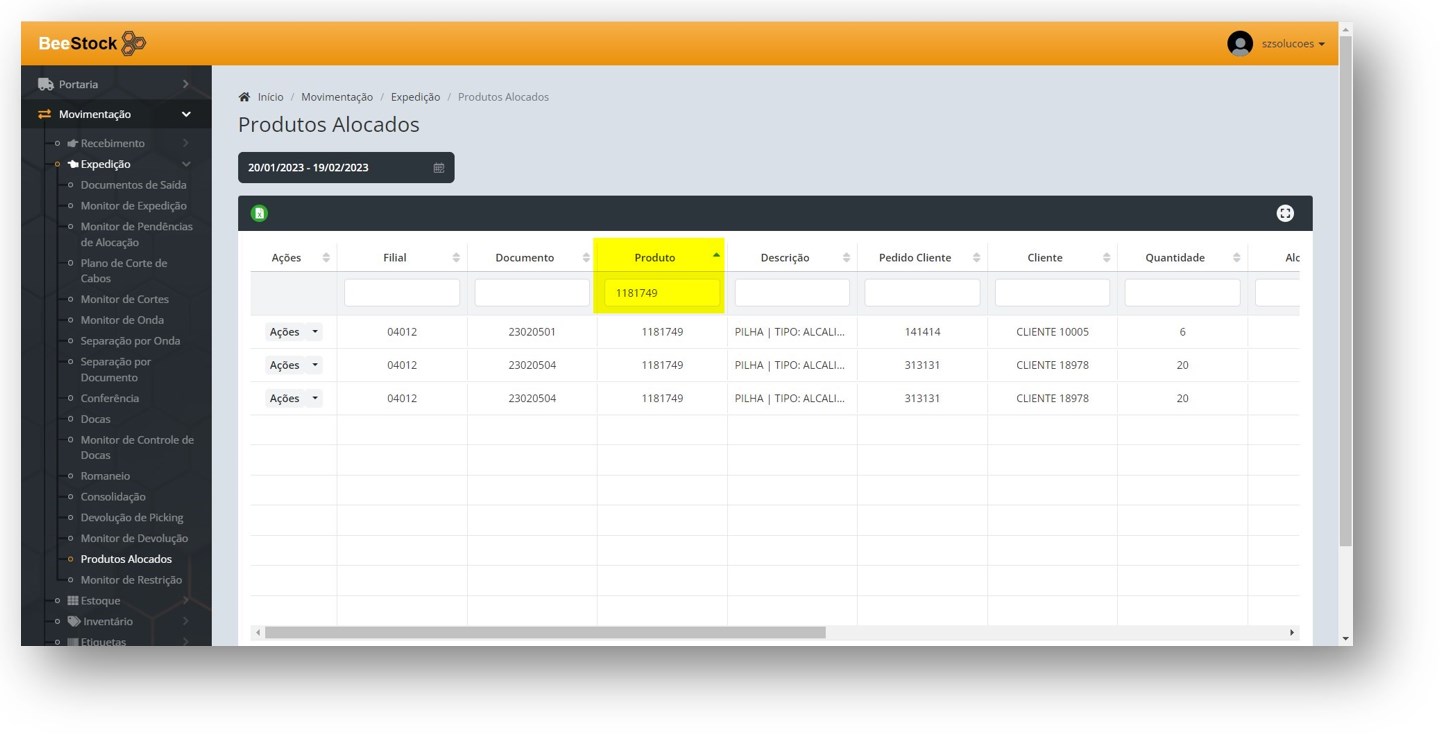

• For example, when filtering only by Product, a filter will be applied displaying all outbound documents where this product has an allocated balance, as shown in the filter example below:

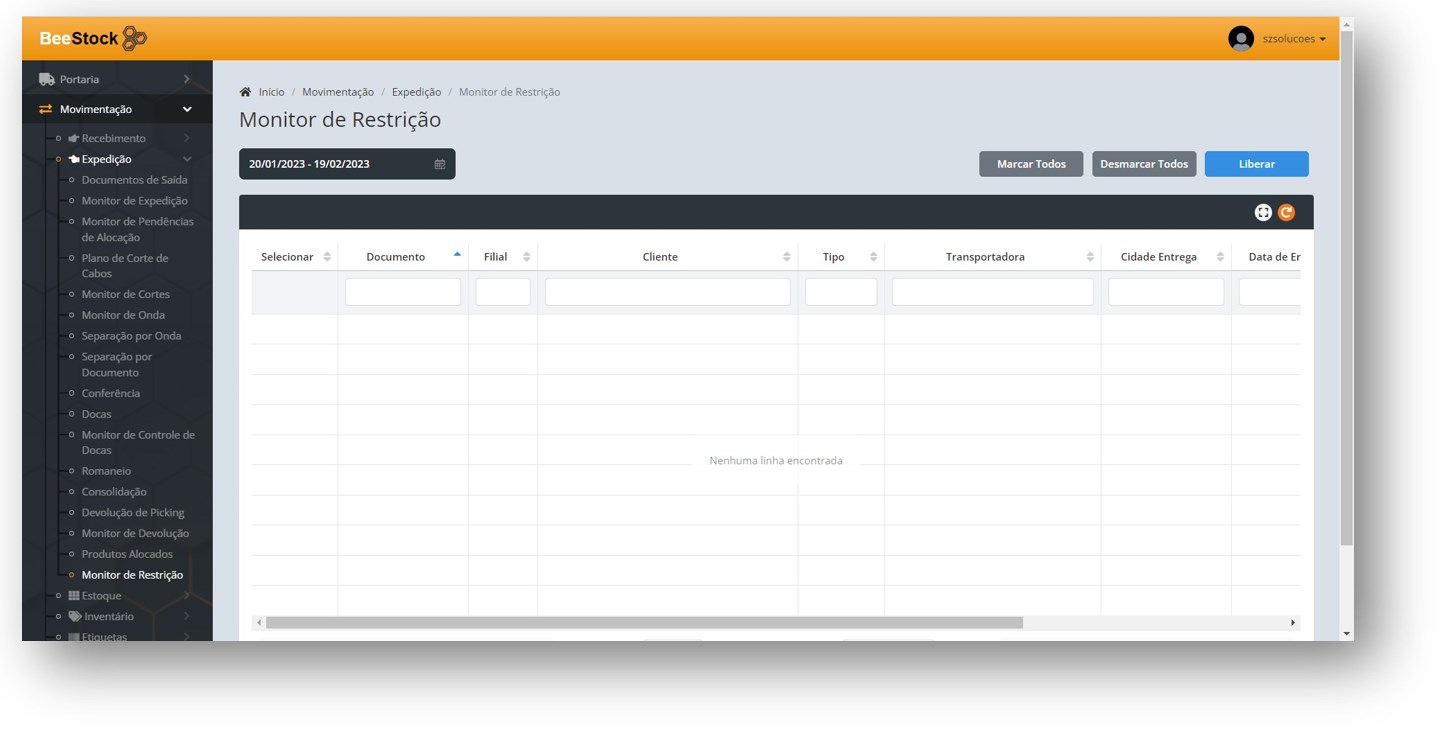

Restriction Monitor

Located in the Movement > Shipping > Restriction Monitor menu, this screen allows you to release outbound documents that are under restriction, according to the parameter configured in the Customer Restriction record in the Customer x Branch registration.

• On this screen, you must select the documents you want to release for shipping.

• Once you have selected the documents, click “Release” to proceed with the Docks process.

Shipping Flow - Collector

Located in the Goods Issue menu on the collector, the shipping flow consists of the following processes:

Issue Menu with shipping processes.

1 - Cable Cutting - has the function of performing the cable cutting in the system so that it can be physically carried out, after having its cutting plan created via WEB.

2 - Picking by Wave - when entering Picking by Wave in the issue menu, the user must click the circular arrow button in the upper right corner. In this way, with each click, the system will add a product to be picked in their wave (the maximum number of products per wave is defined in the Products per Wave Limit parameter located in the Picking tab in the Branch Registration), displaying some of its information on the screen before adding it.

When clicking Confirm, the process of picking the wave products starts.

If the product is not picked by the user who created the wave, it can be deleted via BeeStock® WEB.

After confirming the wave, the picking screen automatically displays some information related to the product to be picked, requiring the user to enter:

Batch

Picking address

Product EAN

Quantity

At the bottom of the screen, the products to be picked in the wave will be listed, and the Pick button confirms the picking of that product.

3 - Document Picking - to start picking by document, the user must enter the desired document or click the + button to add one of the available documents.

When clicking +, the available documents for picking are presented, and upon selecting one of them, the picking process starts.

Unlike the picking by wave process, where multiple products from different documents can be added to a picking wave, in picking by document, it occurs for only one document, but this document may have one or more products.

Similar to the picking by wave process, the steps for picking by document are identical.

In picking by document, all products of that document are displayed.

4 - Checking - on the checking screen, the user must enter the batch to be checked. At this moment, the screen is filled with some information about the picking that occurred in that batch, requiring the user to enter the package of the volume, the EAN, and the physically checked quantity.

After entering the above information, the user must click the Confirm button to check that product.

Checking confirmation.

After checking all products, the user must click the Finish button and enter the number of packages and weight to finalize the package checking.

When finalizing the check, the user must select the desired printer to print the check label (Package).

5 - Docks - after confirming the check, the document must be inserted into a Dock so that the packing list can be generated later, consolidated, and received by the carrier.

On the Docks screen, the user must first enter the name of the Dock where they will add the packages, then enter the package label and Confirm.

After that, the package is added to the dock, and when clicking Finish, the dock is finalized, and the packing list is generated automatically.

Example of adding a package to the dock. When clicking the Confirm button, the system asks the user to confirm the inclusion of the document in the dock.

After adding all packages to the dock, it must be finalized by clicking Finish.

When finalizing the dock, the packing list is automatically generated and integrated with the ERP.

As the last step in the shipping process, after generating the packing list, the consolidation process of the checked packages inserted in the dock must be performed.

6 - Consolidation - the Consolidation screen aims to ensure the delivery of the correct packages to the carrier, basically checking if the package check label matches the consolidation label (Invoices) of the package to be shipped, thus ensuring the delivery of the correct material to the carrier.

To perform the consolidation process, the user should follow these steps:

Enter the package label information in the Package Label field. The consolidation label will be printed automatically.

After that, the fields Document, Pending (with the number of pending packages), and the sequence and package information at the bottom will be filled in automatically.

Scan the barcode of the printed label in the Consolidation Label field.

The message Completed successfully will be displayed.

This process should be repeated for the remaining packages in the document until all are consolidated.

Cable Cutting Flow - Collector

Cable Cutting - has the function of performing the cable cutting in the system so that it can be physically carried out, after having its cutting plan created via WEB.

When clicking Cable Cutting in the issue menu, the user must enter the cutting number generated via WEB or click the + button to select the cutting.

Cut selection screen.

After selecting the cut, the user must enter the name of the cutting equipment (1), the EAN of the product (2), the quantity to be cut, and the batch.

The remaining information is filled in automatically after entering the product EAN.

At the bottom of the cable cutting screen, the user has access to the data of the product being cut, the option to print the label related to the cut, and the Cut button to perform the cutting.

After finishing the cut, the system displays the message Cut Finished as shown below.

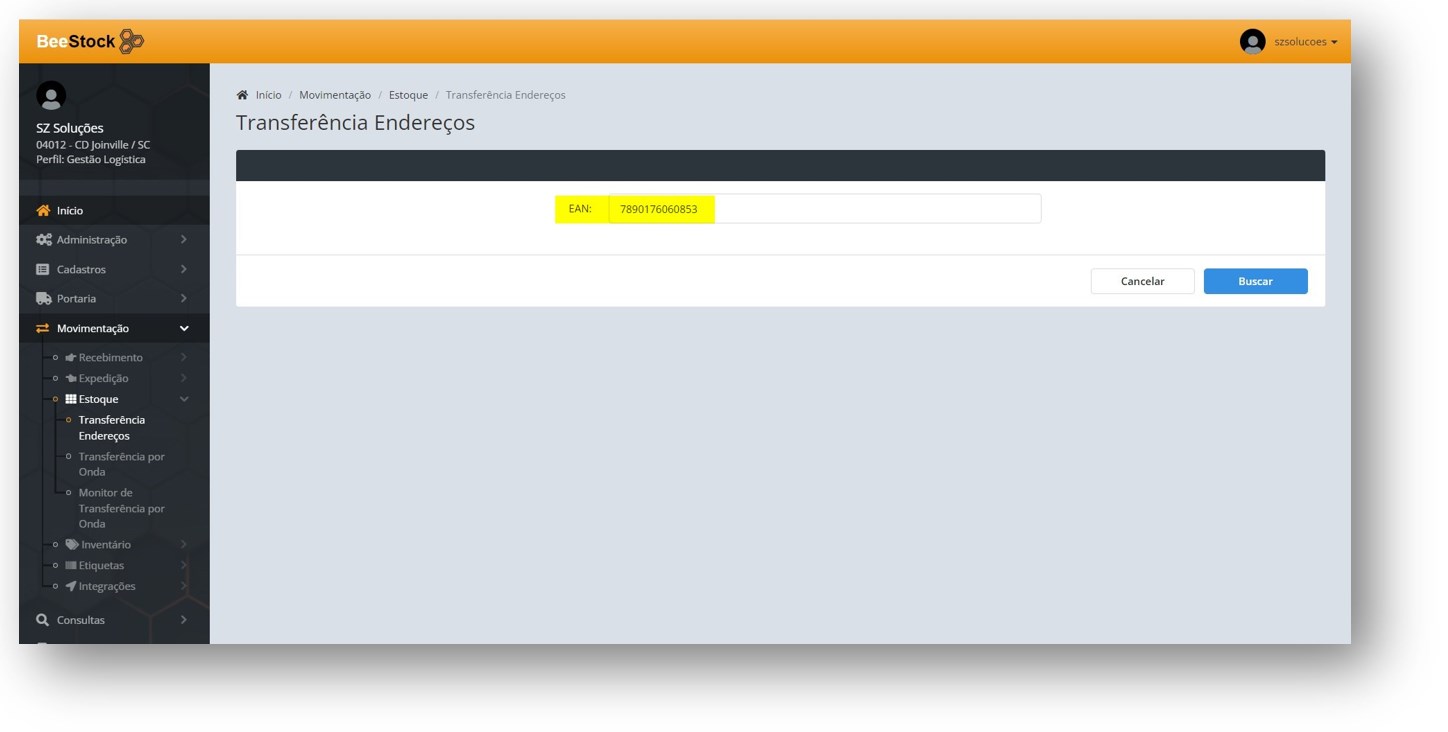

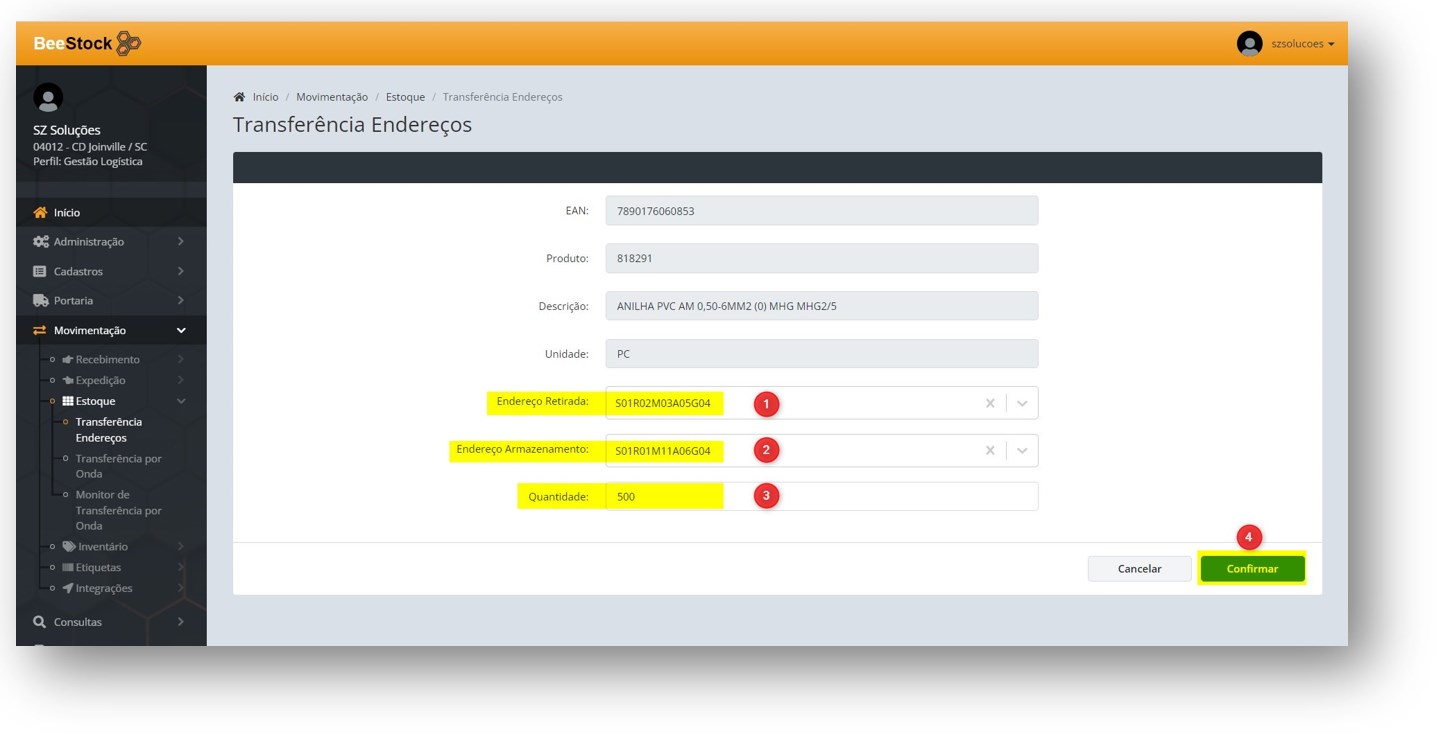

Address Transfer

Located in the Movement > Inventory > Address Transfer menu, it is used to transfer balances between addresses within the same resale warehouse.

Access the Address Transfer screen and enter the EAN of the product you want to transfer between addresses.

Confirm the data for the address transfer as numbered in the screenshot below:

Picking Address

Storage Address

Quantity

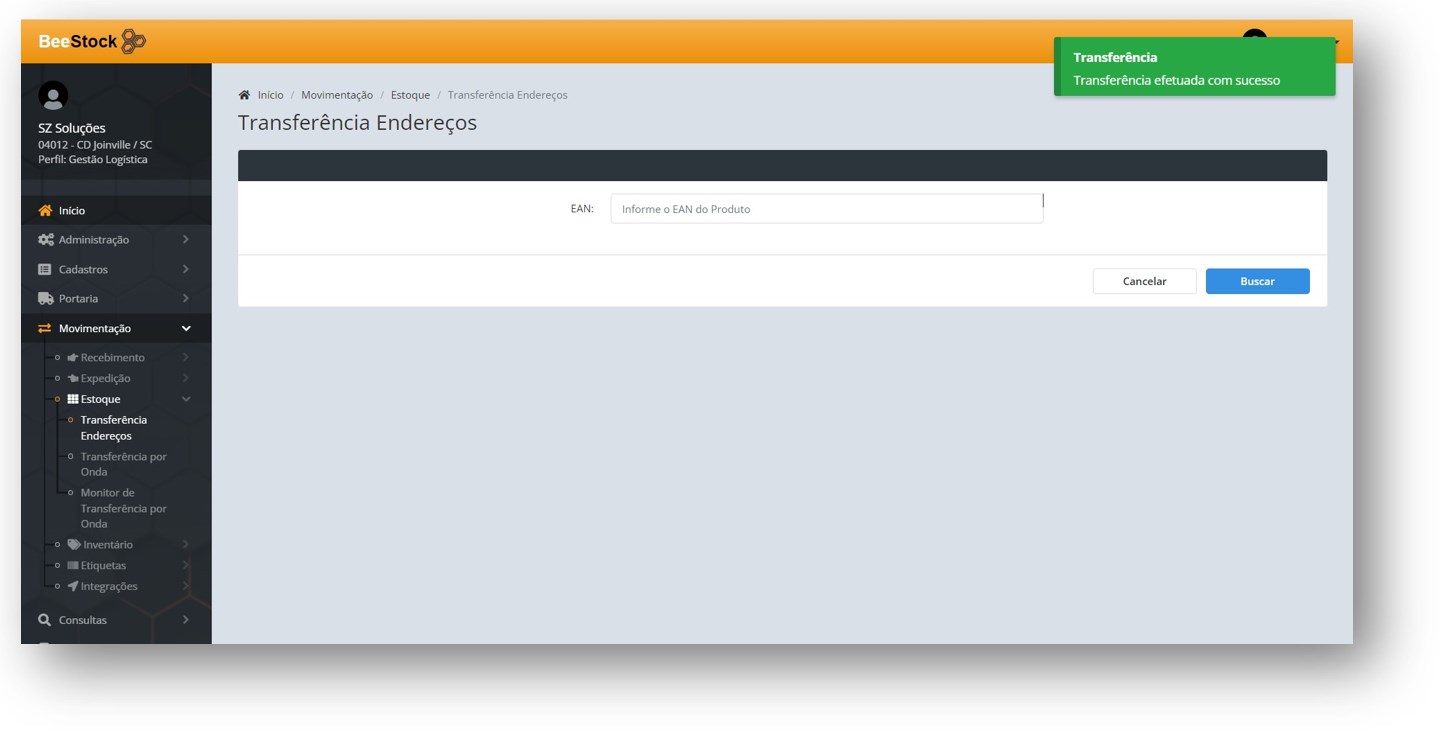

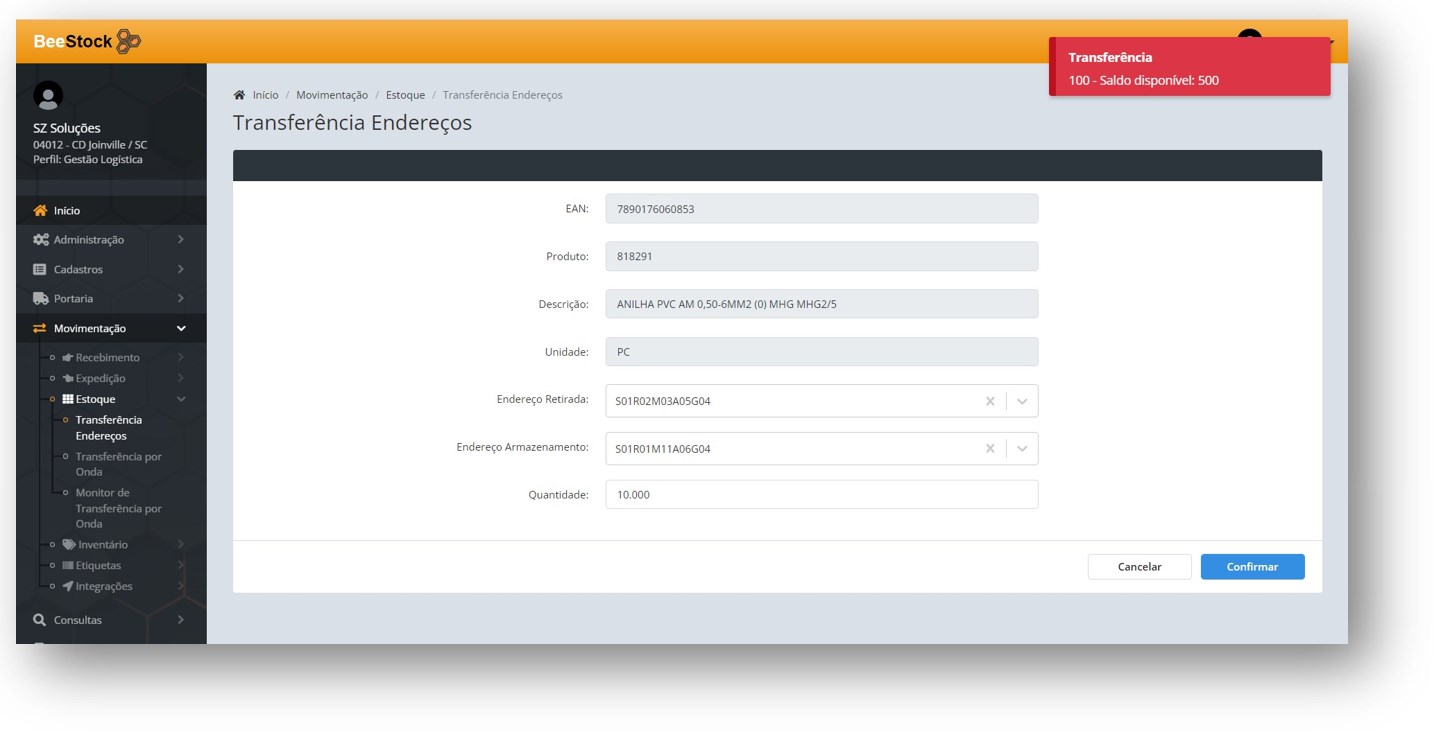

The confirmation message Transfer successfully completed will be displayed:

If the entire balance entered in the Quantity field is not available at the Picking Address, the error message 100 Available balance XXXX will be displayed, indicating that the available balance at the address is insufficient to perform the requested transfer.

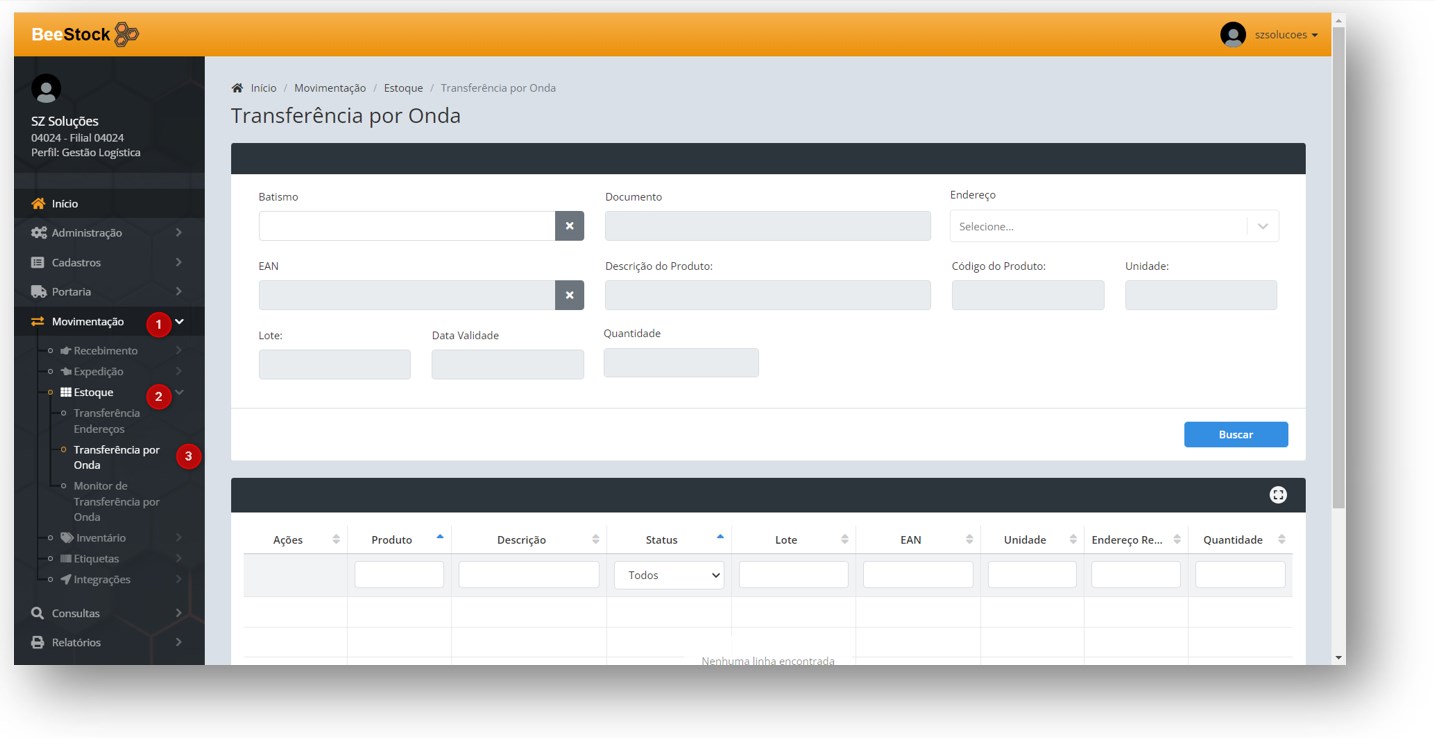

Wave Transfer

Located in Movement > Inventory > Wave Transfer, it is the process used to transfer products between warehouses, allowing the transfer of multiple products within the same wave.

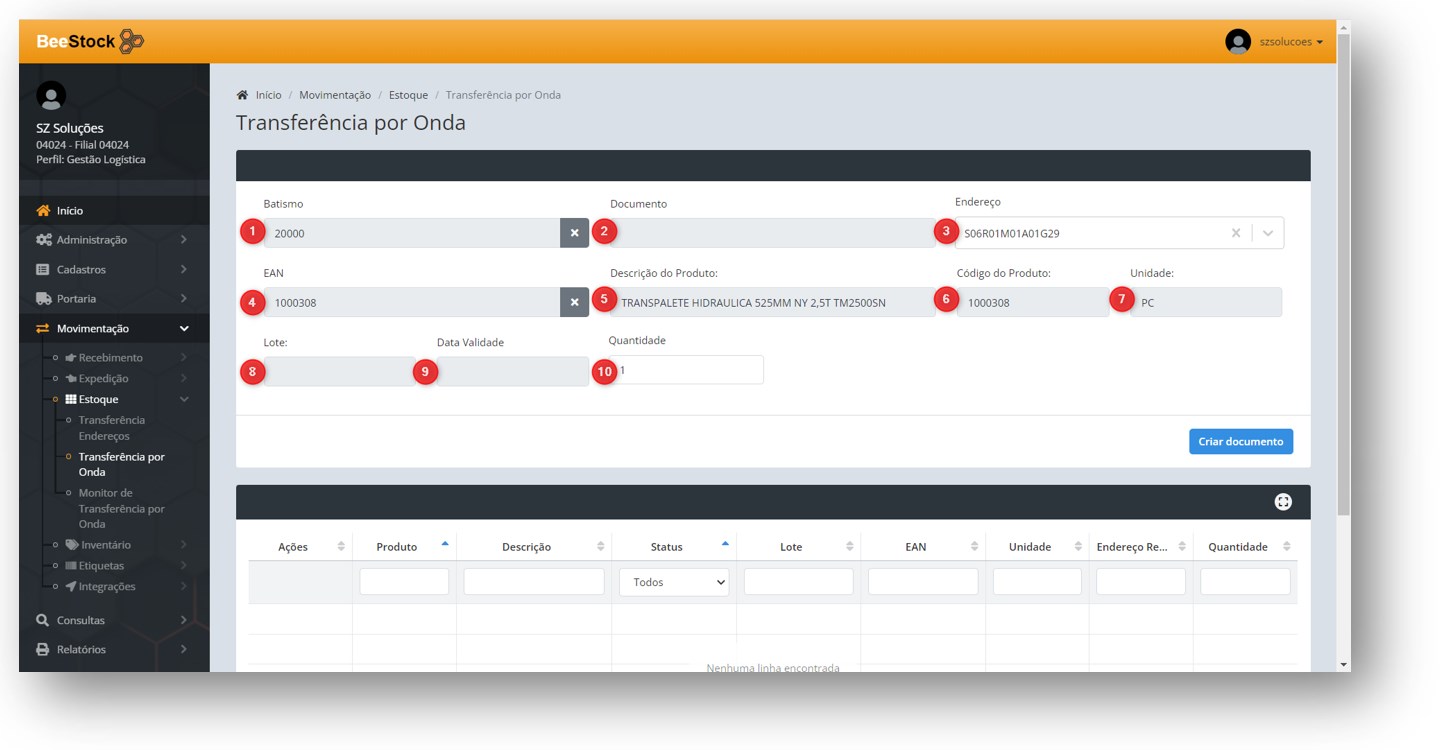

Wave transfer process:

Enter a batch number.

The document number will be generated only when finishing the wave creation in Create Document.

Enter the address from which you are picking the product to be transferred.

Enter the EAN of the product to be transferred.

Product Description – The system automatically retrieves it after entering the product EAN.

Product Code – The system automatically retrieves it after entering the product EAN.

Unit - The system automatically retrieves it after entering the product EAN.

Batch – When the product is batch-controlled, the user must enter the batch registered in stock for that product.

Expiration Date – When the product is expiration date-controlled, the user must enter the expiration date registered in stock for that product.

Enter the quantity to be transferred.

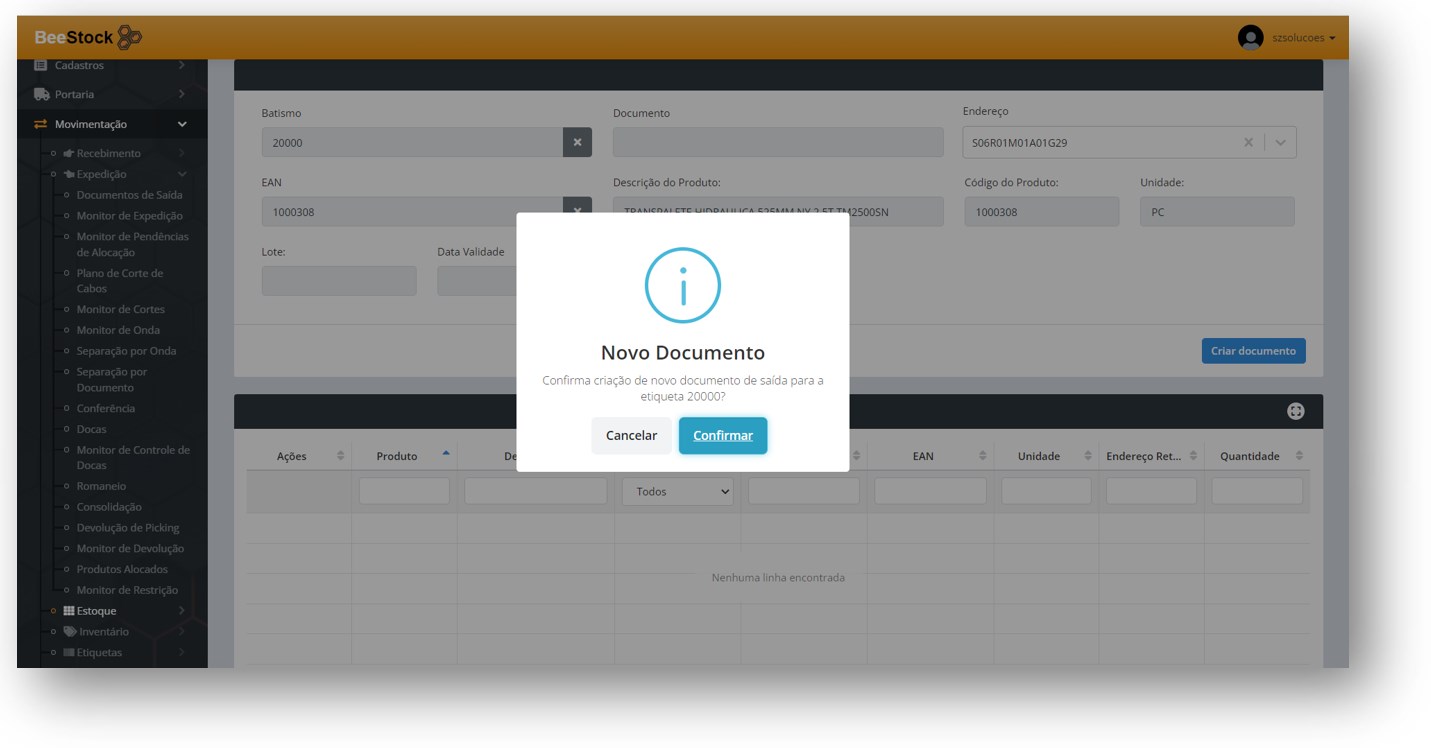

After completing the previous steps and clicking Create Document, the system displays an alert requesting confirmation of the wave transfer document (Image 1), and if confirmed, the transfer document is generated, and the product to be transferred is added to the document (Image 2).

Image 1:

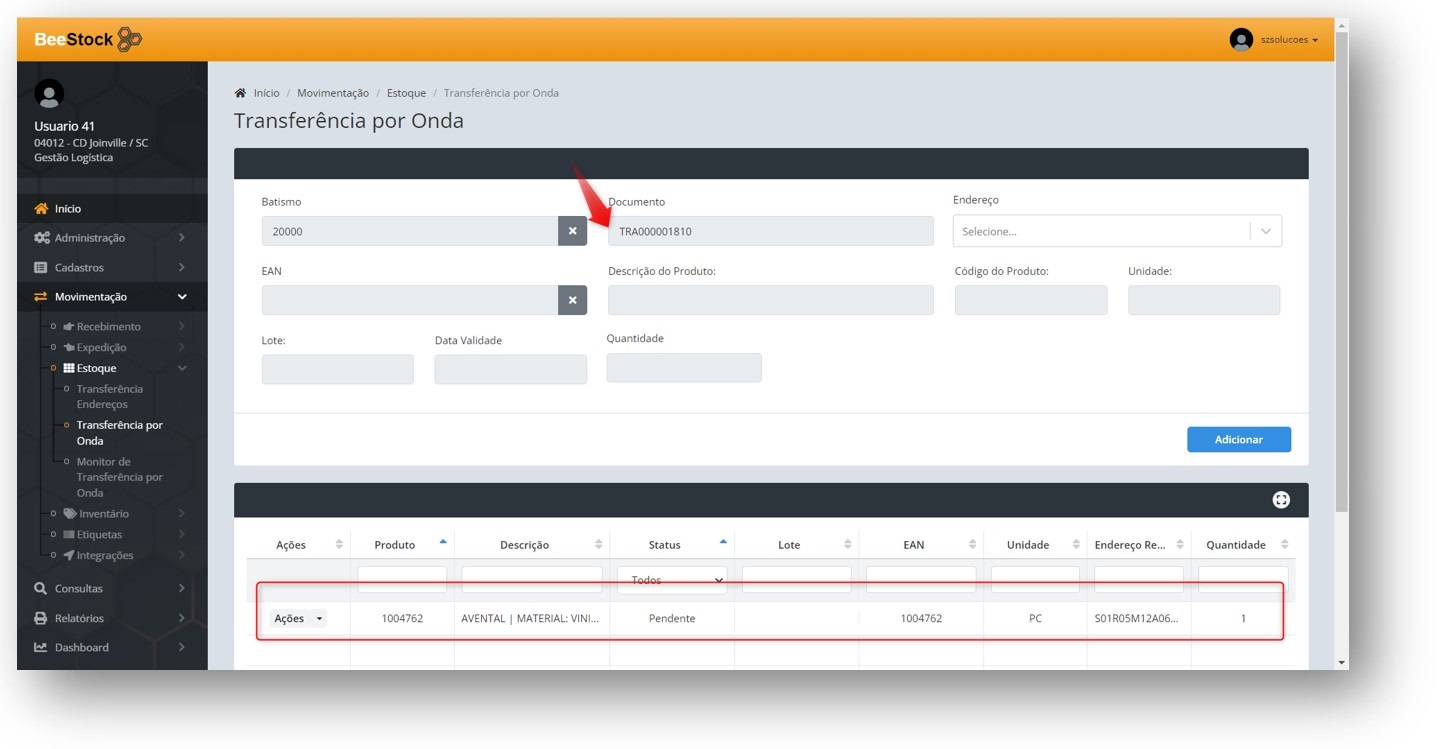

Image 2:

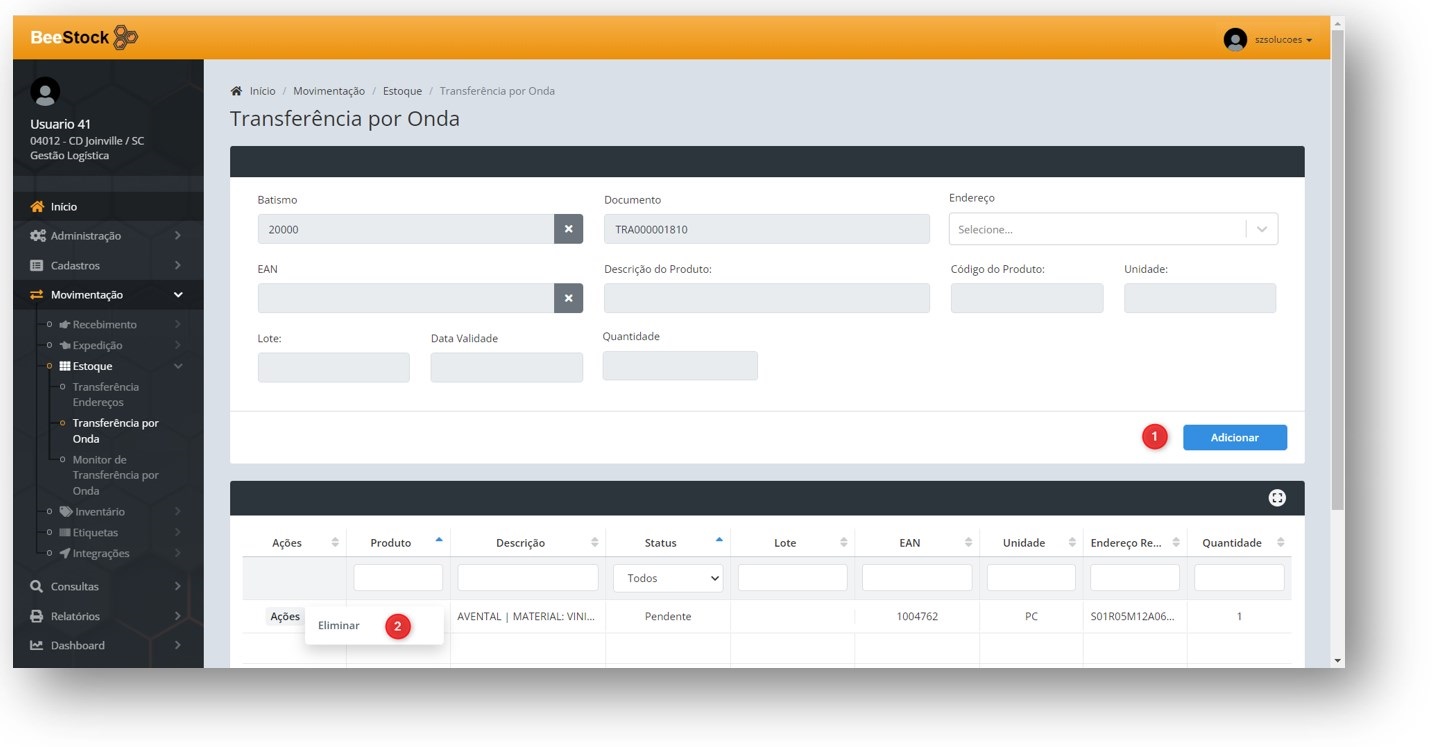

If the user wishes to add more products to the document, they must repeat the process for the data related to the desired product and click Add (1).

If they wish to delete a product included in the document, simply select the Actions option and click Delete (2).

After adding the desired products to the document, it will be available for the user, via collector or web, to enter the products in the desired warehouse and address through the Wave Transfer Monitor.

Wave Transfer Monitor

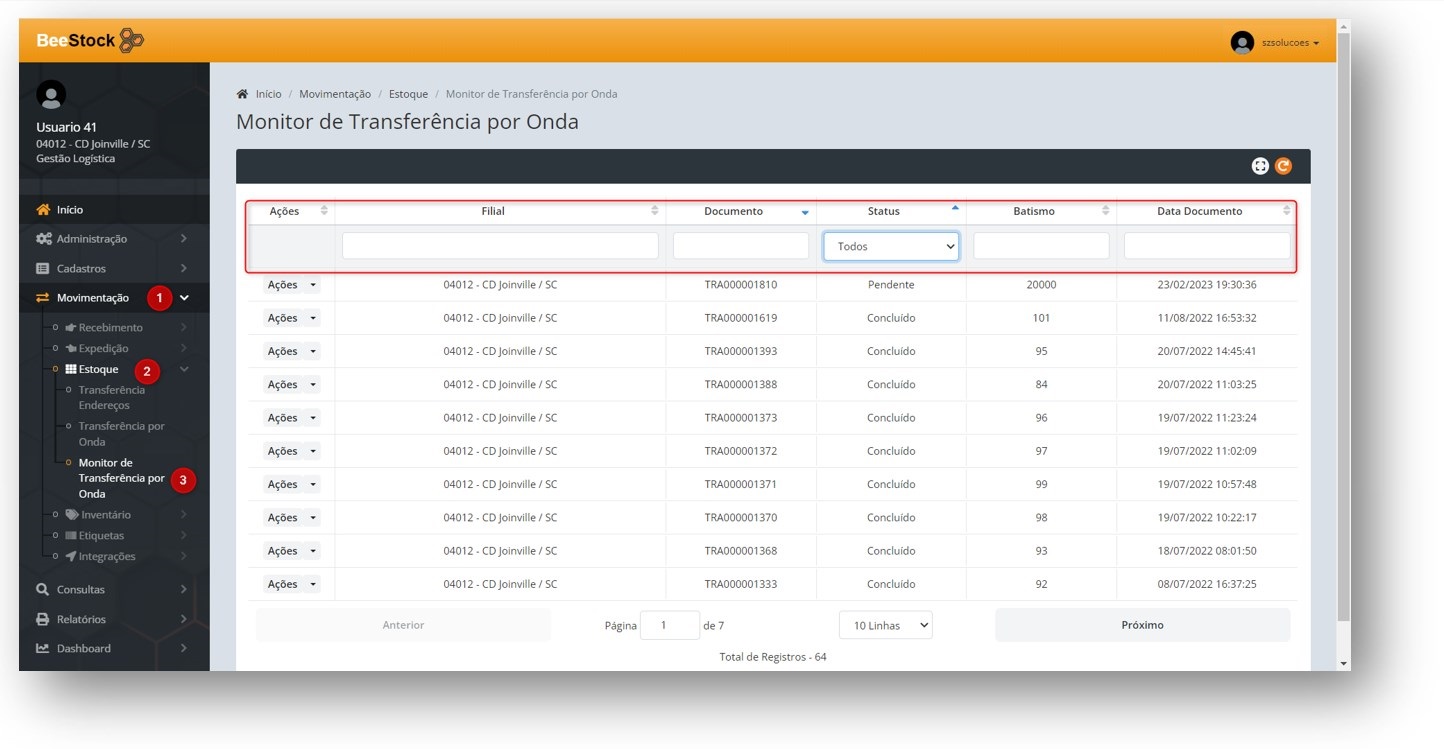

Located in Movement > Inventory > Wave Transfer Monitor, this screen contains all created, pending, and completed wave transfer documents.

Through it, the user can enter the products from the transfer document into the desired destination warehouse and address.

As shown in the previous image, from the Wave Transfer Monitor the user has access to the following information:

Branch

Documents (Document generated in “Wave Transfer”)

Status (Documents already completed and those still pending completion)

Batch (Batch number entered when creating the “Wave Transfer”)

Document Date (Date of document creation)

Transfer process in the Wave Transfer Monitor.

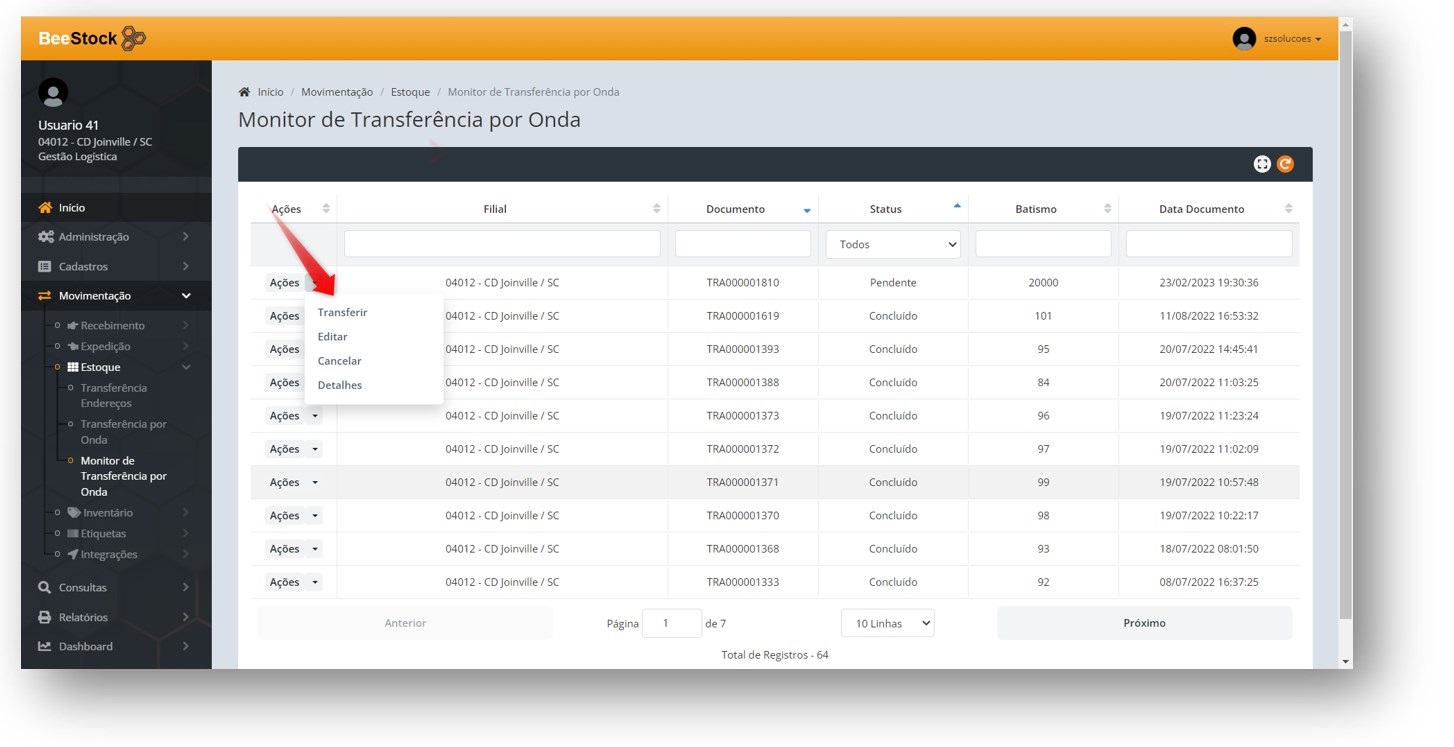

As shown in the previous image, in Actions, the user can Transfer, Edit, Cancel, and Detail a transfer document in Pending status. Only the Details option will be available for a Completed document.

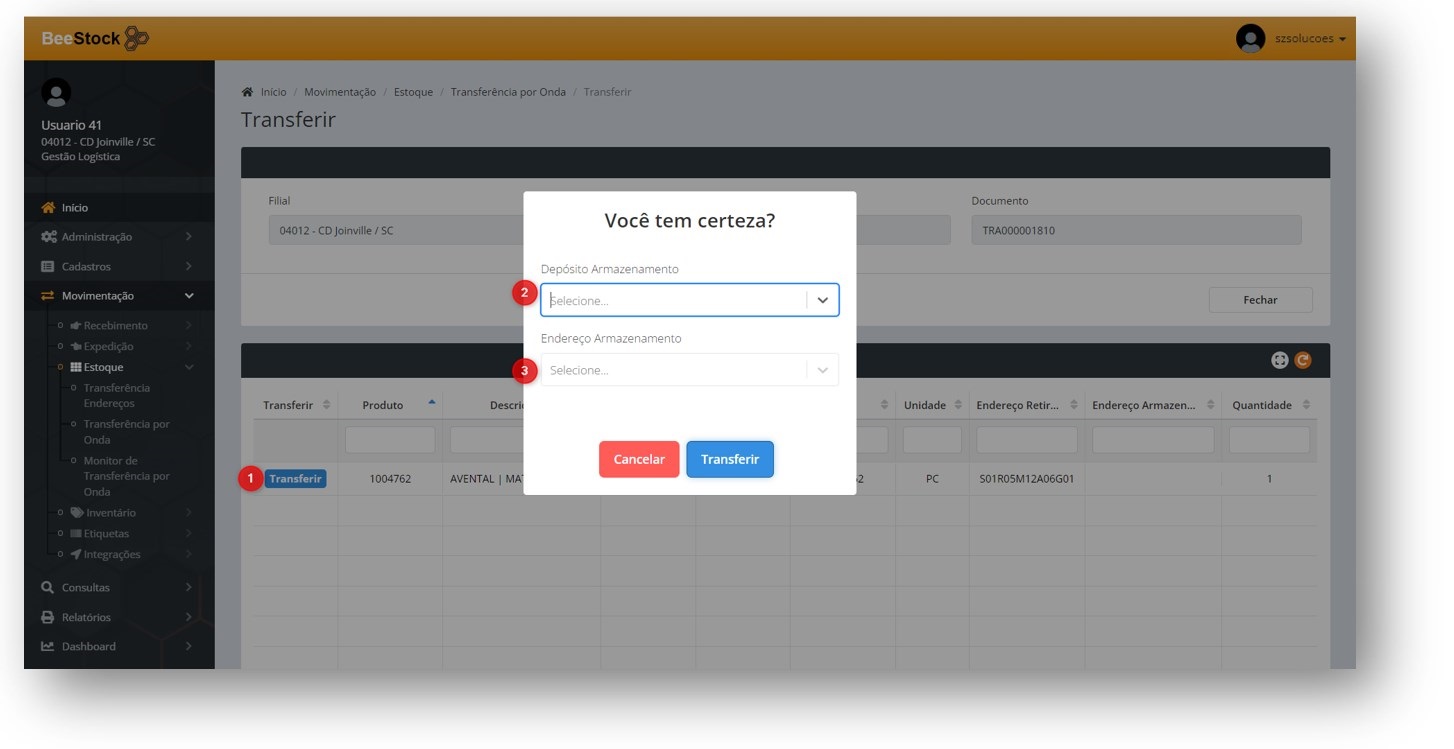

Transfer – The user will have access to the document data with the transfer products and must follow the steps below to transfer the products to the desired address:

Click Transfer.

Enter the destination warehouse for the product.

Enter the address where you want to store the product.

After that, by clicking the Transfer button in the frame where the warehouse and address were entered, the transfer process is completed, and the document status changes to Completed.

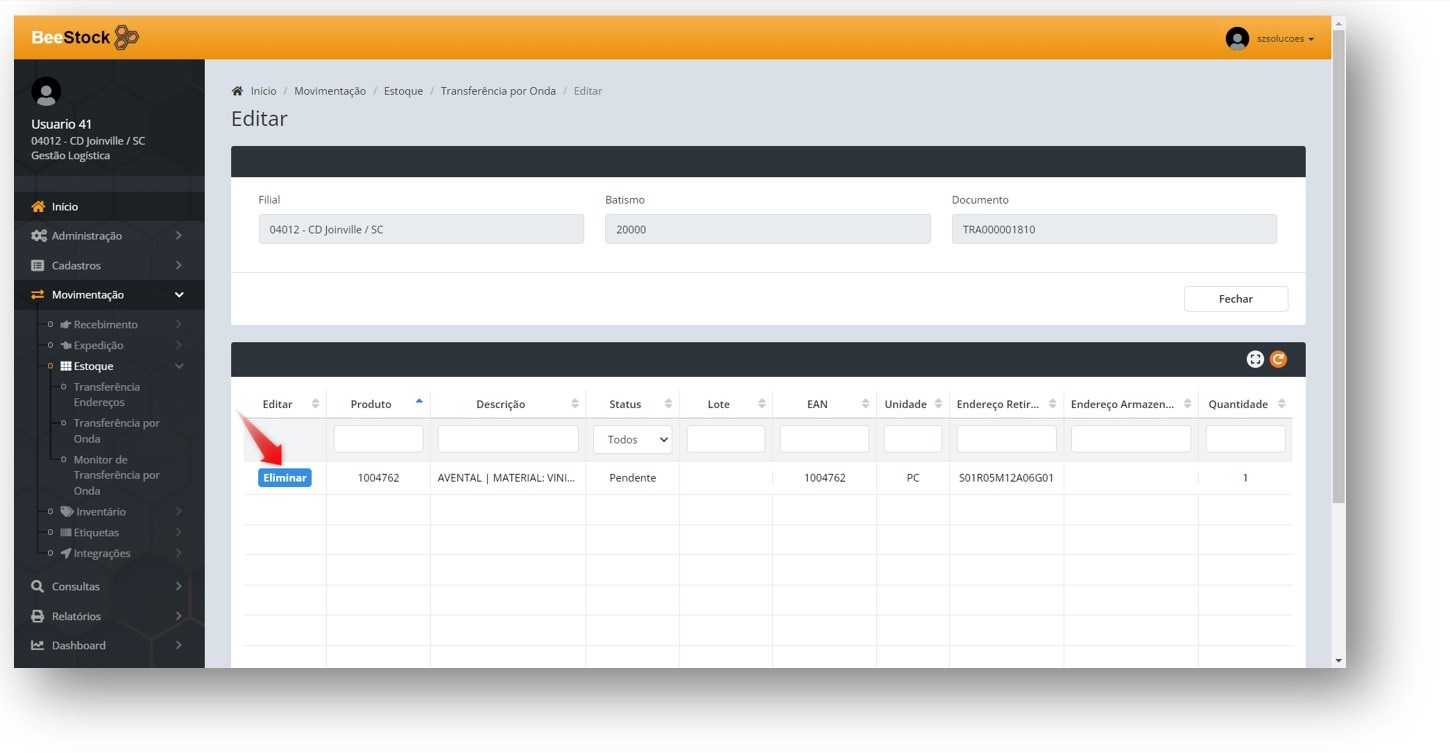

Edit – When clicking this option, the user can delete one of the products from the document before completing the transfer.

Cancel – When clicking this option, the document is canceled and cannot be completed.

Details – The only option also available for completed documents, it allows viewing the details of the transfer document.

Stock Flow - Collector

Located in the Goods Receipt > Address Transfer menu, this screen should be used to perform the transfer between addresses of the same Resale warehouse RV1.

Access the Goods Receipt menu.

Access the Address Transfer screen.

With the screen open, to perform a simple address transfer, you must follow these steps:

Scan the barcode of the product you want to move.

Scan the picking address.

Scan the storage address.

Confirm the quantity to be moved (the total quantity available at the address will be suggested, and you can change it manually if needed).

Click TRANSFER.

When you click TRANSFER, the message Transfer successfully completed! will be displayed.

At this moment, the balance transfers will be performed only in WMS BeeStock®, without generating transfers to the ERP. This is because these are only transfers between addresses.

Collector Flow Screen - Wave Transfer

Located in the Goods Issue > Wave Transfer - Outbound menu, this screen should be used to perform the first stage of the Wave Transfer, which is divided into: Picking the product from the origin address and storing it at the destination address.

To start a wave transfer via collector, follow these steps:

Access the Goods Issue > Wave Transfer - Outbound screen.

Scan the Transfer Batch Label previously printed.

The confirmation below will be requested. Click Confirm.

Proceed with filling in the requested information:

Picking Address

EAN

Quantity

Scroll down the screen and click TRANSFER.

The confirmation message Transfer successfully completed! will be displayed.

Now you are ready to take the material to the destination address and start the storage process.

To do this, access the Goods Issue > Wave Transfer - Inbound menu and follow these steps:

Scan the Transfer Batch Label.

Select the warehouse where you want to store the material. Remember that in wave transfer, it is possible to move balances between different warehouses.

In this example, we will perform a movement to the destination warehouse RV1.

Next, enter the destination address, previously registered in the system.

Scan the destination address label.

The confirmation message Transfer successfully completed! will be displayed.

With this, the transfers between warehouses will be performed in WMS BeeStock®, and the integrations for transfers between warehouses will also be sent to the ERP.

Collector Flow Screen - Remnant / Expiration Date Maintenance

Located in the Goods Receipt > Remnant / Expiration Date Maintenance menu, this screen should be used to change the Batches or Expiration Dates of products, reflecting these changes only in WMS BeeStock®, without sending integrations to the ERP.

Access the Goods Receipt menu.

Access the Remnant / Expiration Date Maintenance screen.

On the screen, confirm all the requested information:

EAN

Quantity

Batch (Current)

New Batch

Picking Address

Storage Address

Click TRANSFER.

When you click TRANSFER, the confirmation message Transfer successfully completed! will be displayed.

At this moment, the balance will be picked from the old batch and entered with the new batch.

The same procedure should be used to change the Expiration Date. If the item is expiration date controlled, the Expiration Date and New Expiration Date fields will be enabled.

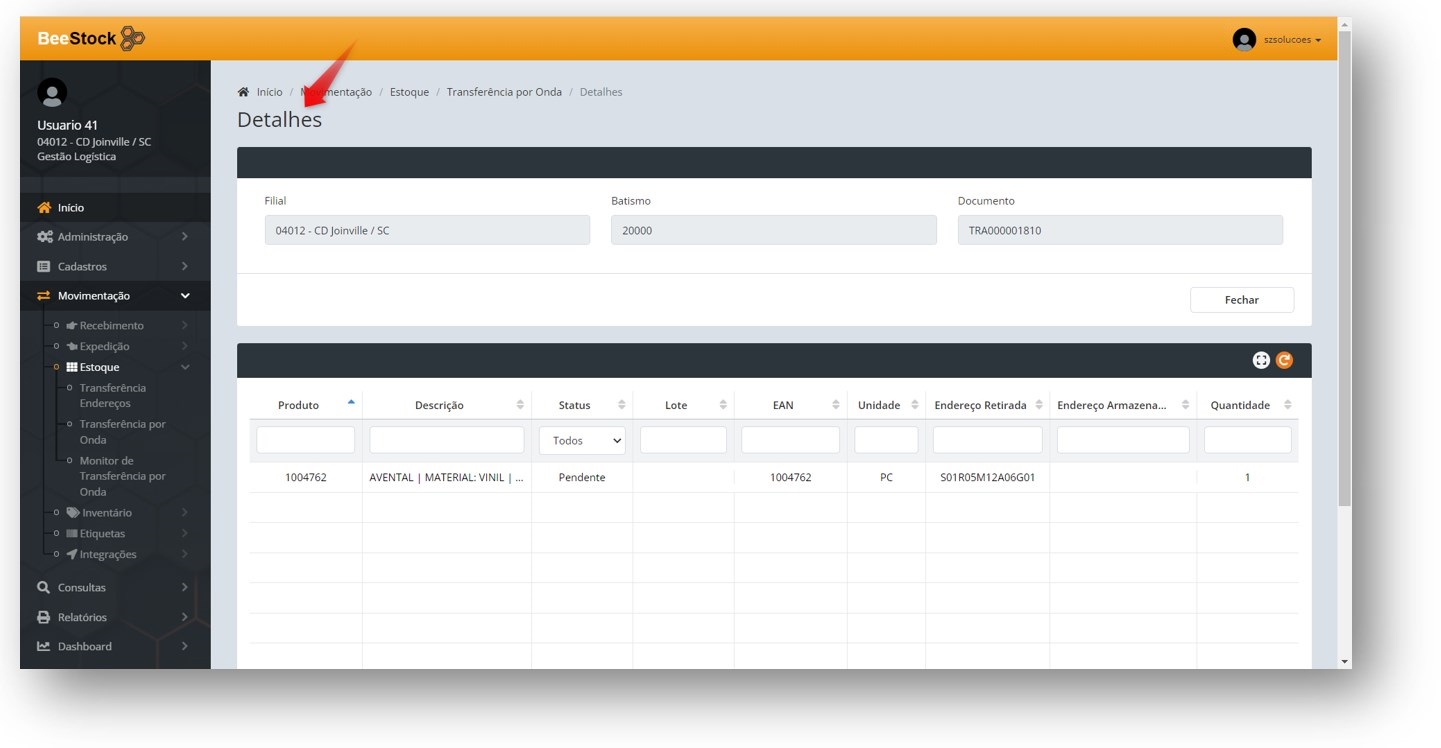

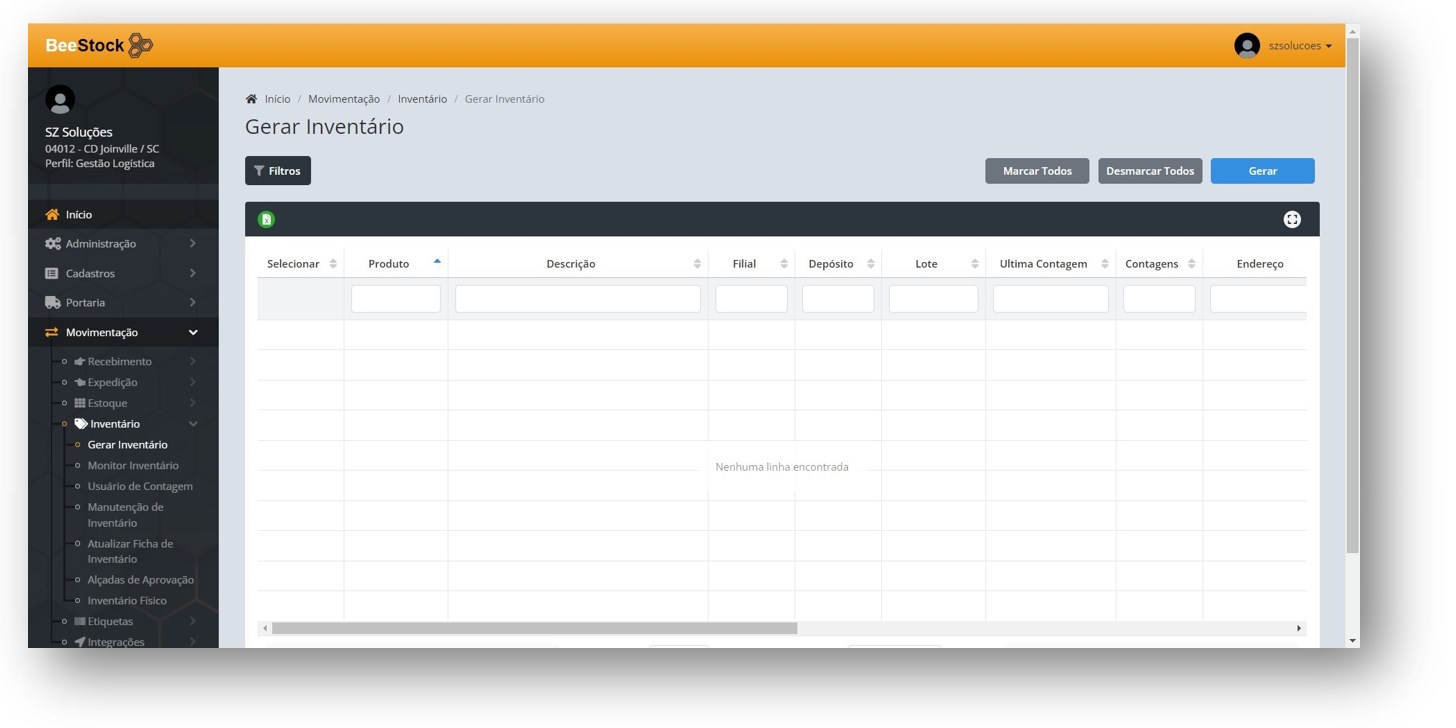

Generate Inventory

Located in the Movement > Inventory > Generate Inventory menu, this screen will generate inventory tags based on the filters used.

Step-by-step instructions to generate a new inventory tag:

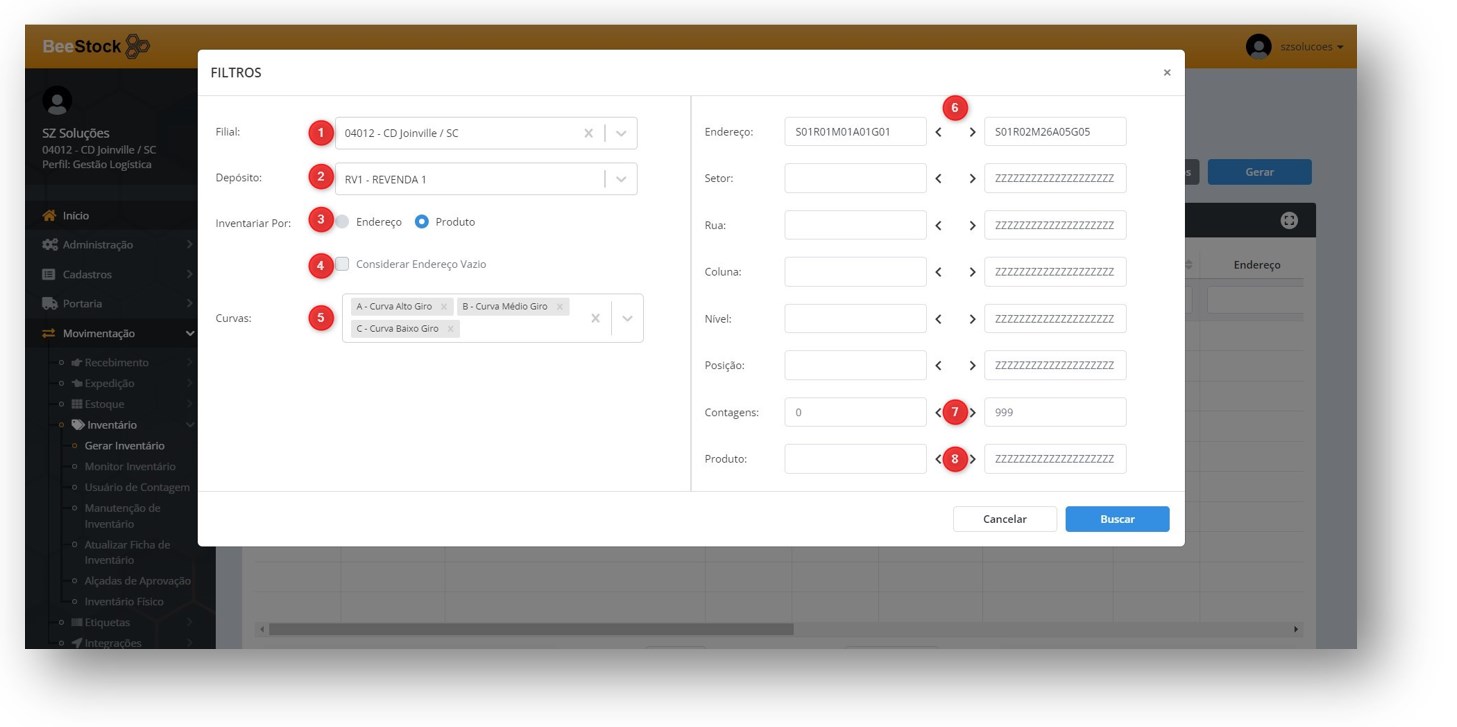

Click the Filters button, and the following options will be displayed:

Branch.

Warehouse.

Inventory By:

Address

Product

Consider Empty Address.

Curves.

Address filter frame.

Counts.

Products.

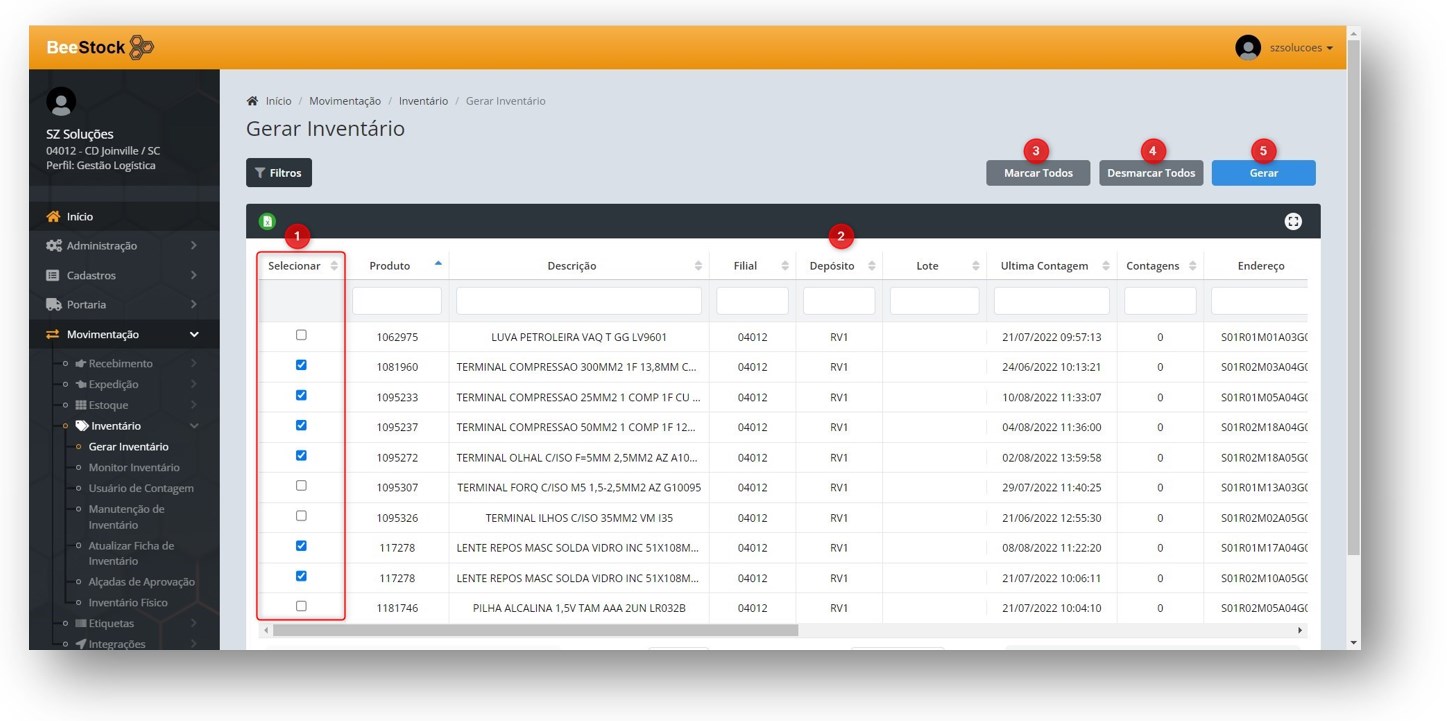

Define the filters to be used and click Search.

The screen below will be loaded, listing all products available for inventory.

Select (Checkbox to manually select the products/addresses you want to inventory).

On-screen filters.

Select All.

Deselect All.

Generate.

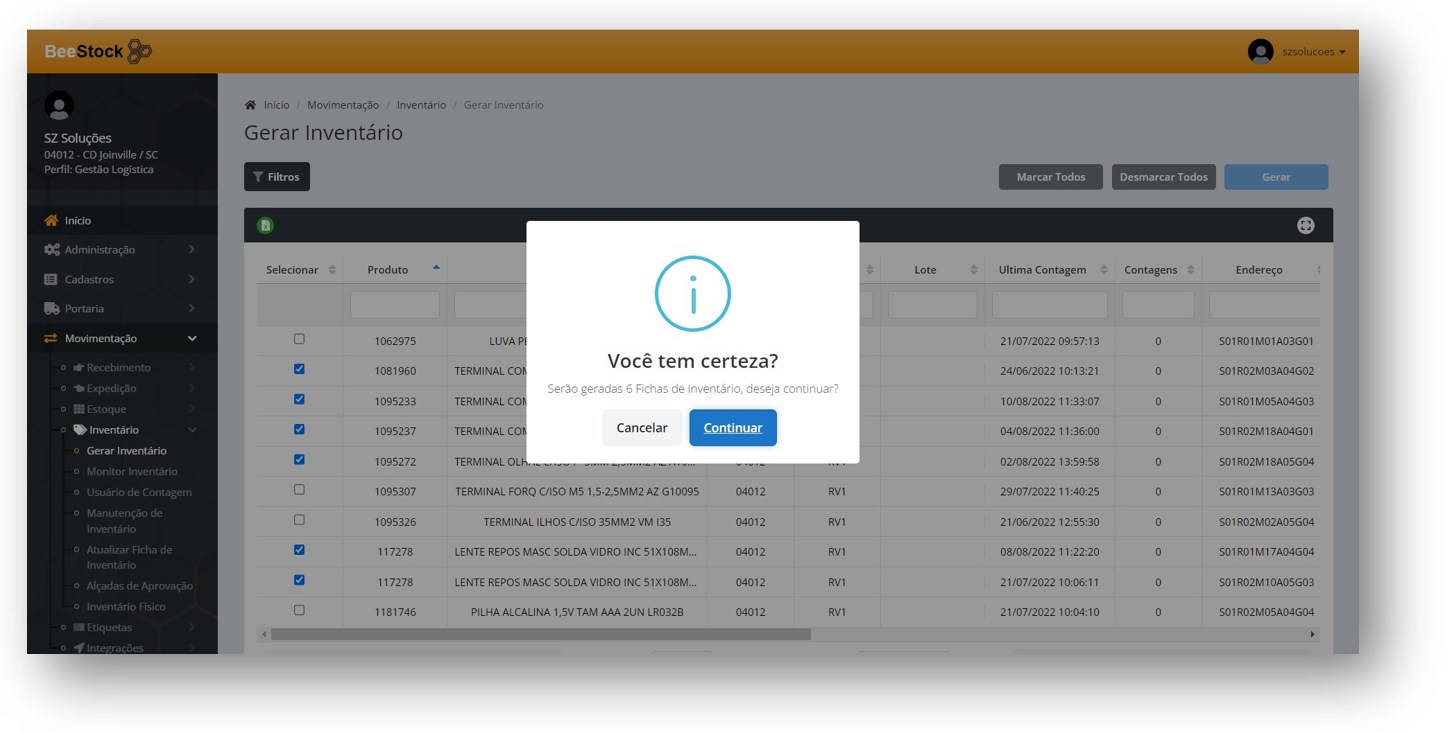

Select the products/addresses you want to inventory and click Generate (5).

The confirmation screen below will open, informing you of the initial number of tags to be generated. Click Continue.

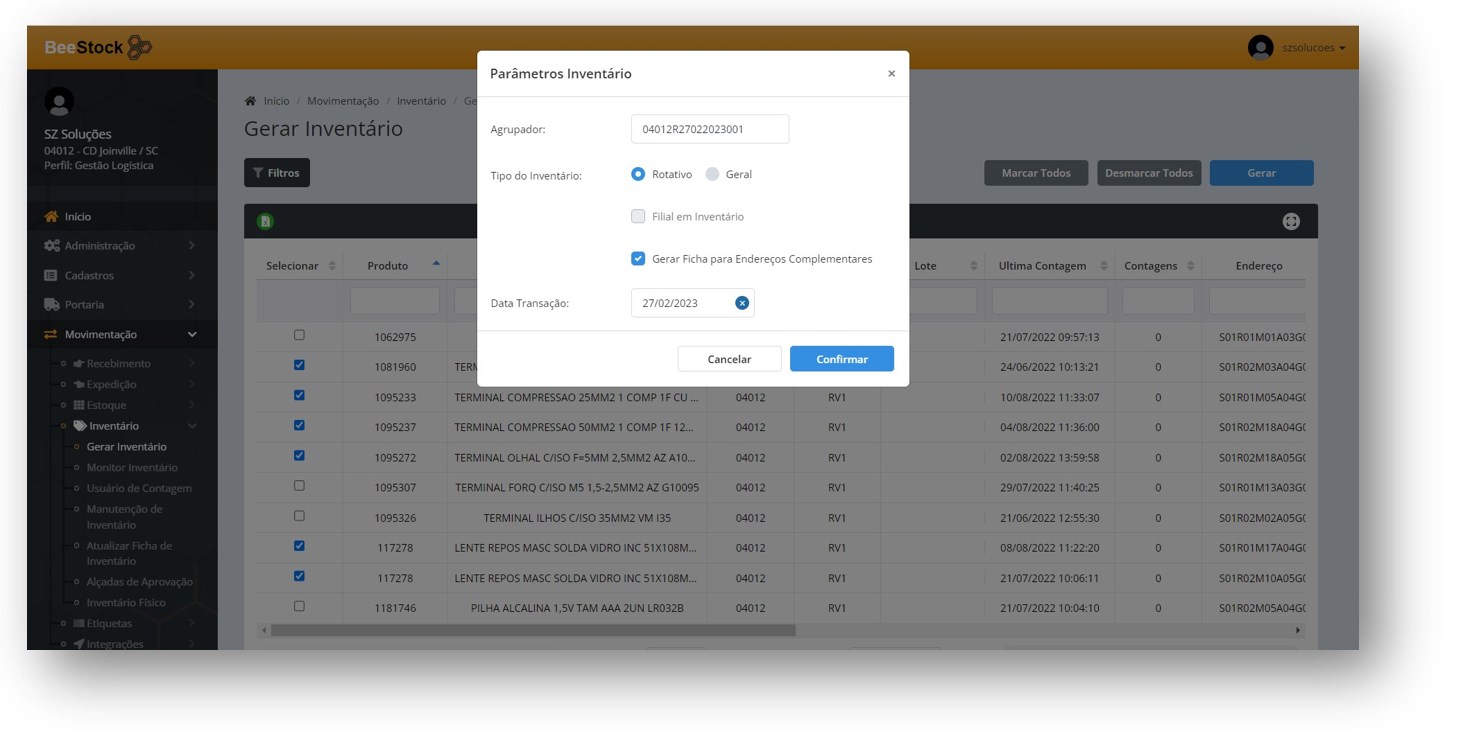

The screen below will open, showing:

Grouper, an editable field where the suggested grouper is formed by:

Branch with (5 characters)

R for Cycle Counting or G for General Inventory (1 character)

Creation Date DDMMAAAA (8 characters)

Sequence (3 characters)

Inventory Type

Branch in Inventory

Generate Tag for Complementary Addresses

Transaction Date

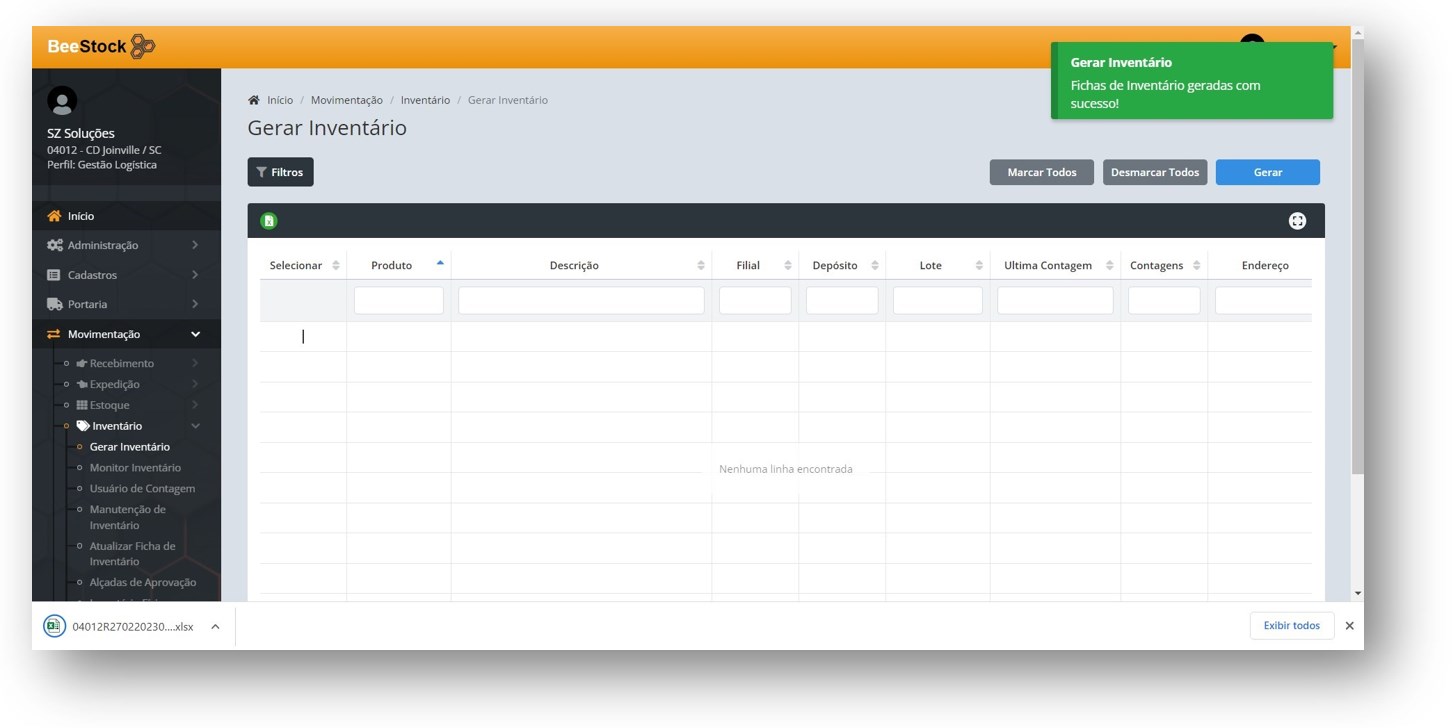

The message Inventory tags successfully generated! will be displayed.

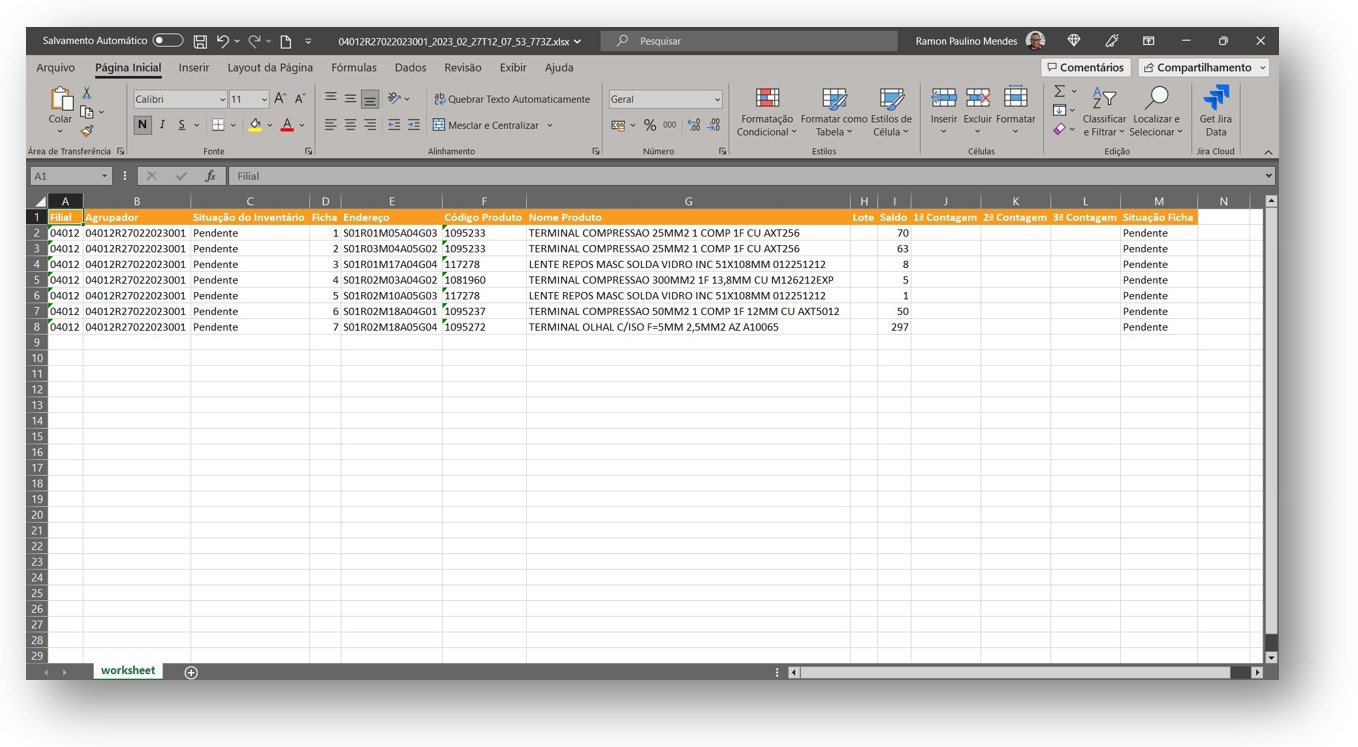

Automatically download the inventory tag, an Excel file containing all the information of the generated tags.

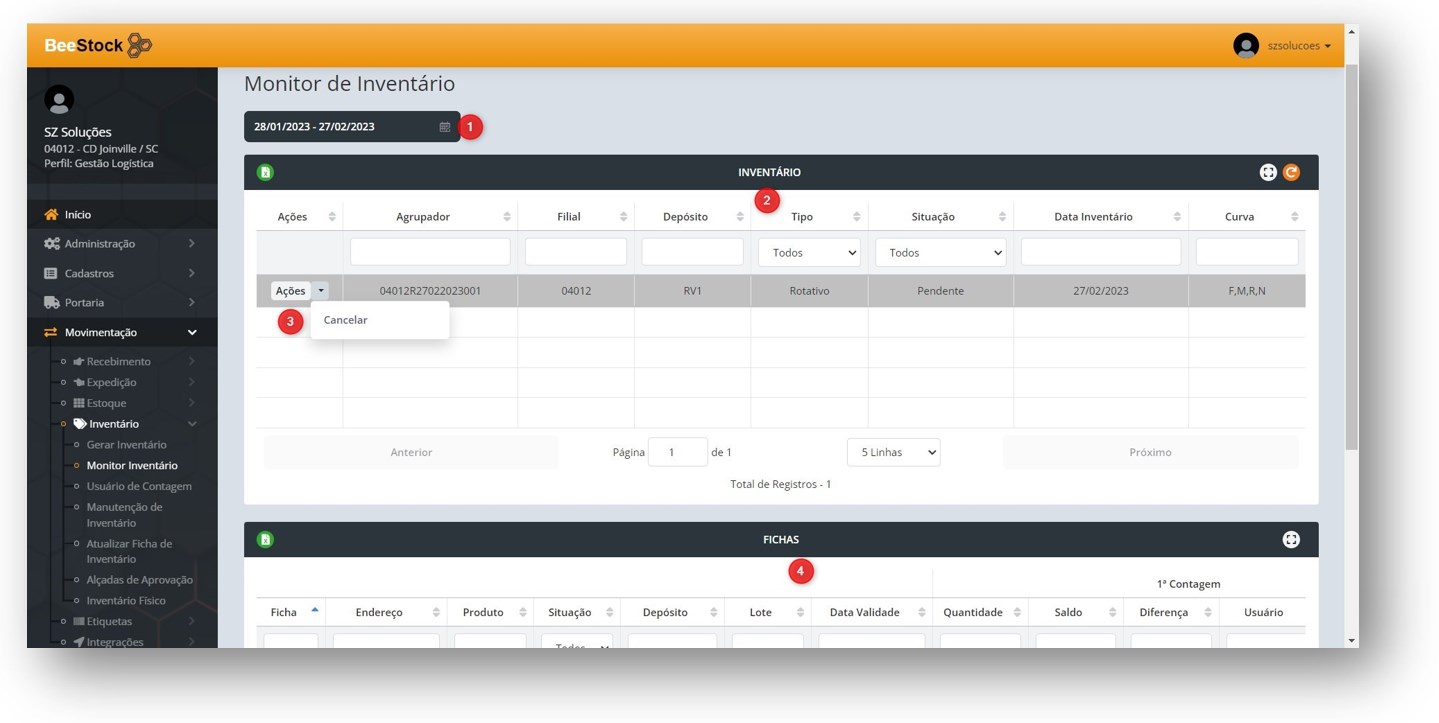

Inventory Monitor

Located in the Movement > Inventory > Inventory Monitor menu, this monitor will display all.

It can be used to monitor:

Date filter

Inventories grid

Actions > Cancel option

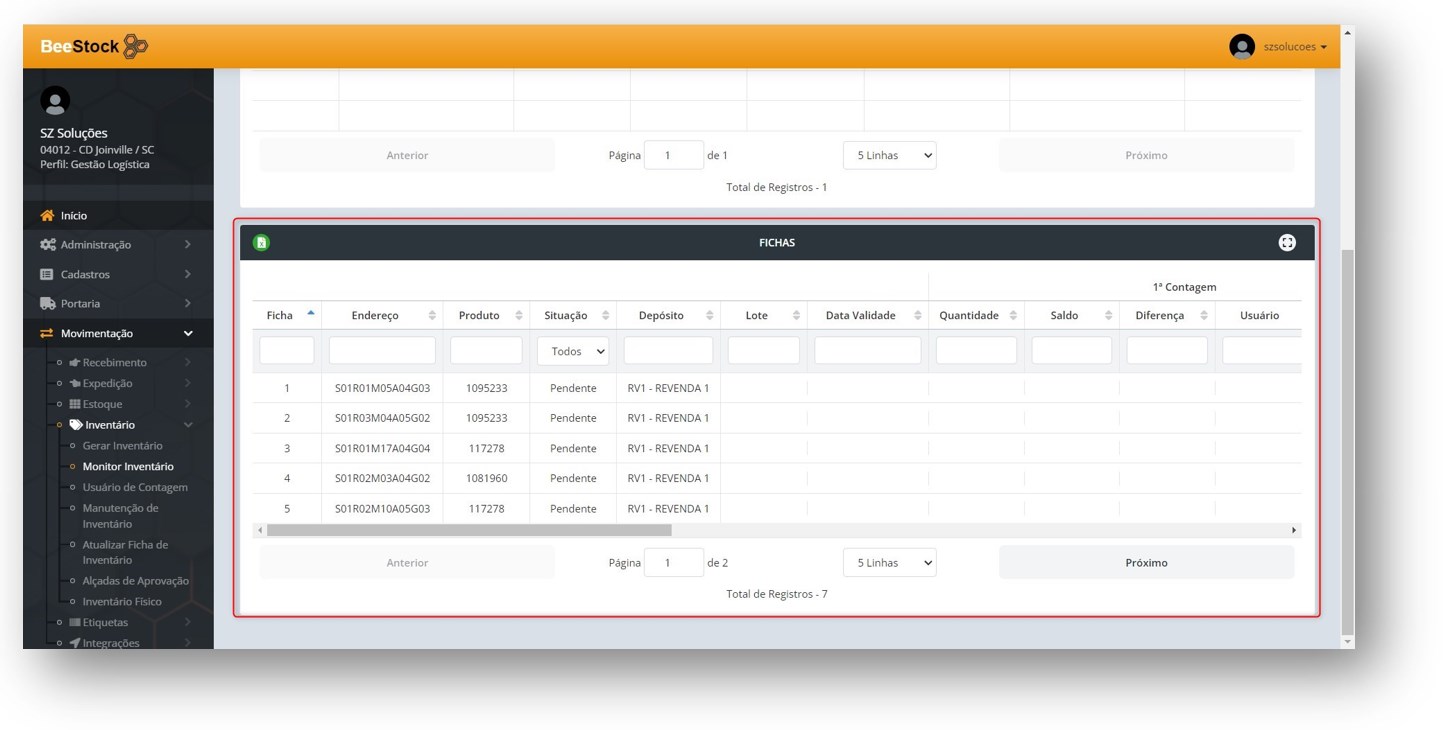

Tags grid, where all products will be listed.

In the bottom Tags grid, all products contained in this grouper and their respective statuses will be listed.

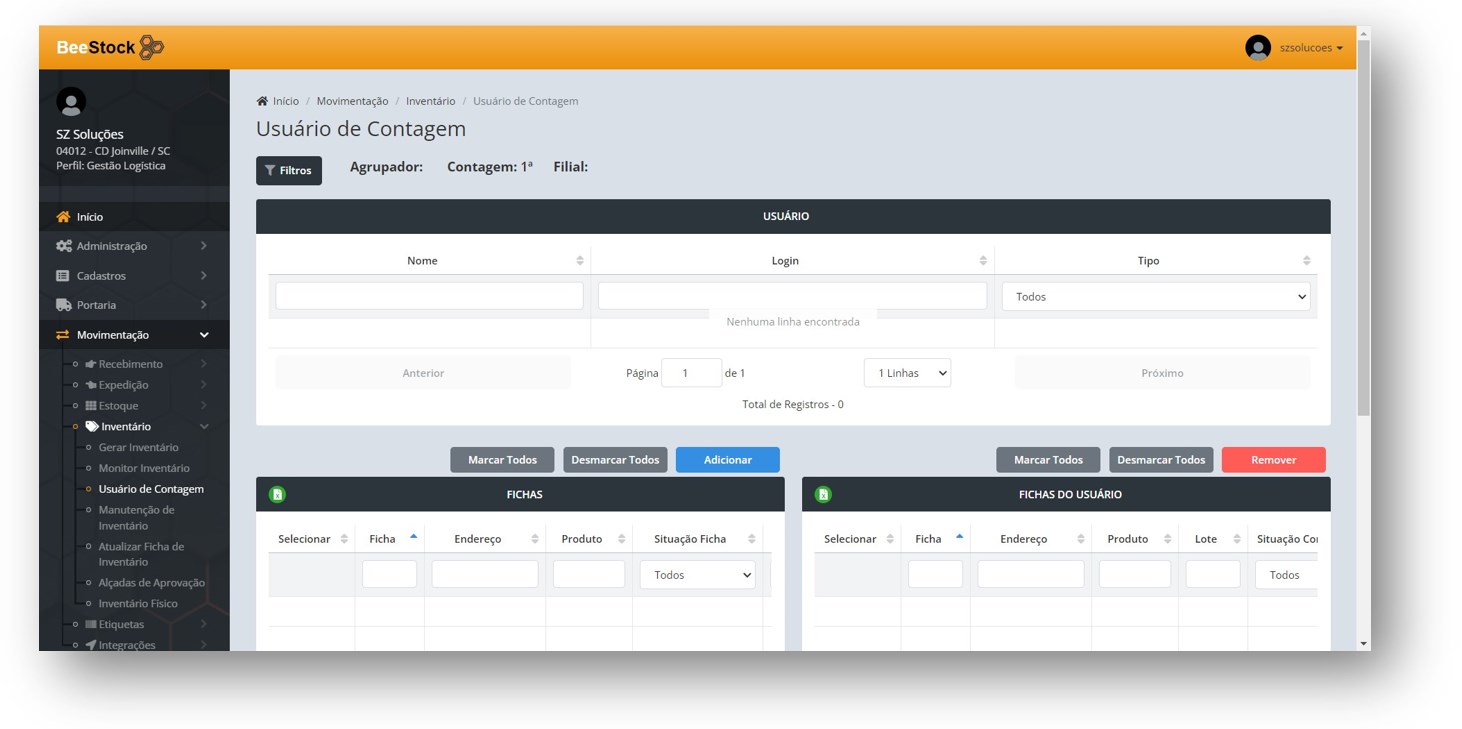

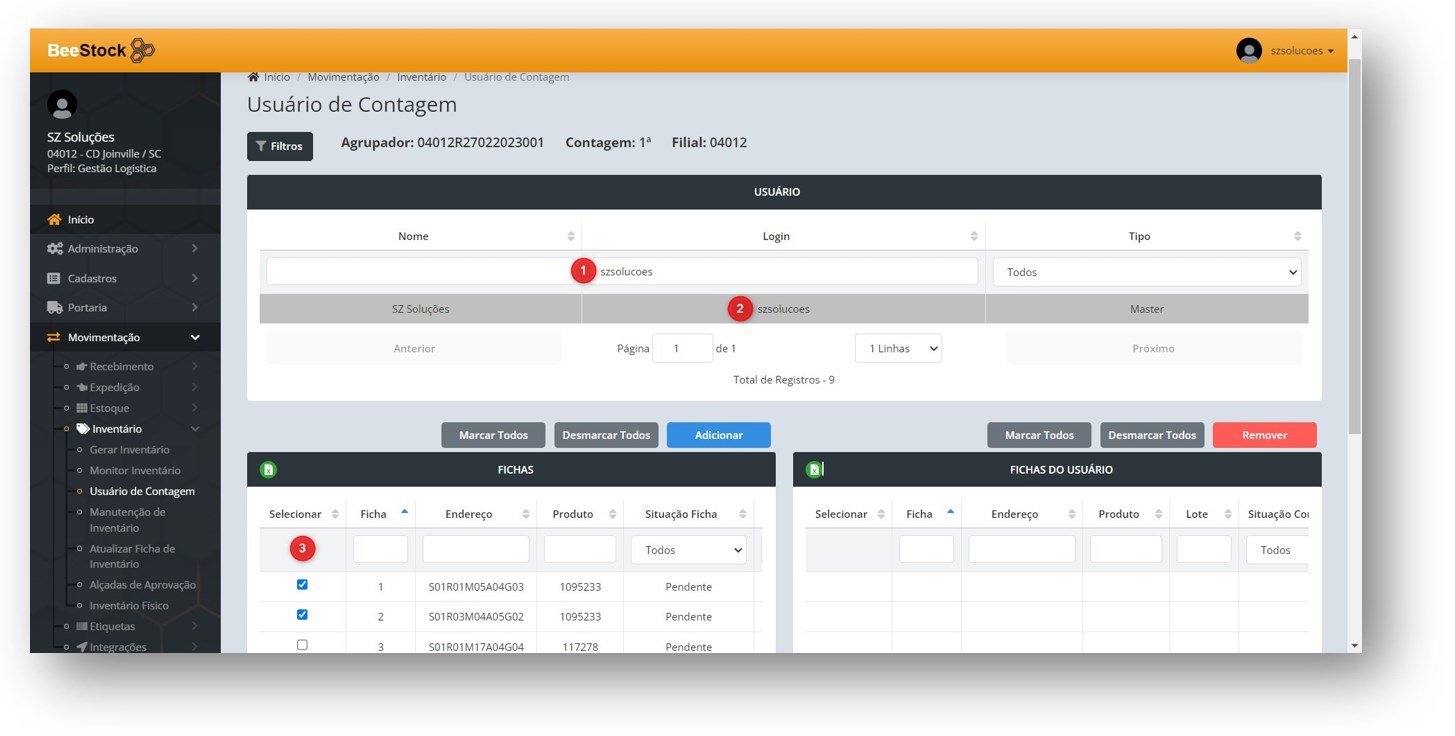

Counting User

Located in the Movement > Inventory > Counting User menu, this screen allows you to associate counting tags to those responsible for counting. Remember that each user cannot inventory the same tag more than once.

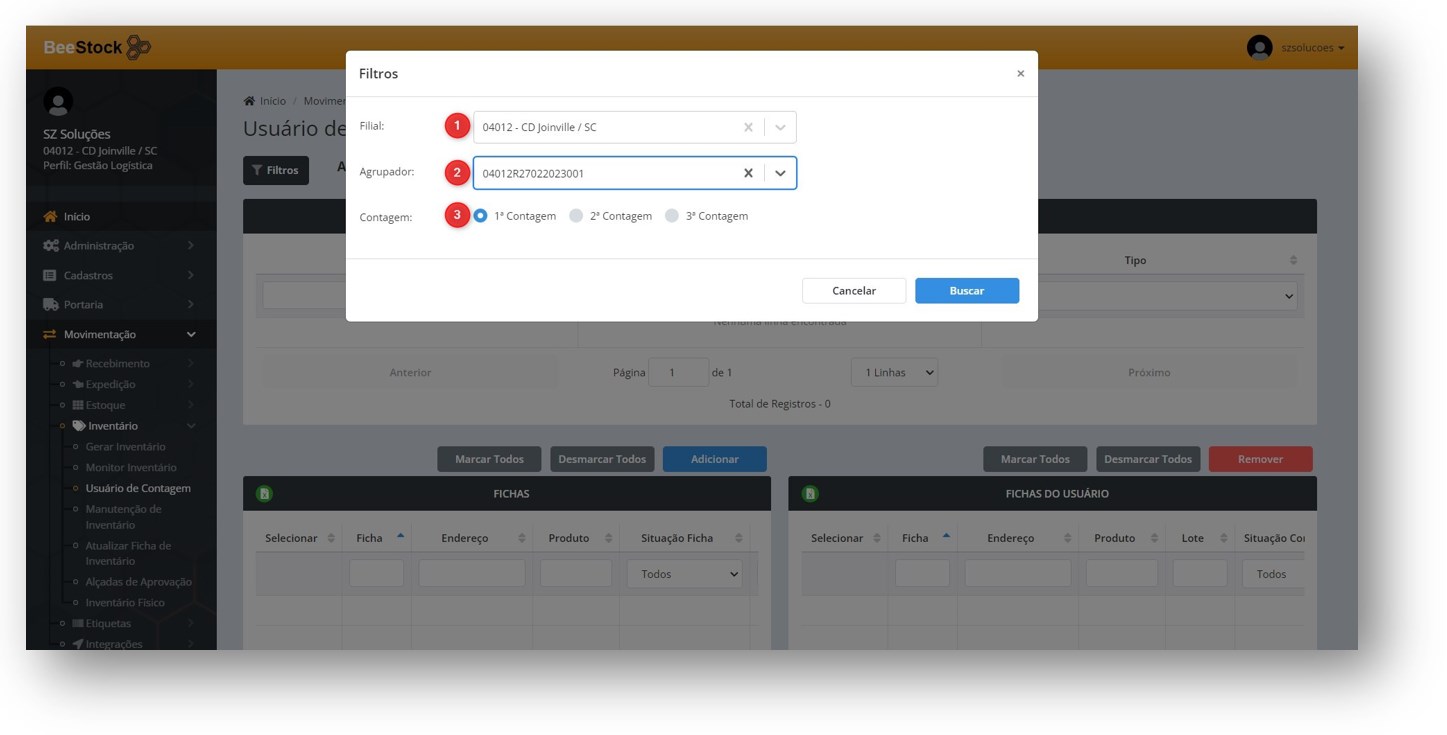

When you click Filters, the screen below will open. You must enter the following fields:

Branch – Only branches that the user has access to will be displayed.

Grouper – Select from the list.

Count.

Filter by 1st Count, 2nd Count, and 3rd Count.

After applying the above filter, the tags will be loaded in the TAGS grid on the left. To assign them to a counting user, you must:

Filter the user by searching for their name in the USER grid filter.

Select the desired user by clicking their login.

Select the tags you want to assign to this user.

You can apply filters directly in the grid:

Address

Product

Sector

Aisle

Column

Level

Position

Batch

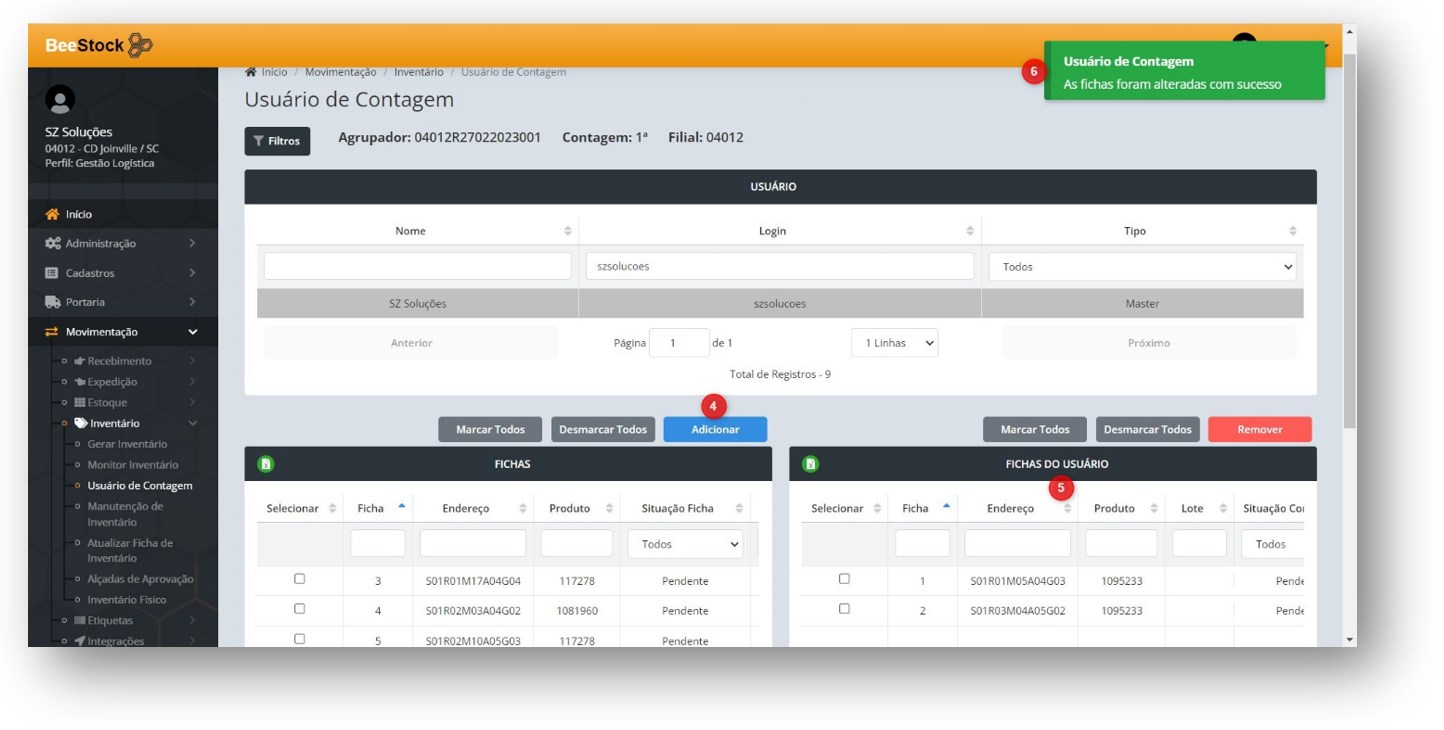

Once the selections are complete, click the blue Add button.

The tags will be moved to the USER TAGS grid on the right side of the screen.

The message Tags were successfully changed will be displayed.

Now, when the assigned user accesses the Inventory menu on the collector, they will be directed to inventory the addresses/items assigned above.

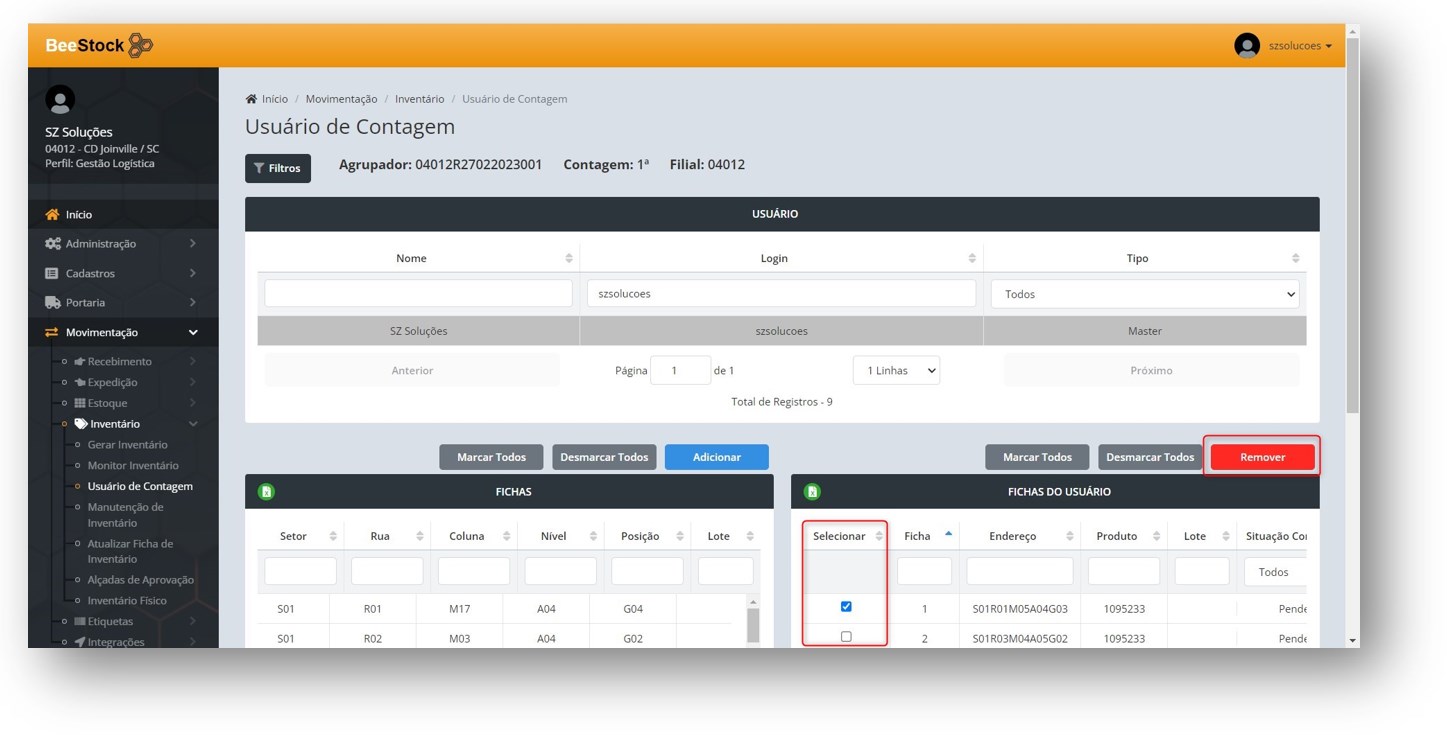

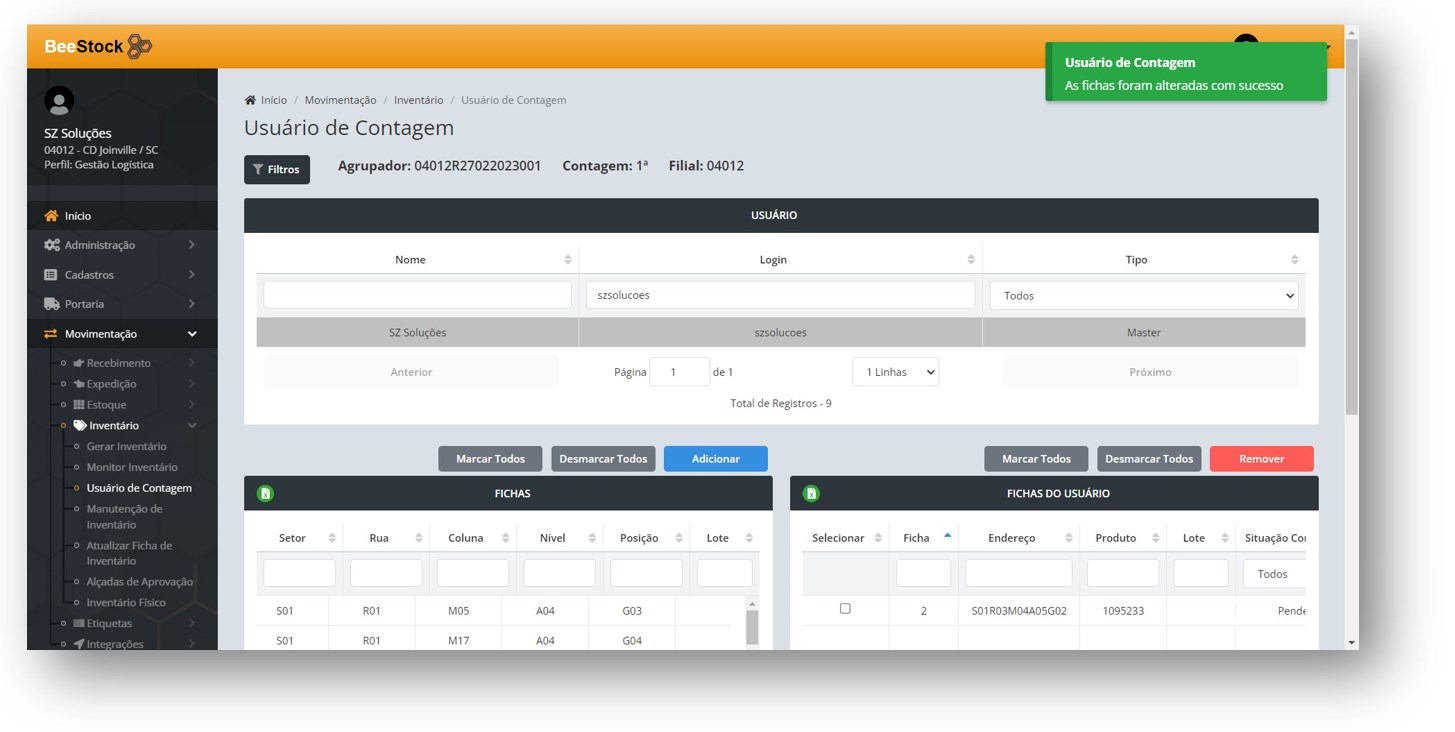

It is also possible to remove tags from the user. To do this, make the same tag and user filter selections at the top of the screen.

Select in the USER TAGS grid and click the red Remove button.

The confirmation message Tags were successfully changed will be displayed, and the selected tags will be removed from this user, becoming available to be associated with a new user.

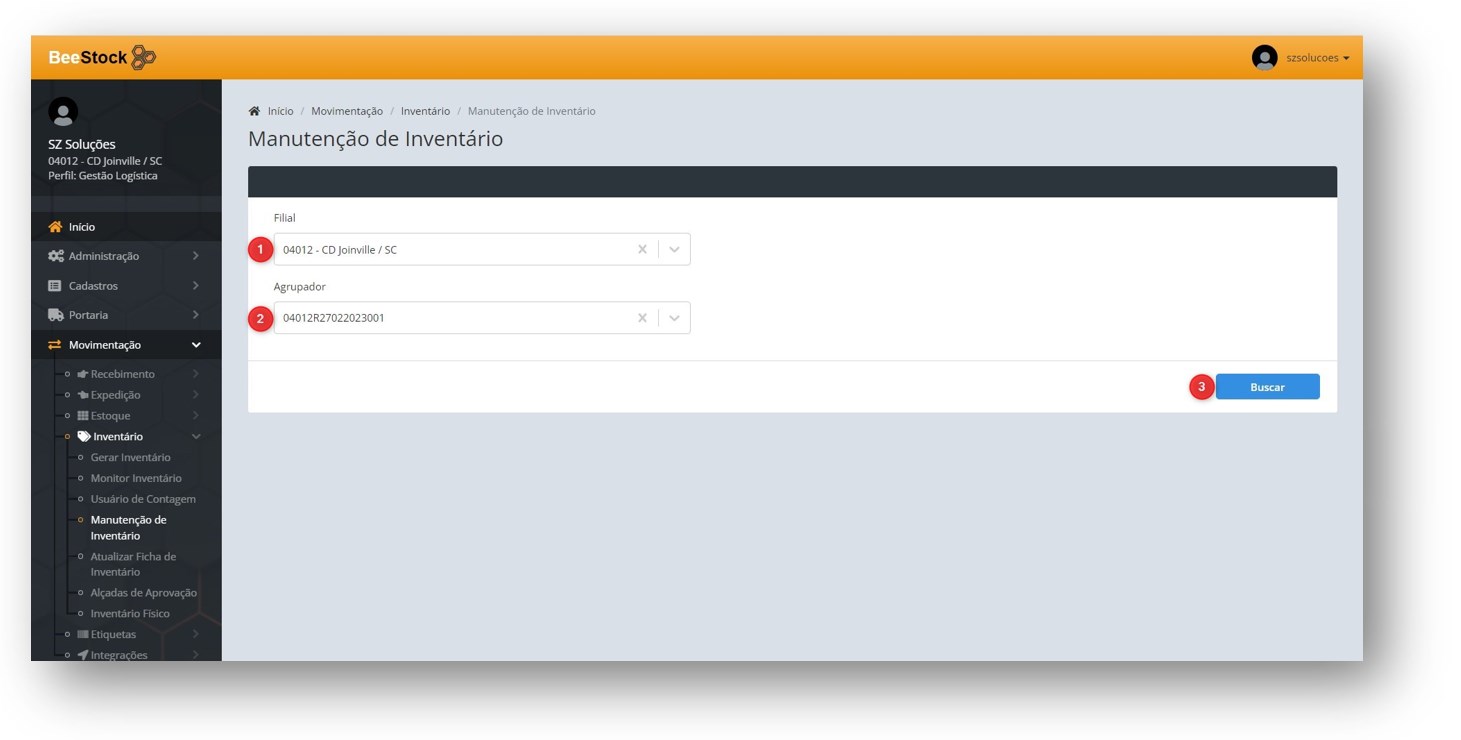

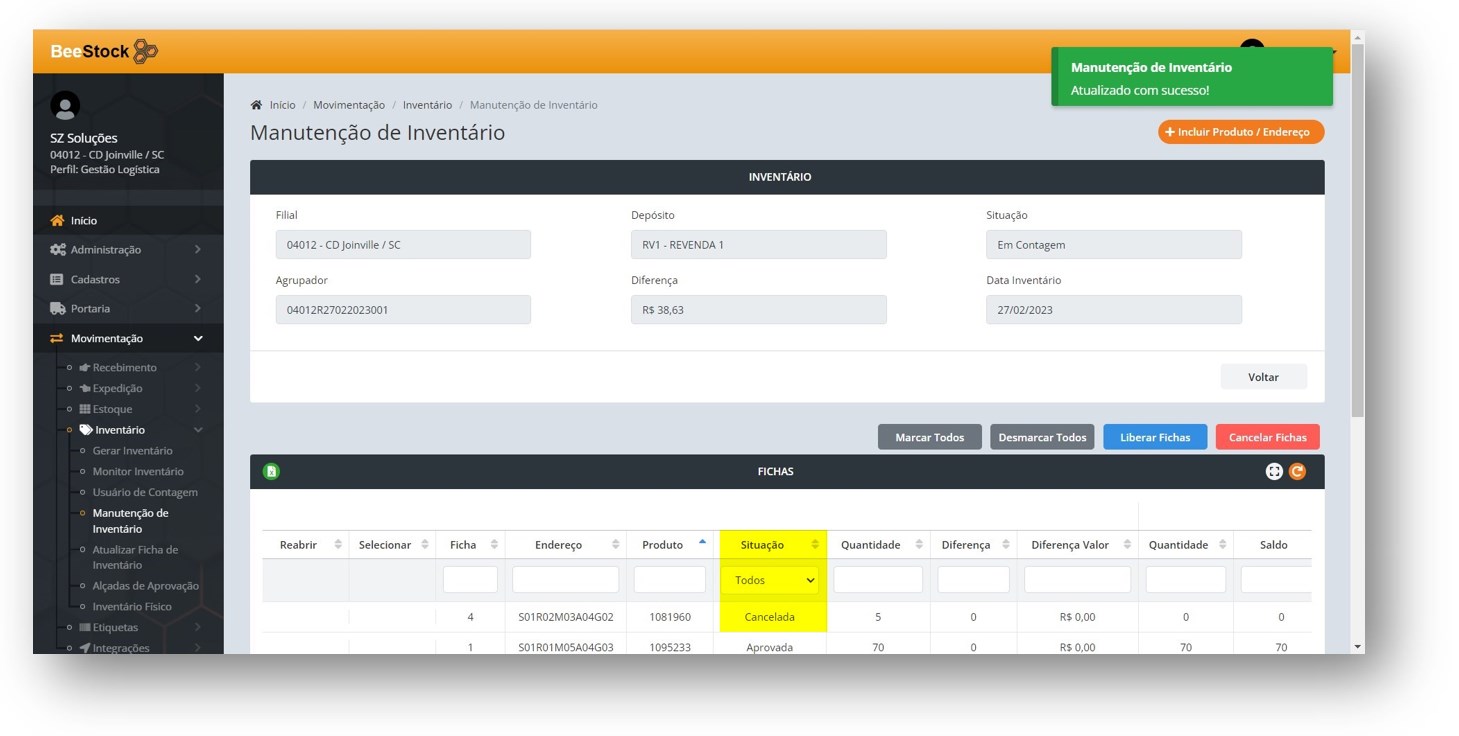

Inventory Maintenance

Located in the Movement > Inventory > Inventory Maintenance menu, this screen allows you to perform maintenance on inventory tags. You can:

Select the branch (only branches that the user has access to will be listed).

Select the desired grouper.

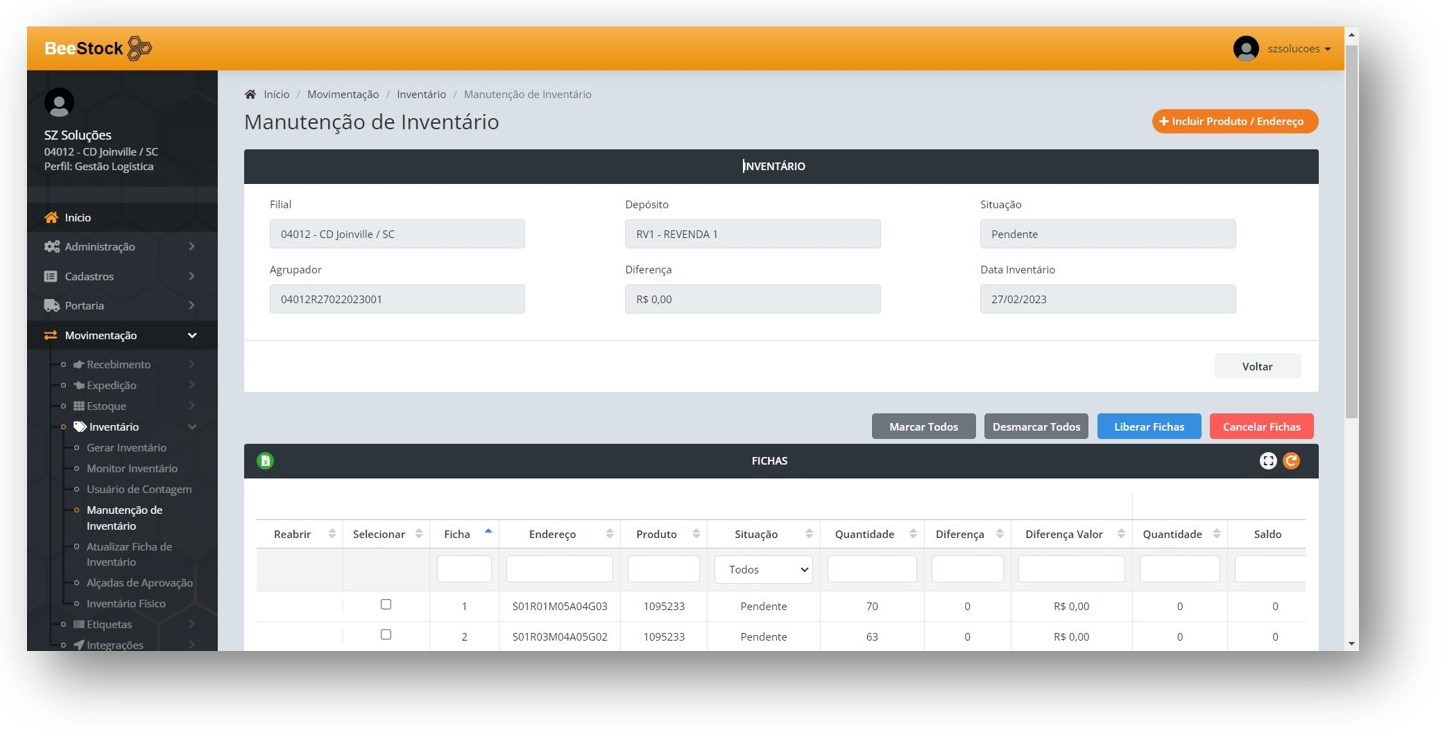

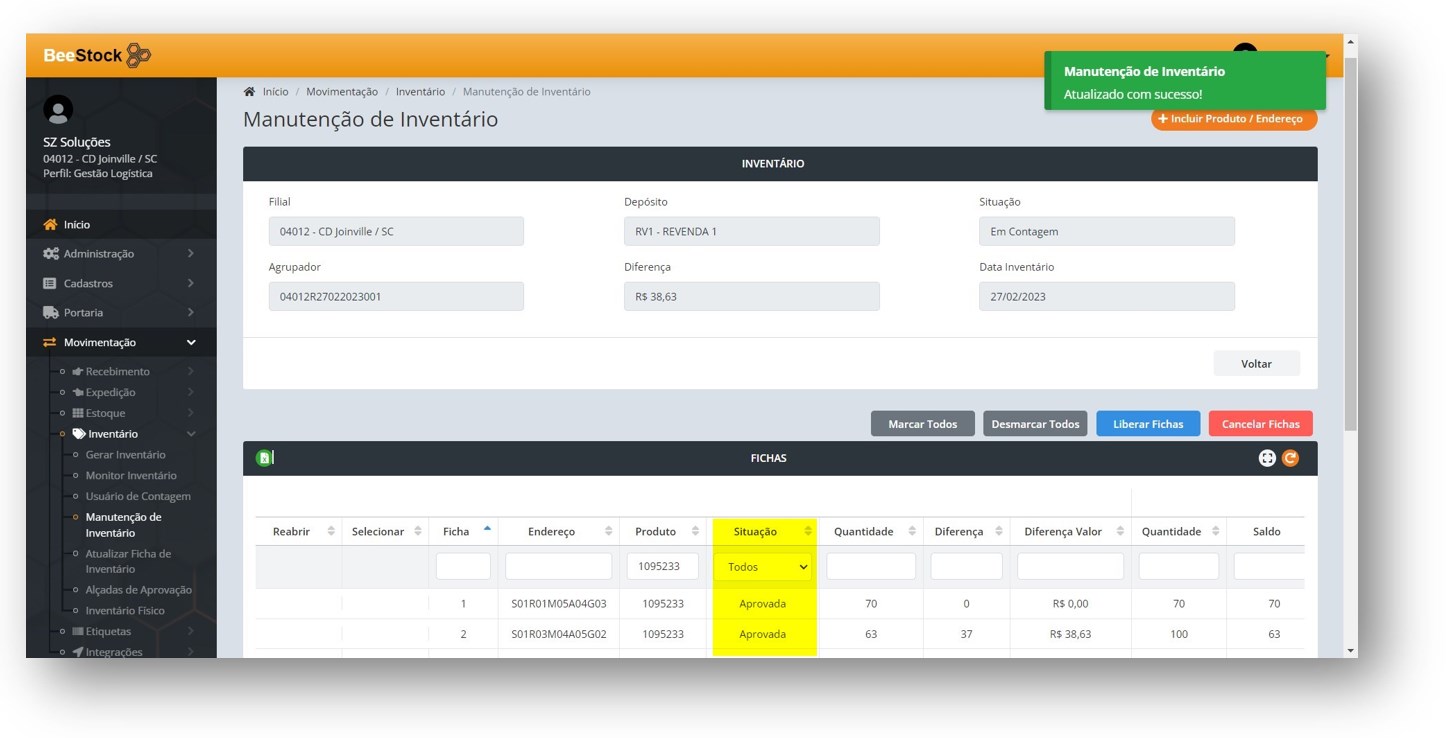

When you click Search, the screen below will open, containing the data of the selected grouper.

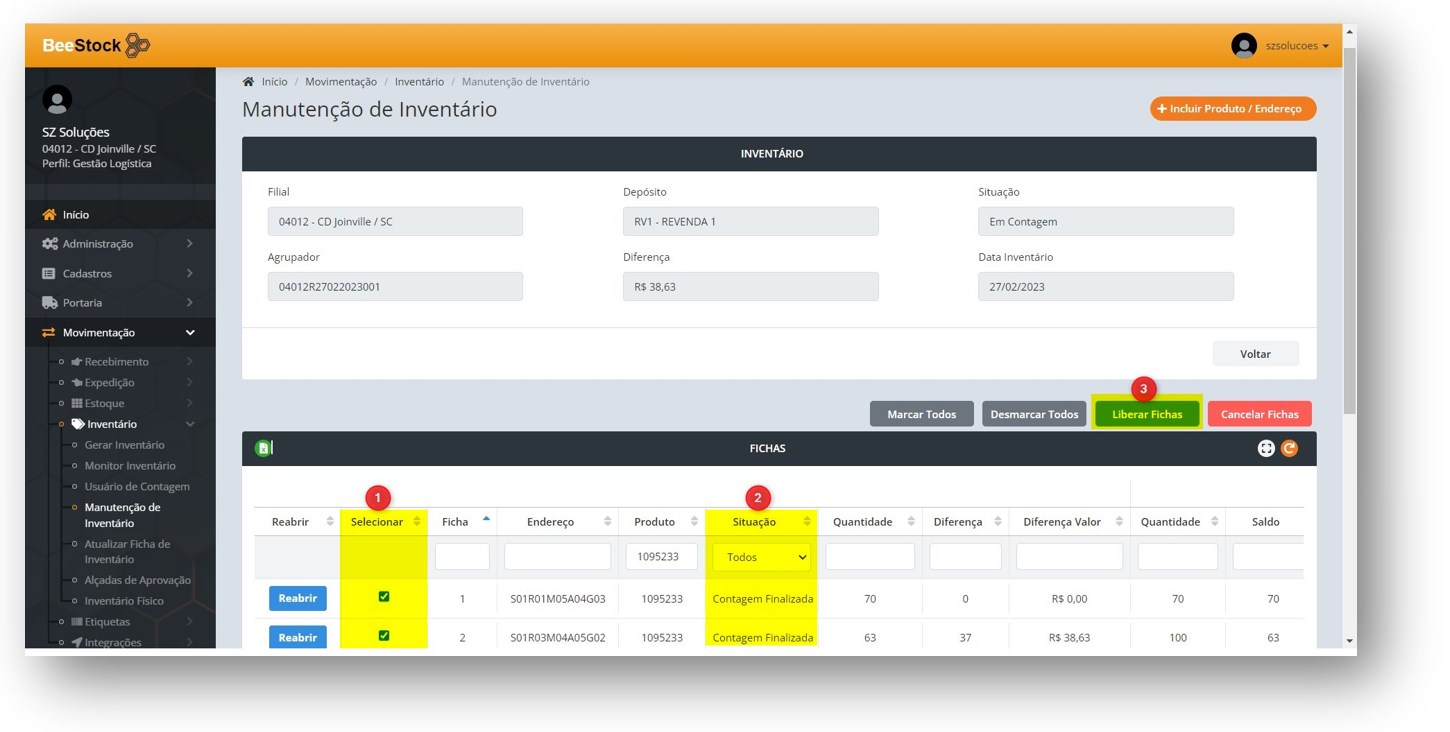

As the first, second, and third counts are performed (if necessary), in this same Inventory Maintenance screen, the tags with the Counting Finished status will be available to Release Tags, as in the selection below:

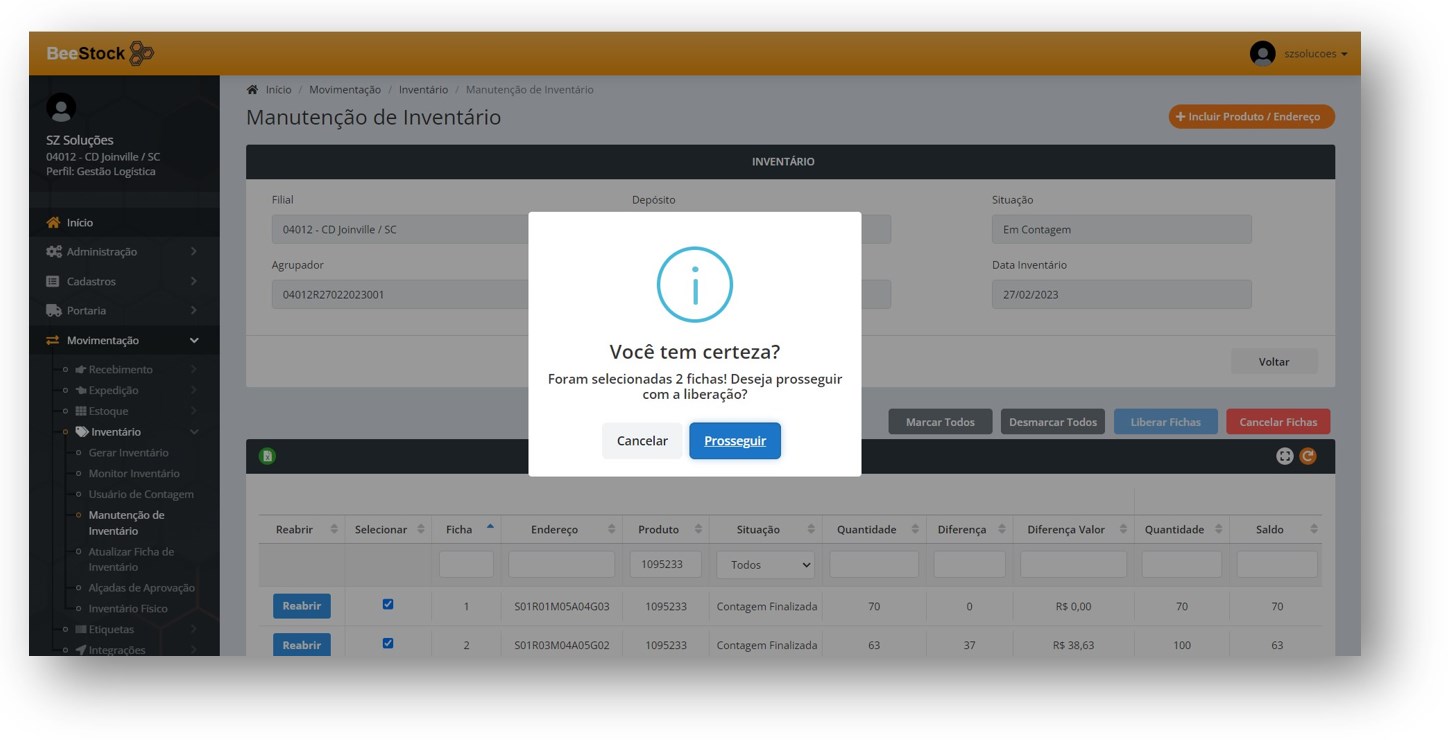

Release Tags, this action only releases the tags so that they can be actually updated on the Update Inventory Tags screen by the management that has approval authority.

When you click Release Tags, the following confirmation message will be displayed:

When you click Proceed, the confirmation message Successfully updated! will be displayed, and the statuses of the previously selected tags will change to Approved.

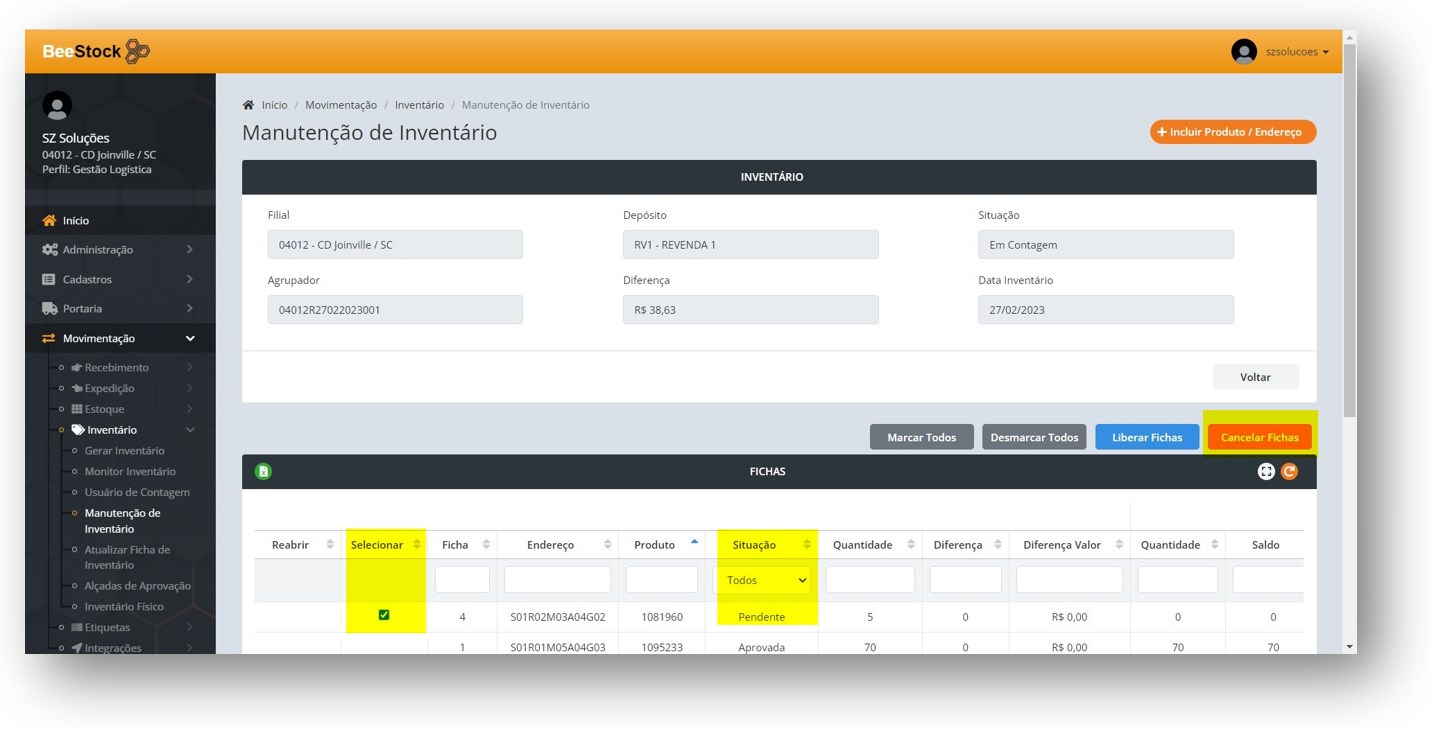

It is also possible to Cancel Tags by selecting the desired tags and clicking Cancel Tags.

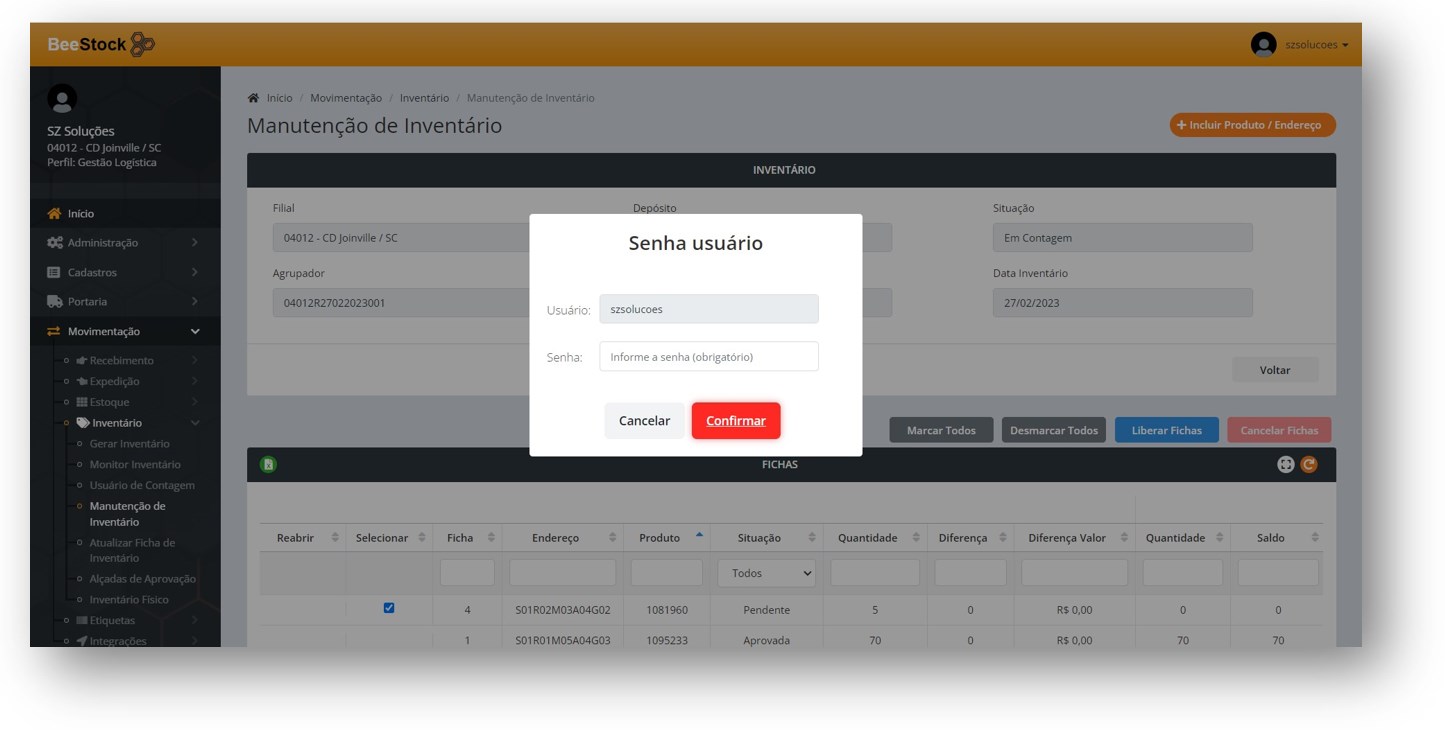

You will be asked to confirm the logged-in user’s password.

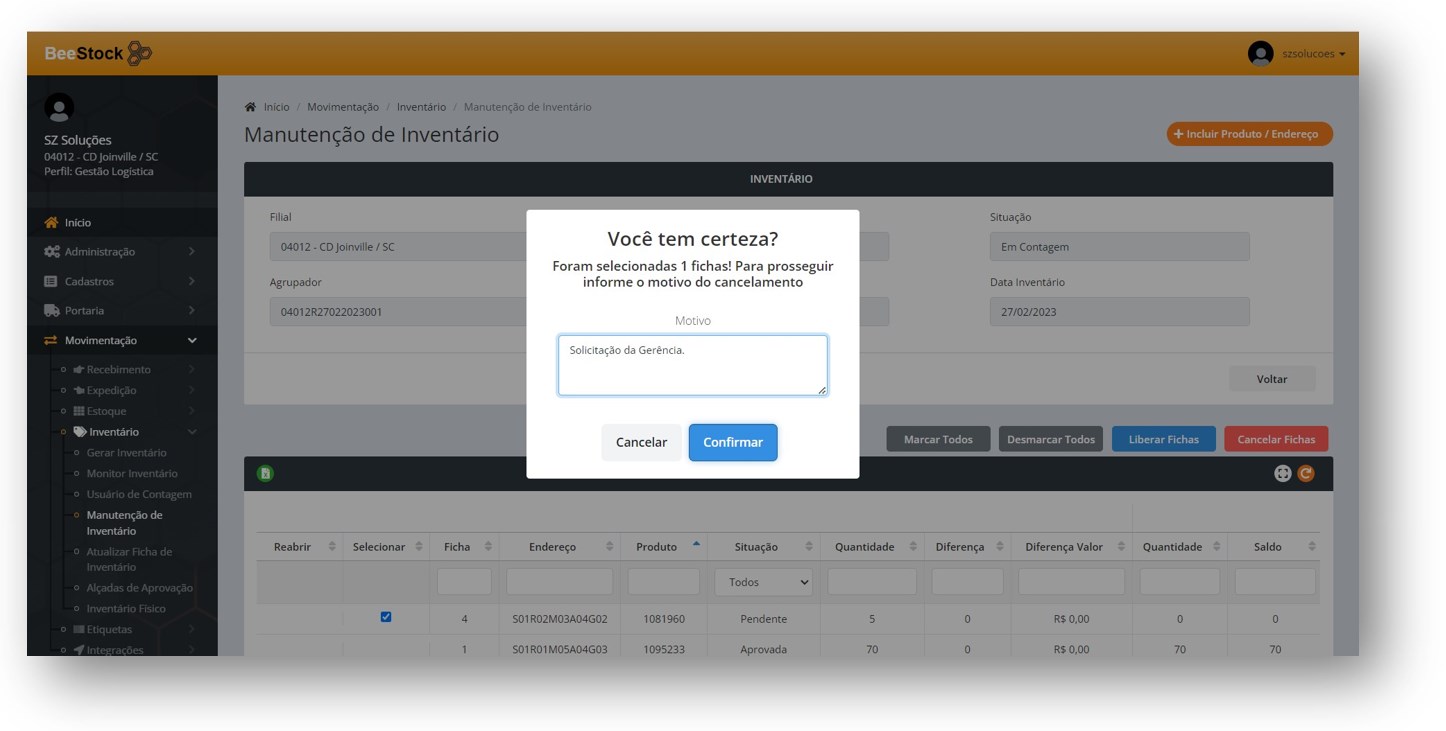

You must enter the reason for cancellation.

The confirmation message Successfully updated! will be displayed, and the tag status will change to Canceled.

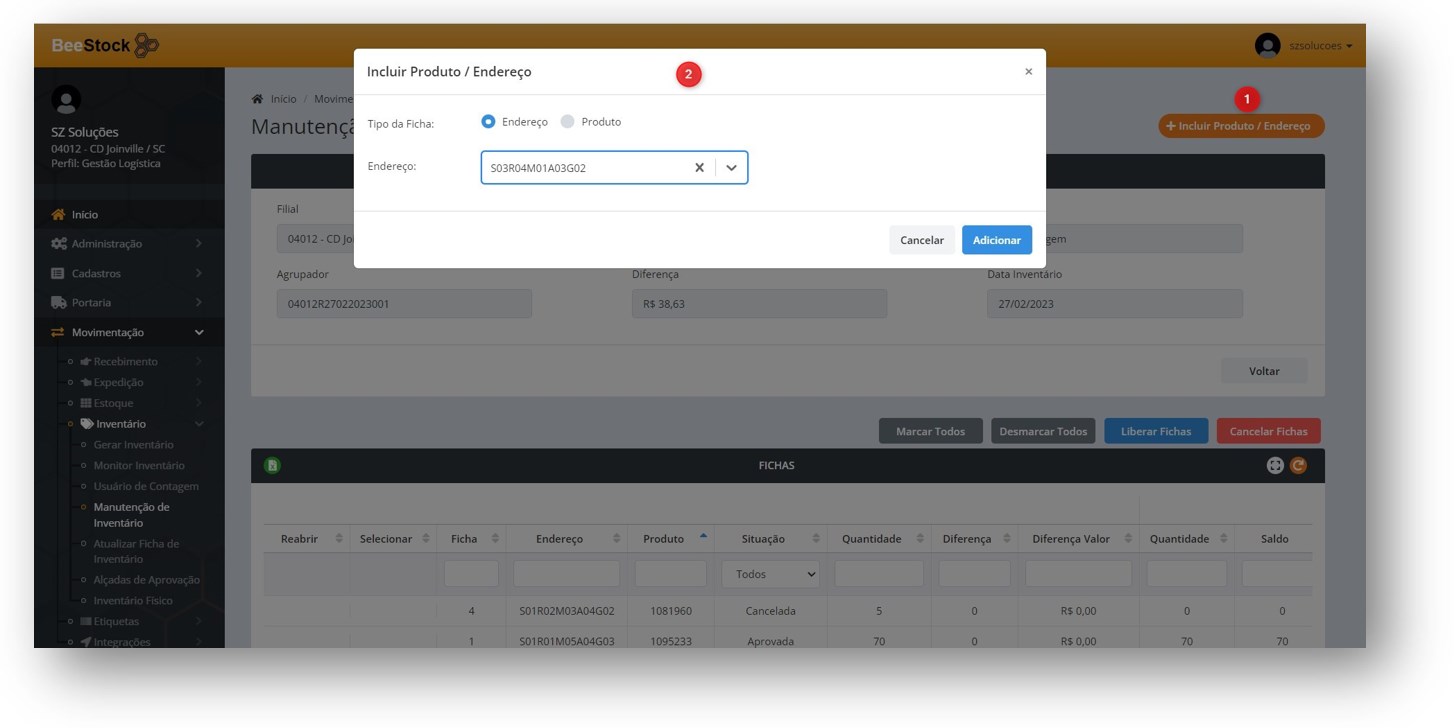

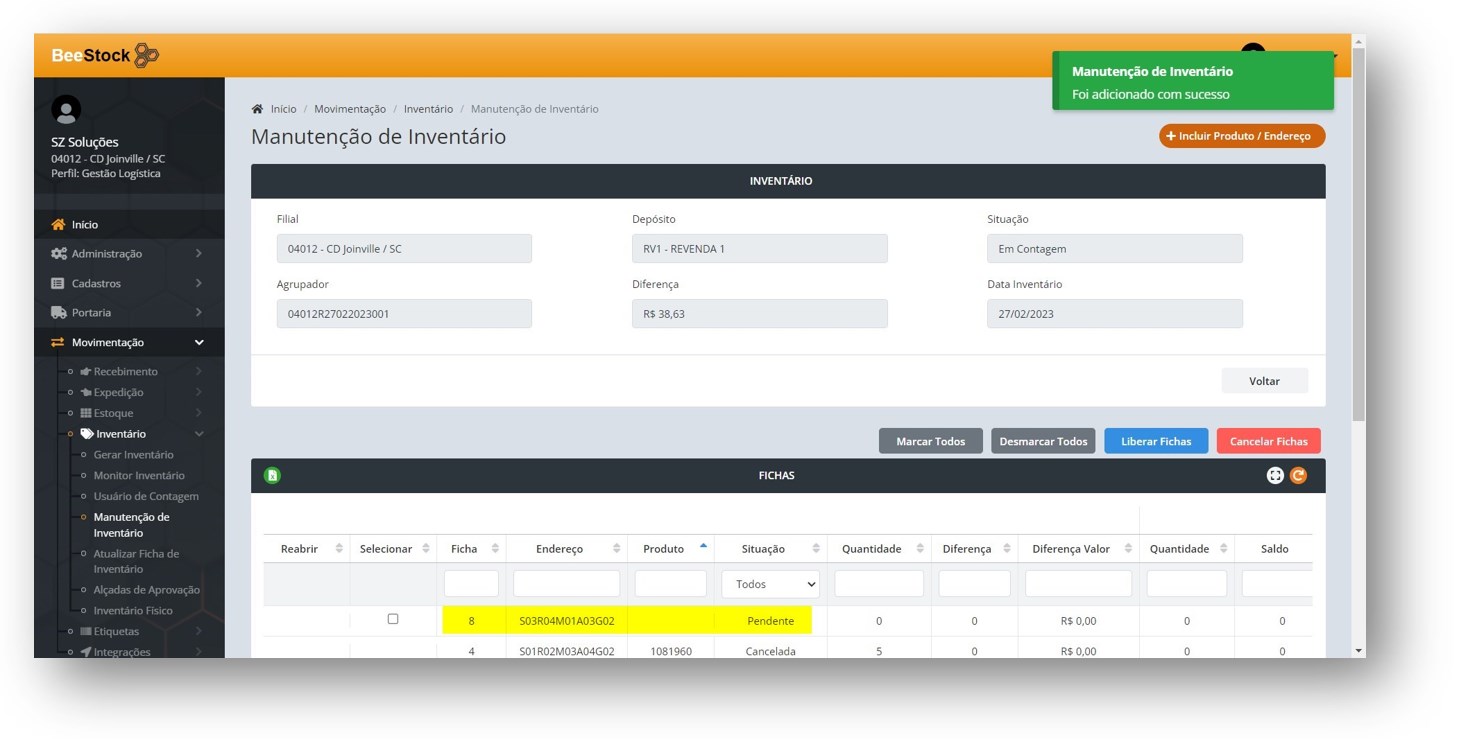

On this screen, you can also add a new Product/Address to the current grouper. To do this:

Click +Add Product/Address.

Select Address or Product, make the selection, and click Add.

The confirmation message Successfully added will be displayed, and the address/product in question will be included in this grouper so that it can be associated with a user and inventoried on the Counting User screen normally.

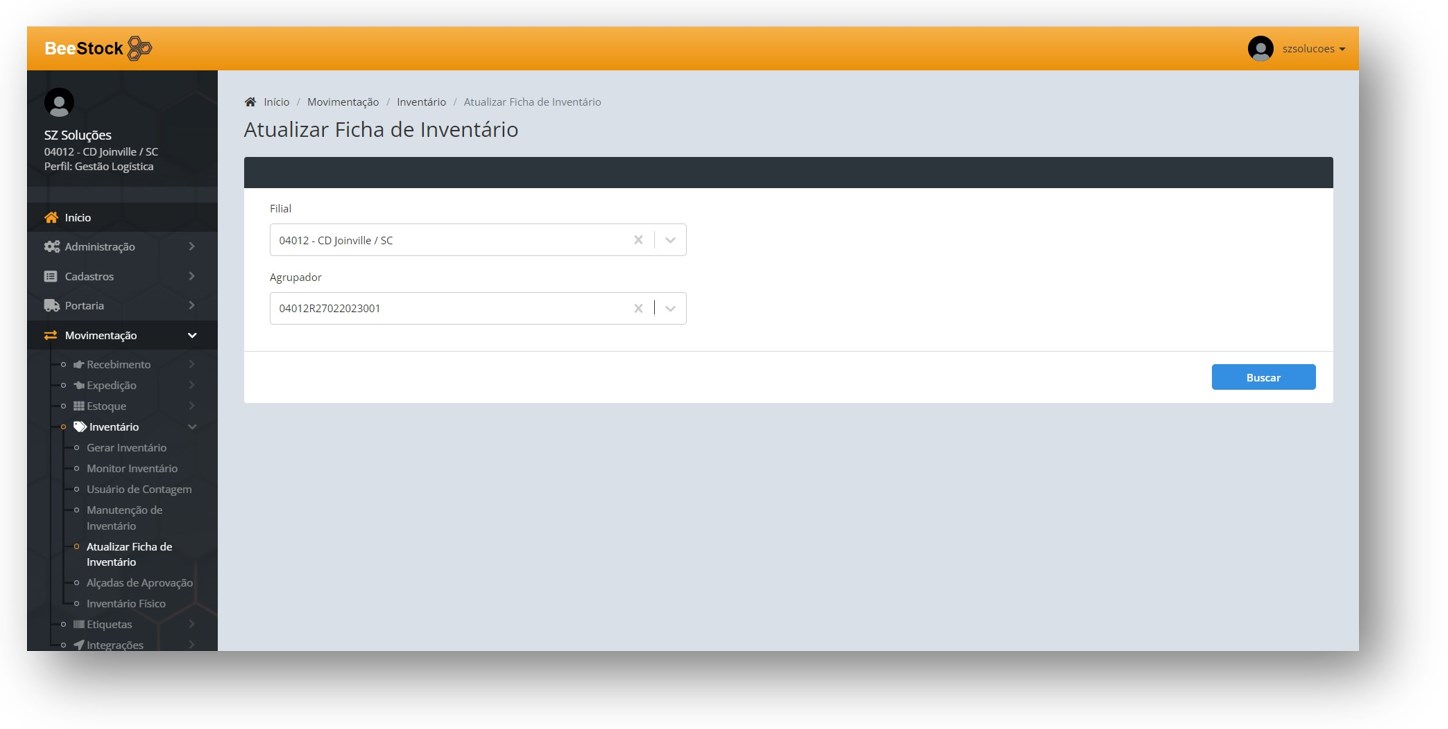

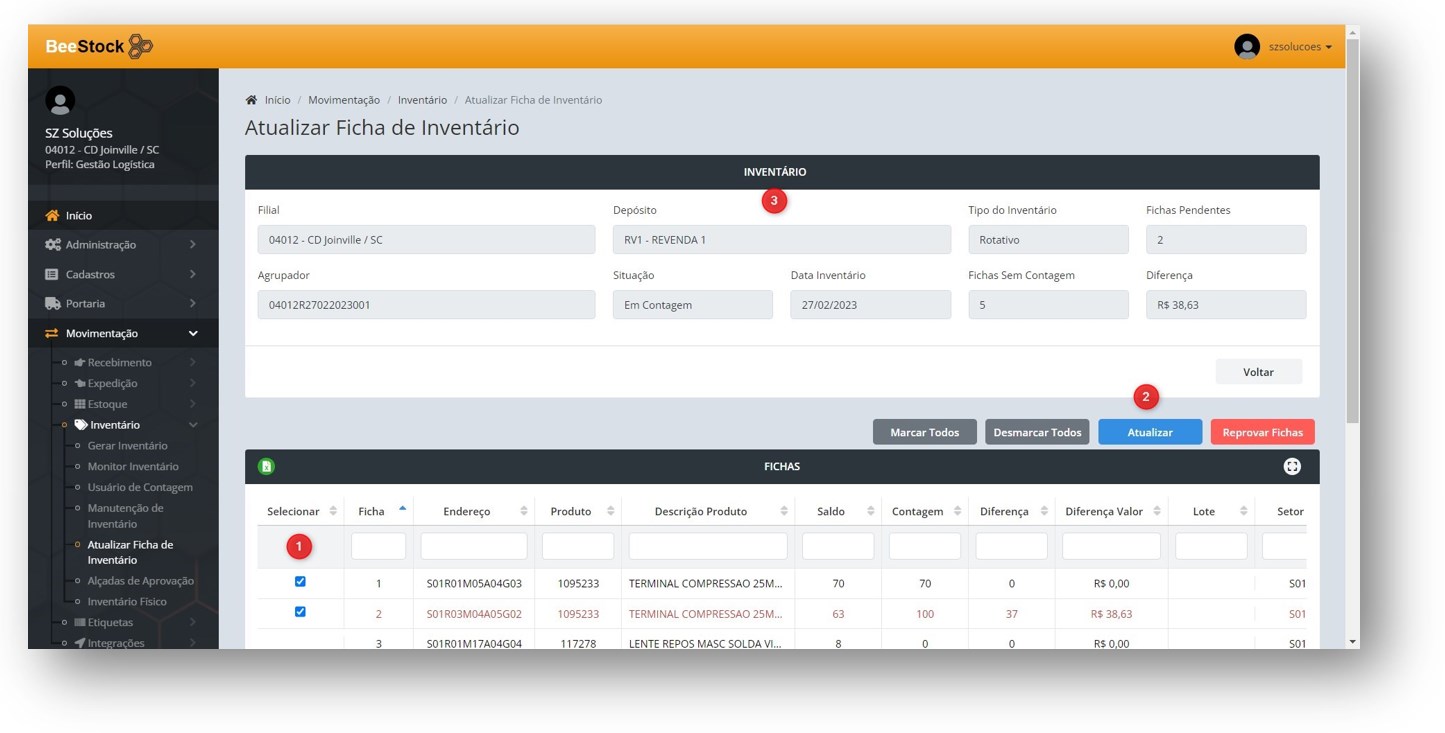

Update Inventory Tag

Located in the Movement > Inventory > Update Inventory Tag menu, on this screen you can update inventory tags. To do this:

Select the Branch.

Select the Grouper.

Click Search.

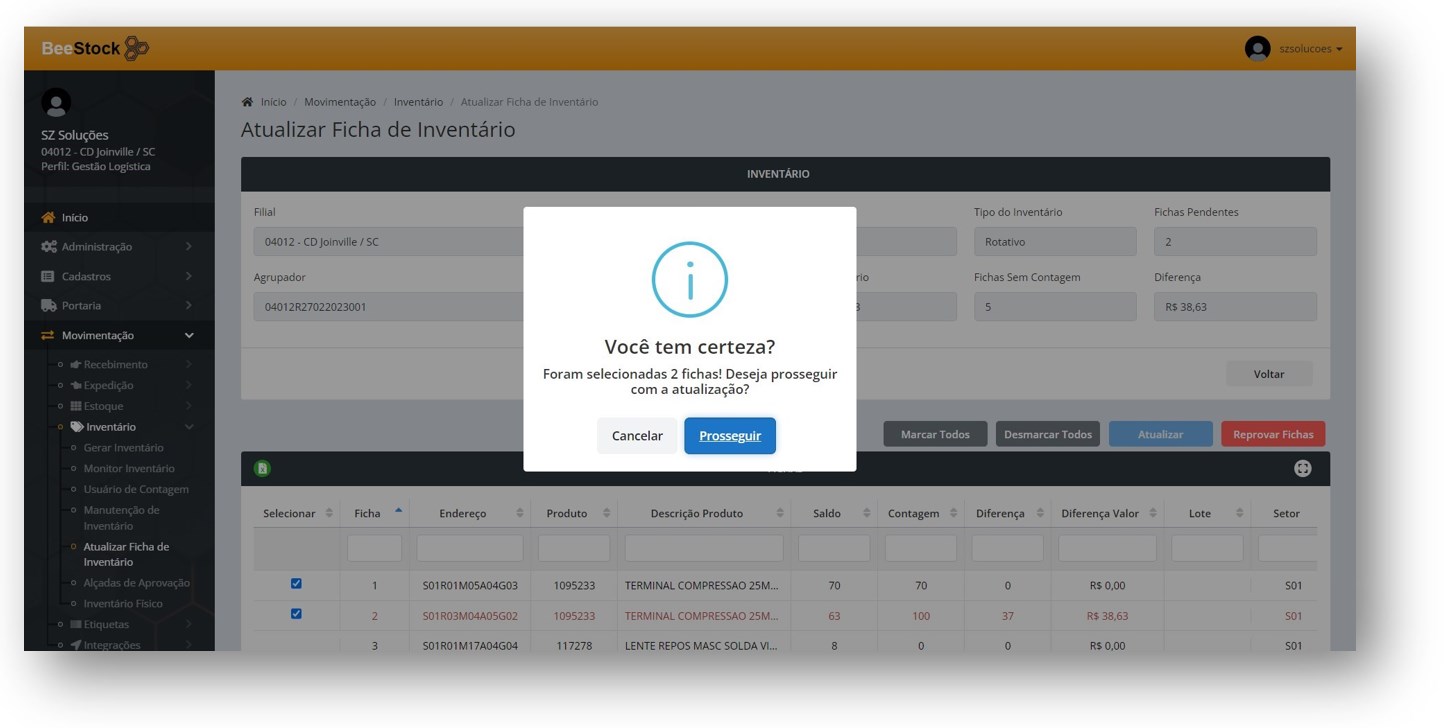

On the screen below, select the tags you want to update using the checkbox. Use code with caution. \ 2. Click Update.

The message XX tags were selected! Do you want to proceed with the update? will be displayed. Click Proceed.

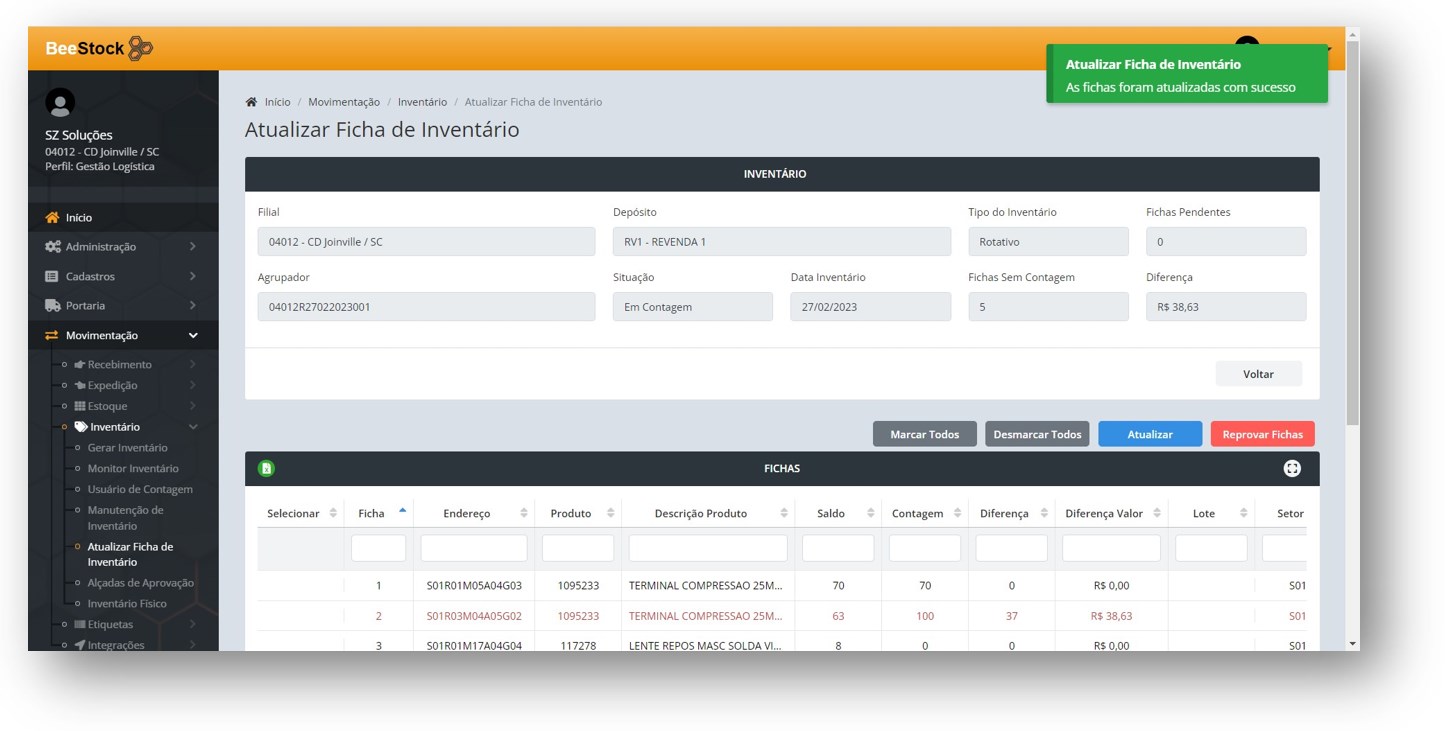

The confirmation message Tags were successfully updated will be displayed.

If you want to Reject Tags, you must select them and click Reject Tags.

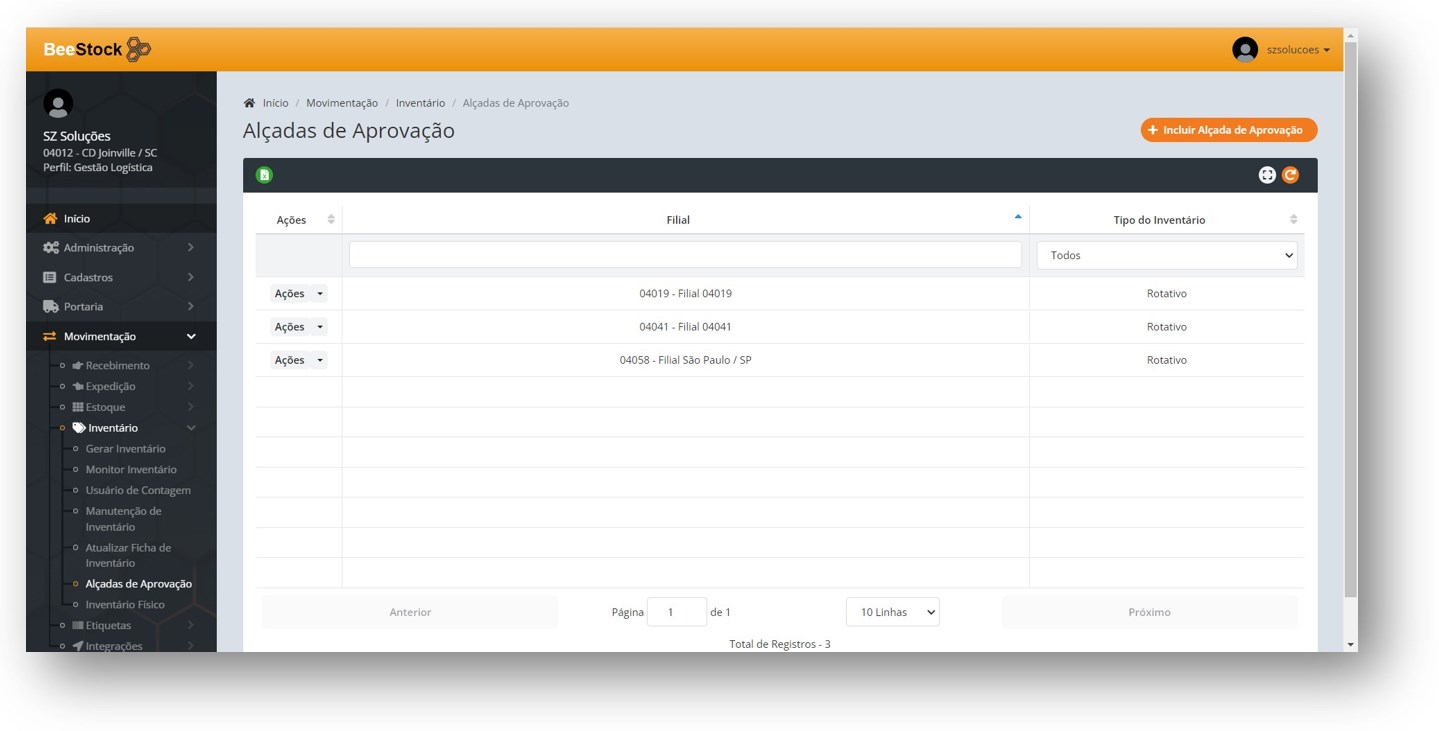

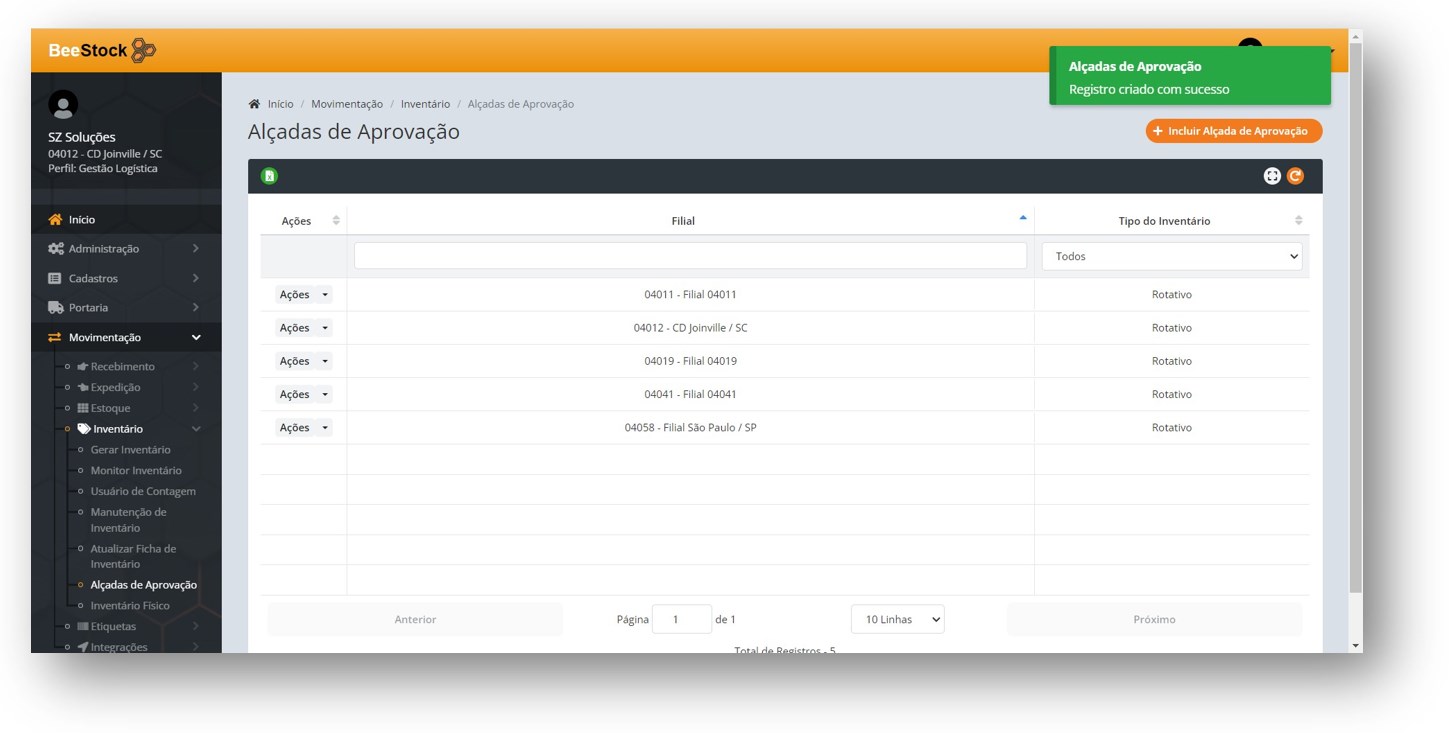

Approval Levels

Located in the Movement > Inventory > Approval Levels menu, this screen is used to configure the approval levels for each user by branch and inventory type.

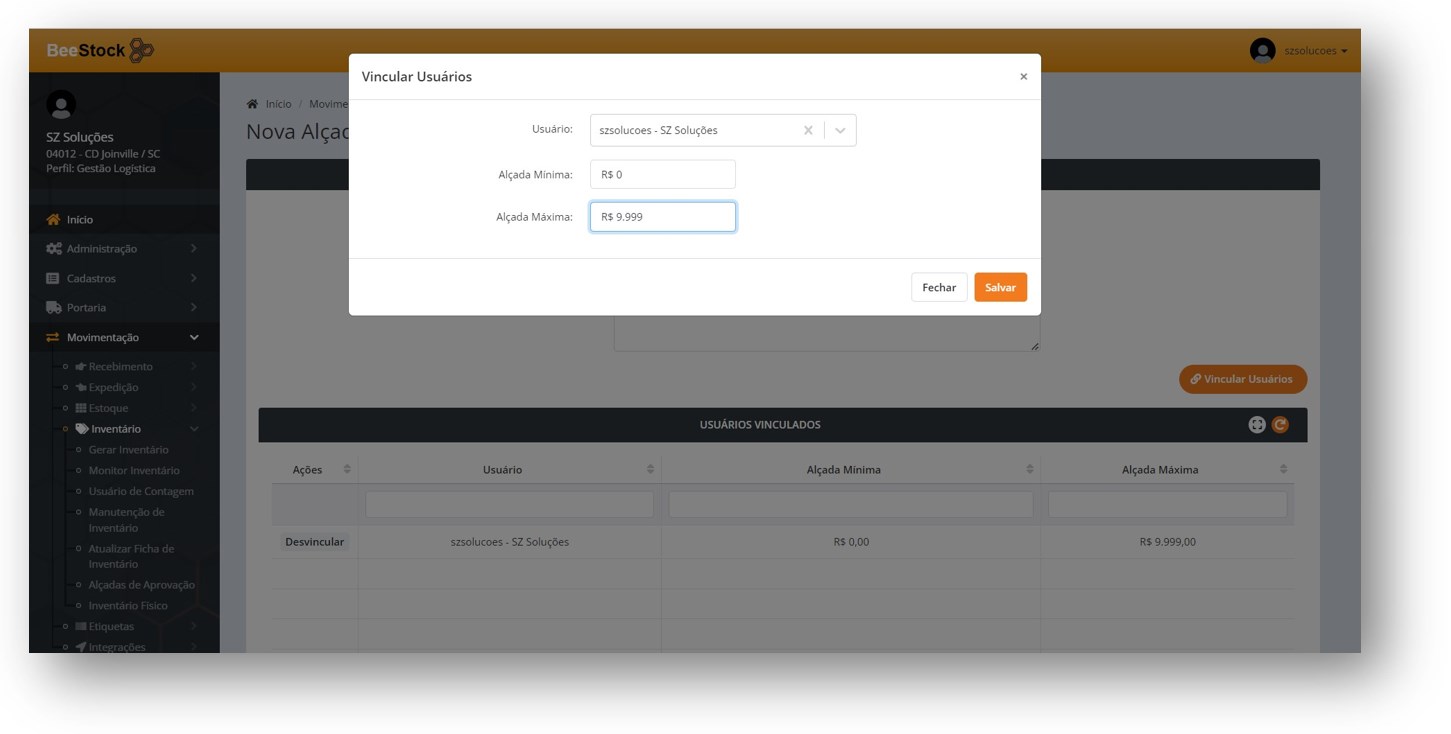

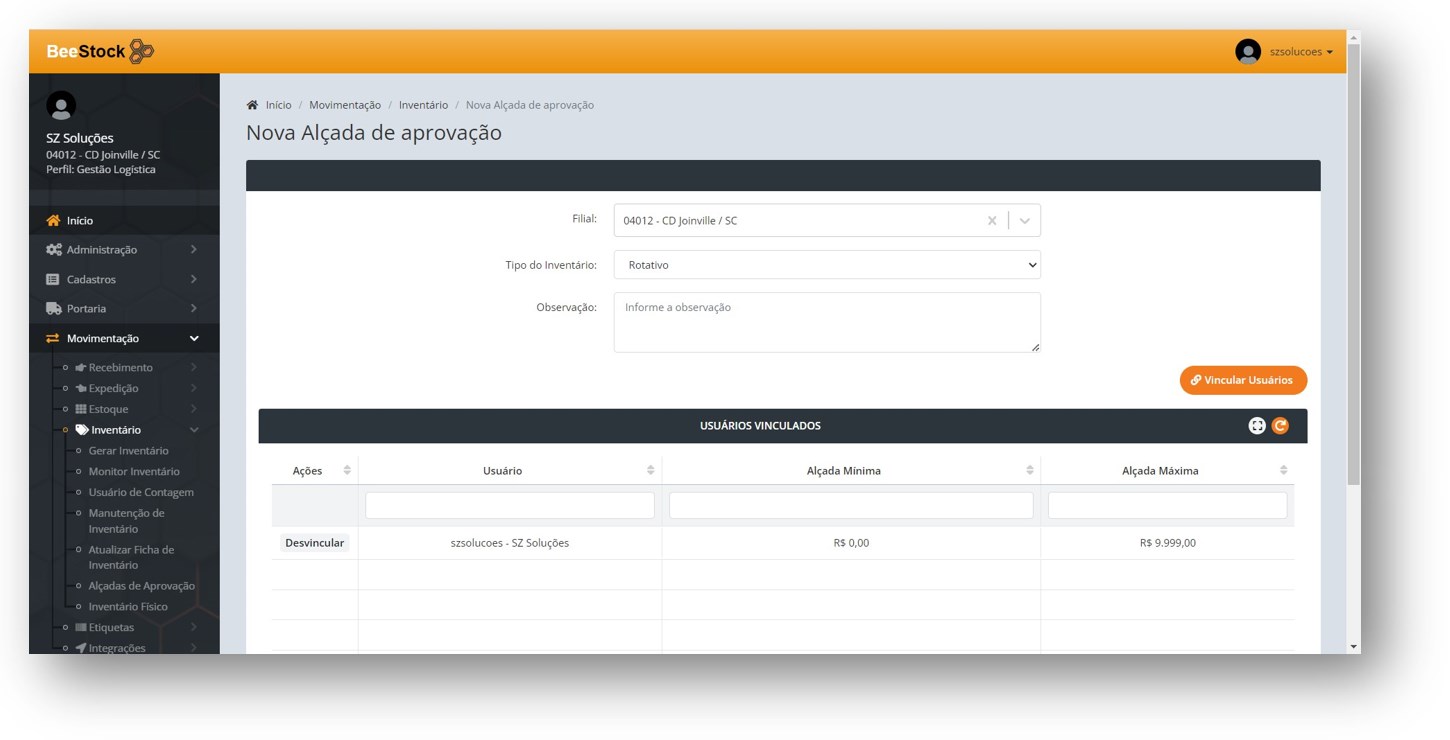

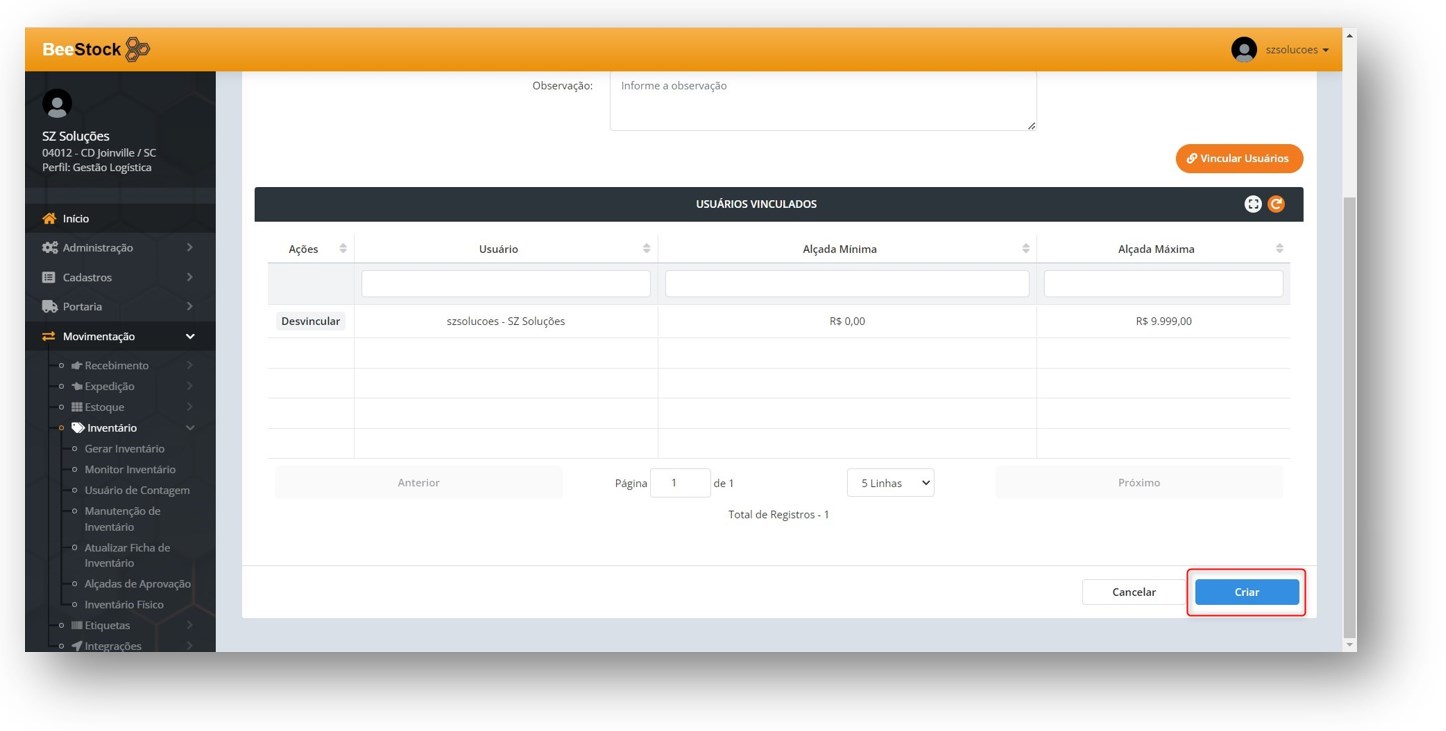

When you click +Add Approval Level, the following screen will open:

Select:

• Branch • Inventory Type.

Cycle Counting

General • Observation (Optional).

Click Create at the bottom of the screen.

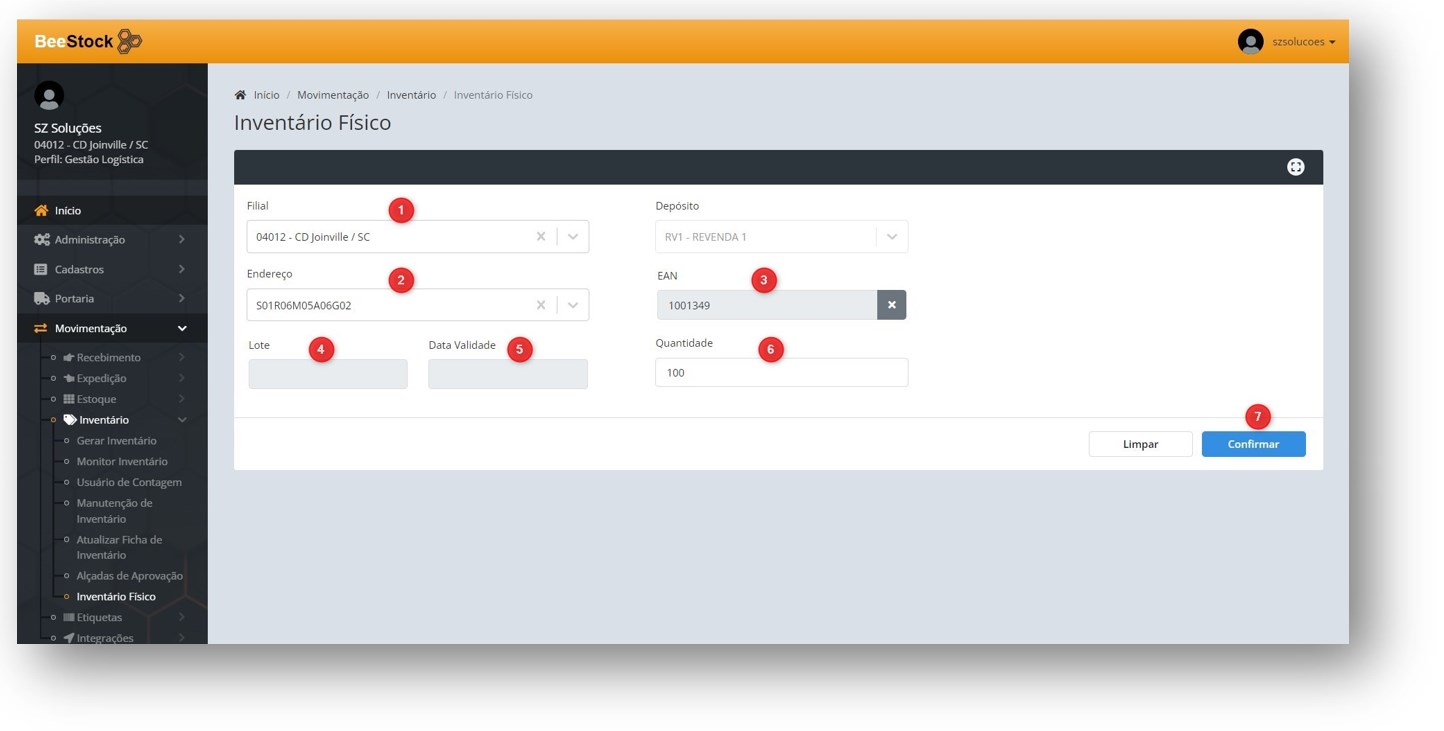

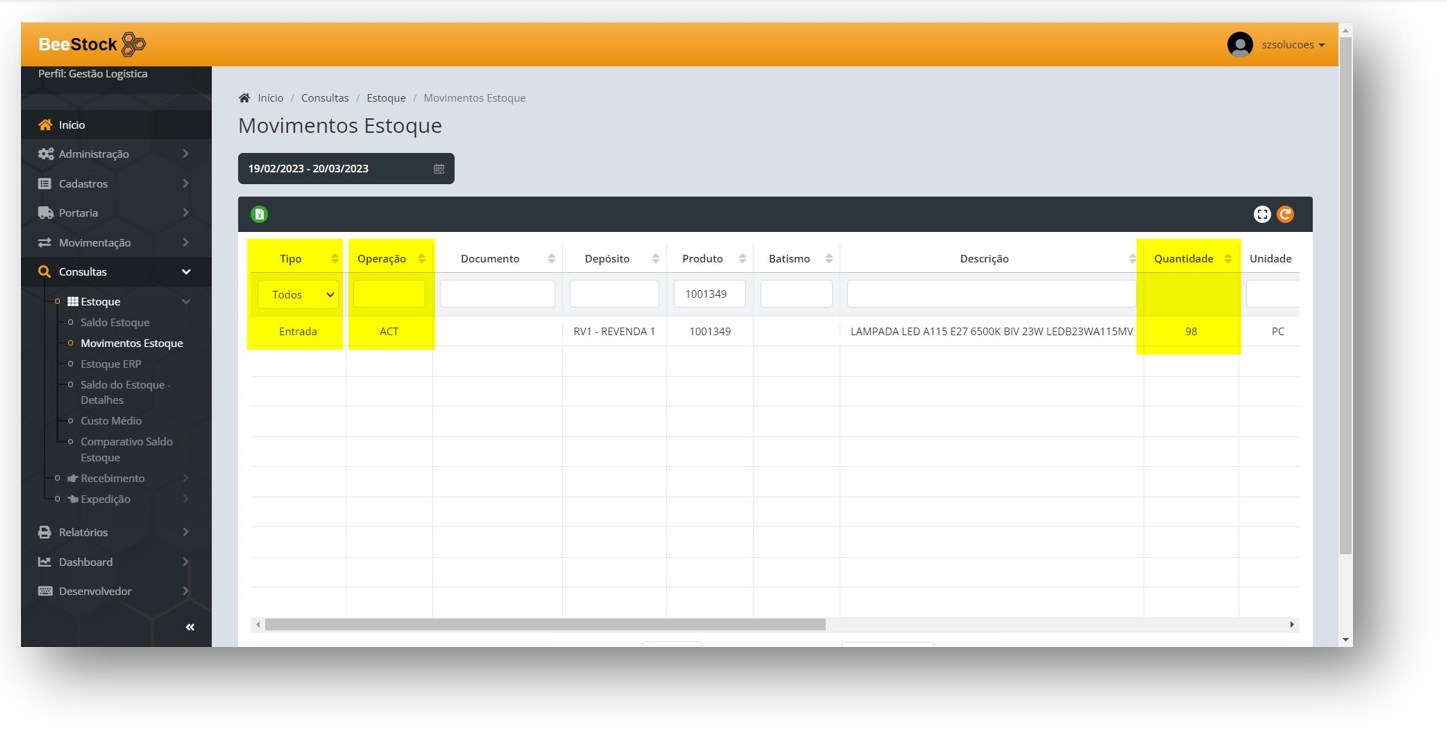

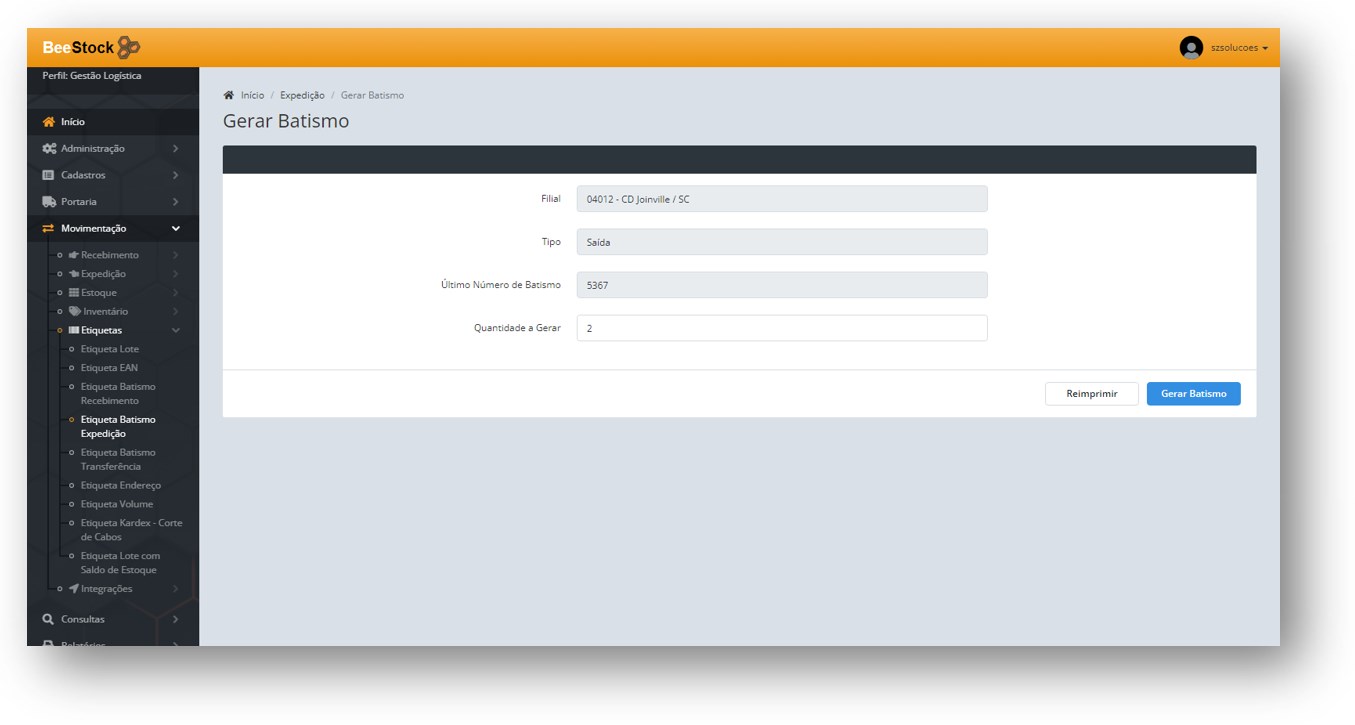

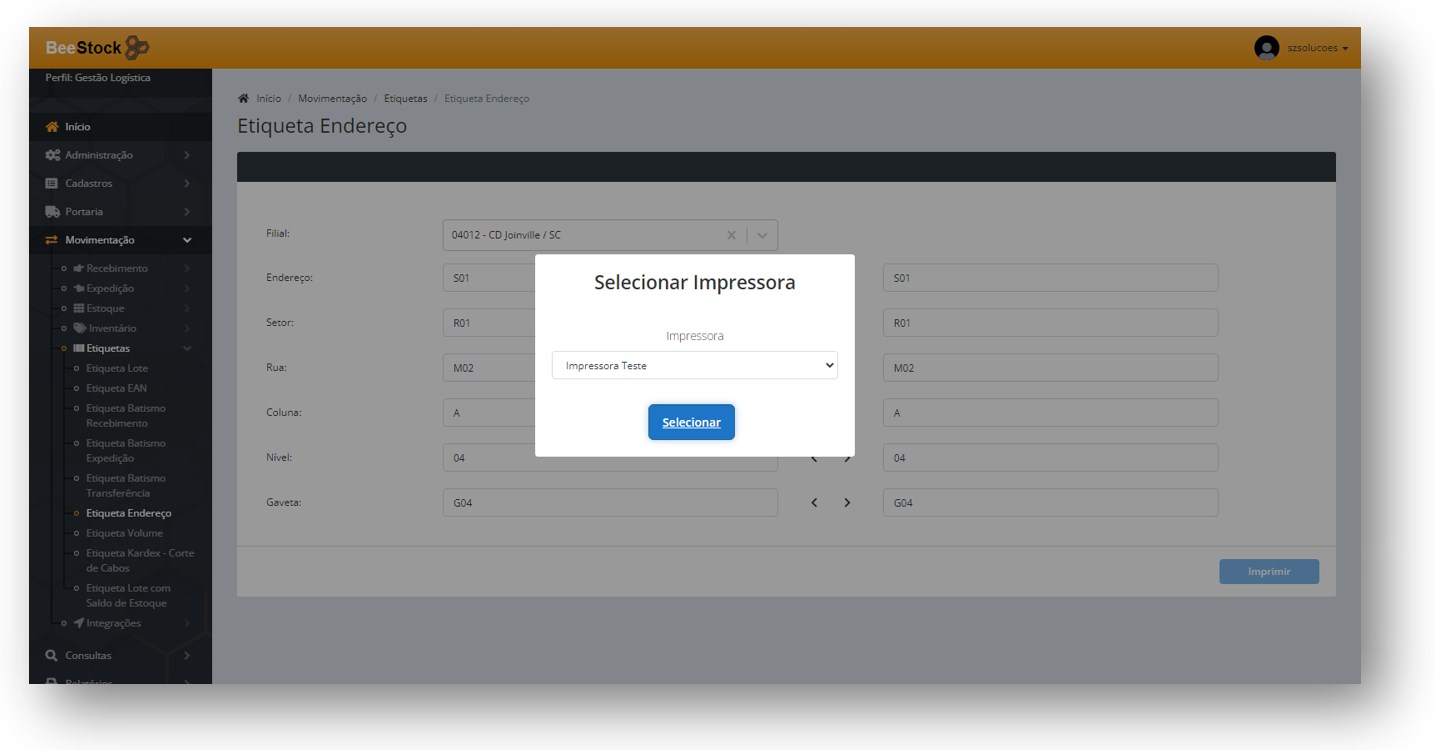

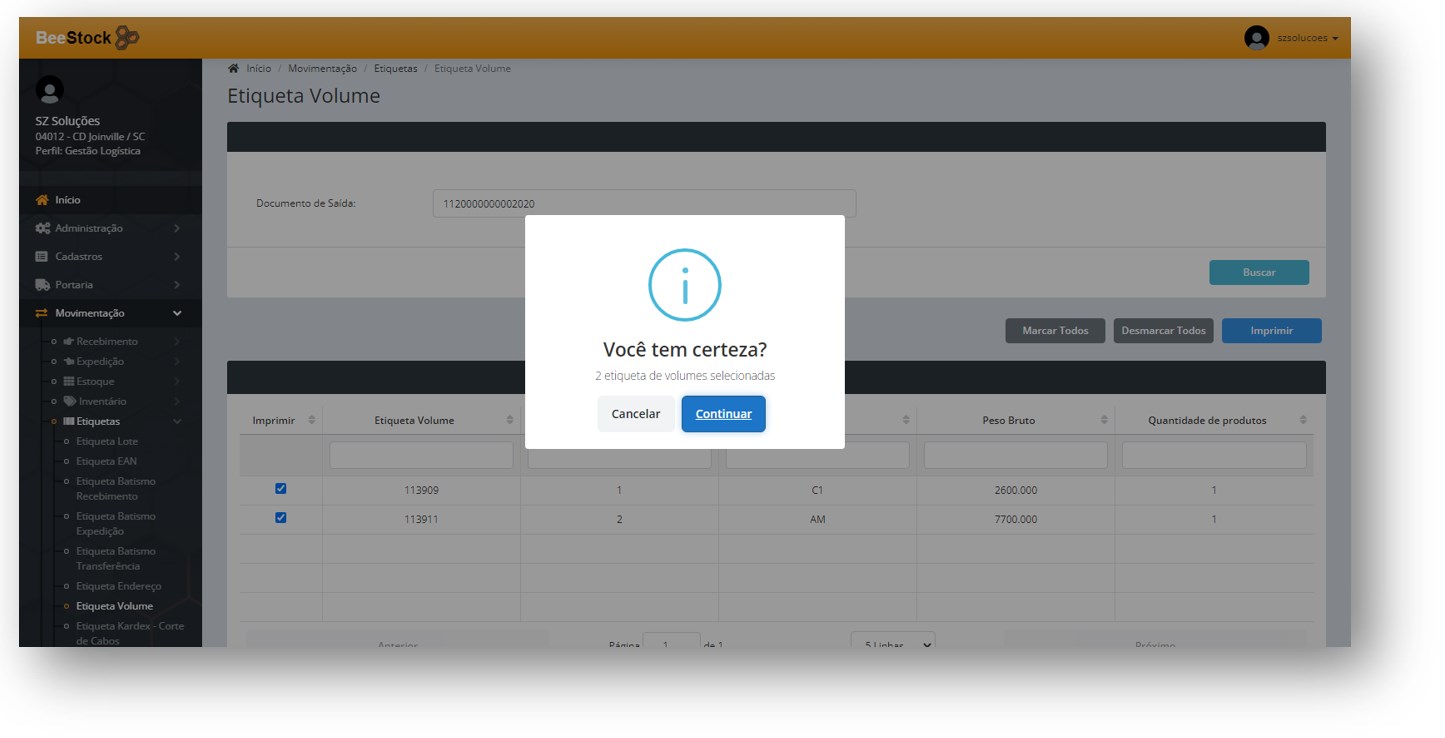

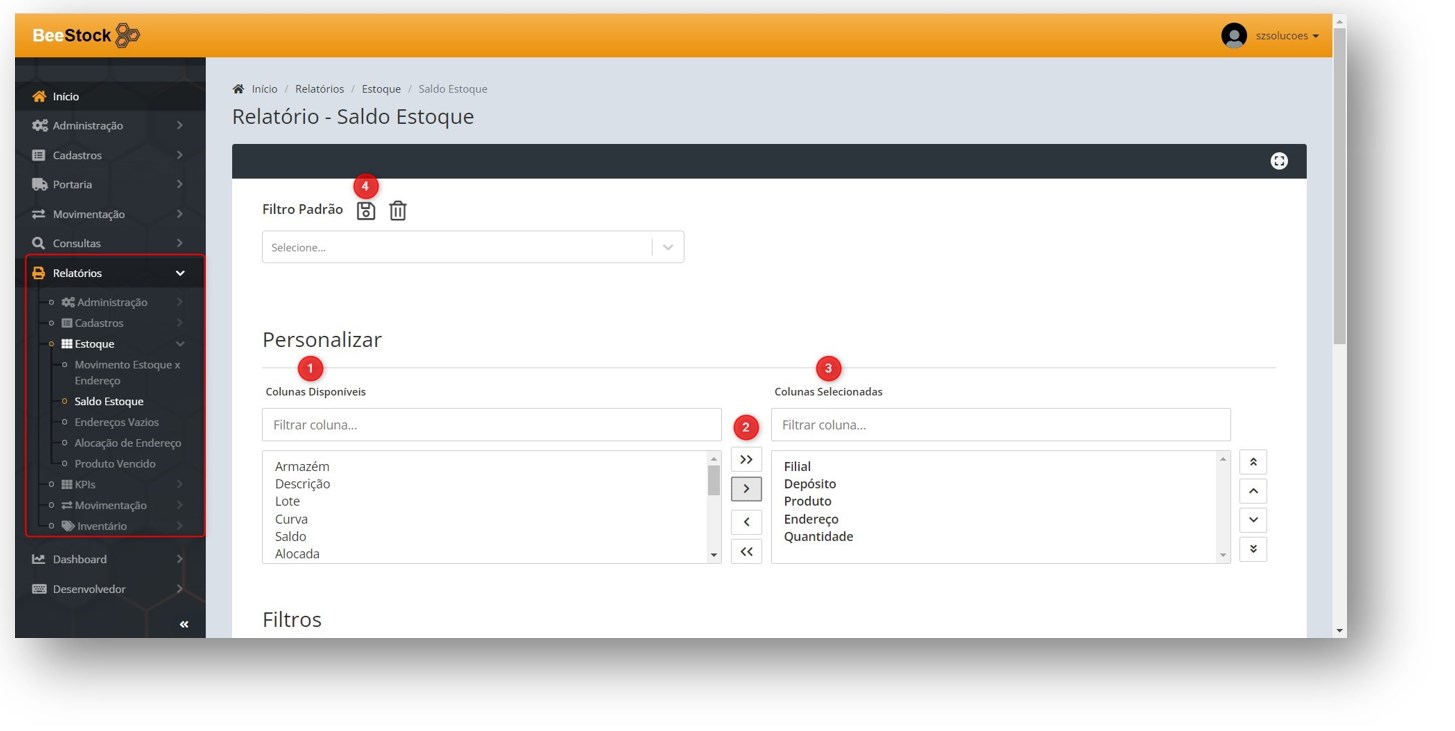

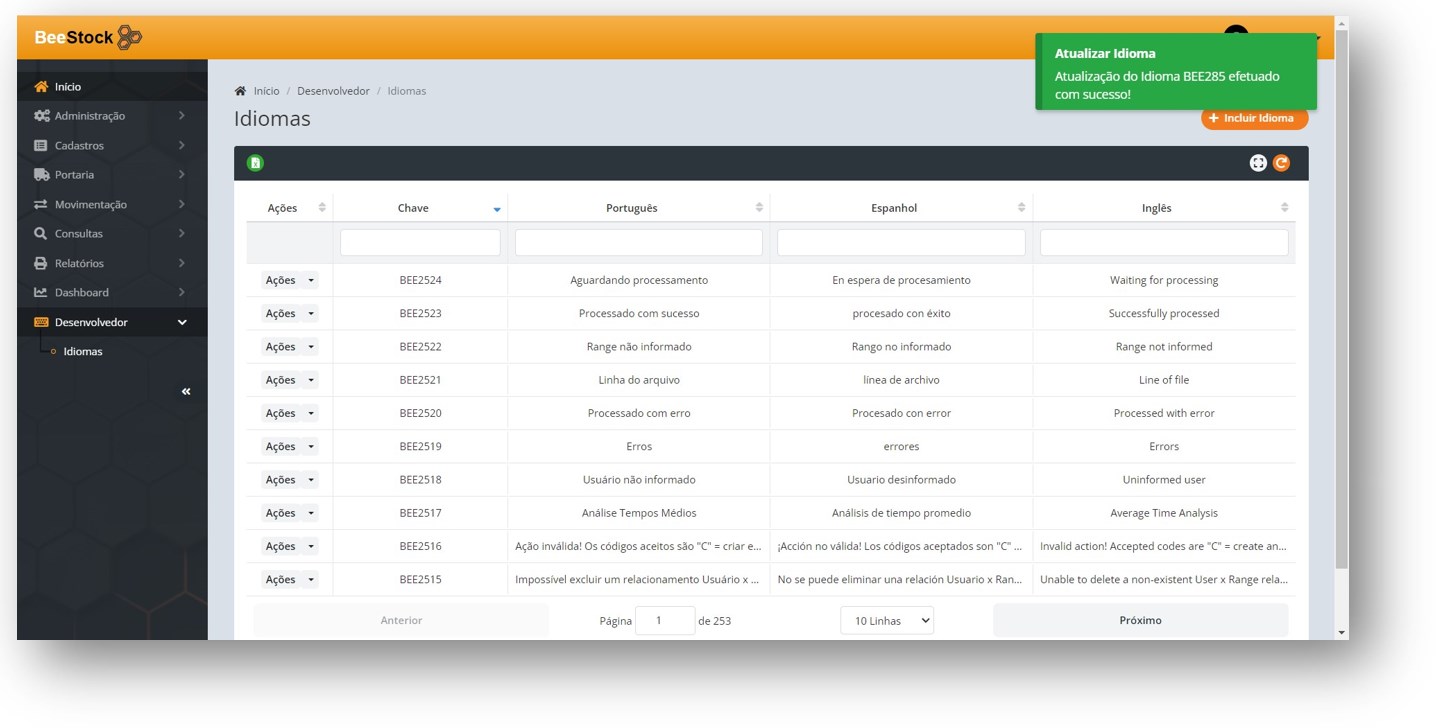

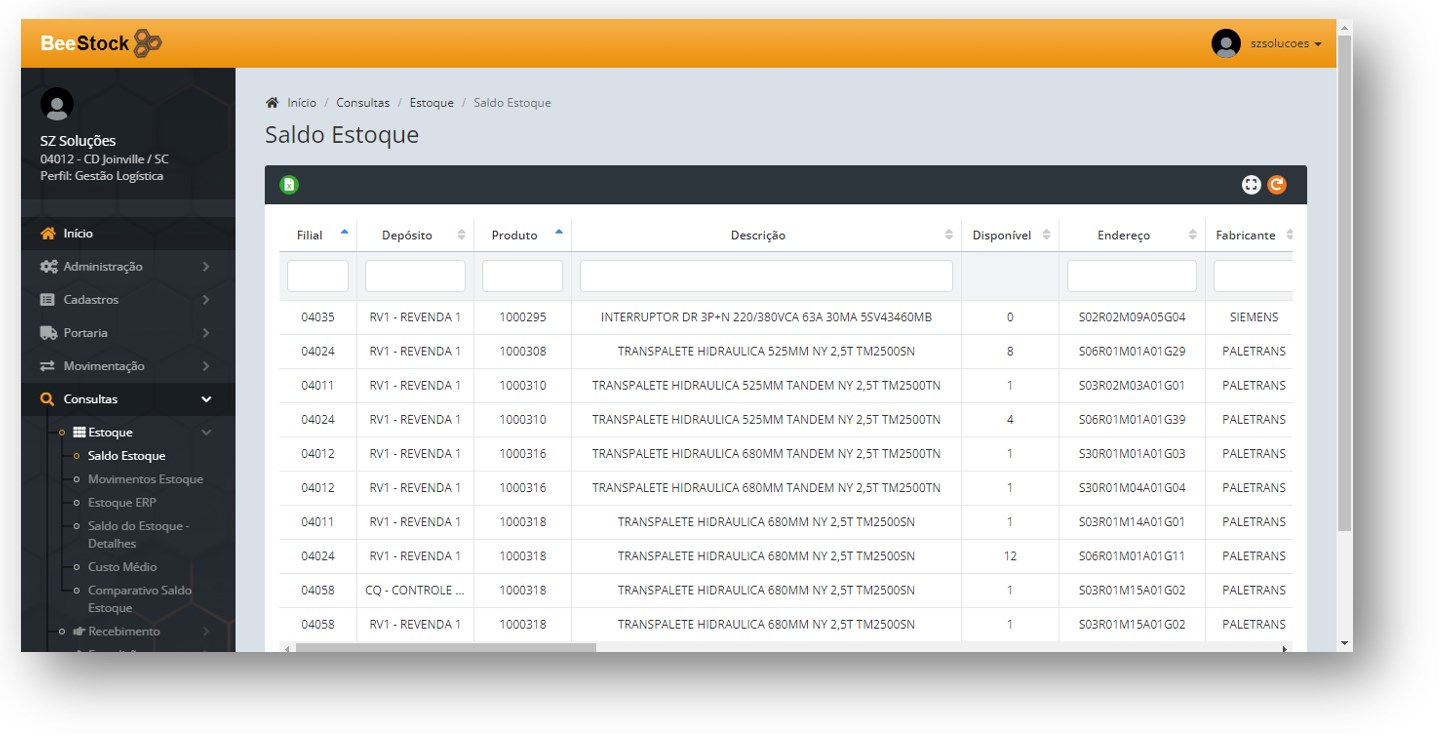

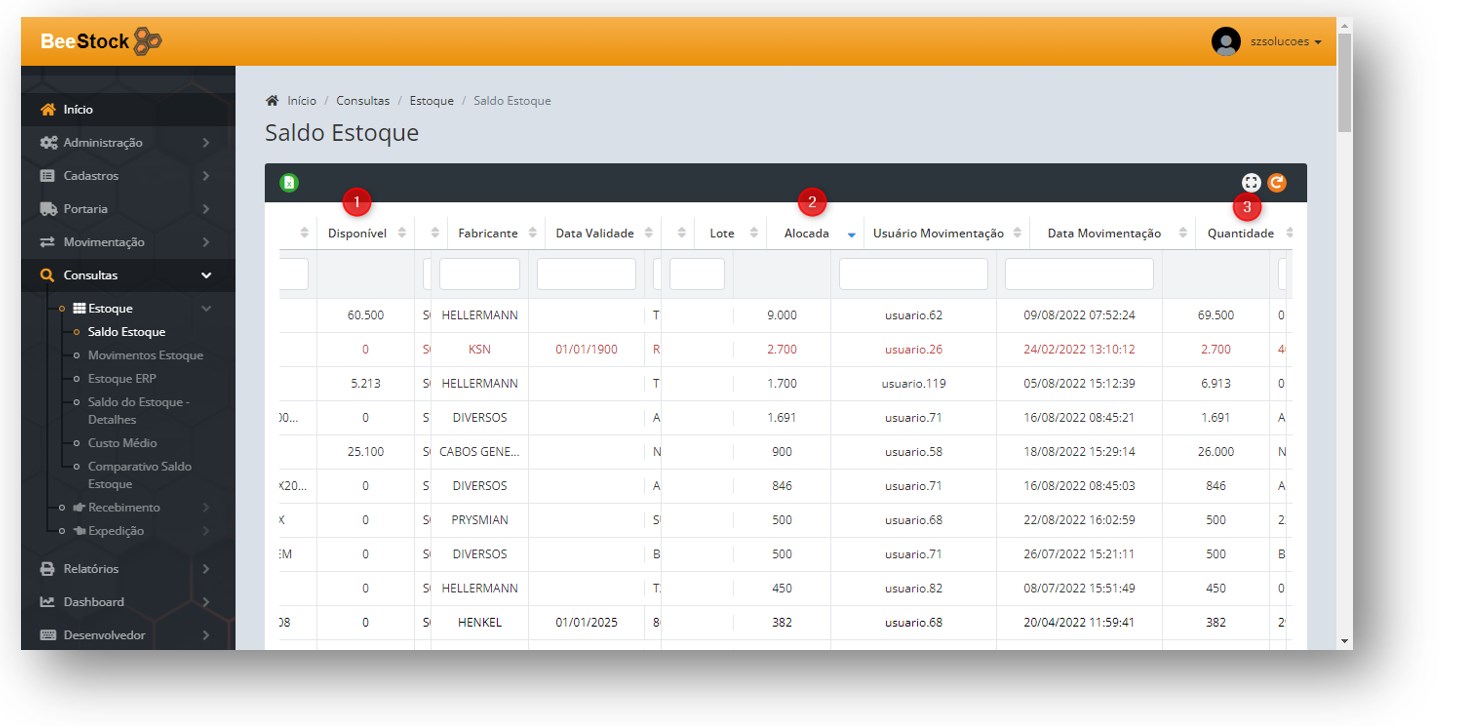

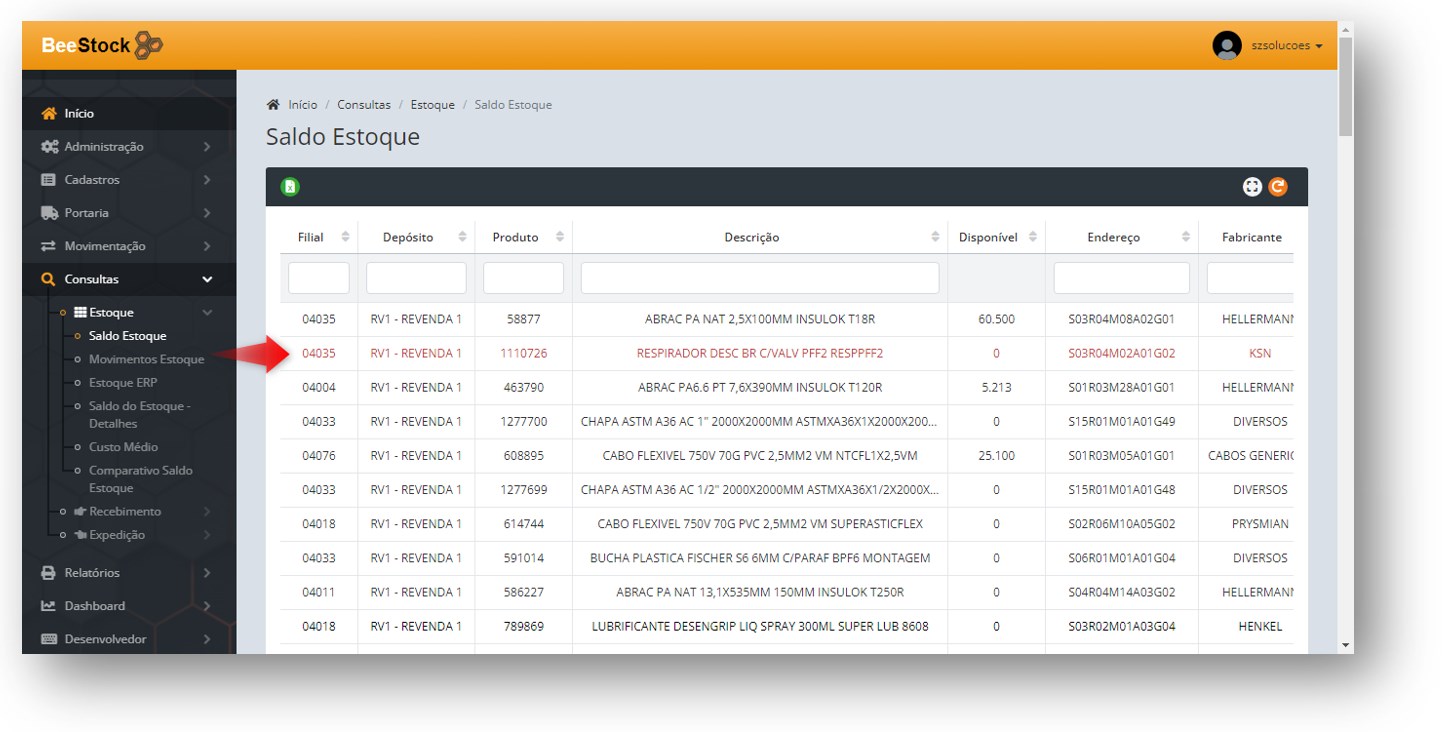

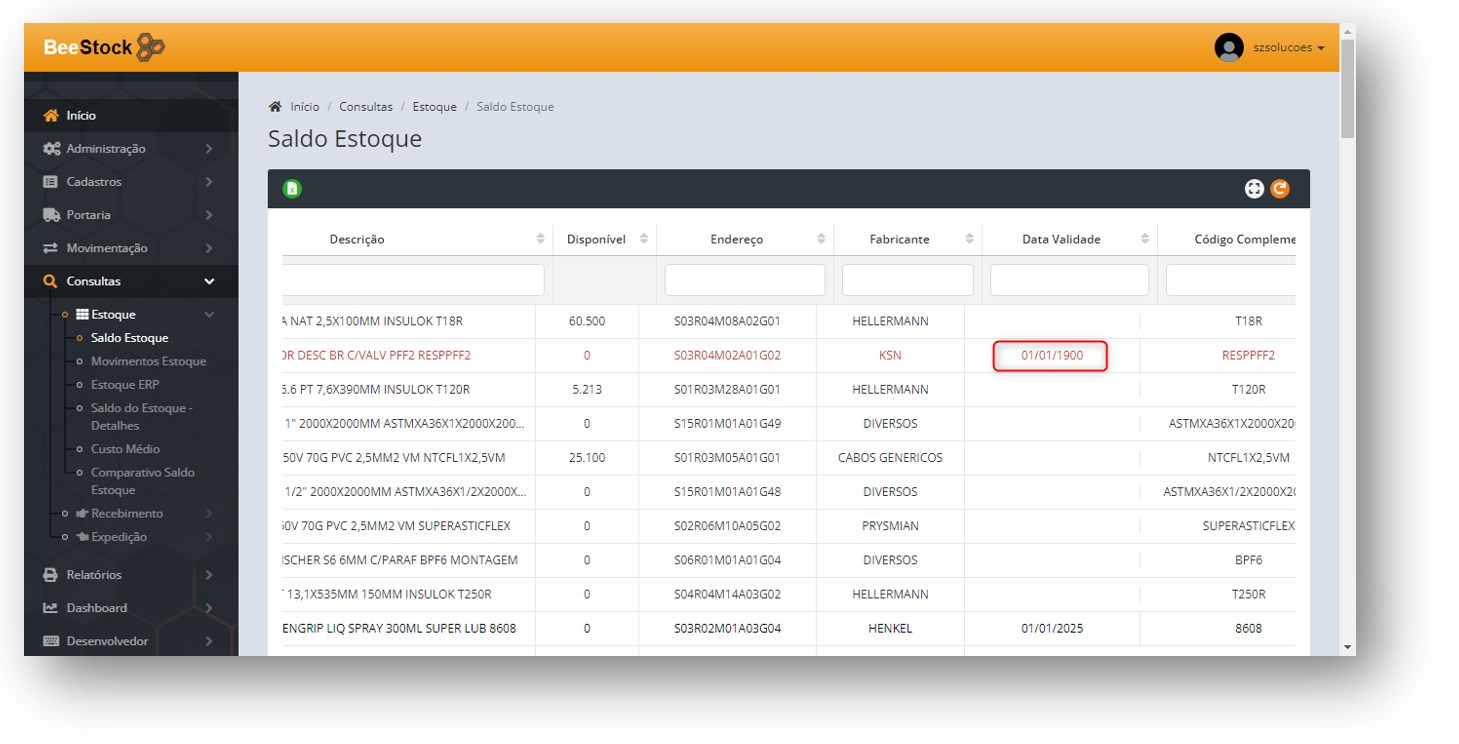

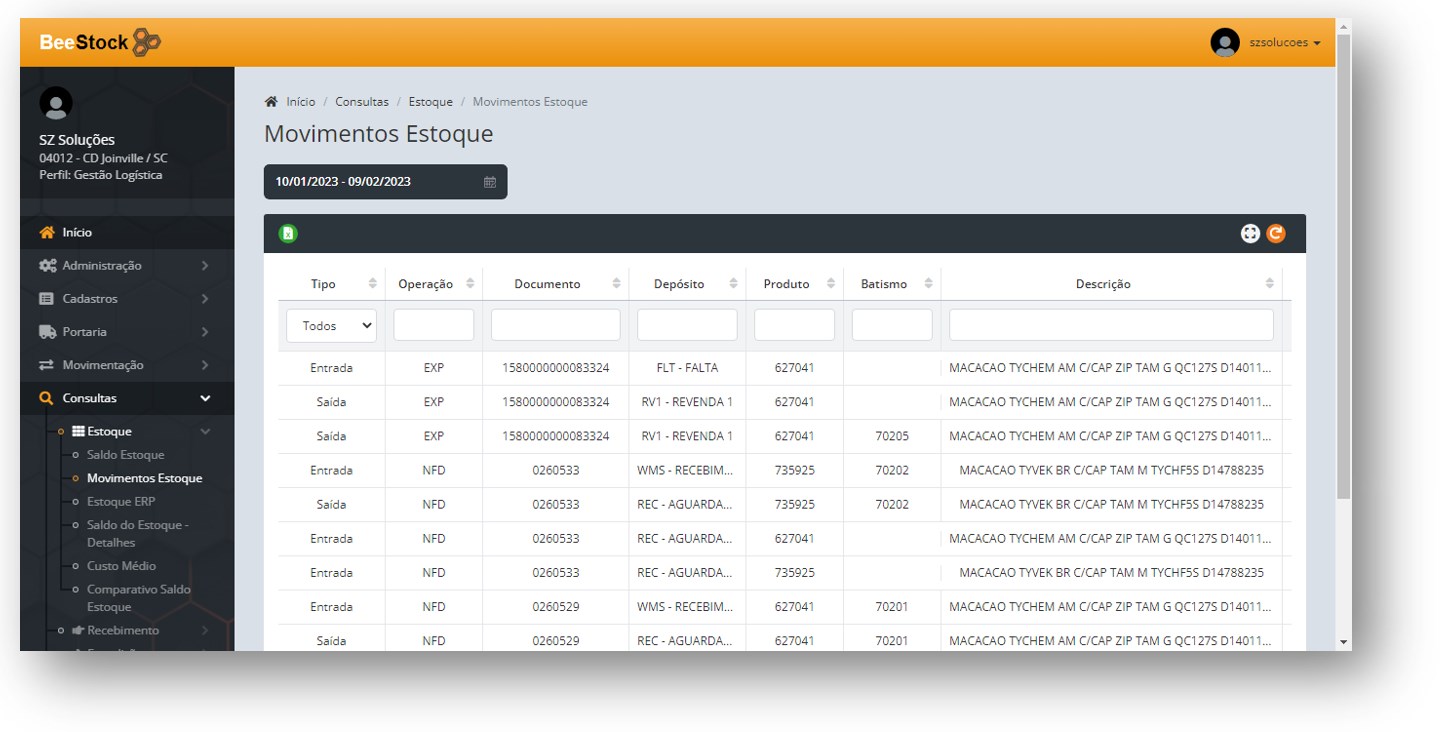

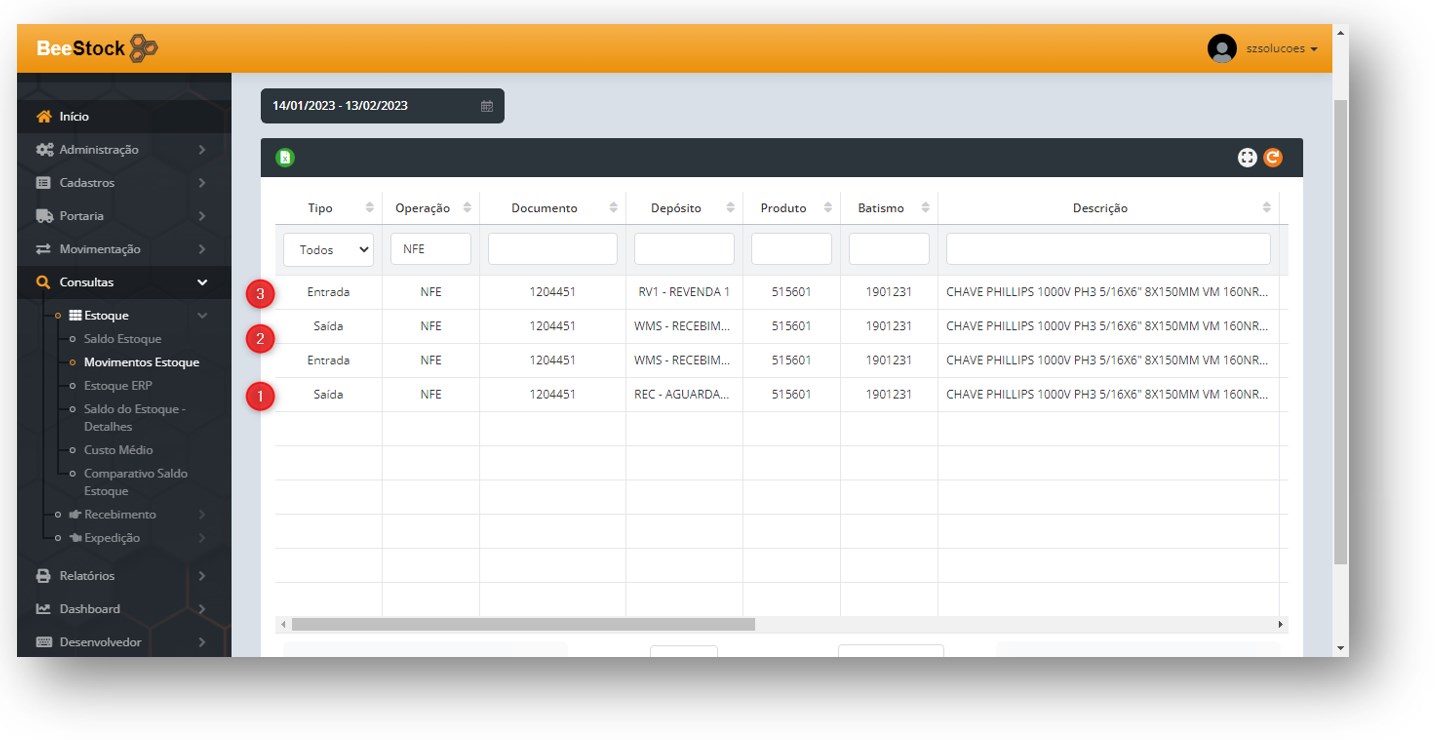

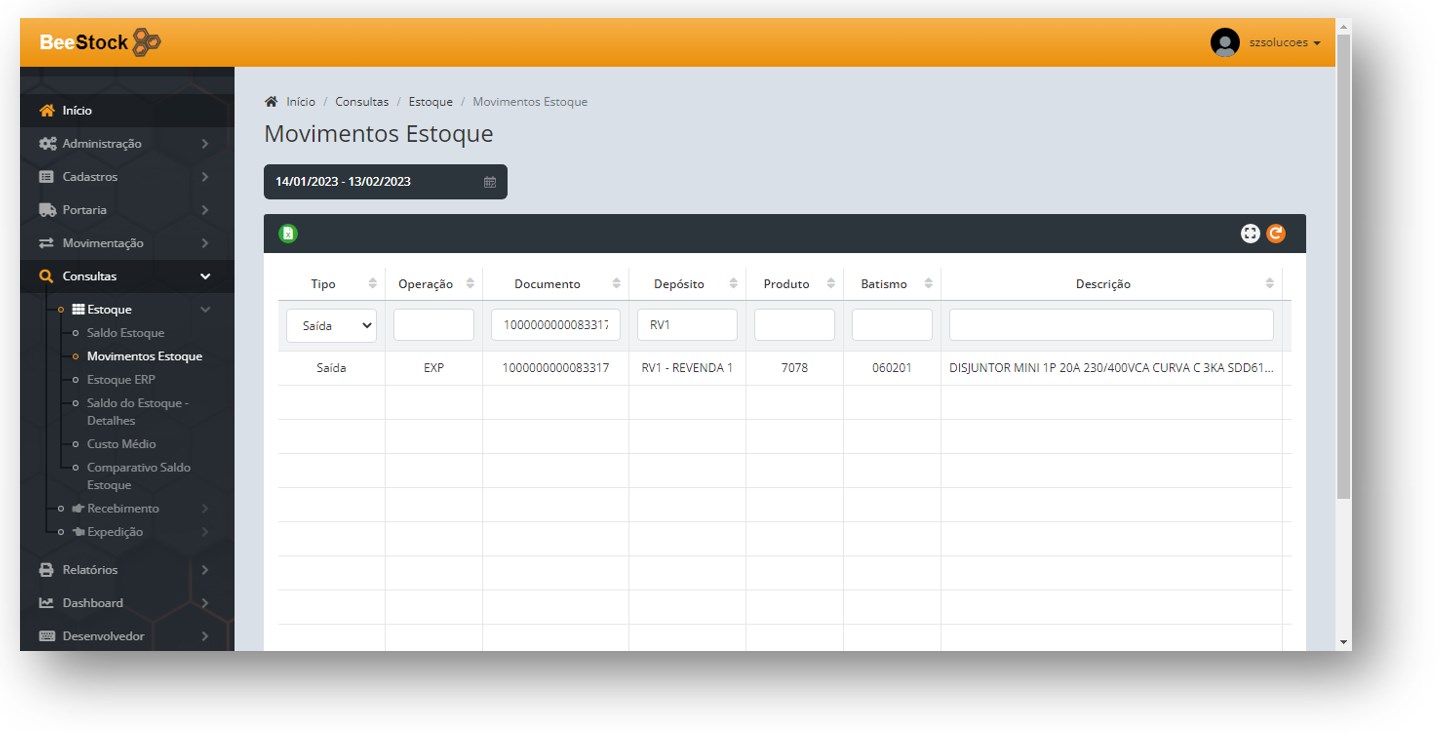

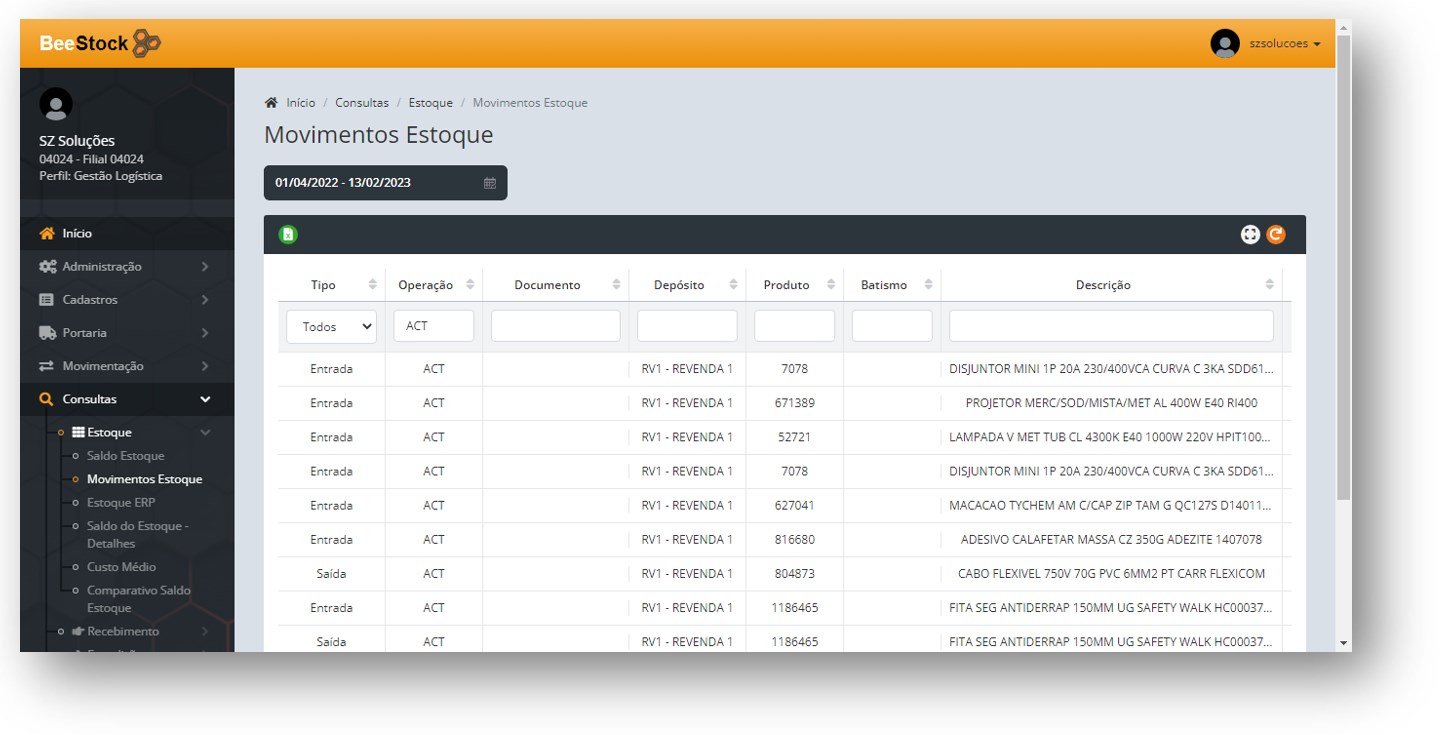

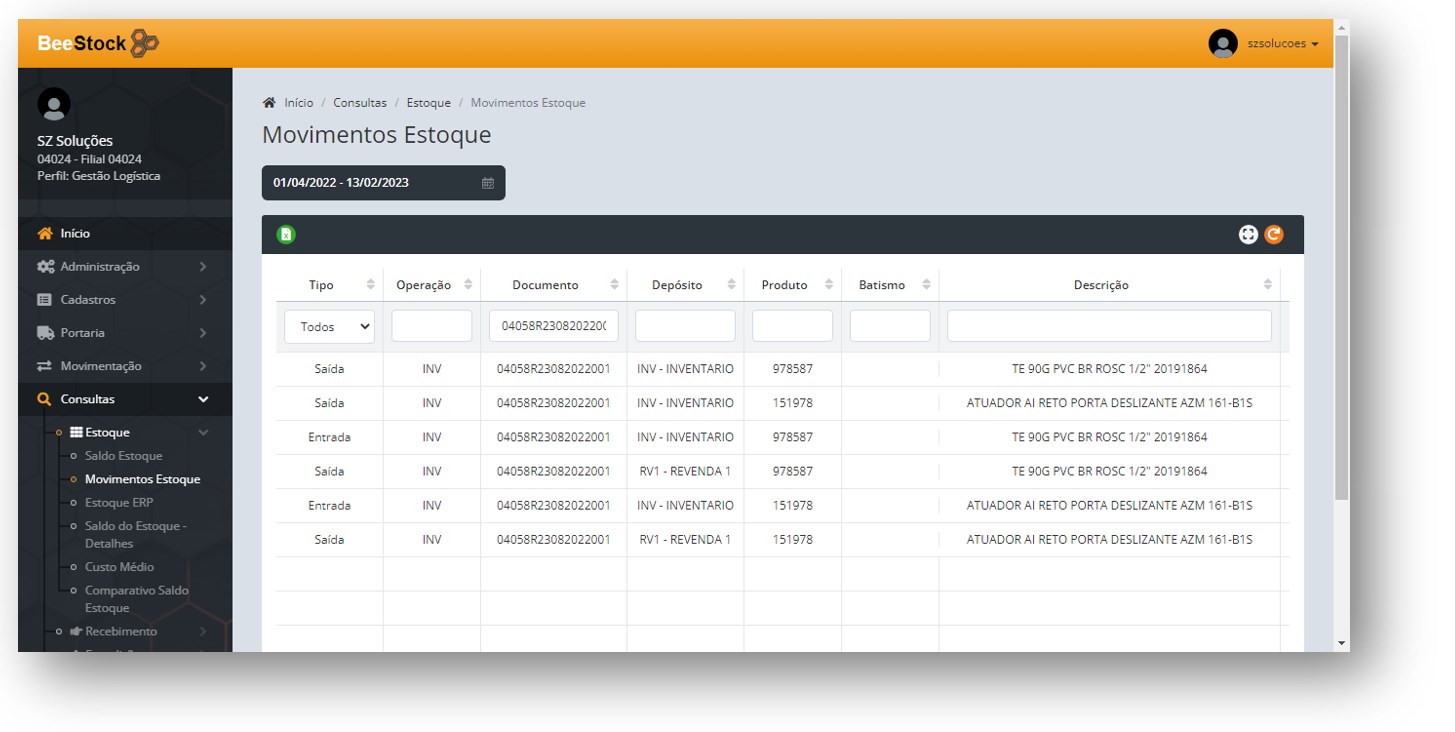

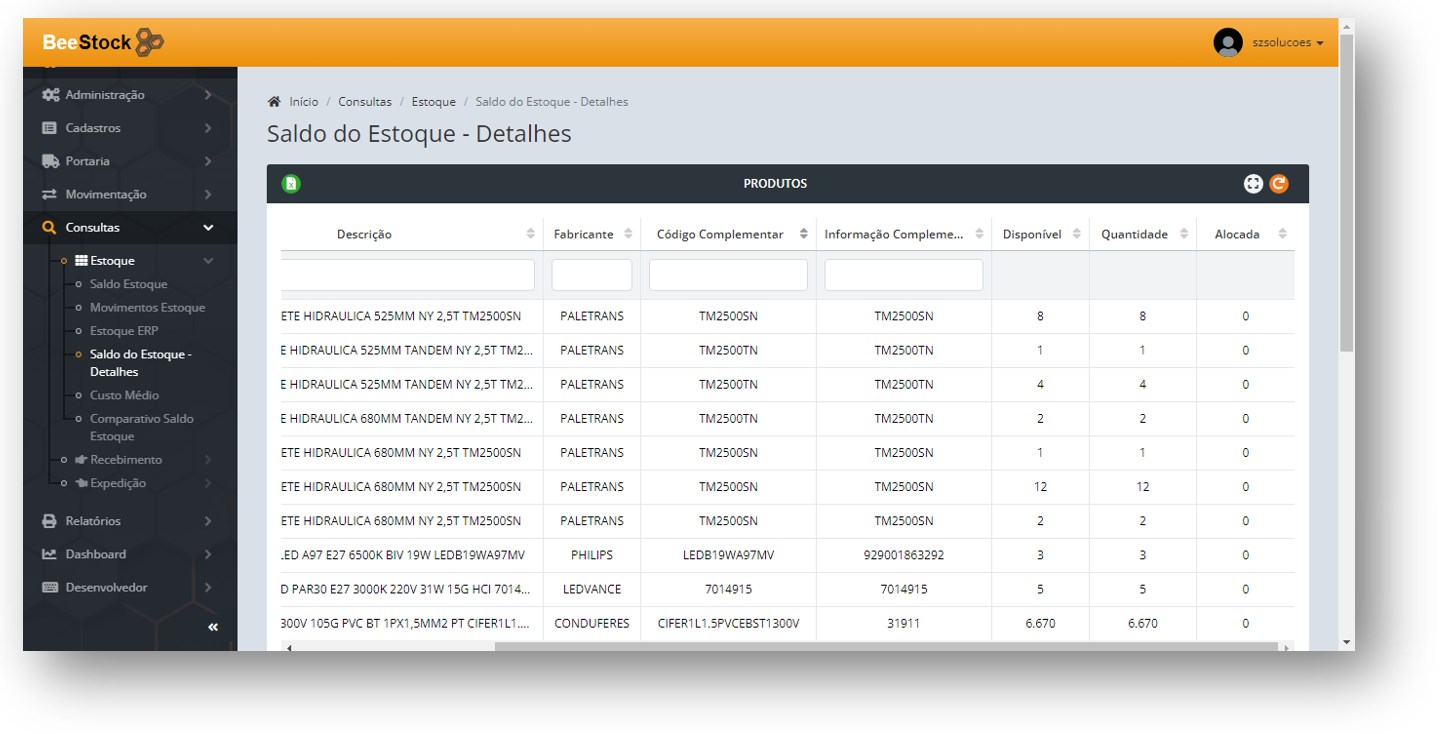

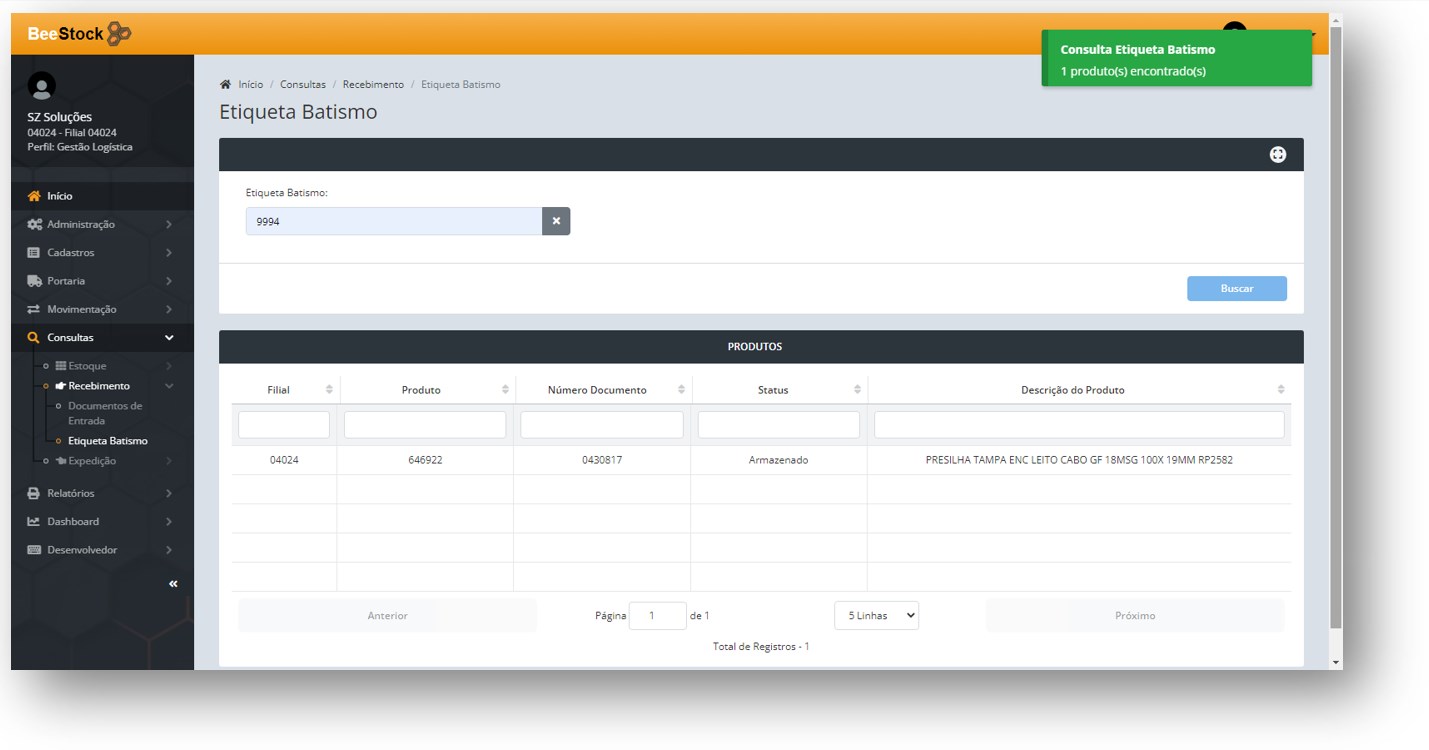

The confirmation message Record successfully created will be displayed.